High-strength environment-friendly waterproof polyurethane coating and preparation method thereof

A polyurethane waterproof and high-strength technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of not involving high temperature yellowing, inability to cure film formation, difficult operation, etc., achieving low cost, overall system stability, Easy-to-save effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

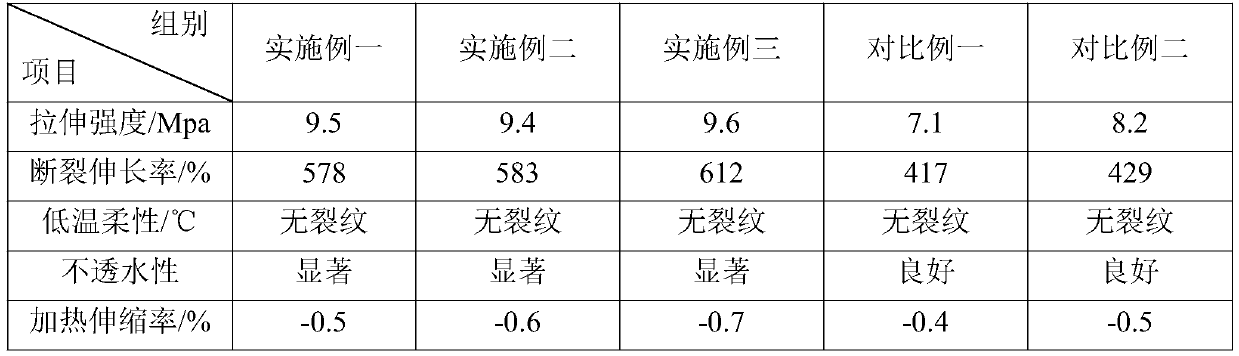

Examples

Embodiment 1

[0029] A high-strength environment-friendly polyurethane waterproof coating, the raw materials of which include by weight: 40 parts of modified polyurethane, 10 parts of hydrophilic modified polyisocyanate, 16 parts of polyester polyol, 7 parts of potassium tripolyphosphate, 3 parts of zinc stearate Parts, 13 parts of filler, 4-6 parts of butyl acetate, 0.1 part of film-forming aid, 0.1 part of defoamer, 0.2 part of leveling agent, 0.3 part of dispersant, 1 part of catalyst;

[0030] Wherein, the hydrophilic modified polyisocyanate is POSS modified polyethylene glycol modified polyisocyanate, and the polyisocyanate is HDI dimer.

[0031] Wherein, the film-forming aid is ethylene glycol monobutyl ether; the defoamer is a polyether modified silicone defoamer, i.e. polyether modified polydimethylsiloxane; the leveling The agent is an acrylic ester copolymer; the dispersant includes sodium polycarboxylate or ammonium polyacrylate; the catalyst is allophanate isocyanate.

[0032] ...

Embodiment 2

[0040] A high-strength environment-friendly polyurethane waterproof coating, the raw materials of which include by weight: 40-50 parts of modified polyurethane, 20 parts of hydrophilic modified polyisocyanate, 22 parts of polyester polyol, 10 parts of potassium tripolyphosphate, stearic acid 5 parts of zinc, 25 parts of filler, 6 parts of butyl acetate, 1 part of film-forming aid, 0.4 part of defoamer, 0.5 part of leveling agent, 0.6 part of dispersant, 10 parts of catalyst;

[0041] Wherein, the hydrophilic modified polyisocyanate is POSS modified polyethylene glycol modified polyisocyanate, and the polyisocyanate is selected from HDI dimer, HDI trimer, IPDI dimer, IPDI trimer kind of.

[0042] The film-forming aid is mixed in any ratio of lauryl alcohol ester and propylene glycol butyl ether; the defoamer is a polyether modified silicone defoamer, which is polyether modified Methylsiloxane; the leveling agent is an acrylic copolymer; the dispersant is polycarboxylate sodium s...

Embodiment 3

[0050] A high-strength environment-friendly polyurethane waterproof coating, the raw materials of which include by weight: 45 parts of modified polyurethane, 15 parts of hydrophilic modified polyisocyanate, 20 parts of polyester polyol, 8 parts of potassium tripolyphosphate, 4 parts of zinc stearate 20 parts, 20 parts of filler, 5 parts of butyl acetate, 0.6 parts of coalescent, 0.3 parts of defoamer, 0.4 parts of leveling agent, 0.4 parts of dispersant, 6 parts of catalyst;

[0051] Wherein, the hydrophilic modified polyisocyanate is POSS modified polyethylene glycol modified polyisocyanate, and the polyisocyanate is selected from HDI dimer, HDI trimer, IPDI dimer, IPDI trimer kind of.

[0052] The film-forming aid is a mixture of ethylene glycol monobutyl ether, lauryl alcohol ester and propylene glycol butyl ether in any proportion; the defoamer is a polyether modified silicone defoamer, which is polyether in this embodiment Modified polydimethylsiloxane; the leveling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com