Rubber track

A technology of rubber crawler and raw rubber, applied in the field of high-strength rubber crawler and its preparation, can solve the problems of crawler aging, lowering the use level of crawler, lowering the strength of rubber crawler, etc., so as to enhance the strength, prolong the service life and improve the anti-aging performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

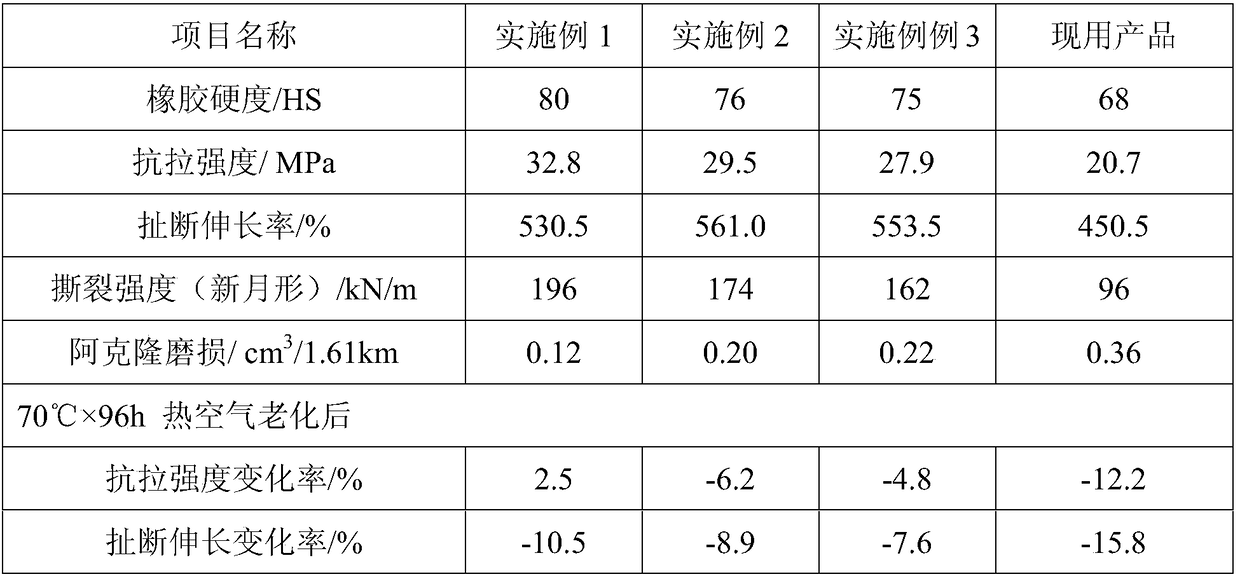

Examples

preparation example Construction

[0036] The preparation method of described high-strength rubber track is as follows:

[0037] step one:

[0038] Raw material preparation: prepare raw rubber, cut it into wedge-shaped pieces of 8kg, and then dry; crush and dry the compounding agent, sieve it, and weigh it according to the proportion.

[0039] Step two:

[0040] Mastication: Set the speed ratio of the front and rear rollers of the mill to 1:1.2, adjust the roller distance of the mill to 0.8mm, add raw rubber for plastication, and make triangular bags, 5 times.

[0041] Step three:

[0042] Mixing: Adjust the roller distance of the open mill to 0.8mm, and add raw rubber into the mixing.

[0043] Step four:

[0044] Final refining: Add mixed rubber into the open mill, and then add various compounding agents for final refining. After the powder is finished, pack it several times to evenly disperse the raw rubber and compounding agents. Then the rubber material was unloaded and parked for 4 hours.

Embodiment 1

[0046] A kind of high-strength rubber track provided in this embodiment, the high-strength rubber track includes the following raw materials in parts by weight: 70 parts of natural rubber, 30 parts of styrene-butadiene rubber, 1.5 parts of sulfur, 1 part of accelerator DTDM, 2.5 parts of magnesium oxide 2 parts of zinc oxide, 2 parts of anti-aging agent DFC-345 parts, 2 parts of titanate coupling agent HY311W, 0.8 parts of antiscorch agent NA, 50 parts of carbon black N220, 2 parts of antimony trioxide, 4 parts of microcrystalline wax, Light stabilizer PDS1.5 parts.

[0047] step one:

[0048] Raw material preparation: prepare raw rubber, cut it into wedge-shaped pieces of 8kg, and then dry; crush and dry the compounding agent, sieve it, and weigh it according to the above ratio.

[0049] Step two:

[0050] Masticating: Set the speed ratio of the front and rear rollers of the mill to 1:1.2, adjust the roller distance of the mill to 0.8mm, masticate the styrene-butadiene rubb...

Embodiment 2

[0056]A kind of high-strength rubber track provided by the present embodiment, the high-strength rubber track comprises the following raw materials in parts by weight: 60 parts of natural rubber, 40 parts of EPDM rubber, 2 parts of sulfur, 1.5 parts of accelerator BZ, 2 parts of magnesium oxide, 2 parts of zinc oxide, 5 parts of antioxidant MB, 3 parts of titanate coupling agent HY311W, 1 part of anti-scorch agent NA, 60 parts of carbon black N234, 1.5 parts of chlorinated paraffin, 3 parts of microcrystalline wax 1 part of light stabilizer PDS.

[0057] step one:

[0058] Raw material preparation: prepare raw rubber, cut it into wedge-shaped pieces of 8kg, and then dry; crush and dry the compounding agent, sieve it, and weigh it according to the above ratio.

[0059] Step two:

[0060] Masticating: Set the speed ratio of the front and rear rollers of the mill to 1:1.2, adjust the roller distance of the mill to 0.8mm, and masticate the EPDM rubber and natural rubber separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com