Economic anti-saltpetering inside and outside walls facing mortar

An anti-efflorescence and economical technology, applied in the field of mortar, can solve the problem of high cost of mortar, and achieve the effect of rich shape, lower cost and increased compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The following formulations do not add metakaolin, but use different amounts of modified bentonite for comparison.

[0034] 1. Formula

[0035] 1# 2# 3# 4#

[0036] Portland cement (42.5R) 350.00g 350.00g 350.00g 350.00g

[0037] Heavy calcium (fineness ≥ 200) 200.00g 200.00g 200.00g 200.00g

[0038] River sand (40-70 mesh) 172.00g 170.00g 169.00g 167.00g

[0039] River sand (70-140 mesh) 250.00g 250.00g 250.00g 250.00g

[0040] Redispersible latex powder 10.00g 10.00g 10.00g 10.00g

[0041] Modified bentonite - 2.00g 3.00g 5.00g

[0042] Wood fiber 3.00g 3.00g 3.00g 3.00g

[0043] Cellulose ether 1.00g 1.00g 1.00g 1.00g

[0044] Pigment 14.00g 14.00g 14.00g 14.00g

[0045] Total 1000.00g 1000.00g 1000.00g 1000.00g

[0046] 2. Coating and outdoor observation

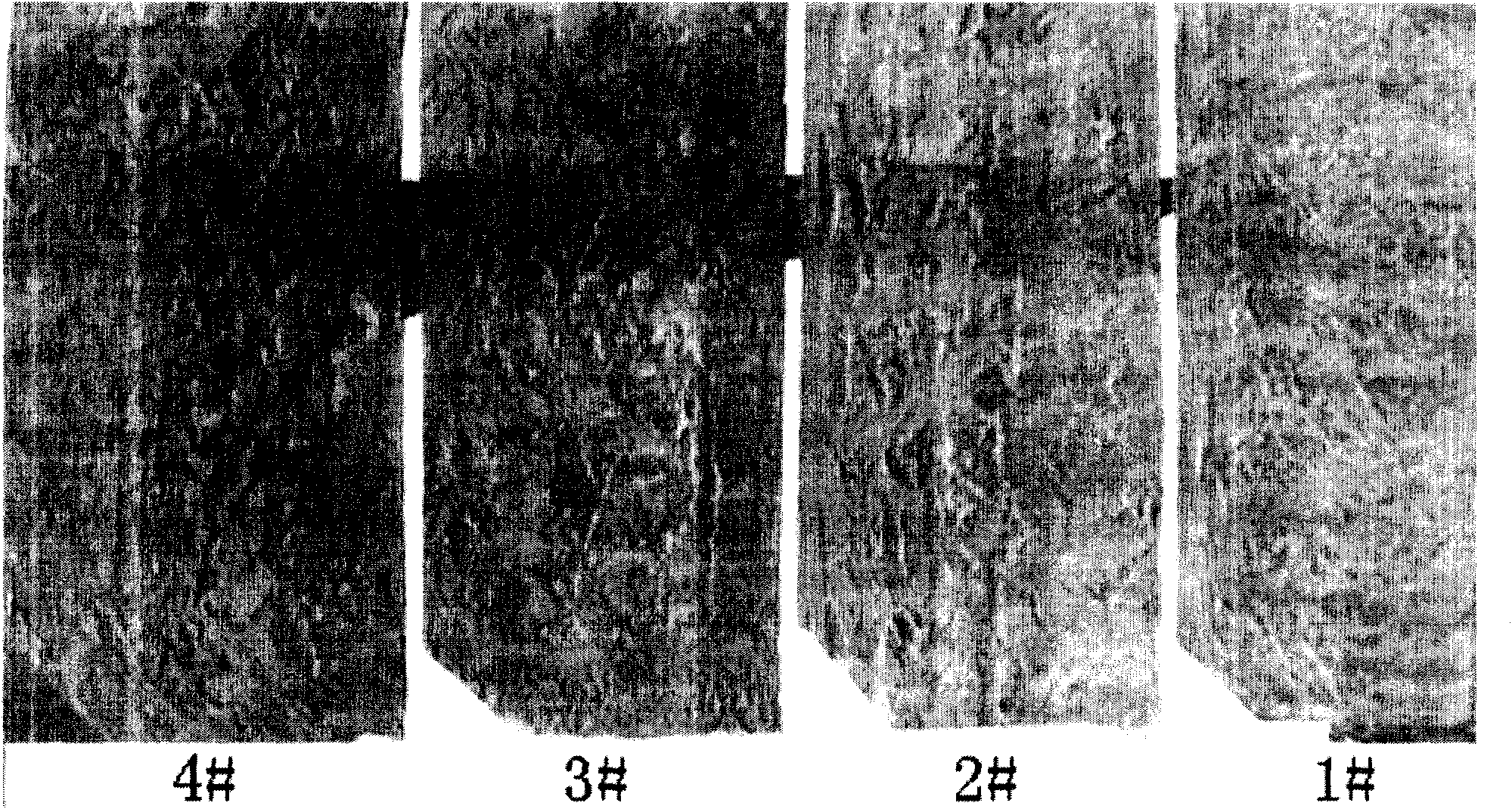

[0047] Mix the components of the above 1#, 2#, 3#, 4# formulations evenly, add 24% water, stir evenly with a mixer, and spread evenly on the outer wall board to make a coating; outdoor ob...

Embodiment 2

[0049] The following recipes add metakaolin and compare different amounts of metakaolin.

[0050] 1. Formula

[0051] 5# 6#

[0052] Portland cement (42.5R) 350.00g 350.00g

[0053] Heavy calcium (fineness ≥ 200) 200.00g 200.00g

[0054] River sand (40-70 mesh) 151.00g 158.00g

[0055] River sand (70-140 mesh) 250.00g 250.00g

[0056] Vinyl acetate / ethylene binary copolymer rubber powder 10.00g 10.00g

[0057] Modified bentonite 5.00g 5.00g

[0058] Wood fiber 3.00g 3.00g

[0059] Cellulose ether 1.00g 1.00g

[0060] Metakaolin (Basf MetaMax, Germany) 15.00g 8.00g

[0061] Polycarboxylate superplasticizer 1.00g 1.00g

[0062] Pigment 14.00g 14.00g

[0063] Total 1000.00g 1000.00g

[0064] 2. Coating and outdoor observation

[0065] Mix the components of the above 5# and 6# formulas evenly, add 24% water, stir evenly with a blender, and spread evenly on the outer wall board to make a coating; outdoor observation, if it is as good as figure 2 , 3...

Embodiment 3

[0067] 1. Formula

[0068] 7#

[0069] Portland cement (42.5R) 350.00g

[0070] Heavy calcium (fineness ≥ 200) 200.00g

[0071] River sand (40-70 mesh) 151.00g

[0072] River sand (70-140 mesh) 250.00g

[0073] Vinyl acetate / ethylene binary copolymer rubber powder 10.00g

[0074] Modified bentonite 5.00g

[0075] Wood fiber 3.00g

[0077] Metakaolin 15.00g (domestic)

[0078] Polycarboxylate superplasticizer 1.00g

[0079] Pigment 14.00g

[0080] Total 1000.00g

[0081] 2. Coating and outdoor observation

[0082] Mix the components of the above 7# formula evenly, add 23% water, stir evenly with a blender, and spread evenly on the exterior wall board to make a coating; outdoor observation, as shown in the figure after one year Figure 4 shown by Figure 4 It can be seen that the coating obtained by the 7# formula has local efflorescence phenomenon. It can be seen that the activity of metakaolin also has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com