Preparation method for manganese violet coated pigment

A technology of manganese violet and pigments, which is applied in the field of preparation of coated manganese violet pigments, and can solve the problems of unmentioned preparation method and unpredictable coating of manganese violet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

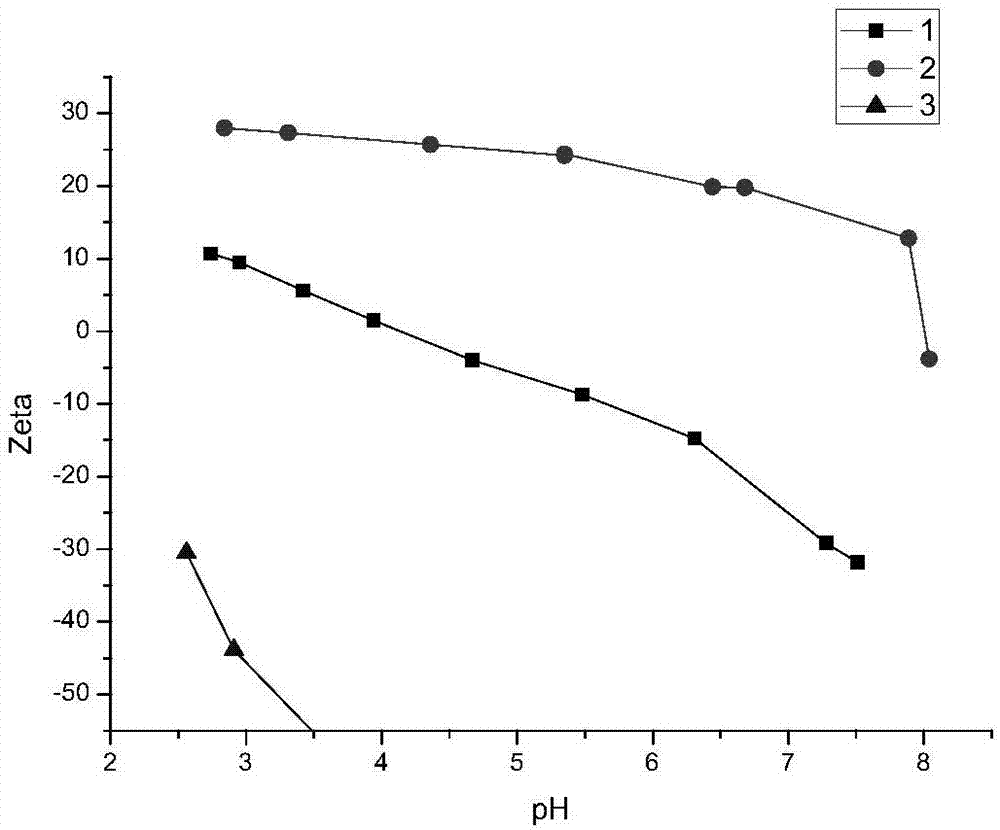

Image

Examples

Embodiment 1

[0060] In the reactor, add 60g of spherical silica with an average particle size of 3μm, add 900mL of water according to the solid-to-liquid weight ratio of 1 / 15 to prepare a slurry, first use sodium hydroxide to adjust the pH of the system between 5.5-6.0, Add at 78°C, use sodium hydroxide to control the pH of the system under the condition of 5.5-6.0, add 6mL of 1M aluminum chloride solution (0.3g as alumina, 0.5% to the substrate) within 0.5h; after the addition is completed Adjust the pH value of the system to 3.0, add 1mL triethoxyoctylsilane (accounting for about 1.7% of the weight of the substrate), and stir at 78°C for 0.5h; add 0.5g of MOA-9p (accounting for about 0.83% of the weight of the substrate %), stirred at 78°C for 0.5h; added 10g of color paste containing 40% manganese violet (about 4g of manganese violet, about 6.7% of the weight of the substrate), stirred at 78°C for 0.5h; then at 78°C, the pH Under the condition of =3.0, add 0.1gMOA-9p (accounting for abo...

Embodiment 2

[0062] In the reactor, add 60g of spherical silica with an average particle size of 3μm, add 600mL of water according to the solid-liquid weight ratio of 1 / 10 to make a slurry, and at this time the pH of the system is about 8, add 3mL of 1M Aluminum chloride solution (0.15g as alumina, 0.25% (by weight) to the base material), (in the process of adding aluminum chloride aqueous solution, ensure that the system pH is greater than 2, if the system pH value is less than 2, use it at the same time Sodium hydroxide neutralizes to control the pH value, if the pH value in this process is greater than 2, no need to control); then adjust the system pH value to 3.0, add 2mL triethoxyoctylsilane (accounting for about 3.4% of the substrate weight ), stirred at 78°C for 0.5h (subsequent operations maintained the system pH=3.0); added 1.0g MOA-9p (accounting for about 1.7% of the weight of the substrate), stirred at 78°C for 0.5h; added manganese-containing violet 20g of 40% color paste (abo...

Embodiment 3

[0064] In the reactor, add 60g of spherical silica with an average particle size of 3μm, add 600mL of water according to the solid-liquid weight ratio of 1 / 10 to make a slurry, and at this time the pH of the system is about 8, add 3mL of 1M Aluminum chloride aqueous solution (0.15g as alumina, 0.25% to the base material), (in the process of adding aluminum chloride aqueous solution, ensure that the pH is greater than 2, if the system pH value is less than 2, use sodium hydroxide to neutralize the control pH value, if the pH value in this process is greater than 2, then no need to control); then adjust the pH value of the system to 3.0, add 2mL triethoxyoctylsilane (accounting for about 3.4% of the weight of the substrate), at 78 ° C Stir for 0.5h; when the pH value of the system is 3.0, add 20g of color paste containing 40% manganese violet (about 8g of manganese violet, which is about 13.3% of the weight of the substrate), and stir for 0.5h at 78; At 3.0, add 1.0g MOA-9p (acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com