Pervious concrete

A technology of permeable concrete and cement, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve excellent performance and improve pozzolanic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

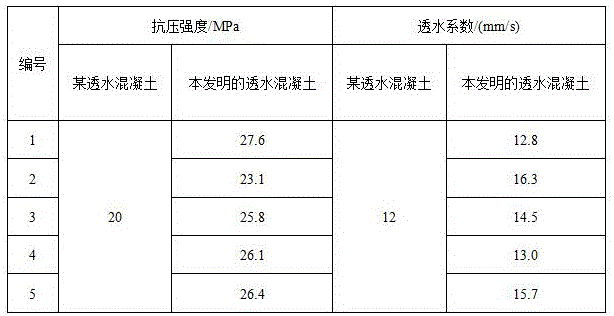

Examples

Embodiment 1

[0026] A kind of permeable concrete includes the following raw materials configured by weight: cement 460kg / m 3 , sulfur-fixed ash 80kg / m 3 , stone 1170kg / m 3 , sand 100kg / m 3 , water 152kg / m 3 , Water reducer: 1.5kg / m 3 , numbered 1.

[0027] Cement is P.O42.5R in the present embodiment.

[0028] In this example, the particle size of the original ash of sulfur-fixed ash satisfies D after proper grinding. 50 15.2 μm, D 10 3μm, D 90 The water demand ratio of sulfur-fixing ash is 105%, and the 28d activity index is 95% (refer to Appendix B and Appendix D of GB1596-2005 "Fly Ash Used in Cement and Concrete" for water demand ratio and activity index).

[0029] In this embodiment, the stones are crushed stones with a particle size of 9.5-16mm.

[0030] In this embodiment, the water reducer is a polycarboxylate high-efficiency water reducer.

[0031] The concrete molding method in the present embodiment is as follows:

[0032] The concrete in this embodiment is poured in ...

Embodiment 2

[0034] A kind of permeable concrete includes the following raw materials configured by weight: cement 320kg / m 3 , sulfur-fixed ash 220kg / m 3 , stone 1300kg / m 3 , sand 0kg / m 3 , water 190kg / m 3 , Water reducer: 1.7kg / m 3 , numbered 2.

[0035] Cement is P.O42.5R in the present embodiment.

[0036] In this example, the particle size of the original ash of sulfur-fixed ash satisfies D after proper grinding. 50 22 μm, D 10 4.2 μm, D 90 The water demand ratio of sulfur-fixing ash is 100%, and the 28d activity index is 86% (refer to Appendix B and Appendix D of GB1596-2005 "Fly Ash Used in Cement and Concrete" for water demand ratio and activity index).

[0037] In this embodiment, the stones are crushed stones with a particle size of 9.5-16mm.

[0038] In this embodiment, the water reducer is a polycarboxylate high-efficiency water reducer.

[0039] The concrete molding method in the present embodiment is as follows:

[0040] The concrete in this embodiment is poured in ...

Embodiment 3

[0042] A kind of permeable concrete includes the following raw materials configured by weight: cement 380kg / m 3 , sulfur-fixed ash 160kg / m 3 , stone 1200kg / m 3 , sand 80kg / m 3 , water 162kg / m 3 , Water reducing agent: 1.6kg / m 3 , numbered 3.

[0043] Cement is P.O42.5R in the present embodiment.

[0044] In this example, the particle size of the original ash of sulfur-fixed ash satisfies D after proper grinding. 50 25 μm, D 10 5μm, D 90The water demand ratio of sulfur-fixing ash is 95%, and the 28d activity index is 80% (refer to Appendix B and Appendix D of GB1596-2005 "Fly Ash Used in Cement and Concrete" for water demand ratio and activity index).

[0045] In this embodiment, the stones are crushed stones with a particle size of 9.5-16mm.

[0046] In this embodiment, the water reducer is a polycarboxylate high-efficiency water reducer.

[0047] The concrete molding method in the present embodiment is as follows:

[0048] The concrete in the embodiment is poured i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com