A kind of fire-free lightweight brick and its preparation method

A light-weight brick and pre-fired technology, which is applied in the field of building materials, can solve the problems of low temperature resistance of unburned bricks, etc., and achieve the effects of increasing bonding force, saving energy, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

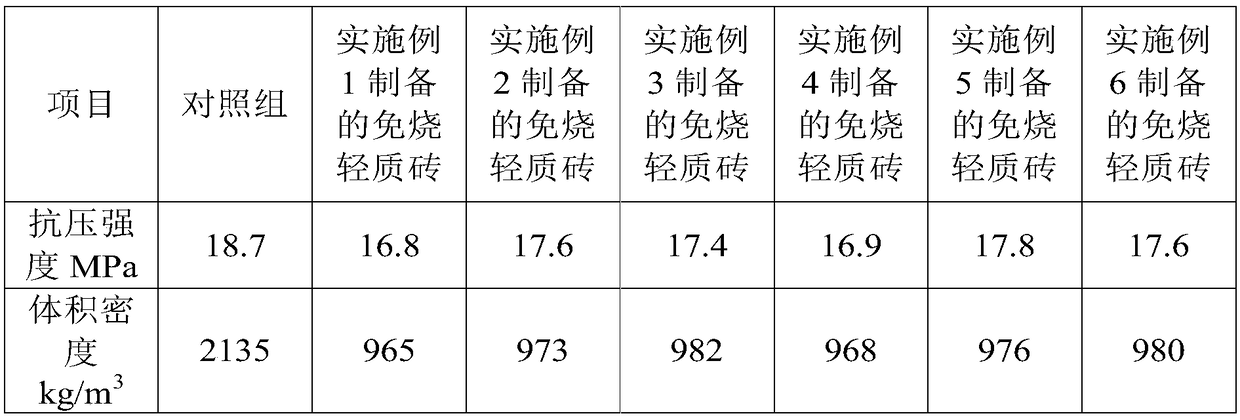

Examples

Embodiment 1

[0027] An unfired lightweight brick, the raw materials and mass percentages of the unfired light brick are: 40% blast furnace slag, 30% red mud, 15% magnesite, 10% dolomite, and 5% alumina fiber; , the particle size of blast furnace slag is 15 μm; the particle size of red mud is 20 μm; the particle size of magnesite is 1 μm; the particle size of dolomite is 1 μm; the length of alumina fiber is 3 mm; the diameter of alumina fiber is 4 μm.

Embodiment 2

[0029] An unfired lightweight brick, the raw materials and mass percentages of the unfired light brick are: 50% blast furnace slag, 25% red mud, 12% magnesite, 5% dolomite, and 8% alumina fiber; , the particle size of blast furnace slag is 20 μm; the particle size of red mud is 30 μm; the particle size of magnesite is 3 μm; the particle size of dolomite is 3 μm; the length of alumina fiber is 5 mm; the diameter of alumina fiber is 7 μm.

Embodiment 3

[0031] An unfired lightweight brick, the raw materials and mass percentages of the unfired light brick are: 60% blast furnace slag, 20% red mud, 10% magnesite, 7% dolomite, and 3% alumina fiber; , the particle size of blast furnace slag is 18 μm; the particle size of red mud is 25 μm; the particle size of magnesite is 2 μm; the particle size of dolomite is 2 μm; the length of alumina fiber is 4 mm; the diameter of alumina fiber is 6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com