Method for preparing water permeable bricks based on coal gangue

A technology of permeable bricks and coal gangue, which is applied in the field of preparing permeable bricks based on coal gangue, can solve the problems of high production cost and low compressive strength of permeable bricks, improve compressive strength and mechanical properties, and improve compressive and flexural resistance Strength, effect of increasing binding degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

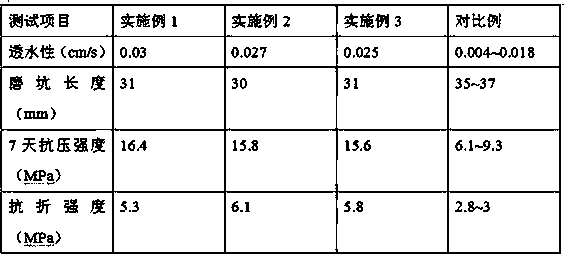

Examples

preparation example Construction

[0022] Preparation of added granules: Put serpentine and boehmite in a pulverizer at a mass ratio of 3:2 for crushing, pass through a 200-mesh sieve, and collect sieved particles to obtain added granules.

[0023] Accelerator preparation: Mix tourmaline powder and montmorillonite at a mass ratio of 1:2.

[0024] A method for preparing permeable bricks based on gangue, the method comprising the steps of:

[0025] (1) Take coal gangue and put it into a ball mill for 2 hours at 800r / min, collect ball mill A, mix ball mill A with 0.3mol / L sodium chloride solution at a mass ratio of 1:3, and let it stand for 1~3h , remove impurities floating on the surface, filter, collect the filter residue, dry the filter residue, pulverize, pass through a 100-mesh sieve, and collect the sieved particles;

[0026] (2) Put the sieved particles and papermaking black liquor into a ball mill at a mass ratio of 7:1~3 for 50 minutes at 500r / min, use carbon dioxide for protection during the ball millin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com