High-rigidity and low-warpage PP enhancement composite material and method for preparing same

A reinforced composite material and low warpage technology, applied in the field of polymer materials, can solve problems such as product performance impact, achieve the effects of small shrinkage, improved performance, and expanded use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

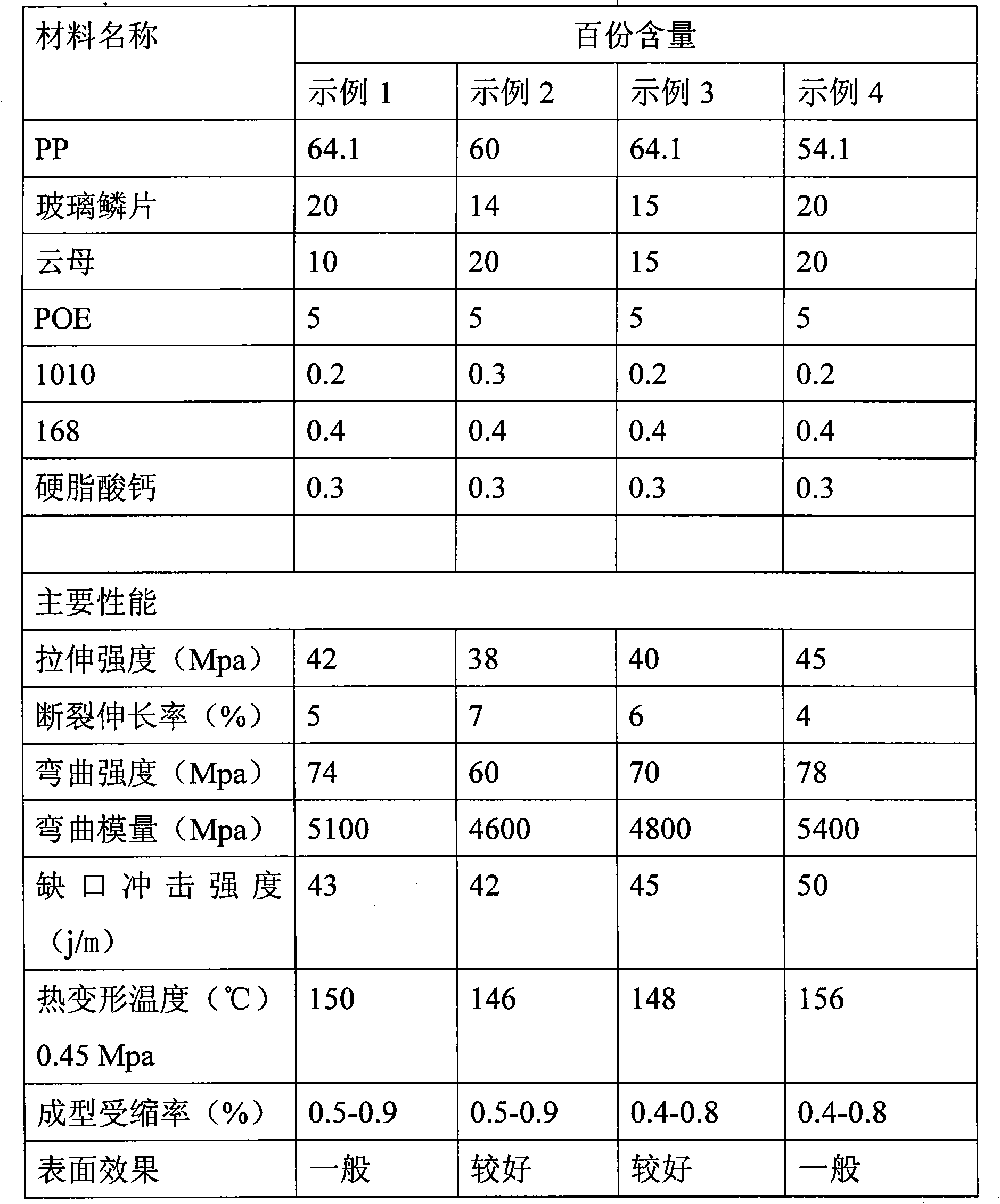

example 1

[0034] Weigh the raw materials and additives of each component by weight percentage, among which, the weight ratio of PP is 64.1%, glass flake is 20%, mica powder is 10%, POE is 5%, 1010 is 0.2%, 168 is 0.4 %, calcium stearate 0.3%. After being pre-mixed by a high-speed mixer, it is granulated by twin-screw extrusion. The temperature setting of each zone of the twin-screw is: 200-215°C for zone 1, 205-220°C for zone 2, 210-220°C for zone 3, 210-220°C for zone 4, 210-218°C for zone 5, 210-215°C for zone 6, Die head temperature 200-215°C. The produced particles are made into test specimens according to the national standard, and various performance tests are carried out to obtain corresponding data.

Embodiment 2

[0036] Weigh the raw materials and additives of each component by weight percentage, among which, the weight ratio of PP is 60%, glass flake is 14%, mica powder is 20%, POE is 5%, 1010 is 0.3%, 168 is 0.4% %, calcium stearate 0.3%. After being pre-mixed by a high-speed mixer, it is granulated by twin-screw extrusion. The temperature setting of each zone of the twin-screw is: 200-215°C for zone 1, 205-220°C for zone 2, 210-220°C for zone 3, 210-220°C for zone 4, 210-218°C for zone 5, 210-215°C for zone 6, Die head temperature 200-215°C. The produced particles are made into test specimens according to the national standard, and various performance tests are carried out to obtain corresponding data.

Embodiment 3

[0038] Weigh the raw materials and additives of each component by weight percentage, among which, the weight ratio of PP is 64.1%, glass flake is 15%, mica powder is 15%, POE is 5%, 1010 is 0.2%, 168 is 0.4 %, calcium stearate 0.3%. After being pre-mixed by a high-speed mixer, it is granulated by twin-screw extrusion. The temperature setting of each zone of the twin-screw is: 200-215°C for zone 1, 205-220°C for zone 2, 210-220°C for zone 3, 210-220°C for zone 4, 210-218°C for zone 5, 210-215°C for zone 6, Die head temperature 200-215°C.

[0039] The produced particles are made into test specimens according to the national standard, and various performance tests are carried out to obtain corresponding data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com