Planar electrode and preparation method and application thereof

A planar electrode and planar technology, which is applied in the field of capacitors, can solve the problems of poor compatibility of electrode structures and achieve the effects of increasing charge and discharge rates, controllable thickness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

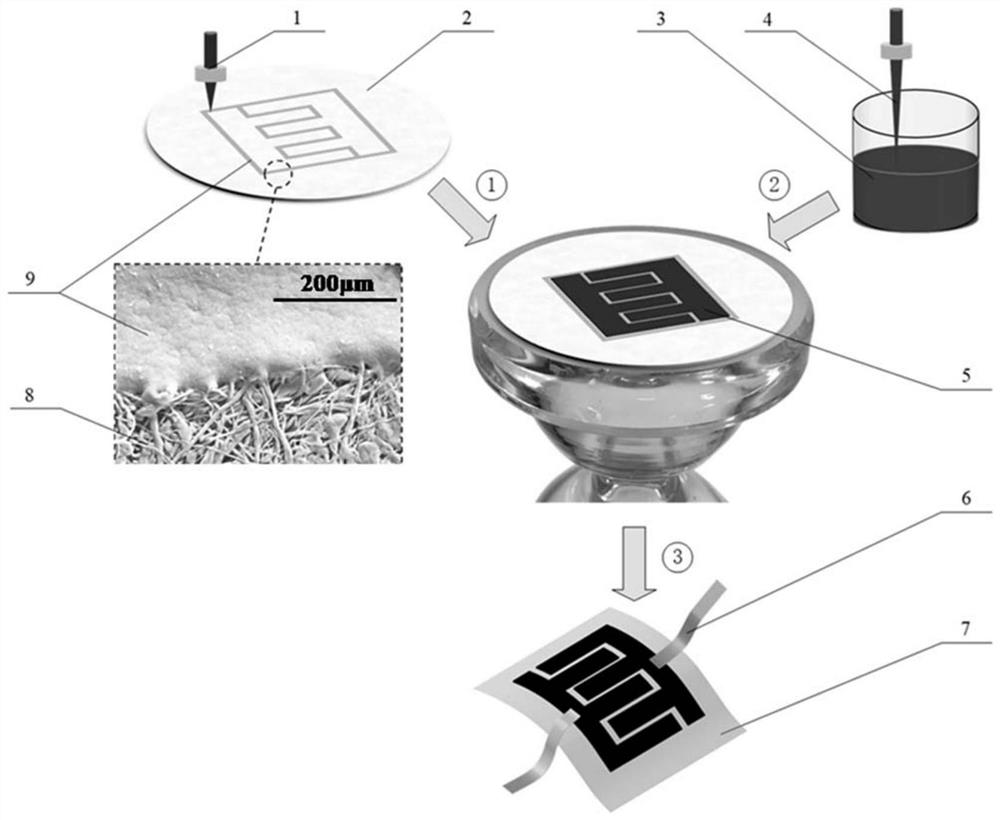

[0048] This embodiment provides a flexible thin film electrode and applies it to assembling micro supercapacitors. The preparation process is as follows figure 1 The specific operation steps are as follows:

[0049] 1) A polypropylene microfiltration membrane with a diameter of 50 mm and a pore size of 0.22 μm was clamped on a stainless steel sheet substrate washed with absolute ethanol and deionized water and dried. The stainless steel sheet with the polypropylene microporous filter membrane clamped was placed on the processing substrate of the laser, and CO was carried out under ambient conditions. 2 Laser local thermal fusion patterning is performed to form a pattern with 3 pairs of interdigitated structures by in-situ cooling and stacking.

[0050] Among them, CO 2 The preparation conditions and parameters of the laser partial hot melt patterning are as follows: a carbon dioxide laser with a wavelength of 10.6 μm is used, the focal length is 23 mm, and the spot diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com