Preparation method for calcinating hydraulic binder at low temperature

A technology of hydraulic cementation and low-temperature sintering, applied in clinker production, cement production and other directions, can solve problems such as unfavorable protection of ecological environment and resource conservation, high carbon dioxide emissions, and contrary to sustainable development, and achieve product Excellent performance, resource saving, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

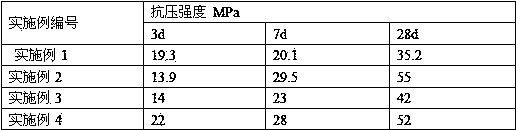

Embodiment 1

[0028] A kind of preparation method of low-temperature firing hydraulic cementitious material, comprises the following steps:

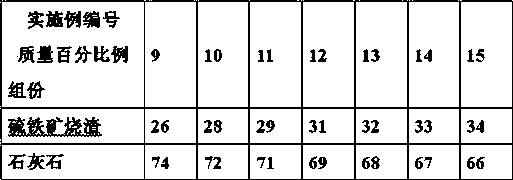

[0029] a, batching: take each component according to the raw material composition and mass percentage of 30% of pyrite slag and 70% of limestone, and mix evenly after crushing and grinding to obtain a mixture;

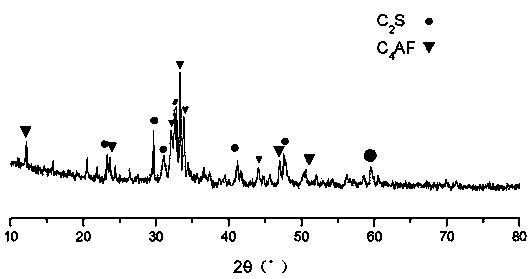

[0030] b. Calcination: place the mixture at a temperature of 1150-1350°C for 80 minutes, and then quench it to obtain clinker; the mineral composition of the clinker: C2S 47%, C4AF53%;

[0031] c. Preparation of cementitious material: grind the clinker until the specific surface area is 400-500m2 / Kg, and then the product hydraulic cementitious material is obtained.

Embodiment 2

[0033] A kind of preparation method of low-temperature firing hydraulic cementitious material, comprises the following steps:

[0034] a, batching: take each component according to the raw material composition and mass percentage of pyrite slag 25.2%, limestone 74.8%, after crushing and grinding, mix uniformly and make mixture;

[0035] b. Calcination: place the mixture at a temperature of 1150-1350°C for 70 minutes, and then quench it to obtain clinker; the mineral composition of the clinker is: C2S 53%, C4AF 47%;

[0036] c. Preparation of cementitious material: Add dihydrate gypsum with 10% of the clinker mass to the clinker, mix and grind until the specific surface area is 400-500m2 / Kg, and the product hydraulic cementitious material is obtained.

Embodiment 3

[0038] A kind of preparation method of low-temperature firing hydraulic cementitious material, comprises the following steps:

[0039] a, batching: take each component according to the raw material composition and mass percentage of pyrite slag 26.1%, limestone 73.9%, after crushing and grinding, mix uniformly and make mixture;

[0040] b. Calcination: place the mixture at a temperature of 1150-1350°C for 90 minutes, and then quench it to obtain clinker; the mineral composition of the clinker: C2S 55%, C4AF 45%;

[0041] c. Preparation of cementitious material: Add dihydrate gypsum with 15% of the clinker mass to the clinker, mix and grind until the specific surface area is 400-500m2 / Kg, and the product hydraulic cementitious material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com