Water-permeable concrete and preparation method thereof

A technology for permeable concrete and cement, applied in the field of concrete, can solve problems such as inapplicability, and achieve the effect of large water permeability coefficient and strong compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

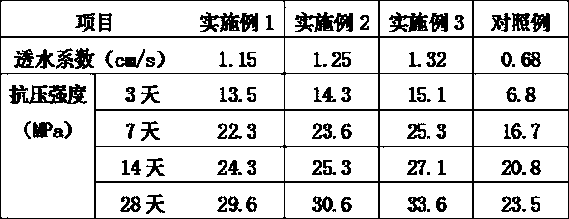

Embodiment 1

[0030] Prepare raw materials: in parts by mass, 300 parts of cement, 1500 parts of aggregate, 9 parts of water reducer, 15 parts of reinforcing agent, and 90 parts of water, wherein the reinforcing agent consists of microsilica fume, ultrafine powder and nanomaterial TiO 2 Composition, the specific surface area of the reinforcing agent is 25000m 2 / kg, the activity index is 102%, and by mass percentage, aluminum oxide accounts for 0.92%, calcium oxide accounts for 0.14%, iron oxide accounts for 0.27%, magnesium oxide accounts for 1.59%, and silicon dioxide accounts for 93.11% in the reinforcing agent, The burning reduction is 3.18%, of which 42.5 ordinary Portland cement is used for cement, single-grade basalt gravel is used for aggregate, and the particle size of aggregate is 2.36mm; aggregate, reinforcing agent and cement are added in sequence after dry mixing, and then added Water and water reducing agent are mixed and stirred to make permeable concrete.

Embodiment 2

[0032] Prepare raw materials: by mass, 500 parts of cement, 1700 parts of aggregate, 15 parts of water reducing agent, 50 parts of reinforcing agent, 125 parts of water, the specific surface area of reinforcing agent is 25000m2 2 / kg, the activity index is 102%, and the reinforcing agent is composed of microsilica fume, ultrafine powder and nanomaterial TiO 2 Composition, by mass percentage, in the described strengthening agent, aluminum oxide accounts for 0.92%, calcium oxide accounts for 0.14%, iron oxide accounts for 0.27%, magnesium oxide accounts for 1.59%, silicon dioxide accounts for 93.11%, and calcination is 3.18%, wherein The cement is made of 52.5 ordinary Portland cement, the aggregate is made of single-grade basalt crushed stone, and the particle size of the aggregate is 4.75mm; all the aggregates, 75% water, and all the reinforcing agents are put in and stirred for 15 seconds, and all the cement is put in again , all water reducing agents, and 25% water were st...

Embodiment 3

[0034] Prepare raw materials: by mass, 400 parts of cement, 1650 parts of aggregate, 12 parts of water reducing agent, 20 parts of reinforcing agent, 115 parts of water, the specific surface area of reinforcing agent is 25000m2 2 / kg, the activity index is 102%, and the reinforcing agent is composed of microsilica fume, ultrafine powder and nanomaterial TiO 2 Composition, by mass percentage, in the described strengthening agent, aluminum oxide accounts for 0.92%, calcium oxide accounts for 0.14%, iron oxide accounts for 0.27%, magnesium oxide accounts for 1.59%, silicon dioxide accounts for 93.11%, and calcination is 3.18%, wherein The cement is 52.5 ordinary Portland cement, the aggregate is single-grade basalt crushed stone, and the particle size of the aggregate is 3.56mm; all aggregates, 75% water, and all reinforcing agents are put in for stirring for 28 seconds, and all cement is put in again , all water reducing agents, and 25% water were stirred until uniform to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com