A kind of high adsorption, high bonding strength roasted diatom mud and its preparation method

A high-adsorption, high-adhesion technology, applied in coatings and other directions, can solve the problems of limited lifting effect and complex methods, and achieve the effect of less useless impurities, simple preparation process and high adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

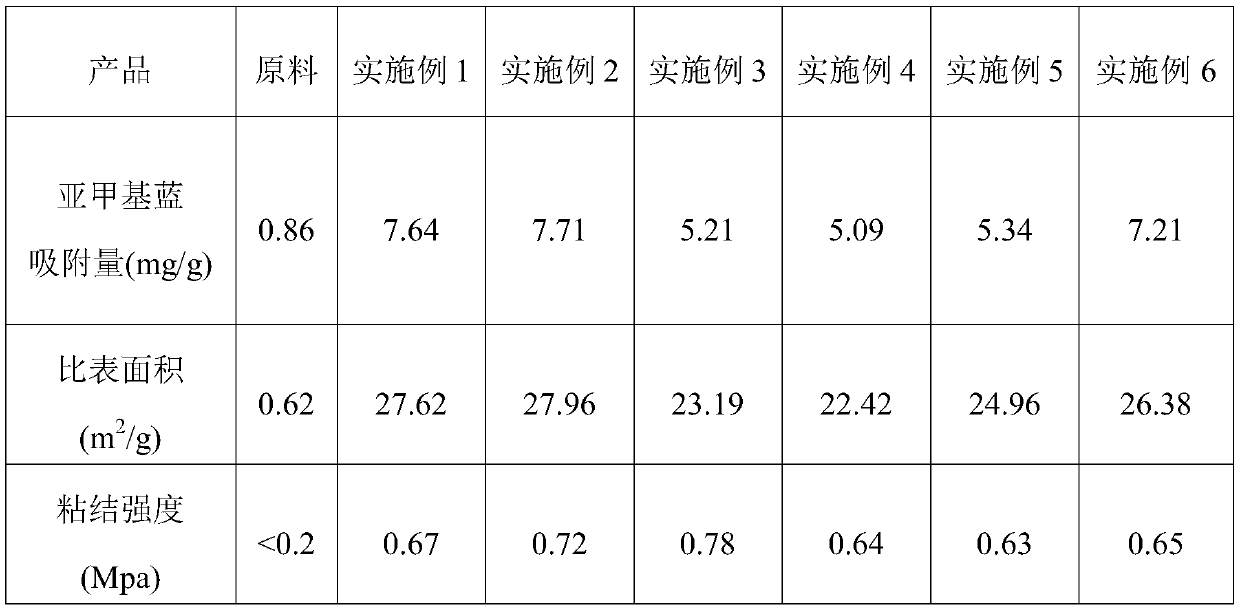

Embodiment 1

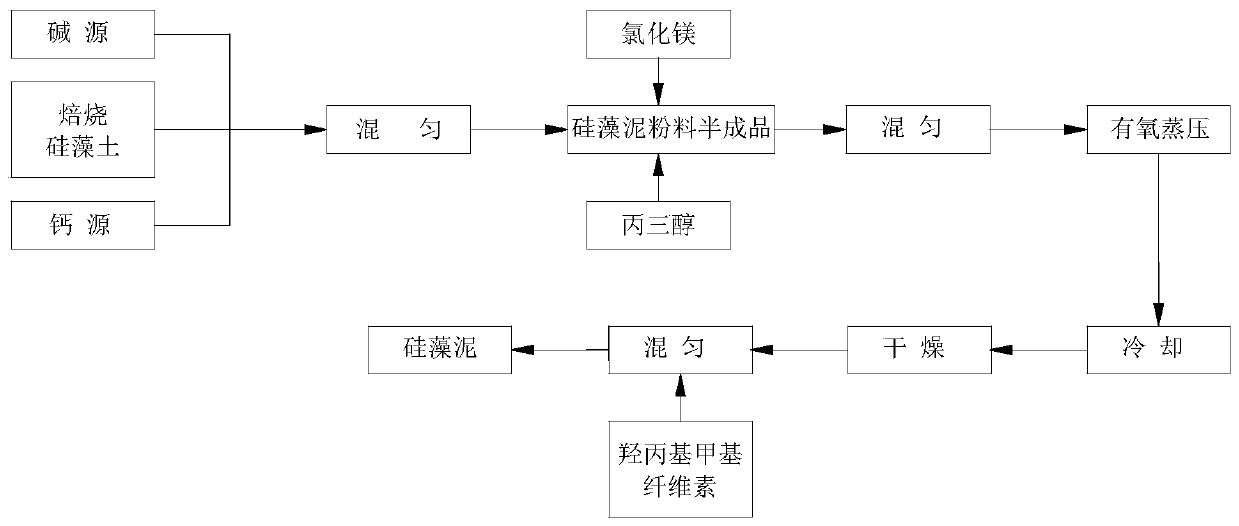

[0023] Such as figure 1 Shown, the preparation method of high adsorption, high strength roasted diatom mud is as follows:

[0024] (1) Take 18g of roasted diatomite and 2g of CaO respectively, stir with a vortex mixer for 30min, and mix evenly to obtain a semi-finished product of diatom mud powder;

[0025] (2) Take 5g Na 2 SO 4 , 2g MgCl 2 and 3g glycerol to make a solution, mix it with the semi-finished diatom mud powder above, and then add it into a 150mL ceramic crucible according to the solid-liquid mass ratio of 1:5, and place it in a high-pressure reactor after fully stirring React at 160°C for 12 hours; no oxygen is emitted during the heating process, ensuring that the reaction process is in an aerobic environment;

[0026] (3) After the reaction is completed, the diatom mud is taken out and cooled to room temperature, and fully dried at 100°C after filtering;

[0027] (4) Mix the dried diatom ooze with 0.4 g of hydroxypropyl methylcellulose evenly, use a powder m...

Embodiment 2

[0029] This example is basically the same as Example 1, except that the amount of calcined diatomaceous earth is 17 g, and the amount of CaO is 3 g.

Embodiment 3

[0031] This example is basically the same as Example 1, except that the amount of calcined diatomaceous earth is 15 g, the amount of CaO is 5 g, the autoclaved reaction temperature is 180° C., and the reaction time remains unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com