Graded variable density well cementation technology

A variable density and cementing technology, which is applied in the direction of sealing/isolation, wellbore/well components, drilling composition, etc., can solve the problem of reducing the strength of cement slurry, prolonging the construction period of sidetracking wells, and the quality of cementing not meeting the requirements and other problems, to achieve the effect of improving the pressure resistance and improving the replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

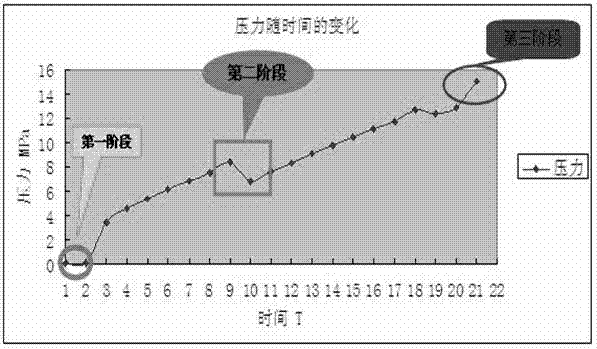

[0027] The new staged variable density cementing process has been tested in 8 wells in Jiangsu Oilfield, and the cementing success rate is 100% (the success rate of one cementing was 75% before such a new process was adopted), and the cementing quality rate is over 80%. It has a good application prospect.

[0028] Here is an application example to illustrate:

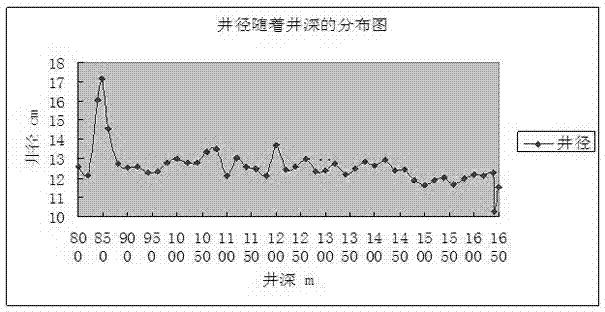

[0029] 1. Treatment of the well diameter before cementing The well diameter shall be treated: (1) drain the well; (2) wash the well with a large displacement, which is about 1.3 times the displacement of the normal drilling mud pump, and observe For the exit situation, when the exit is observed to be stable and no cuttings return, the cementing construction will be carried out.

[0030] Advantages of the above measures: (1) Due to the large electrical measuring instrument during the electrical measurement, it will damage the well wall during the well entry process. The wellbore can be inspected through the well drillin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com