A treatment method for high hydraulic activity blast furnace slag

A treatment method and a technology with high activity, which can be applied in cement production, etc., can solve problems affecting the hydraulic properties of blast furnace slag, achieve the effect of improving hydraulic activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

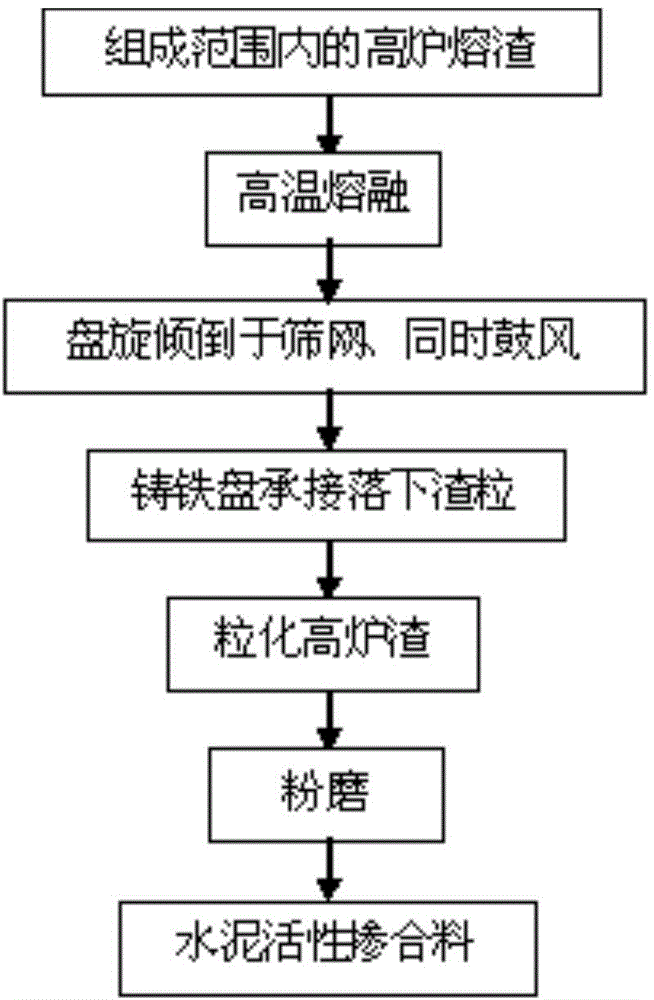

Method used

Image

Examples

example 1

[0018] Set blast furnace slag composition, by mass percentage, CaO (38.6%), SiO 2 (43.7%), MgO (6.0%), Al 2 o 3 (8.7%), and (CaO+MgO) / (SiO 2 +Al 2 o 3 ) The mass percent ratio is 0.85, the mass percent ratio of CaO / MgO is 6.5, SiO 2 / Al 2 o 3 The mass percent ratio of is 5.

[0019] The powdered limestone and fly ash under the 80μm sieve after grinding and sieving are used for chemical composition analysis, which is used to prepare blast furnace slag raw meal, and pure chemical reagent SiO 2 Adjust the ratio of each component with MgO, and use EXCEL software to calculate the amount of each raw material that meets the set blast furnace slag composition when 500g of blast furnace slag raw material is used, which are limestone 295.5g, fly ash 66.2g, SiO 2 Reagent 122.1g, MgO reagent 16.3g, each weighed and mixed evenly to obtain blast furnace slag raw meal; put the blast furnace slag raw meal into a corundum crucible and calcined in a high-temperature furnace from room te...

example 2

[0022] Set blast furnace slag composition, by mass percentage, CaO (42.3%), SiO 2 (38.3%), MgO (3.7%), Al 2 o 3 (12.7%), and (CaO+MgO) / (SiO 2 +Al 2 o 3 ) The mass percent ratio is 0.90, the mass percent ratio of CaO / MgO is 11.5, SiO 2 / Al 2 o 3 The mass percent ratio of is 3.

[0023] The powdered limestone and fly ash under the 80μm sieve after grinding and sieving are used for chemical composition analysis, which is used to prepare blast furnace slag raw meal, and pure chemical reagent SiO 2 Adjust the ratio of each component with MgO, and use EXCEL software to calculate the amount of each raw material that meets the set blast furnace slag composition when 500g of blast furnace slag raw material is used, which are limestone 311.4g, fly ash 102.4g, SiO 2 Reagent 79.4g, MgO reagent 6.8g, each weighed and mixed evenly to obtain blast furnace slag raw meal; put the blast furnace slag raw meal in a corundum crucible and calcined in a high-temperature furnace from room tem...

example 3

[0026] Set blast furnace slag composition, by mass percentage, CaO (40.4%), SiO 2 (36.1%), MgO (11.5%), Al 2 o 3 (9.0%), and (CaO+MgO) / (SiO 2 +Al 2 o 3 ) The mass percentage ratio is 1.15, the mass percentage ratio of CaO / MgO is 3.5, SiO 2 / Al 2 o 3 The mass percent ratio of is 4.

[0027] The powdered limestone and fly ash under the 80μm sieve after grinding and sieving are used for chemical composition analysis, which is used to prepare blast furnace slag raw meal, and pure chemical reagent SiO 2 Adjust the ratio of each component with MgO, and use EXCEL software to calculate the amount of each raw material that meets the set blast furnace slag composition when 500g of blast furnace slag raw material is used, which are limestone 305.2g, fly ash 67.2g, SiO 2 Reagent 90.8g, MgO reagent 36.7g, each weighed and mixed evenly to obtain blast furnace slag raw meal; put the blast furnace slag raw meal into a corundum crucible and calcined in a high temperature furnace from r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com