Box type evaporator for waste heat utilization of high-temperature solid materials

A high-temperature solid and evaporator technology, which is applied in the field of high-temperature solid material waste heat utilization box-type evaporators, can solve the problems of inability to produce steam, ineffective utilization of waste heat, and inability to use soda-water mixture, etc., and achieves improved utilization of waste heat, compact structure, The effect of increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

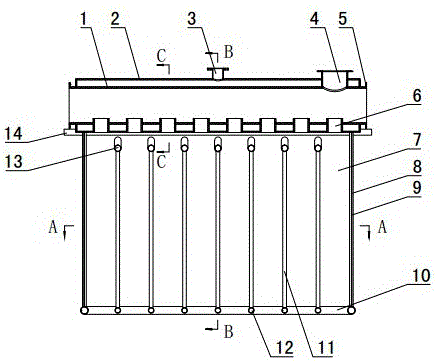

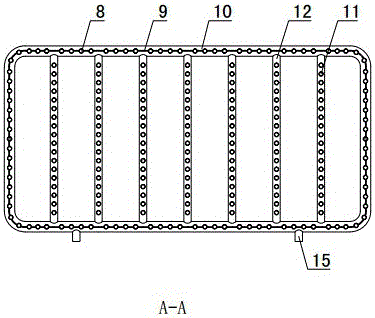

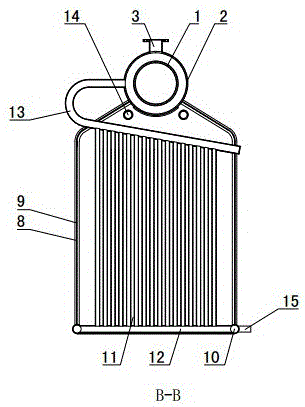

[0032] Such as figure 1 As shown: the length of the outer cylinder 2 is less than the length of the inner cylinder 1, and the inner diameter of the outer cylinder 2 is greater than the outer diameter of the inner cylinder 1, and the two ends of the outer cylinder 2 are provided with annular cover plates, and the outer edge of the annular cover plate and the outer The pipe wall of the cylinder 2 is welded and sealed, and the inner edge is welded and sealed with the outer wall of the inner cylinder 1, thereby forming a sleeve type header between the outer cylinder 2 and the inner cylinder 1. The feed port 4 is arranged at the right end of the sleeve header, and the feed port 4 communicates with the inner cavity of the inner cylinder 1 . A water outlet 3 is arranged in the middle of the sleeve-type header, and the water outlet 3 is arranged on the upper part of the sleeve-type header, and the water outlet 3 communicates with the inner cavity of the outer cylinder 2 .

[0033] Th...

Embodiment 2

[0047] Such as Figure 5~6 As shown: the difference between Embodiment 2 and Embodiment 1 is that the manifold 13 is arranged horizontally, both ends of the manifold 13 are closed, and the upper end of the inner heat exchange tube 11 communicates with the manifold 13 . A connecting pipe 16 is arranged between the collecting pipe 13 and the outer cylinder 2. The connecting pipe 16 is arranged vertically.

Embodiment 3

[0049] Such as Figure 7 As shown: the difference between embodiment 3 and embodiment 1 is that the confluence pipe 13 includes two horizontal parts and a bent part below, and the two horizontal parts are symmetrically arranged on both sides of the outer cylinder 2, and the two horizontal parts are close to the outer cylinder 2 One end communicates with the inner cavity of the outer cylinder 2, and the ends of the two horizontal parts away from the outer cylinder 2 respectively communicate with the two ends of the bending part. The folds are connected.

[0050] The feeding port 4 is arranged in the middle part of the inner cylinder 1, and the helical blades of the water-cooled spiral body are separated from the middle part, and the helical blades on both sides of the middle part are opposite in direction of rotation. When the water-cooled spiral rotates, it pushes the material toward both ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com