Biomass steam generator

A steam generator and biomass technology, applied in the field of boilers, can solve problems such as environmental pollution and trouble, and achieve the effects of fully utilizing waste heat, reducing heat exchange and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

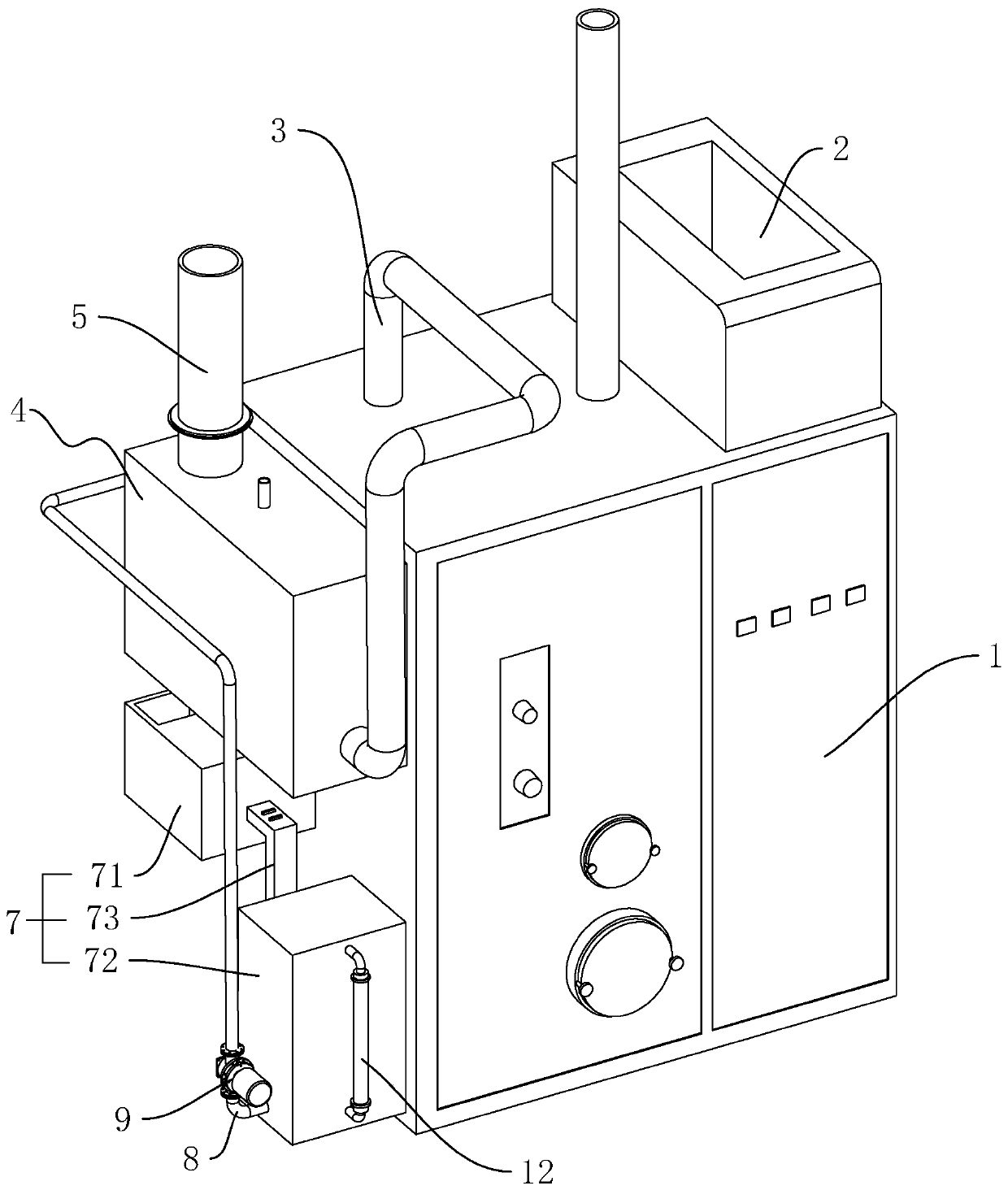

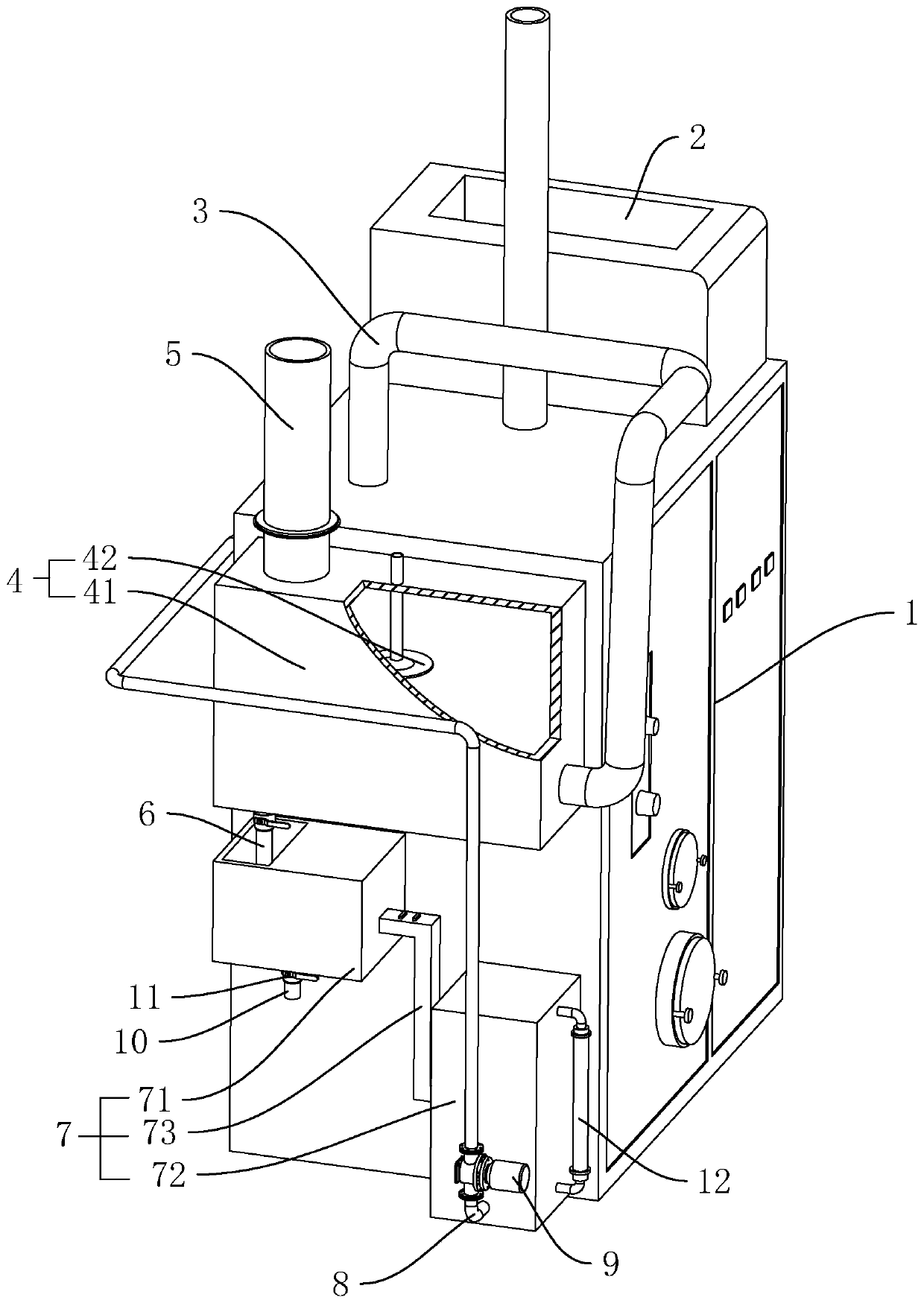

[0038] A biomass steam generator such as figure 1 As shown, the furnace body (not shown) including the frame 1, the biomass combustion chamber arranged in the frame 1, the pot body heated on the furnace body (not shown in the figure) and the top of the pot body and the The steam chamber (not shown in the figure) communicated with the pot body, the furnace body is also communicated with the feed port 2 and the smoke exhaust pipe 3 . The pot body is connected with a water supply pipe. When in use, water is added to the pot body through the water supply pipe connected to the water source, and the pot body is heated by the combustion of biomass fuel in the furnace body, so that the water in the pot body is vaporized to form steam and discharged into the The steam chamber is then channeled to where it is needed.

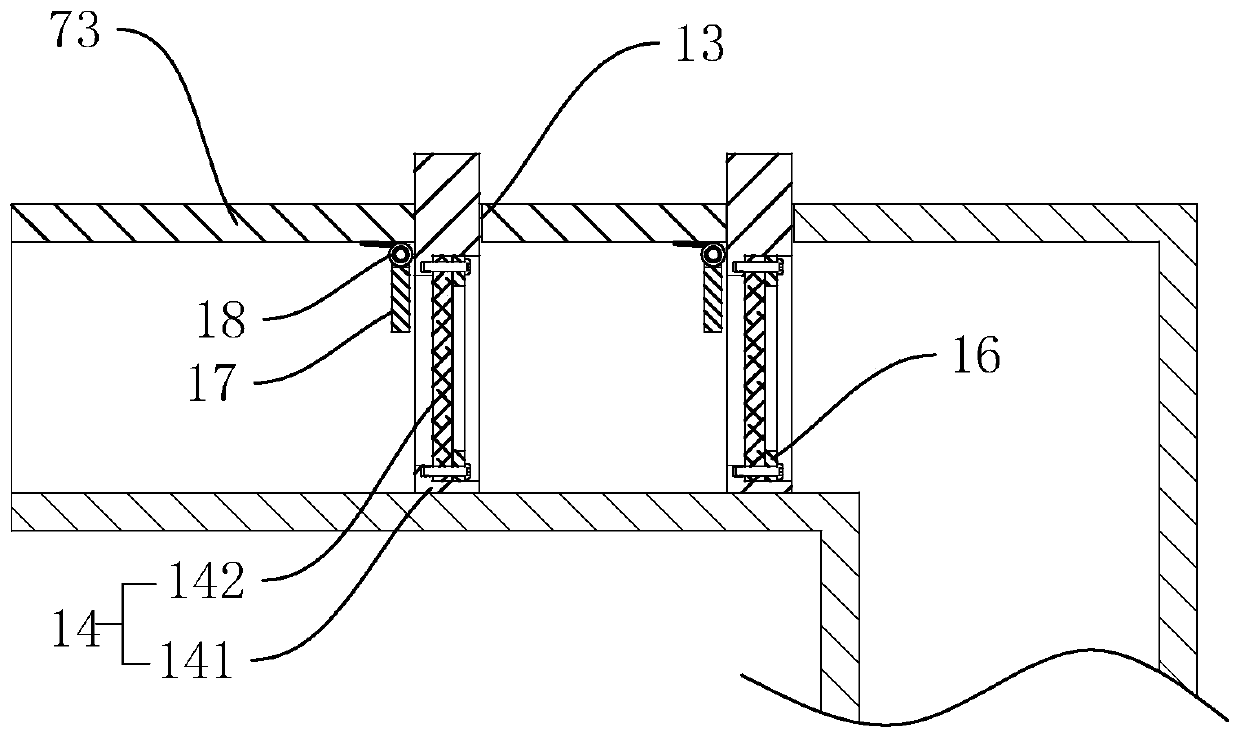

[0039] Such as figure 1 , figure 2 As shown, the side wall of the frame 1 is provided with a dust removal filter device 4 , and the dust removal filter device 4 inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com