Carbon fiber composite material reinforcing hydraulic oil cylinder

A composite material and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problems of unsatisfactory strength, rigidity, anti-fatigue performance and safety, heavy weight of all-metal hydraulic cylinders, etc., and achieve improved fatigue resistance and lightweight vehicle cost. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

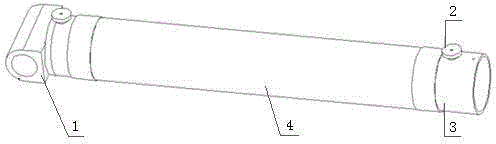

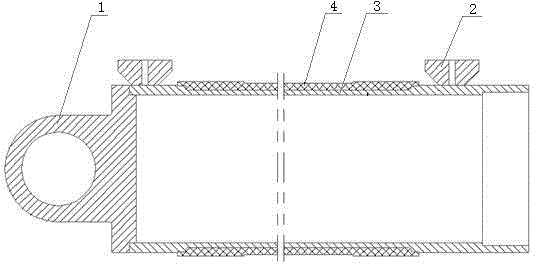

[0024] Such as figure 1 and figure 2 As shown, this embodiment provides a carbon fiber composite material reinforced hydraulic cylinder, which includes a base 1, a cylinder barrel 3 and an oil port 2, and oil ports 2 are provided at both ends of the cylinder barrel 3, and the cylinder barrel 3 is machined thinly. Metal cylinder, the cylinder 3 is wrapped with a reinforcement layer 4, the reinforcement layer 4 is a carbon fiber composite material reinforcement layer, and the carbon fiber composite material reinforcement layer is a carbon fiber composite material reinforcement layer with a thermosetting resin as a matrix and carbon fiber as a reinforcement material. The reinforced layer of composite material contains 23% resin by mass. The reinforced layer of carbon fiber composite material is prepared by a carbon fiber dry winding molding process with a glass transition temperature of 120°C, a curing degree of 80%, and a winding angle of 54.7 degrees. The cylinder 3 has a le...

Embodiment 2

[0026] Such as figure 1 and figure 2 As shown, this embodiment provides a carbon fiber composite material reinforced hydraulic cylinder, which includes a base 1, a cylinder barrel 3 and an oil port 2, and oil ports 2 are provided at both ends of the cylinder barrel 3, and the cylinder barrel 3 is machined thinly. Metal cylinder, the cylinder 3 is wrapped with a reinforcement layer 4, the reinforcement layer 4 is a carbon fiber composite material reinforcement layer, and the carbon fiber composite material reinforcement layer is a carbon fiber composite material reinforcement layer with a thermosetting resin as a matrix and carbon fiber as a reinforcement material. The reinforced layer of composite material contains 55% resin by mass. The reinforced layer of carbon fiber composite material is prepared by a carbon fiber wet winding molding process with a glass transition temperature of 130°C, a curing degree of 85%, and a winding angle of 54.7 degrees. The cylinder 3 has a le...

Embodiment 3

[0028] Such as figure 1 and figure 2 as shown in figure 1 and figure 2 As shown, this embodiment provides a carbon fiber composite material reinforced hydraulic cylinder, which includes a base 1, a cylinder barrel 3 and an oil port 2, and oil ports 2 are provided at both ends of the cylinder barrel 3, and the cylinder barrel 3 is machined thinly. Metal cylinder, the cylinder 3 is wrapped with a reinforcement layer 4, the reinforcement layer 4 is a carbon fiber composite material reinforcement layer, and the carbon fiber composite material reinforcement layer is a carbon fiber composite material reinforcement layer with a thermosetting resin as a matrix and carbon fiber as a reinforcement material. The reinforced layer of composite material contains 32% resin by mass. The reinforced layer of carbon fiber composite material is prepared by the prepreg autoclave molding process with a glass transition temperature of 140°C, a curing degree of 90%, and a prepreg coating angle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com