Patents

Literature

213results about How to "High strength requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid pattern casting special paint and preparation method thereof

InactiveCN102049464AHigh strengthImprove integrityFoundry mouldsFoundry coresGraphiteSuspending Agents

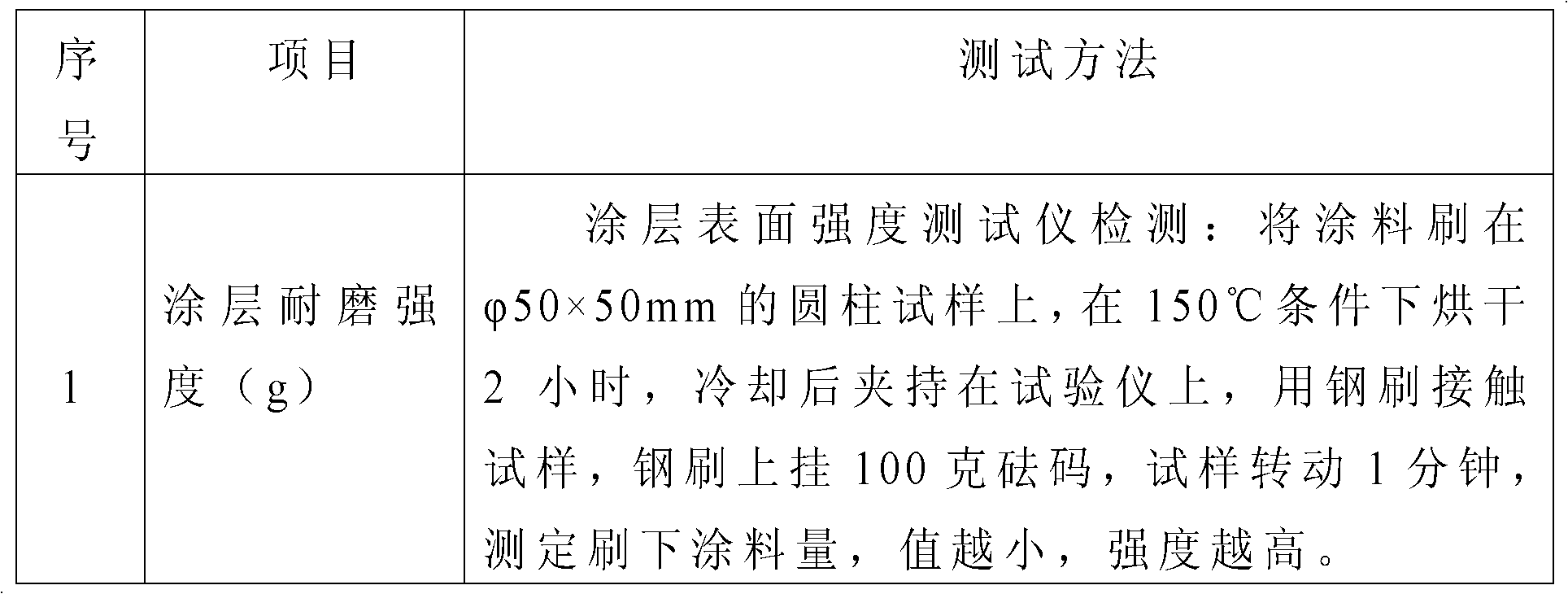

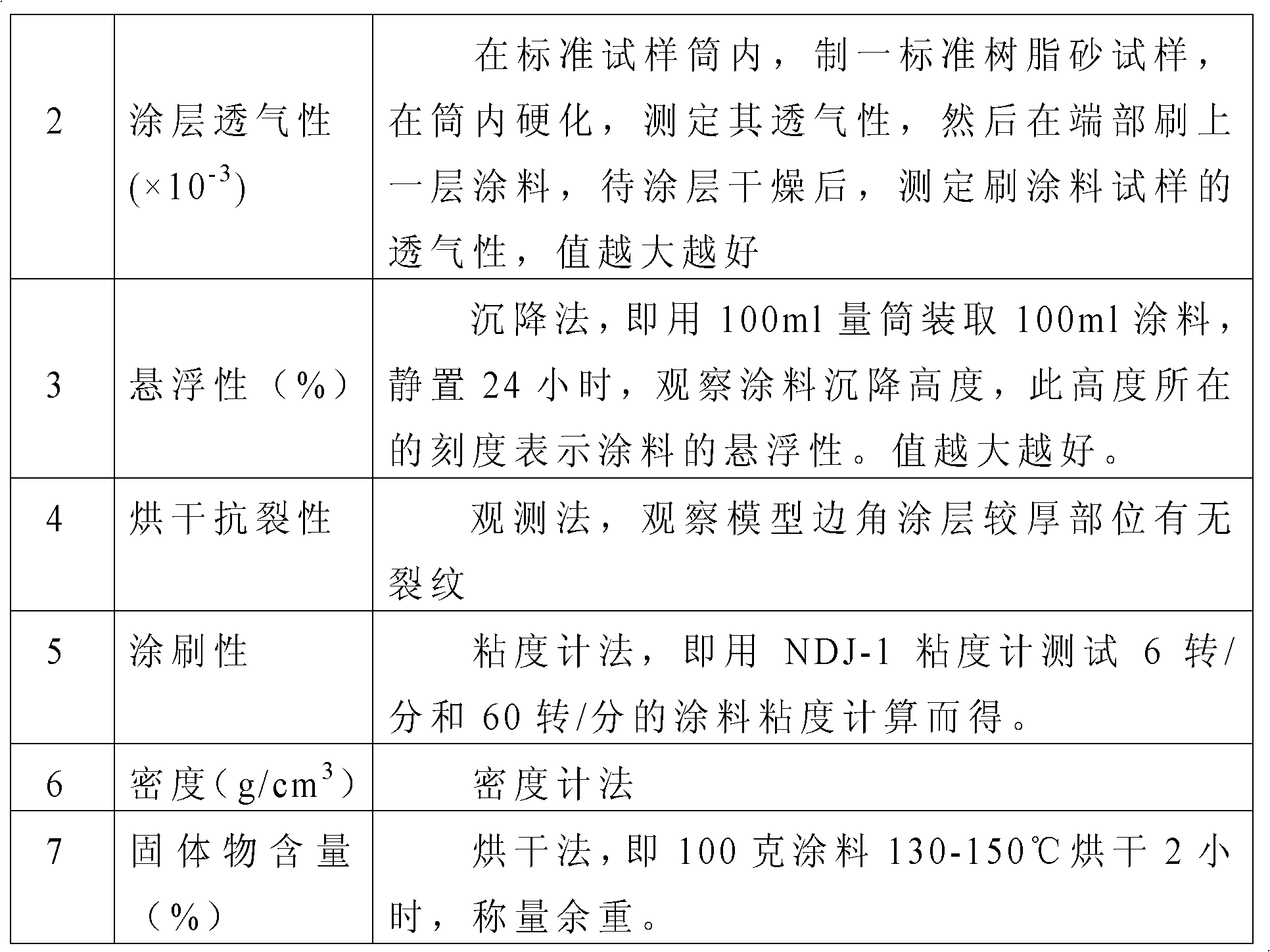

The invention discloses a solid pattern casting special paint and a preparation method thereof. The mass percentages of various constituents in the paint are: 30-40% of bauxite chamotte, 20-30% of flaky graphite powder, 6.3-8.5% of bonder, 1-2% of iron oxide red powder, 4-6% of suspending agent, 0.8-1.5% of water reducing agent and 20-30% of water. The preparation method comprises the steps: mixing the various components of the solid pattern casting special paint according to the mass percentages and loading the constituents into a ball mill; adding 50-80 ceramic balls with a diameter of 30-50 mm into the ball mill; and mixing and stirring the materials evenly to obtain the paint. Practices show that the paint has strong abrasion performance, high adhesiveness, good air permeability and fast-dry performance both in low and high temperature environments; the paint can satisfy the production requirement of large casting production; the preparation method disclosed by the invention is simple; and the cost is low.

Owner:DONGFENG MOTOR CO LTD

Corrosion-resistance iron-based austenite oil well pipe and manufacturing method thereof

InactiveCN104962836AMeet the slow strain test requirementsAchieve smoothSolid solutionElectro-slag remelting

The invention discloses a corrosion-resistance iron-based austenite oil well pipe and a manufacturing method thereof. The main chemical components of the oil well pipe include C larger than 0 and smaller than or equal to 0.03%, Si larger than 0 and smaller than or equal to 1.00%, Mn larger than 0 and smaller than or equal to 2.50%, P smaller than or equal to 0.03%, S smaller than or equal to 0.03%, 20.0%-28.0% of Cr, 20.0%-38.0% of Ni, 3.0%-5.0% of Mo and 0.50%-2.00% of Cu. The manufacturing method includes the first step of smelting; the second step of billet pouring; the third step of electroslag remelting; the fourth step of homogenizing annealing; the fifth step of billet forging; the sixth step of pipe billet preparing; the seventhly step of hot extruding, wherein a seamless steel pipe is formed through pipe billet preheating, power frequency induction furnace heating, pipe billet broaching, secondary induction heating and extruding; the eighth step of solid solution treating; and the ninth step of conducting of a deformation strengthening mode in cold drawing, wherein the percentage reduction of area is controlled within 20-40%, and the oil well pipe is manufactured. According to the corrosion-resistance iron-based austenite oil well pipe and the manufacturing method thereof, the wall thickness of the manufactured oil well pipe ranges from 15 mm to 40 mm, the yield strength is 760 MPa or higher, the tensile strength is 793 MPa or higher, the impact energy is 100 J or higher, the corrosion resistance is good, and the requirement for strictest and slow-strain tests is met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

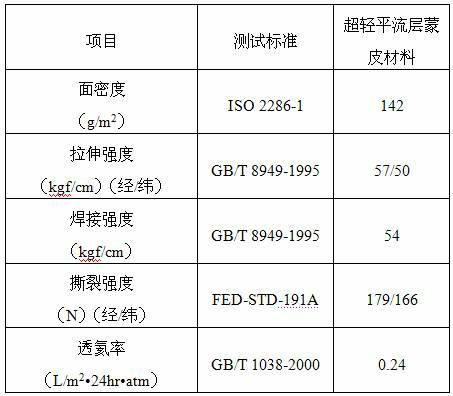

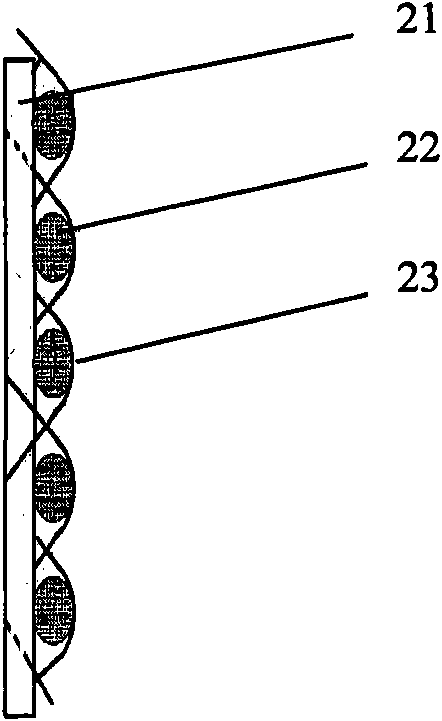

Ultra-light, weather-resistant and high-strength stratosphere skin material

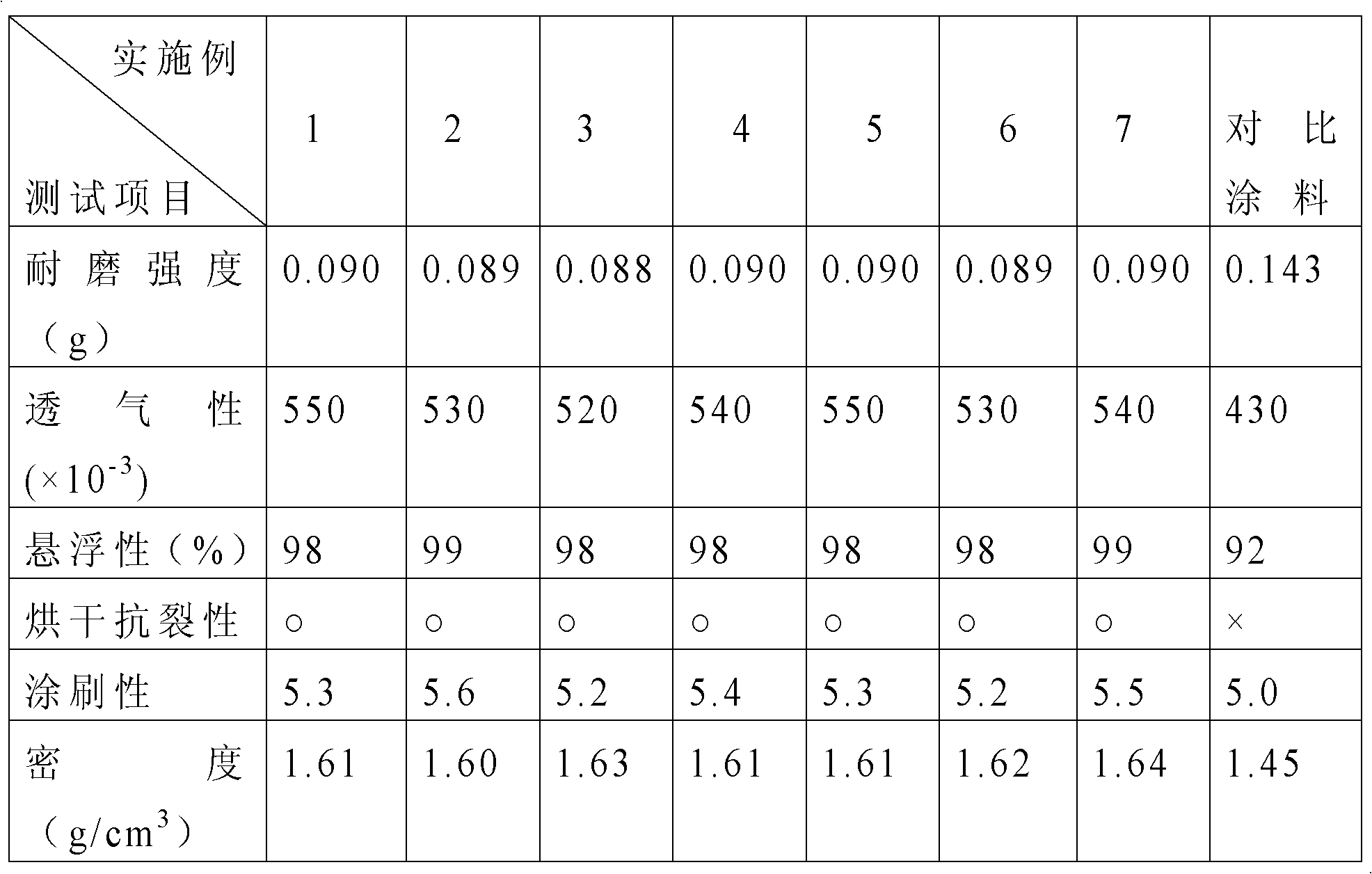

InactiveCN101905557ALight in massGood weather resistanceSynthetic resin layered productsLighter-than-air aircraftPolyesterStratosphere

The invention provides an ultra-light, weather-resistant and high-strength stratosphere skin material which has high strength and weatherability, relating to skin materials. The ultra-light stratosphere skin material consists of a weather-resistant layer, a force bearing layer, a block layer and a heat sealing layer from outside to inside. Vectran fiber 200 Daniel plain woven fabric with ultra-high strength is selected and used as the force bearing layer, the Vectran fiber 200 Daniel plain woven fabric has the strength about 6 times as high as that of common polyesters, and the light weight of 54 g / m<2> and the thickness of 0.16 mm. The produced stratosphere skin material has ultra-light mass.

Owner:HARBIN INST OF TECH

Cardiac muscle tonifying tablet taking acellular biological membrane as carrier as well as preparation method and application of cardiac muscle tonifying tablet

ActiveCN104436305AHelps maintain sterilityImprove decellularization efficiencyProsthesisCross-linkNutrition support

The invention discloses a cardiac muscle tonifying tablet taking an acellular biological membrane as a carrier as well as a preparation method and application of the cardiac muscle tonifying tablet. The cardiac muscle tonifying tablet taking the acellular biological membrane as the carrier is prepared by the following steps: carrying out decellularizing treatment on a natural biological membrane; then, cross-linking nutrient substances on the acellular biological membrane; planting target cells on the acellular biological membrane cross-linked with the nutrient substances; and cultivating a cell sheet which is preliminarily constructed, so that the cardiac muscle tonifying tablet taking the acellular biological membrane as the carrier is prepared. The cardiac muscle tonifying tablet disclosed by the invention is good in proliferation and differentiation activities and mechanical strength, and is sufficient in nutrition support; the cardiac muscle tonifying tablet is not only a breakthrough in tissue engineering but also suitable for the clinical treatment of myocardial infarction. The cardiac muscle tonifying tablet disclosed by the invention is reliable in principle, good in reproducibility, and suitable for standard production.

Owner:JINAN UNIVERSITY

Easy cutting brass alloy containing silicon without lead

The present invention belongs to the field of metal material producing technology, and the easy-to-cut brass alloy contains Cu 80-84 wt%, Si 2.5-5.0 wt%, As 0.02-0.10 wt%, except Zn and 0.05 wt% below impurity. It may be used in replacing widely applied corresponding lead brass alloy to avoid lead pollution while ensuring excellent cutting performance, mechanism performance and conducting performance.

Owner:ZHEJIANG HAILIANG

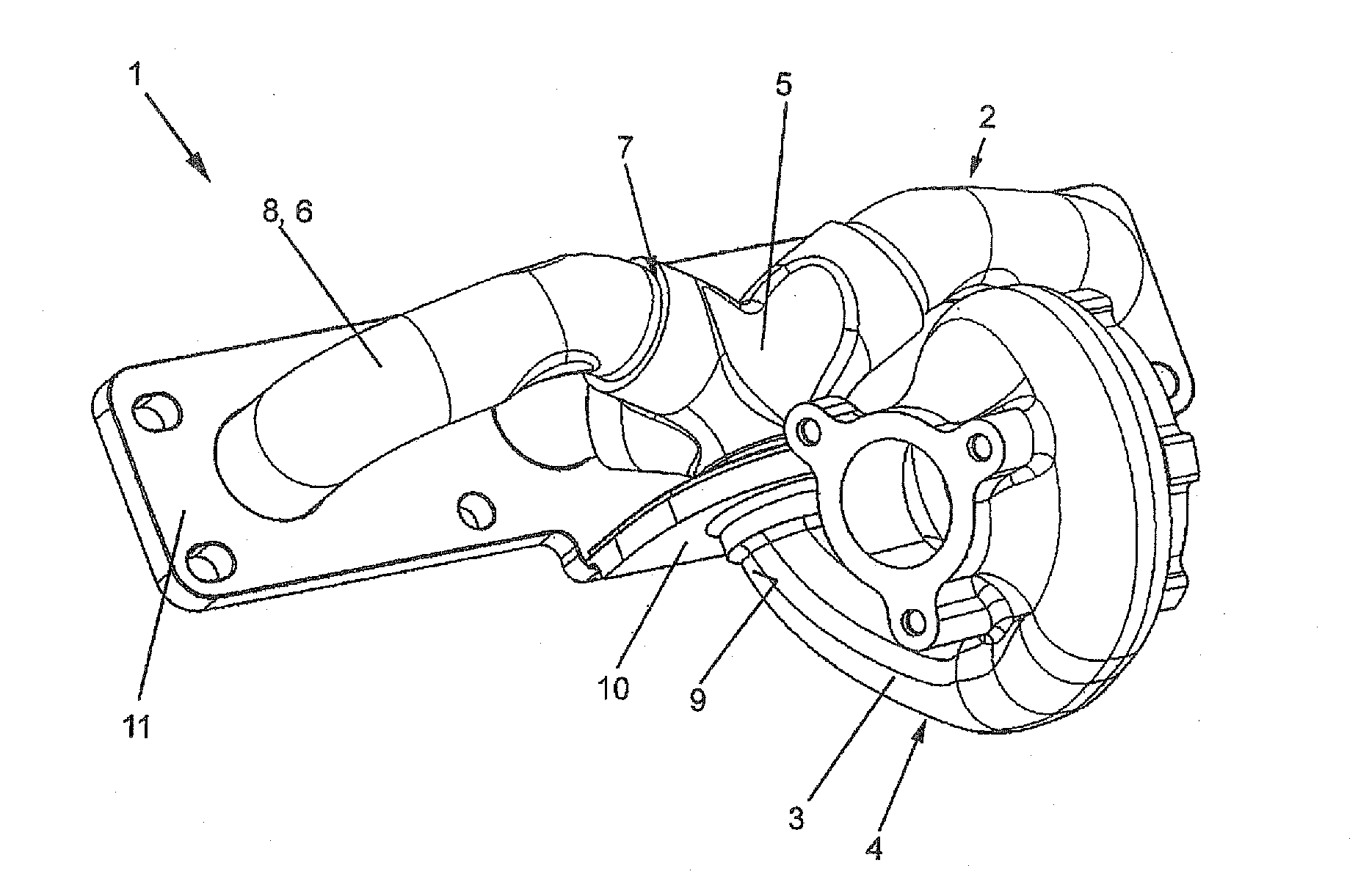

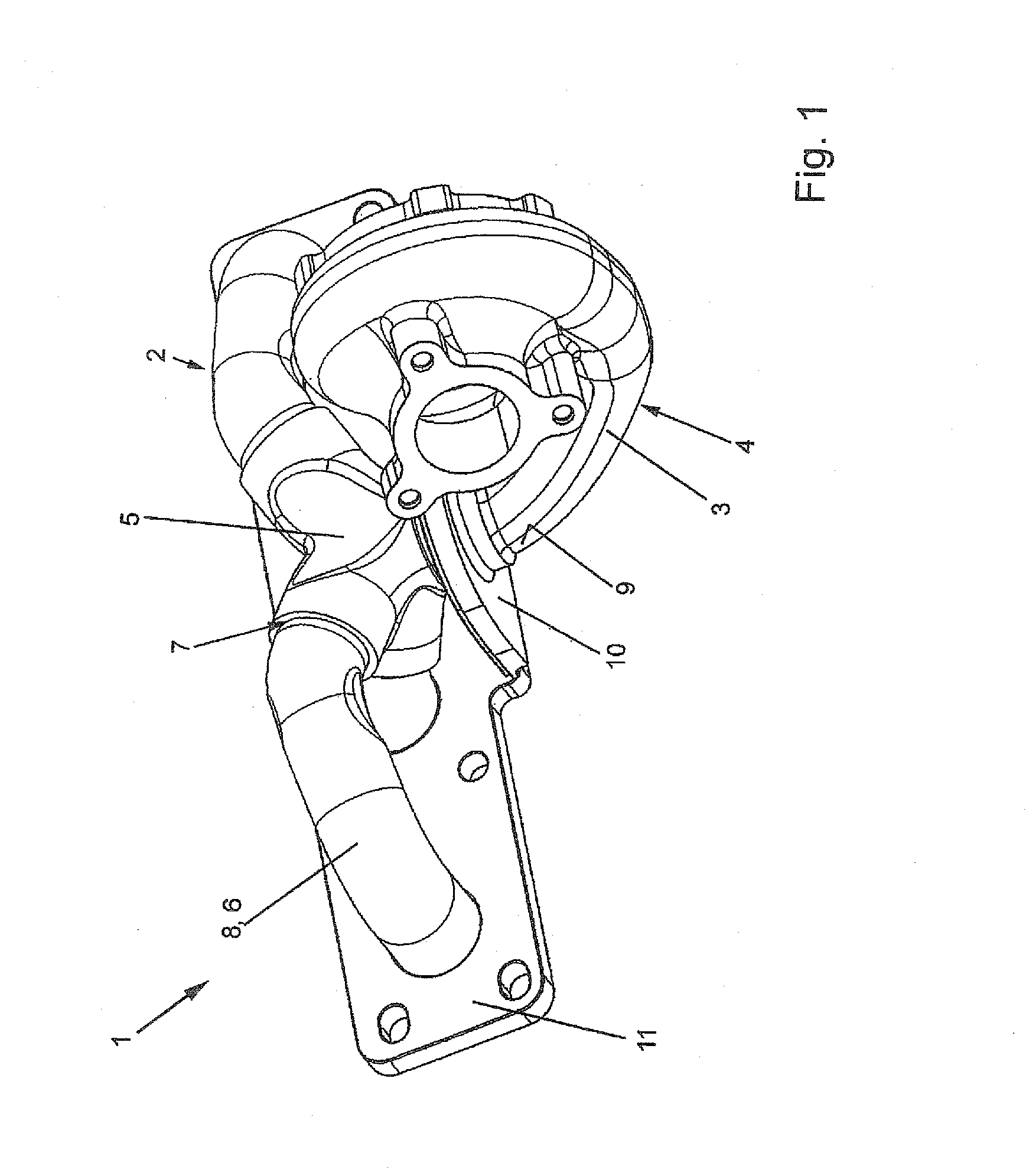

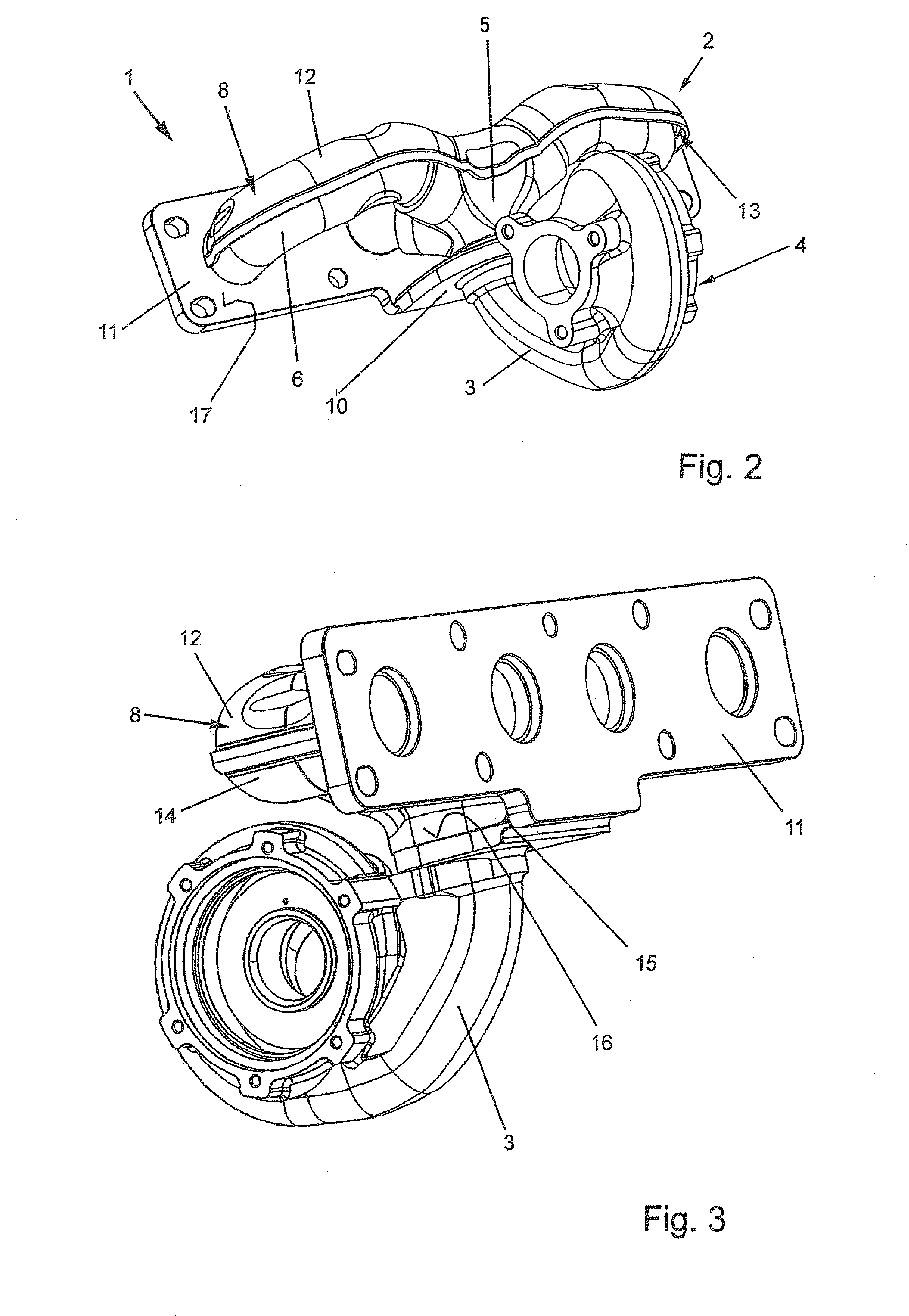

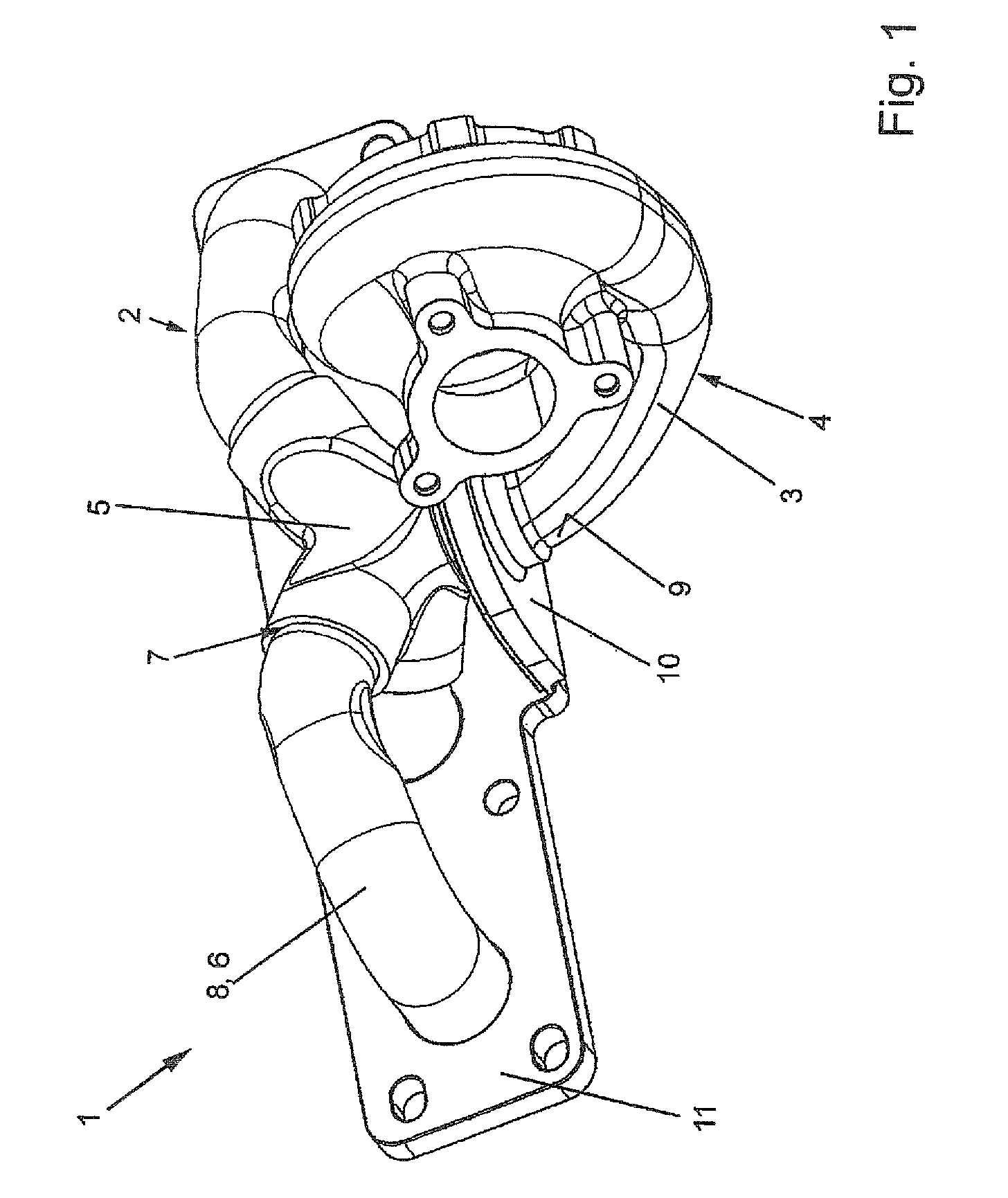

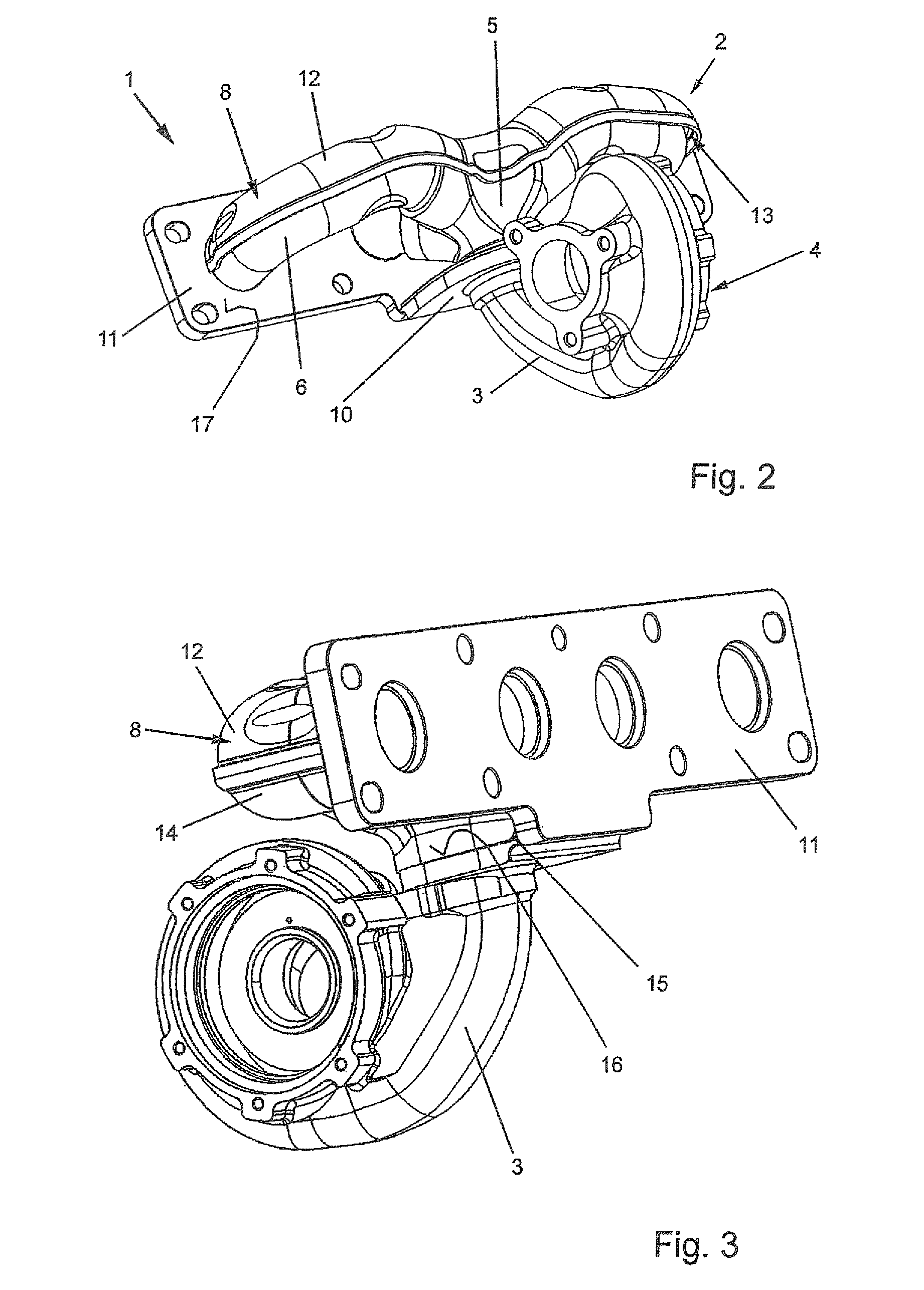

Exhaust gas system

InactiveUS20100223911A1Increased bending stiffnessHigh stiffnessInternal combustion piston enginesExhaust apparatusTurbochargerExhaust fumes

An exhaust gas system includes a turbocharger housing and an exhaust manifold having manifold pipes and connected to the turbocharger housing. The turbocharger housing has a pipe collector extending in a direction of the exhaust manifold for connection of the manifold pipes.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

High-strength absorbable magnesium substrate composite orthopedic fixing device and preparation method thereof

InactiveCN102908672AHigh strength requirementsMeet mechanical safety requirementsInternal osteosythesisCoatingsPlastic surgeryPolylactic acid

The invention relates to a high-strength absorbable magnesium substrate composite orthopedic fixing device and a preparation method thereof. The fixing device is mainly formed by bonding and solidifying a low-porosity porous magnesium alloy substrate of which a pore structure presents a regular gradient distribution and a lower-content polylactic acid high-polymer material filled in the pore structure of the low-porosity porous magnesium alloy substrate, wherein the pore structure in the porous magnesium alloy substrate presents a gradient distribution that the porosity is gradually reduced from the surface of the magnesium alloy substrate to a core part or from the edge to the center, and the size of a pore is gradually diminished; and according to the calculation in percentage by weight, the polylactic acid of the high-polymer material for filling accounts for 5-49.9 percent of total weight, and the porous magnesium alloy substrate accounts for 50.1-95 percent of total weight. The fixing device is closer to magnesium alloy in strength, has the advantages of controllable in-body adsorption speed, slow-quick degradation, less hydrogen evolution moderate quantity and the like, is particularly suitable for the bone trauma surgery with high strength requirement and big volume, the bone defect repair surgery, the plastic surgery and other absorbable orthopedic fixed implantable devices applied to the clinical.

Owner:SOUTHEAST UNIV

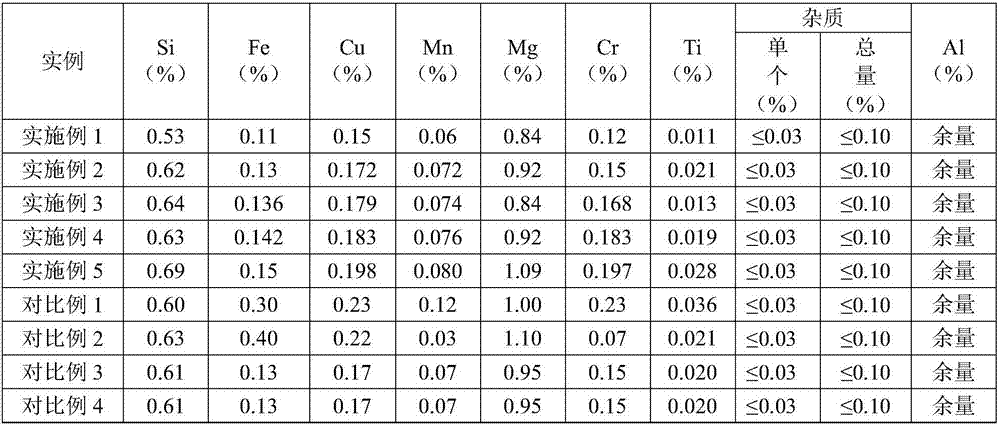

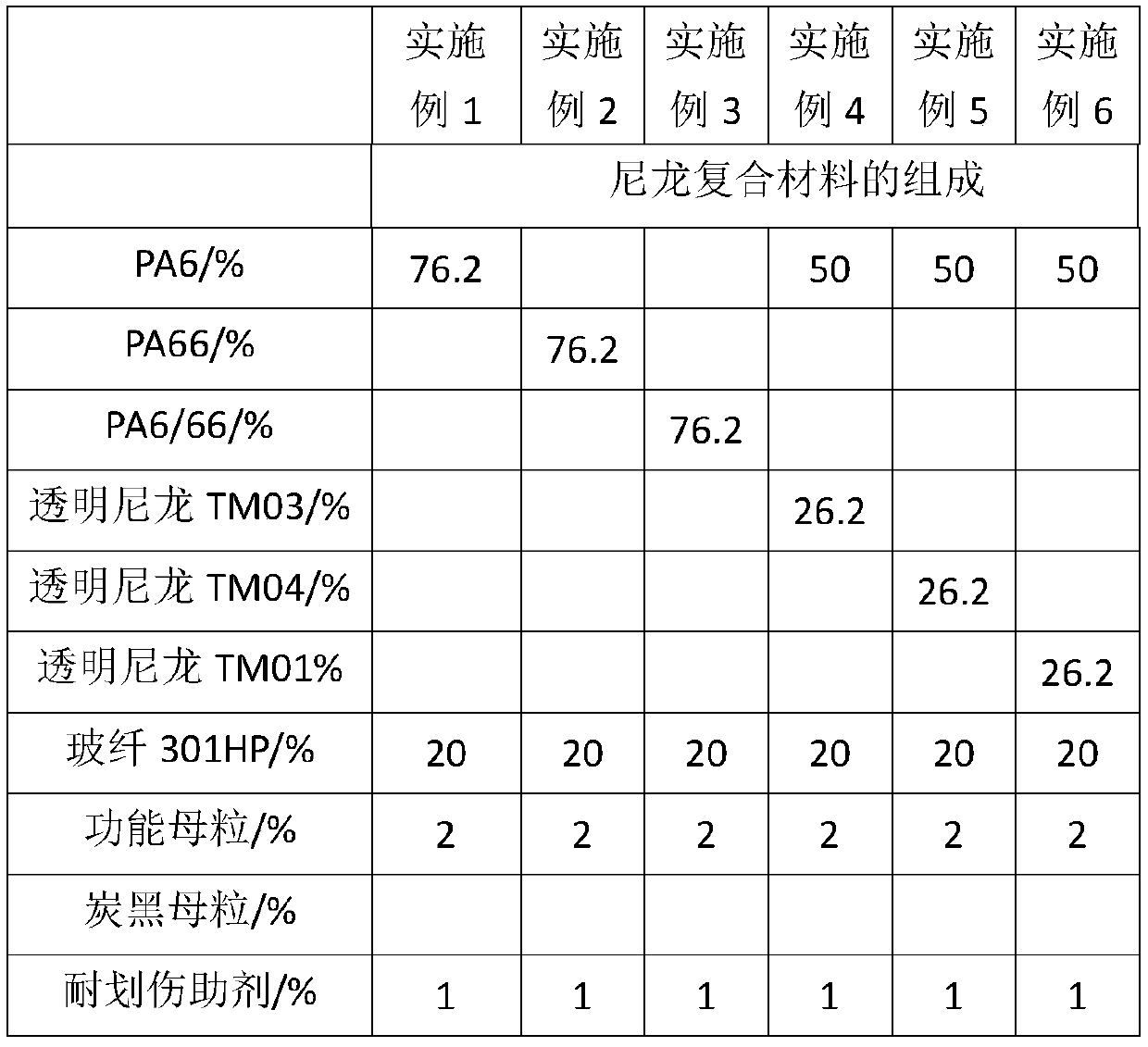

6061G aluminum alloy for smart phone and processing method thereof

The invention discloses a 6061G aluminum alloy for a smart phone and a processing method thereof. The aluminum alloy comprises the following components in percentages by weight: 0.50-0.70% of Si, 0.11-0.15% of Fe, 0.15-0.20% of Cu, 0.06-0.08% of Mn, 0.80-1.10% of Mg, 0.11-0.20% of Cr, 0.01-0.03% of Ti and the balance of Al and inevitable impurities. The corresponding processing method comprises the following eight steps: ingot casting, homogenizing annealing, hot rolling, cold rolling, intermediate annealing, secondary cold rolling, solid solution treatment and final aging treatment successively. An aluminum product, with the components of the aluminum alloy, obtained by means of the processing method has an extremely excellent anodizing effect, meets the sand blasting of extremely thin 205-210-mesh zircon sand, is an ideal aluminum alloy material, which is used for 6-series mobile phone appearance part having high demand on strength and anodizing effect, and is wide in market application prospect.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

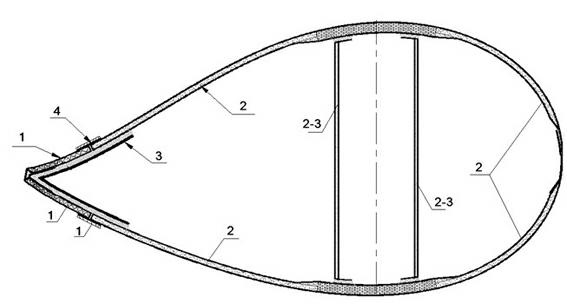

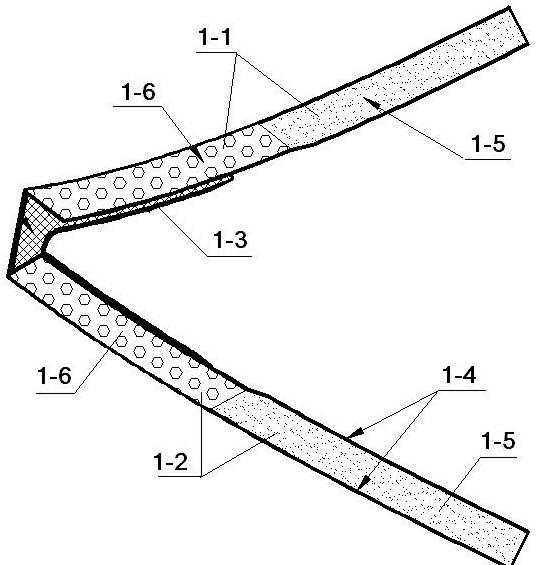

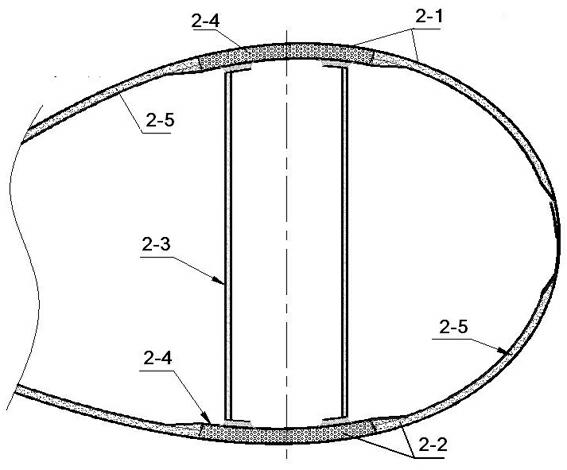

Segmented fan blade as well as preparation and assembly method of segmented fan blade

ActiveCN102661252AReasonable structural designHigh mechanical strengthMachines/enginesWind energy generationStructural engineeringFan blade

The invention discloses a segmented fan blade, which comprises a fan blade back edge segment (1) and a fan blade body segment (2), wherein the fan blade back edge segment (1) comprises an upper casing (1-1), a lower casing (1-2) and an auxiliary pasting corner (1-3), the auxiliary pasting corner (1-3) for connecting the upper casing (1-1) with the lower casing (1-2), the upper casing (1-1) and the lower casing (1-2) consist of skins (1-4), core materials (1-5) and auxiliary beams (1-6), the fan blade body segment comprises a body segment upper casing (2-1), a body segment lower casing (2-2) and a rib plate (2-3), the body segment upper casing (2-1) and the body segment lower casing (2-2) are formed by a crossbeam (2-4) and a sandwich structure (2-4), and the rib plate (2-3) is formed by the sandwich structure (2-4). The segmented fan blade provided by the invention has the advantages that the structural design is reasonable, the mechanical intensity is high, the segmented fan blade design is adopted, the problem of transportation difficulty caused by too high blade loading height can be solved, and the transportation cost is low. In addition, a preparation and assembly method of the segmented flan blade provided by the invention has the advantages that the assembly is convenient, the work efficiency is high, and the reliability is high.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

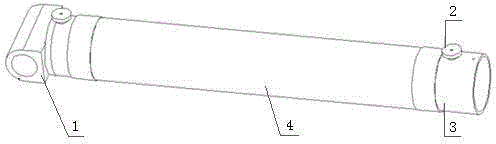

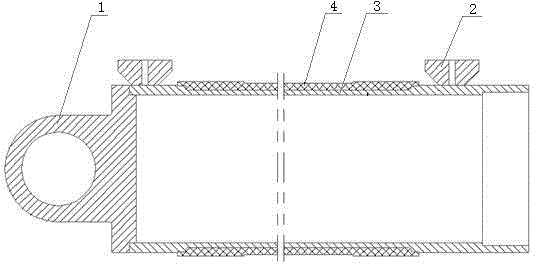

Carbon fiber composite material reinforcing hydraulic oil cylinder

InactiveCN102720721AImprove securityReduce energy consumptionFluid-pressure actuatorsTruckMetal cylinder

The invention provides a carbon fiber composite material reinforcing hydraulic oil cylinder, comprising a base, a cylinder barrel and oil openings. The oil openings are arranged at the both ends of the cylinder barrel; the cylinder barrel is a thinned metal cylinder barrel; a reinforcing layer is coated outside the cylinder barrel; the reinforcing layer is a carbon fiber composite material reinforcing layer; the carbon fiber composite material reinforcing layer uses heat convertible resin as a base body and a carbon fiber as a reinforcing material; and the carbon fiber composite material reinforcing layer contains the resin with a mass ratio of 23-55%. Compared with the full-metal hydraulic oil cylinder in the prior art, the strength, the rigidity and the anti-fatigue property of the carbon fiber composite material reinforcing hydraulic oil cylinder in various working conditions are improved by more than 20%, so that not only can the security of the product be effectively improved in the working conditions, but also more than 30% of the weight is reduced. Therefore, a mechanical pump truck is lightened, and the entire cost is reduced.

Owner:HENGSHEN

Flame-retardant shrinkable anticorrosive packaging film and manufacturing method thereof

InactiveCN102029755ARealize batchImprove packaging efficiencyFlexible coversWrappersBlow moldingEngineering

The invention provides a flame-retardant shrinkable anticorrosive packaging film which is composed of a two-layer or three-layer structure, wherein, the inner layer contains an anti-rusting agent with an anticorrosive protection function on metal; the middle layer and the outer layer contain flame retardants with a flame retardance function; and the layers contain plastic particles with heating contractibility. The packaging film is formed by mixing raw materials according to a certain type and proportion, heating and then performing coextrusion blow molding on double-layer or three-layer coextrusion film blowing equipment according to a certain temperature condition and at thickness ratio, and the obtained packaging film is a novel multifunctional metal anticorrosive protective packaging material. The flame-retardant shrinkable anticorrosive packaging film has the characteristics of heating contractibility, excellent anti-rust property, skin packaging, good tightness, good fastness, flame retardance, being convenient in automated operation, and being economical and practical; and the packaging film can be widely applied to anticorrosive protective package of products such as auto parts, mechanical equipment, hardware tools, metallurgic products, aerospace products, electronic equipment, weapon equipment and the like during the storage and transportation period, thus being a novel material applicable to the current metal protective packaging field.

Owner:沈阳防锈包装材料有限责任公司

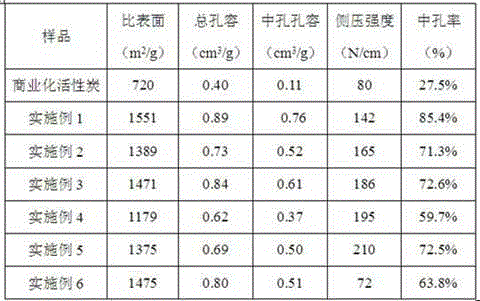

Columnar cocoanut shell activated carbon and preparation method thereof

The invention provides columnar cocoanut shell activated carbon with high strength and high mesoporosity and a preparation method of the columnar cocoanut shell activated carbon. The columnar cocoanut shell activated carbon has the side pressure of 210N / cm, the strength of larger than or equal to 95% and the mesoporosity of 70-90%. The preparation method of the columnar cocoanut shell activated carbon comprises the steps of crushing and sieving pretreated cocoanut shells; uniformly mixing wood powder with a certain particle size and a specific organic binder; adding phosphoric acid and a proper amount of water according to a certain phosphorus / wood ratio; and sequentially dipping, kneading, carrying out extrusion molding, curing, carbonizing, activating, washing and drying to obtain the columnar cocoanut shell activated carbon. Through condition control, the columnar cocoanut shell activated carbon has the specific surface area of 900-1600 m<2> / g, the pore volume of 0.4-0.8 cm<3> / g and the mesoporosity of 70-90% within a certain high-strength range, and the controllability is also one of the advantages of the columnar cocoanut shell activated carbon. Due to the adoption of a porous structure with high strength and high mesoporosity, the columnar cocoanut shell activated carbon can be used as a solid catalyst in a fixed bed reactor and is wide in application prospect in the catalysis field.

Owner:FUZHOU UNIVERSITY

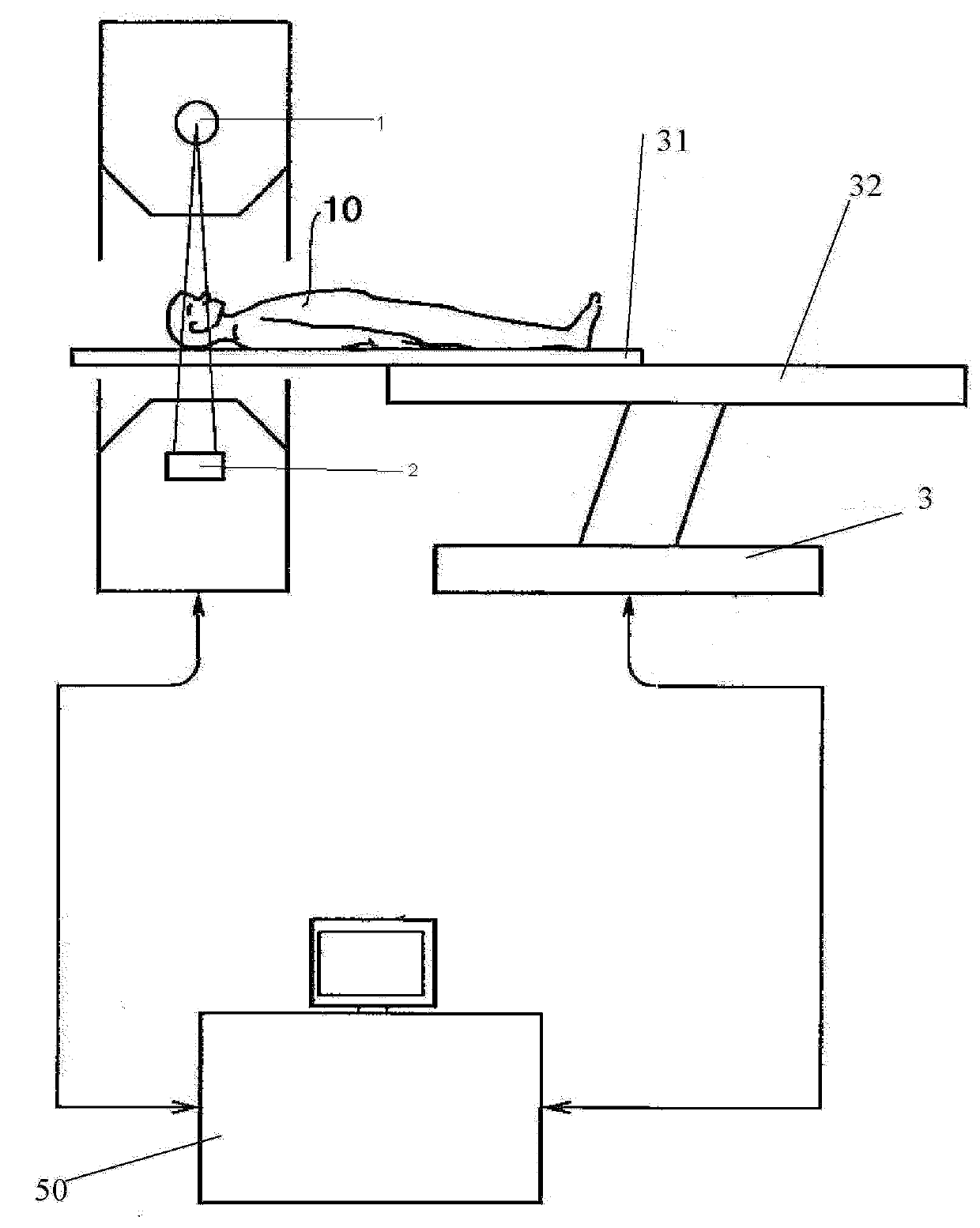

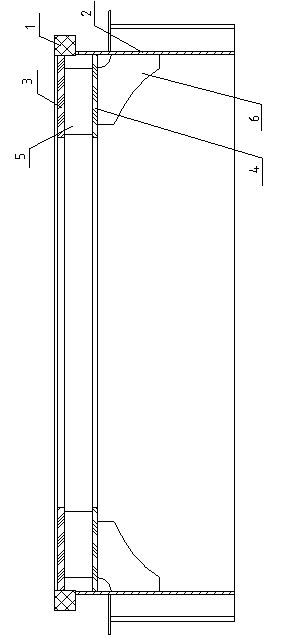

Bed plate, bed comprising bed plate, and computed tomography (CT) equipment

ActiveCN102551785ALow costEasy to scanPatient positioning for diagnosticsComputerised tomographsComputing tomographyEngineering

The invention discloses a bed plate, a bed comprising the bed plate, and computed tomography (CT) equipment. The bed plate comprises an air cushion capable of inflating or deflating, and a bed plate shell for accommodating the air cushion; the bed comprises the bed plate; and the CT equipment comprises the bed or the bed plate. The height and the inclined angle of the bed plate can be adjusted by sampling the air cushion capable of inflating or deflating, so that patients of different sizes can be positioned in the middle of an aperture of a scanning frame to acquire the clearest image; different scanning parts are positioned at proper inclined angles, so that the patients receive the minimum X-ray dose, and a mechanical device for adjusting the height and the inclined angle of the bed plate is not required; and therefore, the cost is reduced.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Gas protection wire for steel

ActiveCN101058134AImprove performanceHigh strengthWelding/cutting media/materialsSoldering mediaHardnessCorrosion

The invention relates to a steel used gas protective welding wire. Its composition is as follows: C: 0. 003%-0. 04%; Mn: 1. 5%-3%; Si: 0. 02%-0. 4%; Ni: 2%-6%; Mo: 1%-3. 2%; Ti: 0%-0. 4%; Cr: 0. 01%-0. 6%; Cu: 0. 2%-0. 4%; Mg: 0%-0. 1%; S: <=0. 01%; P: <=0. 02%, with the rest being Fe. The invented welding juncture has fine comprehensive feature, particularly high strength, and fine low temperature flexibility. The low hardness is beneficial to corrosion resistance.

Owner:JIANGSU ZHONGJIANG WELDING WIRE

Silicate cement adhesive for high-voltage electrical appliance bushing

Owner:DALIAN INSULATOR GRP CO LTD

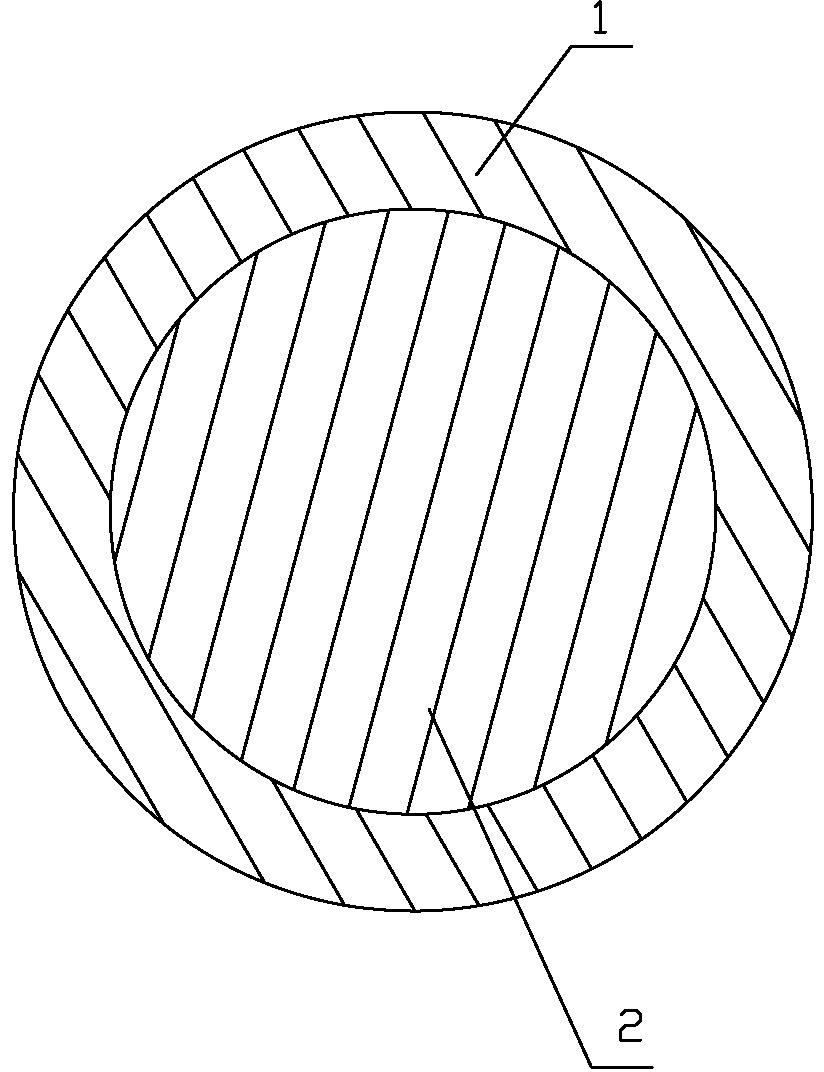

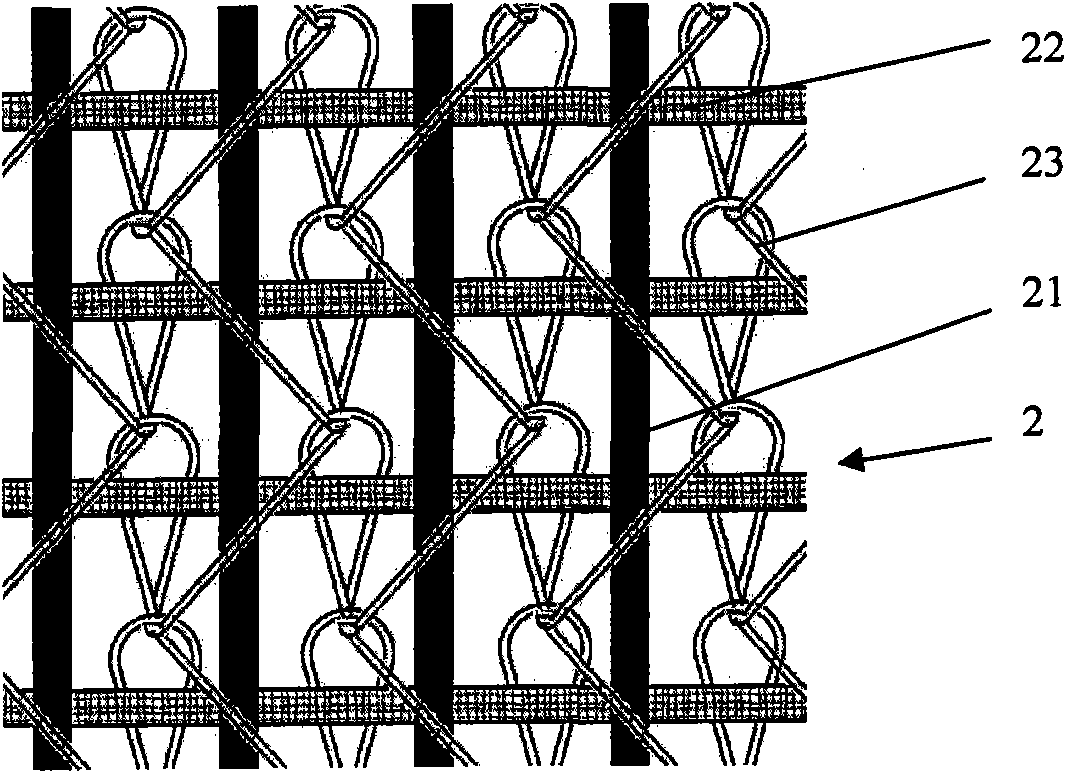

Fiber rope with surface coated with polymer and preparation method of fiber rope

The invention discloses a fiber rope with the surface coated with a polymer and a preparation method of the fiber rope. The fiber rope with the surface coated with the polymer comprises a polymer coating layer and a fiber rope core layer, wherein an outer wall of the fiber rope core layer is coated with the polymer coating layer. The preparation method comprises the following steps that a thermoplastic polymer and an additive are weighed at a mass ratio, mixed uniformly and put into a single screw extruder for mixing and melting; a fiber rope penetrates through a mould, and is coated with the molten polymer uniformly; and a cold water tank is introduced rapidly for cooling and shaping. According to the fiber rope and the preparation method, the strength and the usability of a fiber are improved; the fiber can be bonded with various resin for preparing a composite; the fiber rope has a wide application space in the fields of optical cables, electric cables, fishing nets, net cages, protecting nets, reinforcing wires, complex fibers and the like; the fishing net woven by the fiber rope can meet a requirement of high tenacity; the fiber rope is smooth in surface, so that an attachment space of parasites is reduced; and the fishing net is easy to clean, convenient, long-lasting and durable.

Owner:SHANDONG ICD HIGH PERFORMANCE FIBRES CO LTD

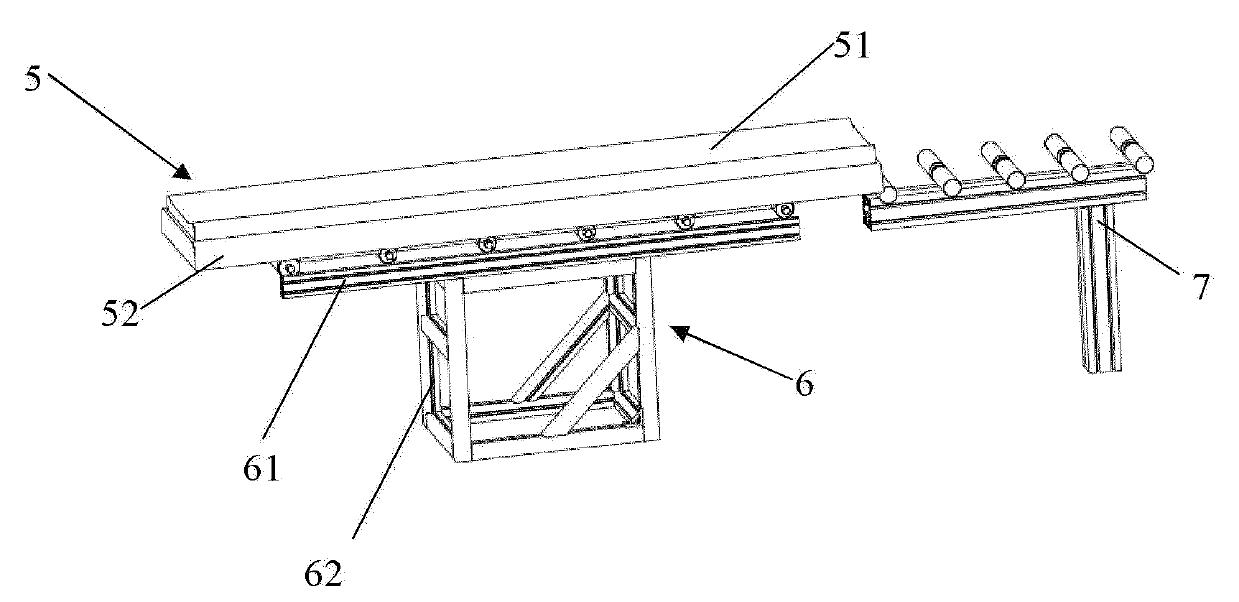

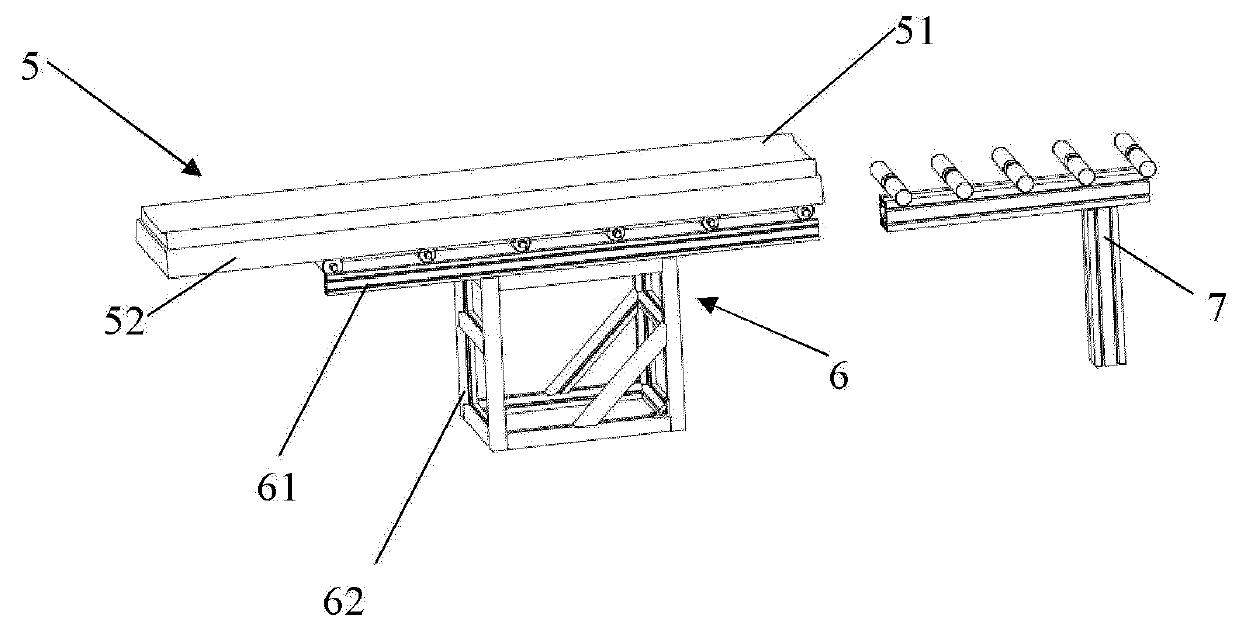

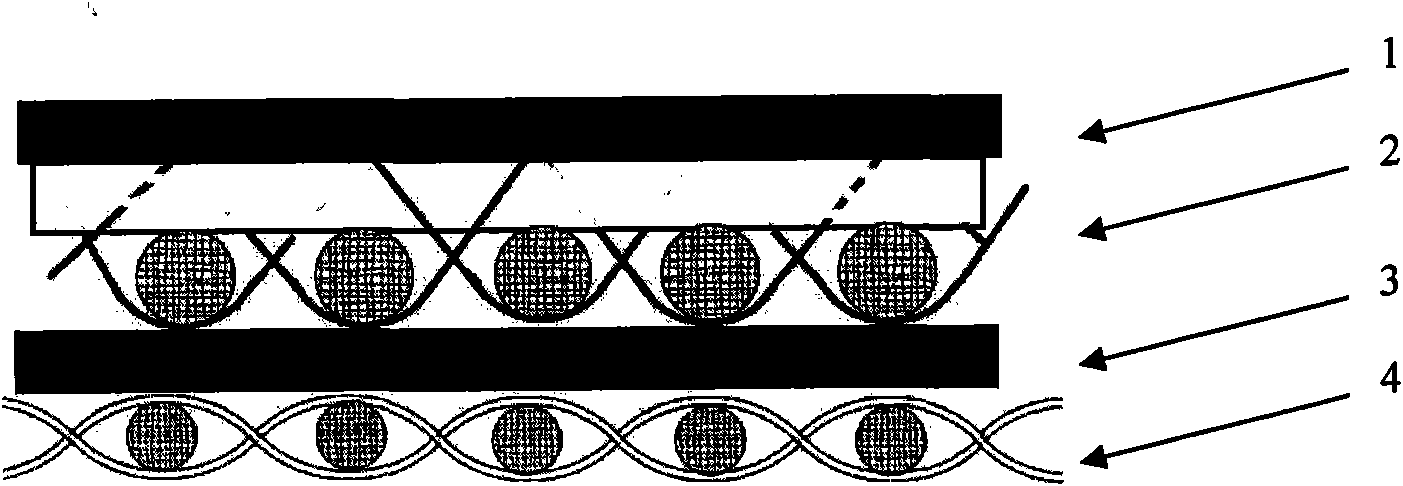

Conveyer belt taking warp-knitted bi-axial fabric as framework and manufacturing method thereof

InactiveCN101830335AHigh strength requirementsThere is no up and down staggered mutual pressure phenomenonConveyorsSynthetic resin layered productsSurface layerPolyvinyl chloride

The invention relates to a conveyer belt taking a warp-knitted bi-axial fabric as a framework and a manufacturing method thereof. The conveyer belt sequentially comprises a woven fabric, a polyvinyl chloride laminated layer, the warp-knitted bi-axial fabric and a polyvinyl chloride surface layer from bottom to top. The manufacturing method comprises the following steps of: finalizing the design of the woven fabric, carrying out primary coat, and coating polyvinyl chloride paste resin to form the laminated layer; finalizing the design of the warp-knitted bi-axial fabric, jointing with the woven fabric of the bottom layer; and carrying out surface layer coating on the warp-knitted bi-axial fabric to form the conveyer belt structure of a double-framework double- polyvinyl chloride layer. The utilization rate of the intensity of warp in the warp-knitted bi-axial fabric reaches the highest, and the warp is always in a straight state and does not have creep relaxation. Self-cementing between the PVC (polyvinyl chloride) surface layer and the PVC laminated layer can be formed, the primary coat process is left out, the racking strength is greatly enhanced, the requirements on roll diameter and tension length of a conveyer are reduced, the service life is improved, and the cost is 40% lower than the woven fabric.

Owner:SHANGHAI YONGLI BELTING +1

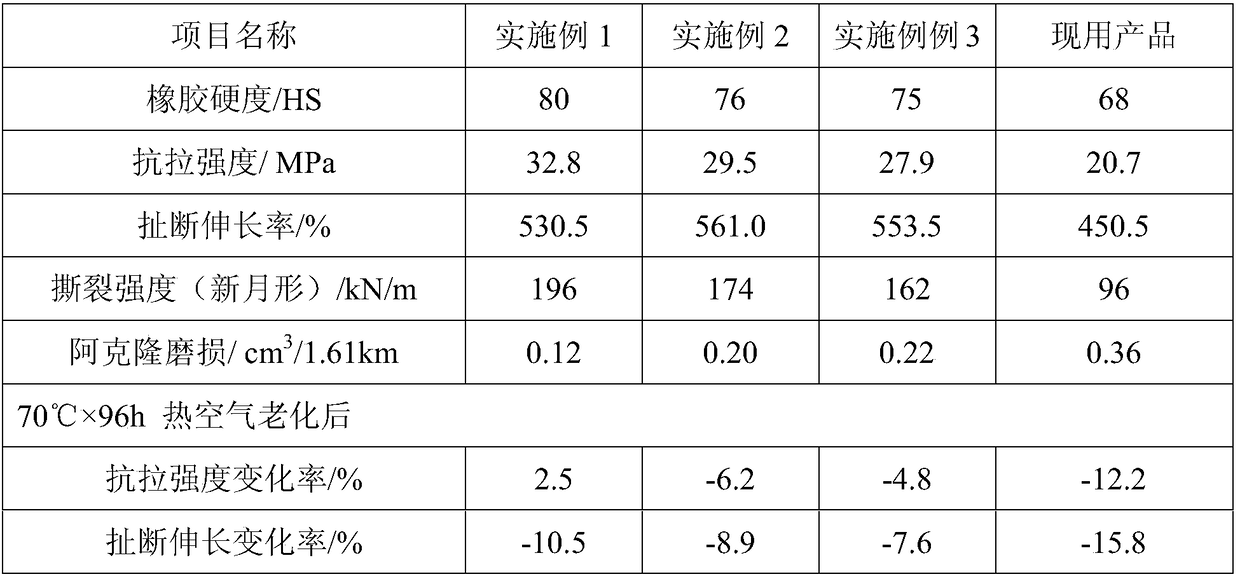

Rubber track

The invention discloses a rubber track. The rubber track is prepared from raw materials including raw rubber, sulfur, an accelerant, magnesia, zinc oxide, an anti-aging agent, a titanate coupling agent, an anti-coking agent, carbon black, a flame retardant, micro-crystal wax and a light stabilizer through plastication, mixing and final refining. The strength and wear resistance of rubber are enhanced by adding different raw rubber components, carbon black, the titanate coupling agent and the like. The aging resistance of rubber is improved and the service life of rubber is prolonged by addingthe anti-aging agent, the anti-coking agent and the light stabilizer. Thus, the rubber track has the characteristics of high strength and high reliability.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

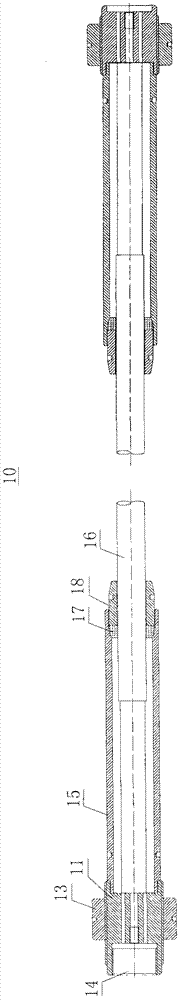

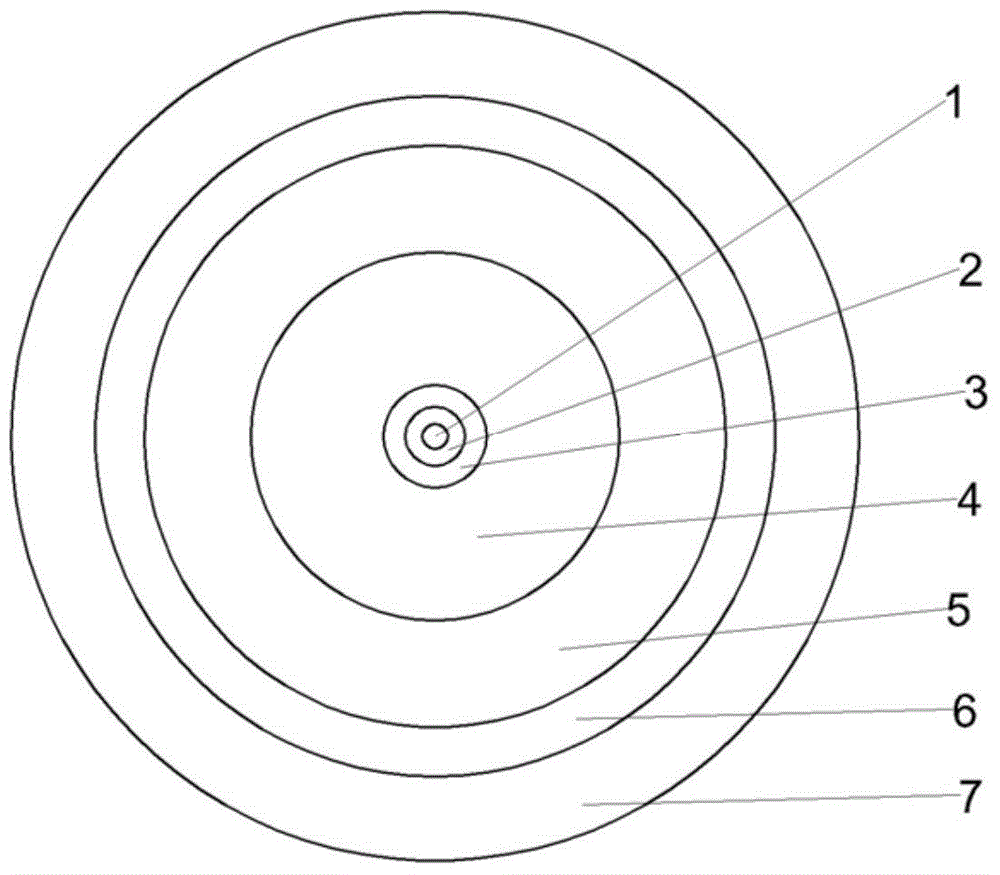

Stainless steel pulling cable device for bridge

ActiveCN103088754AImprove the cumbersome structureHigh strength requirementsBridge structural detailsPull forceEngineering

The invention discloses a stainless steel pulling cable device for a bridge. The stainless steel pulling cable device is arranged on a pulling cable bridge and comprises a cable for bearing tension, a fixed end anchor, a tensioning end anchor and a protective member. The cable is integrated of stainless steel wires; the fixed end anchor and the tensioning end anchor are respectively used for anchoring the cable in matched mode and transmitting the cable force; and the protective member is connected between the fixed end anchor and the tensioning end anchor and used for protecting the part of the cable exposed out of the anchors. The stainless steel pulling cable for the bridge has the good performance of rust protection, corrosion resistance and abrasion resistance and has long service life.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

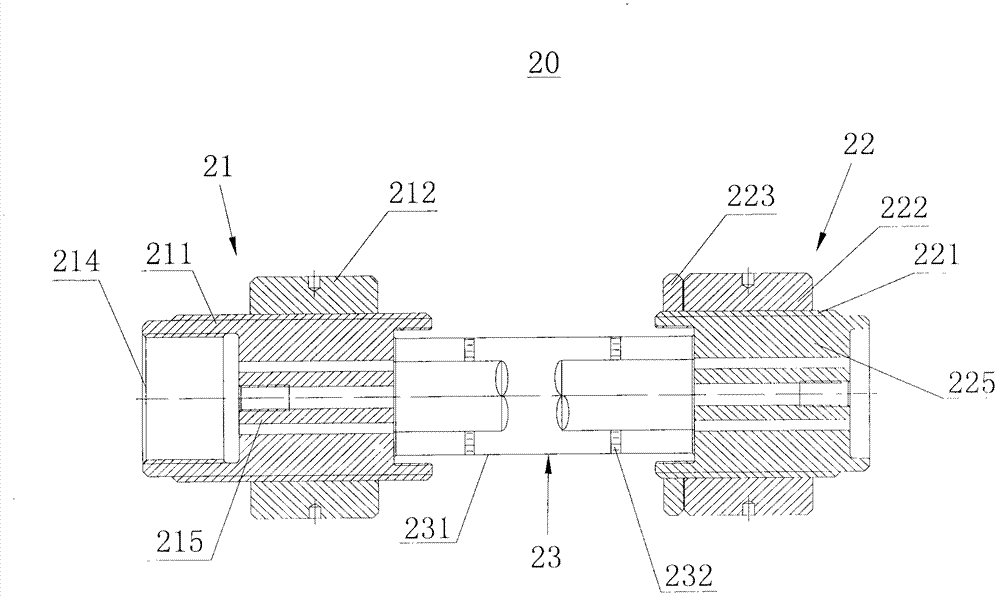

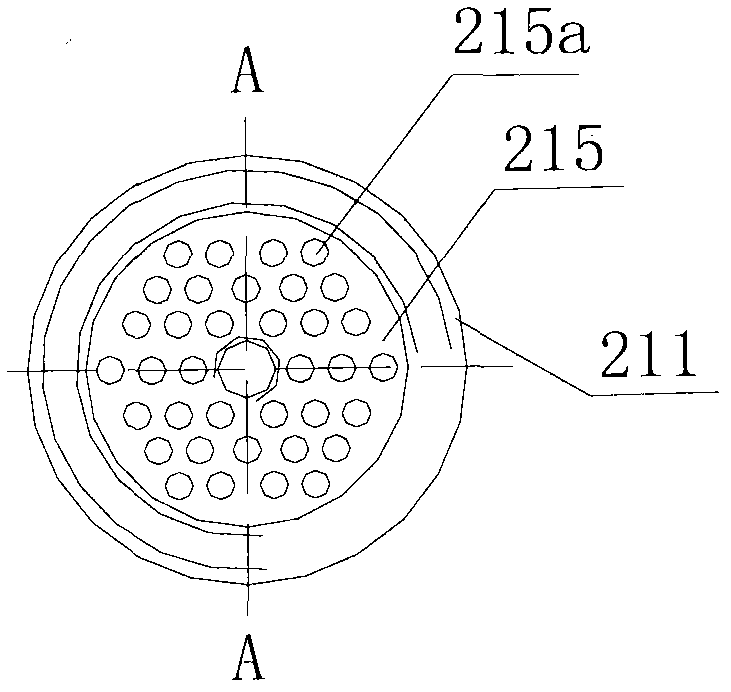

Energy transferring optical cable

ActiveCN104536108AReliable transmissionCoupling stabilityFibre mechanical structuresTetrafluoroethyleneEnergy transfer

The invention discloses an energy transferring optical cable. The energy transferring optical cable comprises a core layer, a cladding, a tight cladding and an outer protective layer. The core layer is made of quartz glass materials, and the diameter of the core layer is 0.195 mm-0.205 mm. The core layer is covered with the cladding, the cladding is made of quartz glass materials, and the thickness of the cladding is 0.012 mm-0.016 mm. The cladding is covered with the tight cladding, the tight cladding is made of ethylene-tetrafluoroethylene copolymer materials, and the thickness of the tight cladding is 0.3 mm-0.5 mm. The tight cladding is covered with the outer protective layer, the outer protective layer is made of ethylene-tetrafluoroethylene copolymer materials, and the thickness of the outer protective layer is 0.2 mm-0.5 mm. The energy transferring optical cable has the advantages of being resistant to extra-high voltage, high in flame retardance, high in insulation, resistant to dirt, high in strength, long in service life and the like.

Owner:武汉芯微感科技有限公司

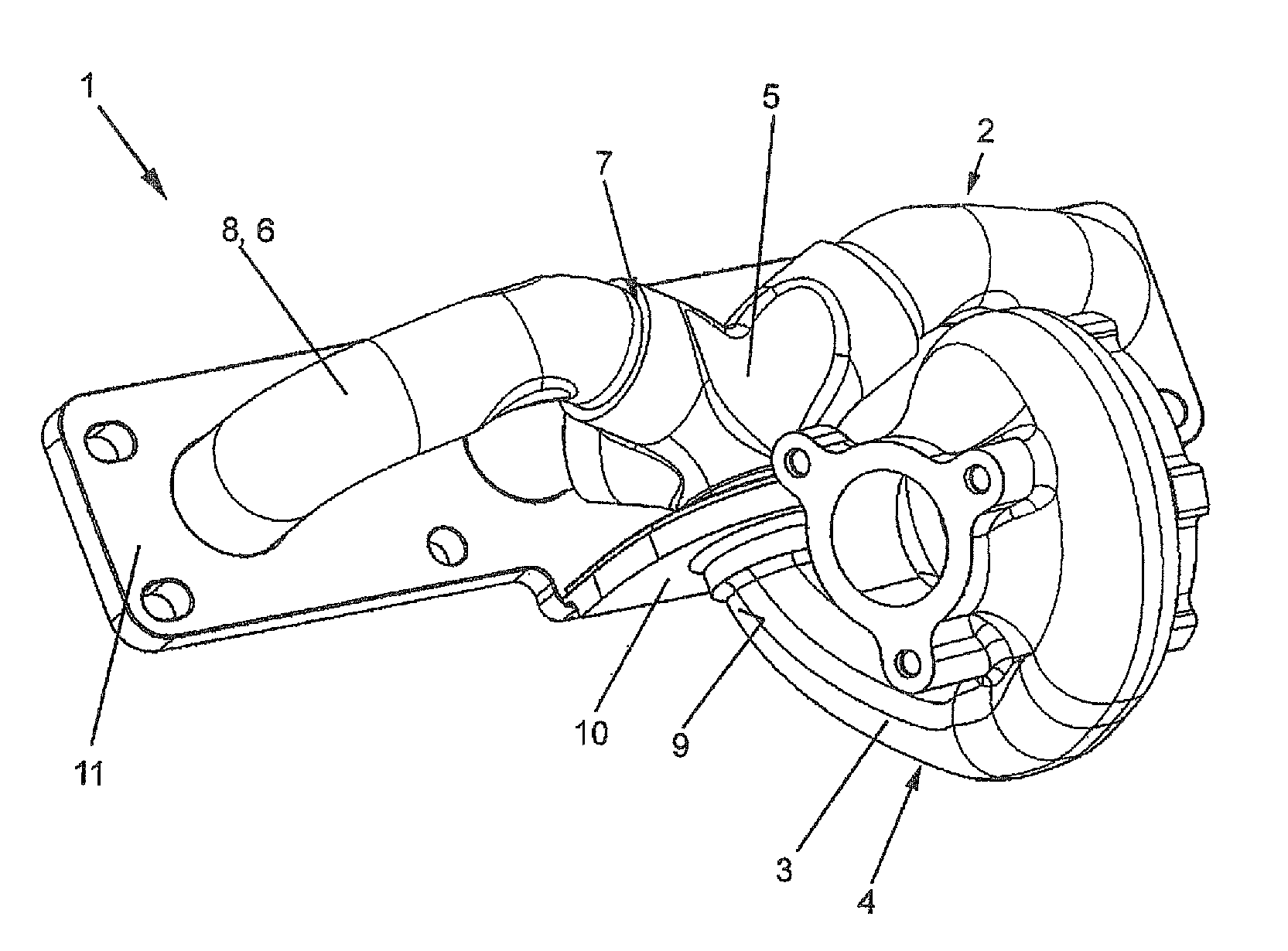

Exhaust gas system

InactiveUS8826660B2High strength requirementsImprove liquidityInternal combustion piston enginesExhaust apparatusTurbochargerExhaust gas

An exhaust gas system includes a turbocharger housing and an exhaust manifold having manifold pipes and connected to the turbocharger housing. The turbocharger housing has a pipe collector extending in a direction of the exhaust manifold for connection of the manifold pipes.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Manufacturing method of nine-hydraulic-motor driven self-discharging boom base

ActiveCN104476133AReduce intensityDifficult to process and weldCranesManufacturing engineeringMechanical engineering

The invention relates to a manufacturing method of a nine-hydraulic-motor driven self-discharging boom base. The method comprises the steps of manufacturing, machining and mounting. The method has the advantages that the manufacturing is simple, and the working efficiency is raised.

Owner:南通润力机械制造有限公司

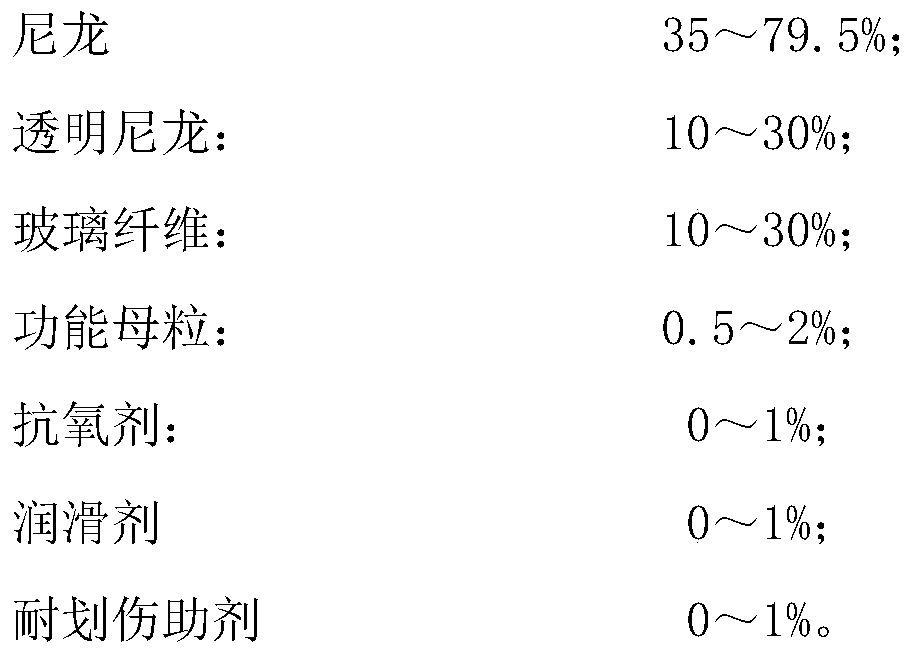

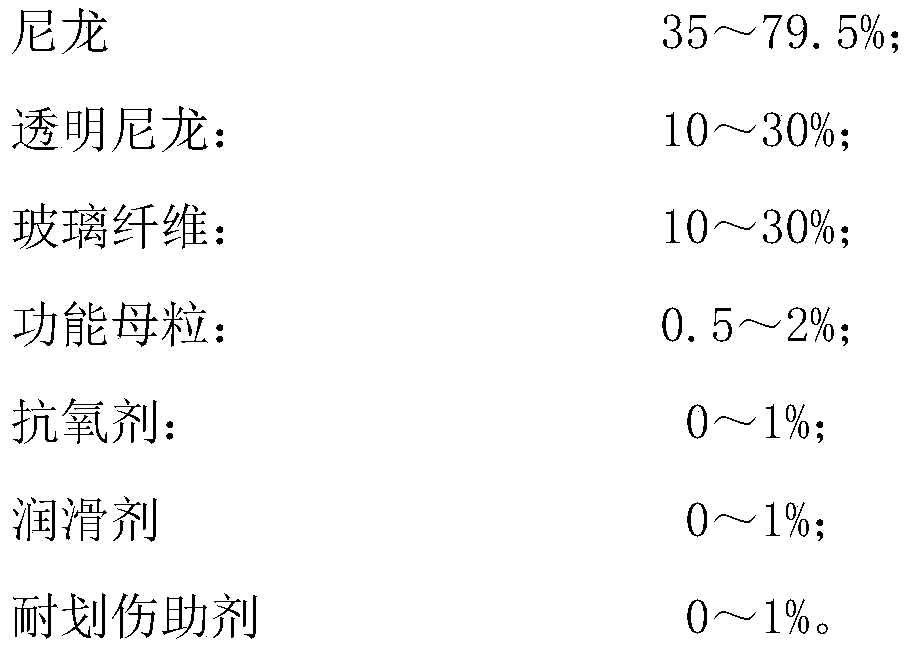

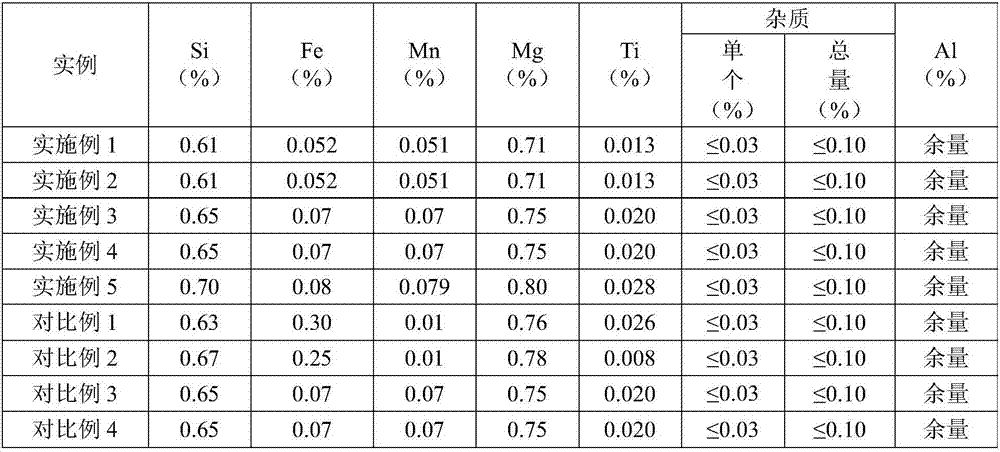

High-strength, high-brightness black and glass fiber reinforced nylon material and preparation method thereof

The invention discloses a high-strength, high-brightness black and glass fiber reinforced nylon material and a preparation method thereof. The material is prepared from the following components in percentage by mass: 35-79.5% of nylon, 10-30% of transparent nylon, 10-30% of glass fibers, 0.5-2% of a functional master batch, 0-1% of an antioxidant, 0-1% of a lubricant, and 0-1% of a scratch-resistant auxiliary agent. The glass fiber reinforced nylon material has the beneficial effects that the crystallinity of the nylon material is controlled and an injection molding process is adopted to ensure that the material has higher glossiness, and the self-made functional master batch is added, so that the reinforced nylon material is covered with the glass fibers, and the blackness and the glossiness are improved. The nylon composite material prepared by the invention not only meets the requirements of parts on the mechanical properties of the material, but also meets the requirement that theappearance effect of high brightness black can be achieved without spraying, and solves the problem that the strength and the appearance cannot be considered at the same time.

Owner:ZHEJIANG PRET NEW MATERIALS

6063G aluminum alloy for smartphone and machining method of 6063G aluminum alloy

The invention discloses a 6063G aluminum alloy for a smartphone and a machining method of the 6063G aluminum alloy. The aluminum alloy comprises, by mass, 0.60%-0.70% of Si, 0.05%-0.08% of Fe, 0.05%-0.08% of Mn, 0.70%-0.80% of Mg, 0.01%-0.03% of Ti and the balance Al and inevitable impurities. The corresponding machining method sequentially includes eight steps including ingot casting, homogenizing annealing, hot rolling, cold rolling, intermediate solid solution treatment, secondary cold rolling, finished product annealing and final aging treatment. An aluminum product has the excellent anodic oxidation effect through the aluminum alloy ingredients and the machining method, extremely-fine 205-210-mesh zircon sand blasting treatment is met, and the 6063G aluminum alloy is a six-serial smartphone appearance piece ideal aluminum alloy material meeting the moderate strength requirement and having very high requirement for anodic oxidation treatment, and the market application prospect is wide.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Method for producing multi-purpose deformed channel steel

InactiveCN102059270AHigh strength requirementsUnified specificationsFurnace typesMetallic material coating processesHead lengthHeating furnace

The invention discloses a method for producing multi-purpose deformed channel steel, which comprises the following steps of: 1, tempering; 2, heading; 3, pickling, phosphating and saponifying; 4, cold drawing and 5, straightening, wherein in the tempering step, a primary blank is subjected to heat treatment in a continuous heating furnace at the temperature of 750DEG C and a rotating speed of 500 revolutions / hour. The method has the advantages that: the process flow of tempering, heading, pickling, saponifying and cold drawing is strictly limited, the furnace temperature, heading length, the preparation of pickling and saponifying solution, and pickling and saponifying time, which are required to be noticed, are confined, and the multi-purpose deformed channel steel with high strength, uniform specification and high toughness is produced.

Owner:CHANGSHU HONGRUN PRECISION STEEL PIPE MFG

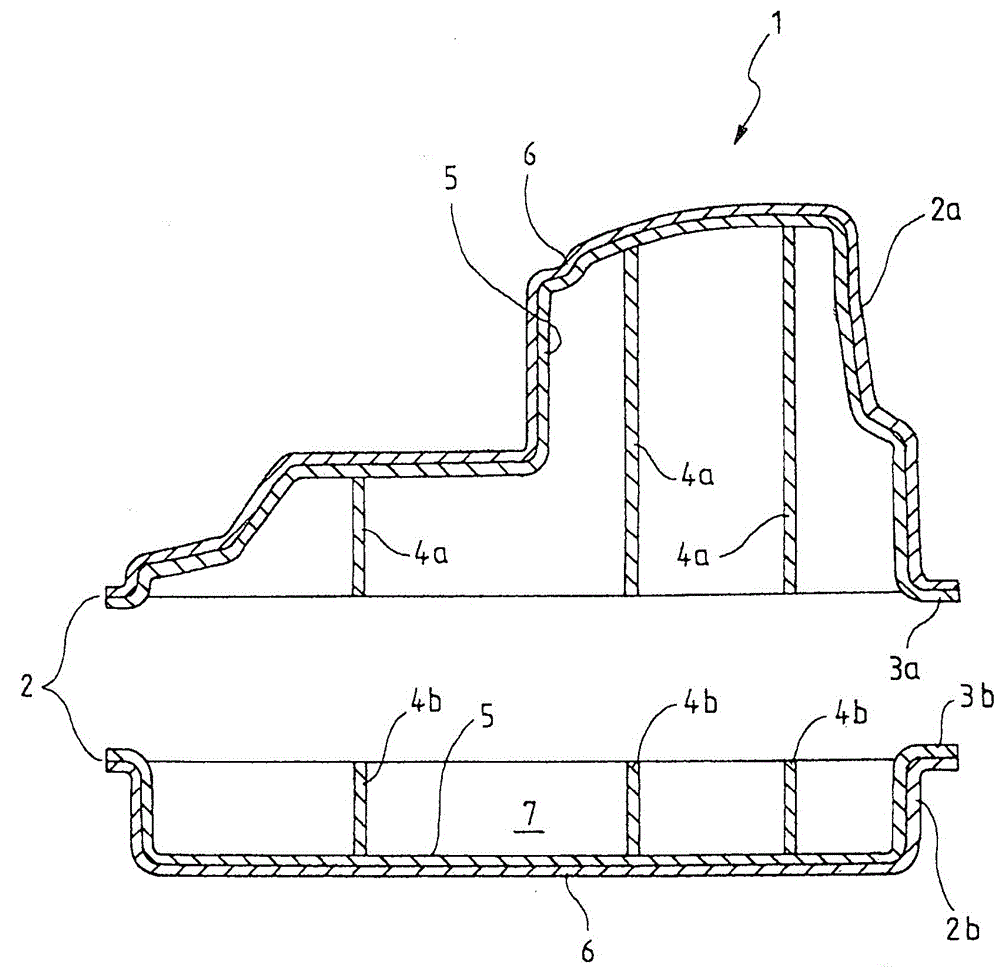

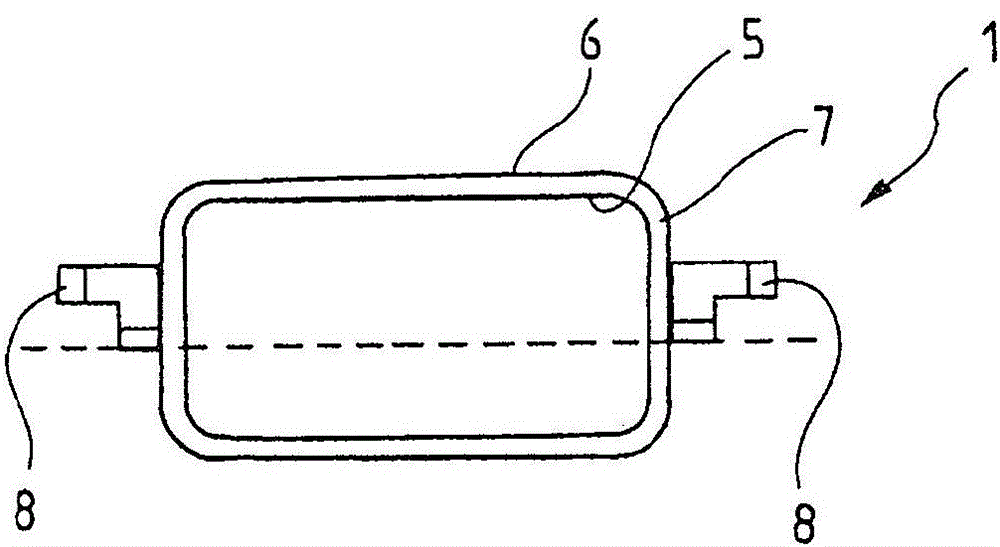

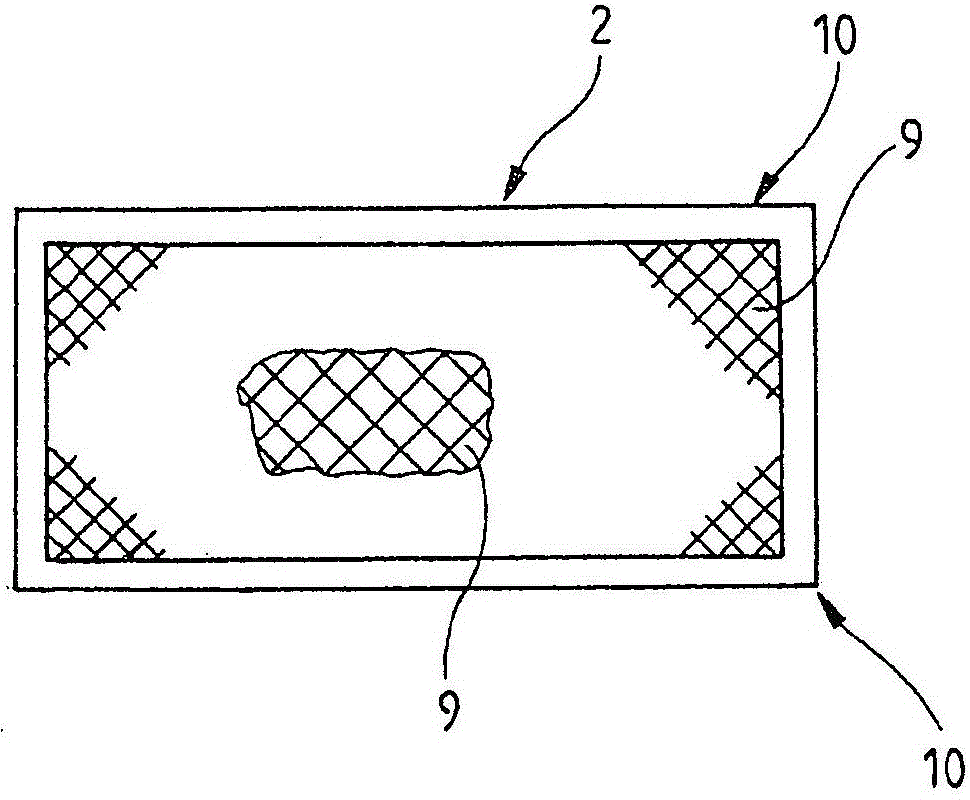

Operating-fluid container

The invention relates to an operating-fluid container (1) for a motor vehicle, comprising a container body which is assembled from two mutually complementary injection-moulded shells (2a, 2b) which consist of thermoplastic material and are welded together in an encircling manner to form a substantially closed hollow body, wherein at least one shell (2a, 2b) is at least in regions formed from thermoplastic materials having different strengths, wherein at least one part-region consists of a thermoplastic material having a fibrous filling, wherein the shell (2a, 2b) has been obtained by way of a co-injection process during injection moulding.

Owner:KAUTEX TEXTRON

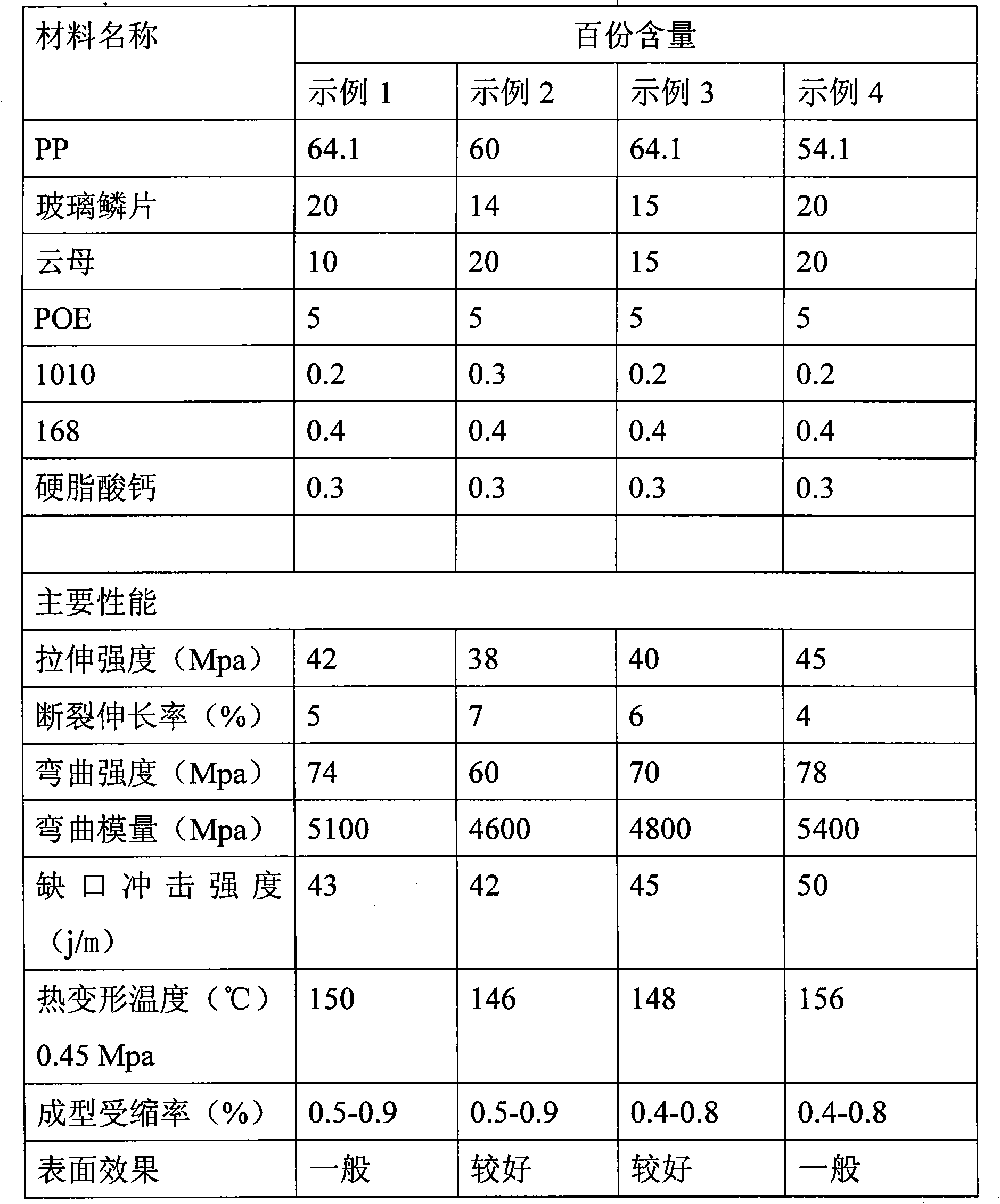

High-rigidity and low-warpage PP enhancement composite material and method for preparing same

The invention discloses a high-rigidity low-warpage PP reinforced composite material and a method for preparing the same. The compositions by weight percentage of the composite material are: 50 to 65 percent of PP, 10 to 20 percent of glass flakes, 10 to 20 percent of mica, 0.2 to 0.4 percent of main antioxidant, 0.2 to 0.4 percent of auxiliary antioxidant, 3 to 10 percent of toughening agent and 0.2 to 1 percent of lubricant. The high-rigidity low-warpage PP reinforced composite material and the method greatly improve the performance of the PP and have superior dimension stability. The use range of the PP is enlarged, thereby the high-rigidity low-warpage PP reinforced composite material can be used on plastic parts with high strength requirement, low shrinkage factor and high assembly precision, and has the advantage in cost.

Owner:SHENZHEN FUHENG PLASTICS PIGMENT

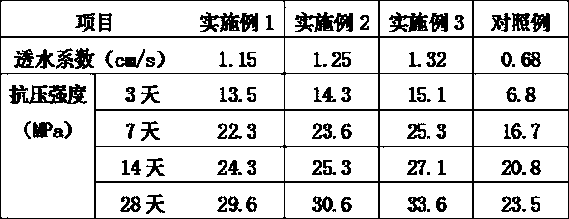

Water-permeable concrete and preparation method thereof

InactiveCN108191341AHigh permeability coefficientHigh compressive strengthCeramicwareRoad surfaceHigh intensity

The invention discloses water-permeable concrete, which is prepared from the following components in parts by mass: 300 to 500 parts of cement, 1,500 to 1,700 parts of aggregate, 9 to 15 parts of water reducing agent, 15 to 50 parts of enhancer and 90 to 125 pars of water, wherein the enhancer is prepared from silica fume, ultrafine powder and a nano material TiO2; in percentage by mass, in the enhancer, alumina accounts for 0.92 percent, calcia accounts for 0.14 percent, iron oxide accounts for 0.27 percent, magnesia accounts for 1.59 percent and silica accounts for 93.11 percent; the iglossis 3.18 percent. The water-permeable concrete prepared by the preparation method is high in water permeability coefficient and high in compressive strength, and meets a high-strength requirement of the construction of a road surface.

Owner:珠海市昂科装饰工程有限公司岳阳分公司

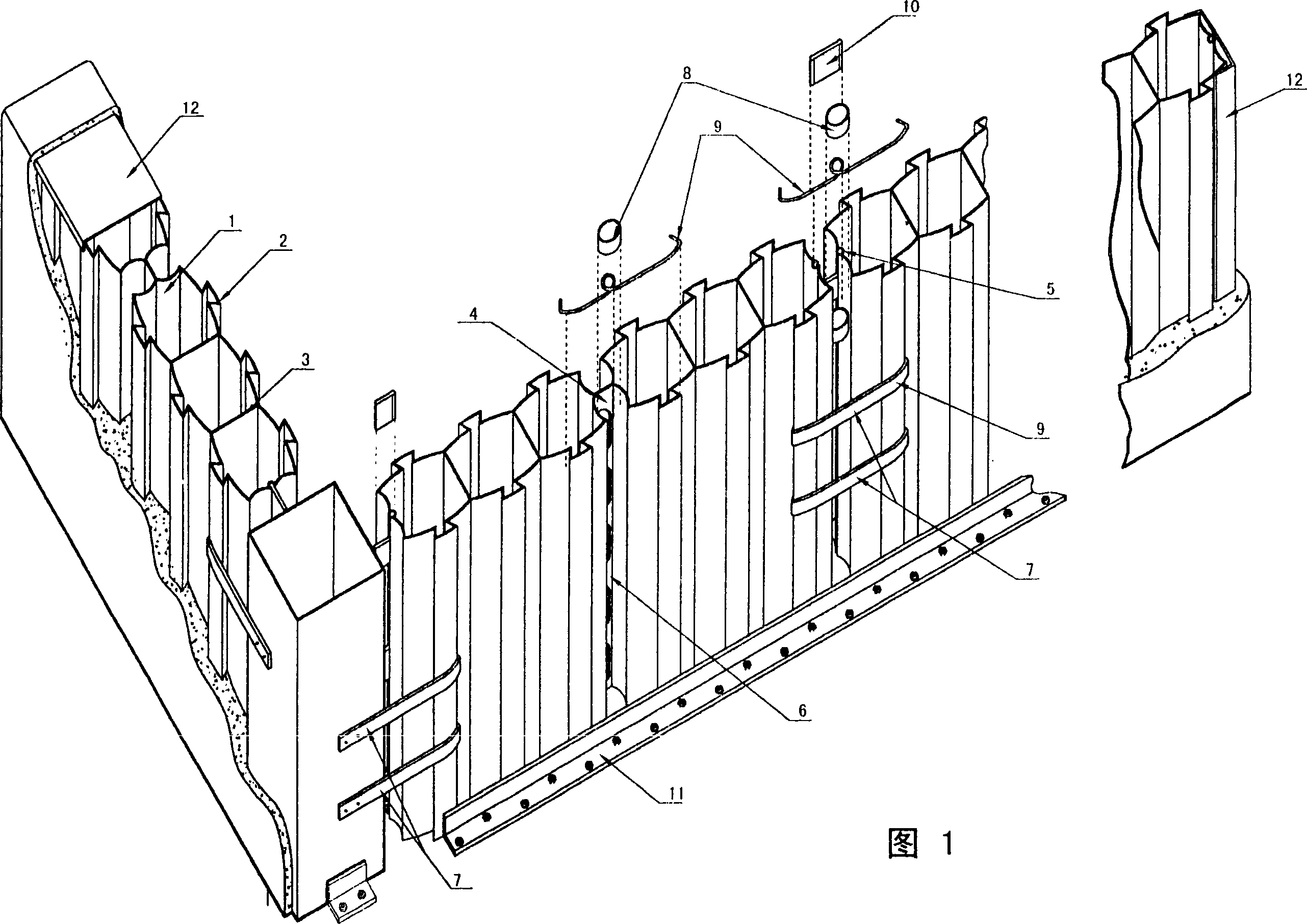

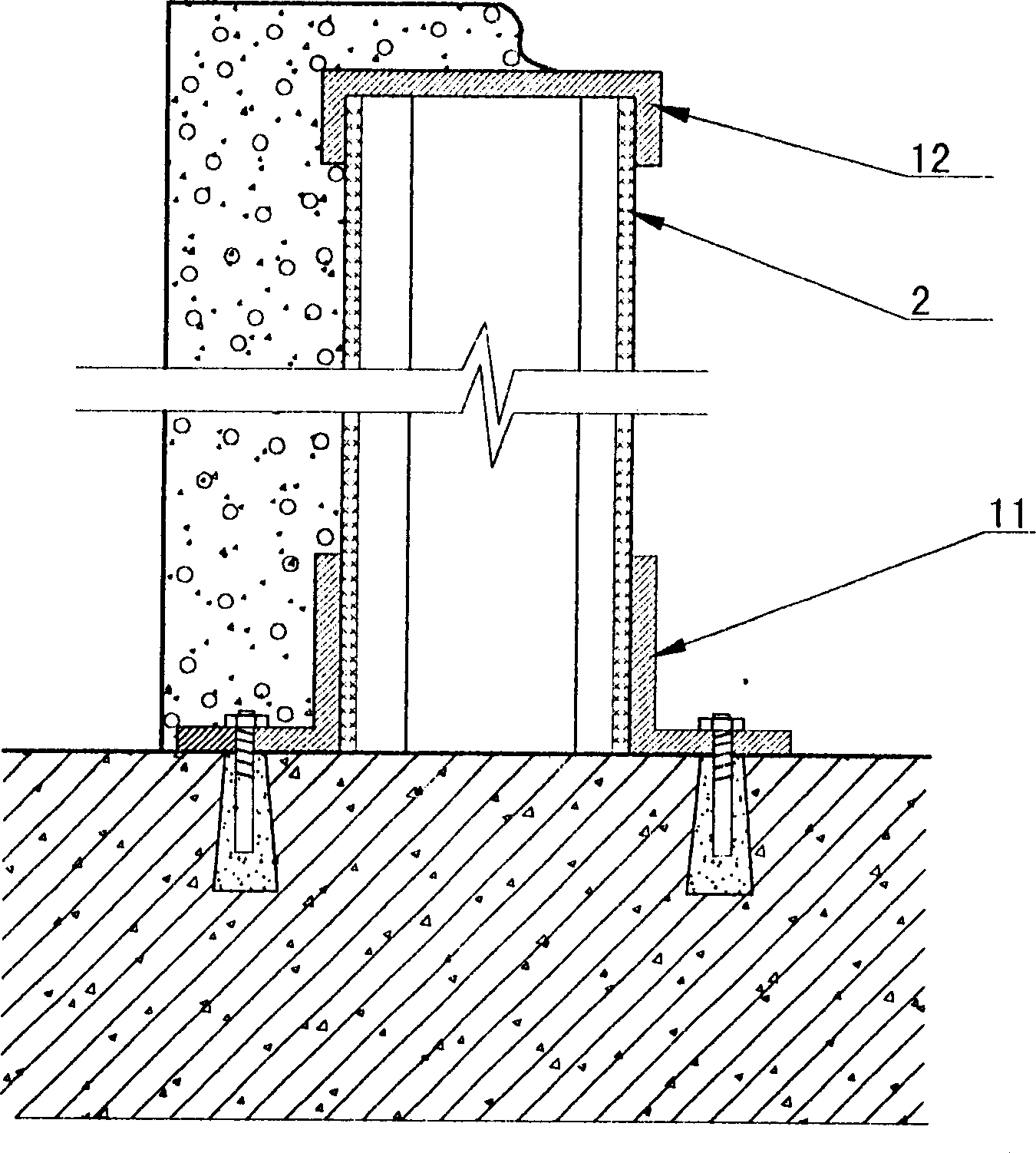

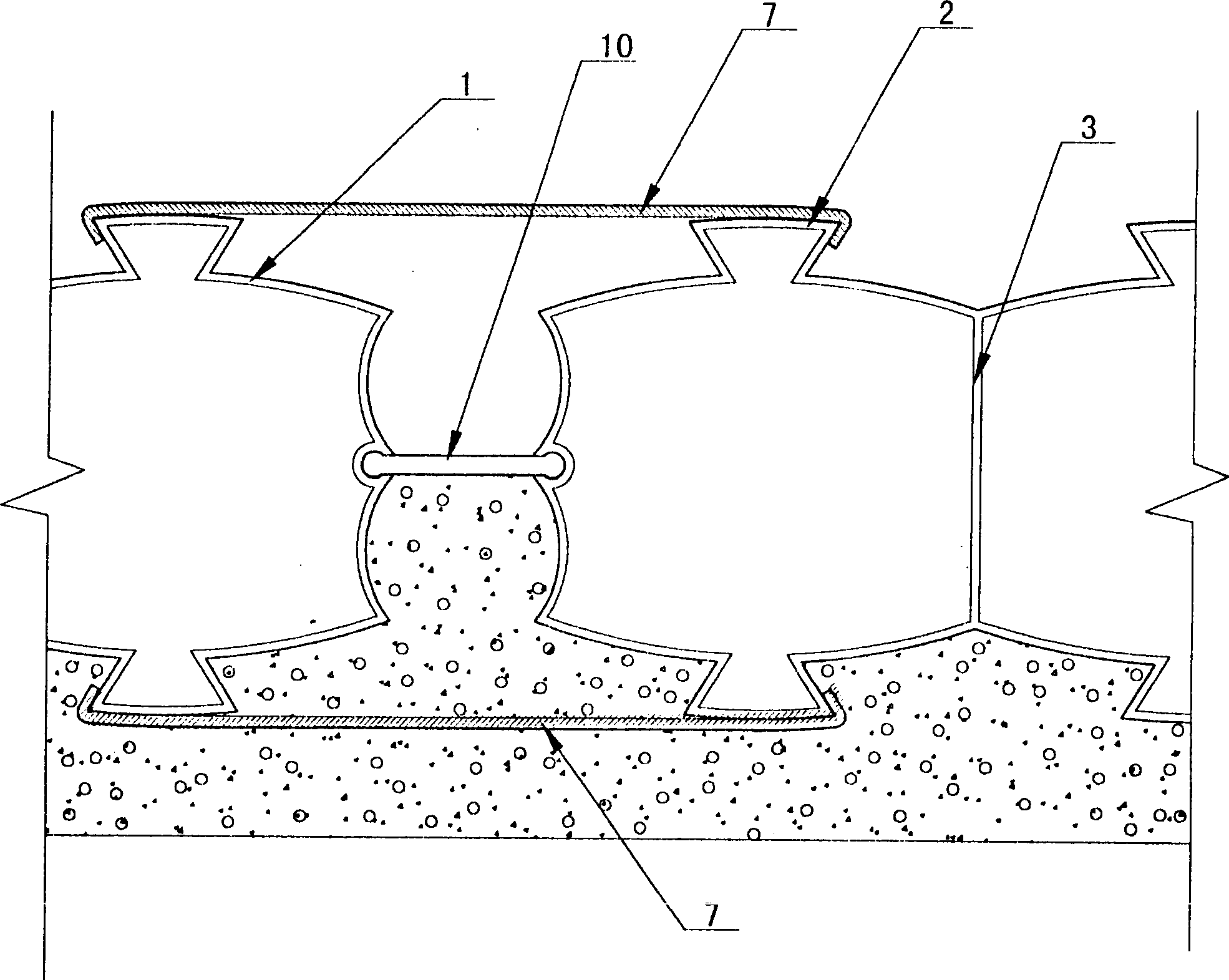

Cellular type hollow internal mould plate for building and its wall forming construction method

InactiveCN1410636AImprove performanceMeet high strength requirementsWallsFluteArchitectural engineering

The characteristics of the internal template (1) are as follows. There are multiple male tabs (2) on the two external surfaces, and there are the partitioning brace rods (3) on the inner surface. Themultifunctional flute (4) is setup at the middle of the internal template, and the units of extension and connection (5) are setup between the adjacent internal templates. The channels (6) setup at the upper and lower sections of the multifunctional flute and the units of extension and connection are utilized to make the spray cementing and the internal template bond to become the wall body. The method provides the features of compact structure, lightweight, small volume, easy of construction. The quality of the wall reaches the national engineering standard. Thus, the method can be applied to building trades.

Owner:刘奕刚 +1

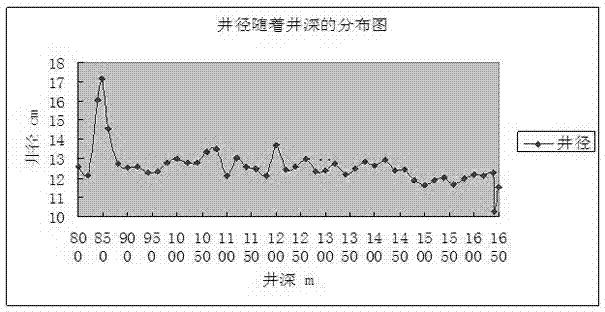

Graded variable density well cementation technology

InactiveCN103362473AImprove replacement efficiencyReduce dosageDrilling compositionSealing/packingHigh densityWell cementing

The invention discloses a graded variable density well cementation technology and relates to the technical field of oil well production. An oil layer and an annular space below the oil layer and between a well bore and a casing are sealed by high-density cement paste, and an annular space above the oil layer and between the well bore and the casing is sealed by low-density cement paste. According to the technology, the consumption of the cement paste is lower, the additional circulating equal yield density is less increased in comparison with low density full hole section cementation, additional damages to a stratum cannot be caused, the additional circulating equal yield density can be effectively reduced, and stratum leak-off is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com