Manufacturing method of nine-hydraulic-motor driven self-discharging boom base

A technology of hydraulic motor and manufacturing method, which is applied in the direction of cranes, etc., can solve the problems that cannot meet the installation requirements of the boom base of special self-unloading ships, and achieve the effect of simple machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

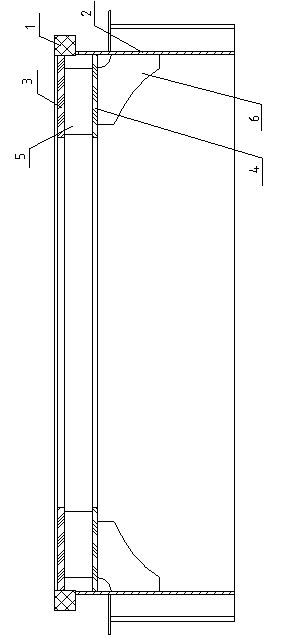

[0047] Such as figure 1 The present invention shows a specific implementation method of a self-unloading boom base driven by nine hydraulic motors, including the following steps:

[0048] 1. Production:

[0049] A. Making the flange: forging the flange base 1 with an overall thickness of 160mm, the inner diameter of the flange base 1 is φ3950mm, and the outer diameter is φ4245mm;

[0050] B. Cylinder body production: use 24mm thick steel plate to make cylinder body 2 with inner diameter of φ3964mm, cylinder height is 1177mm, spot weld cylinder body 2, and spot weld reinforcing ribs on the cylinder body;

[0051] C. Two steel plates with a length of 2000mm, a width of 4000mm and a height of 50mm are pre-assembled and welded and then cut by numerical control to form the first flange 3 with an inner diameter of φ2735mm and an outer diameter of φ3948mm, and process the groove;

[0052] D. Two steel plates with a length of 2100mm, a width of 4000mm, and a height of 40mm are pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com