Patents

Literature

108results about How to "Enhance binding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

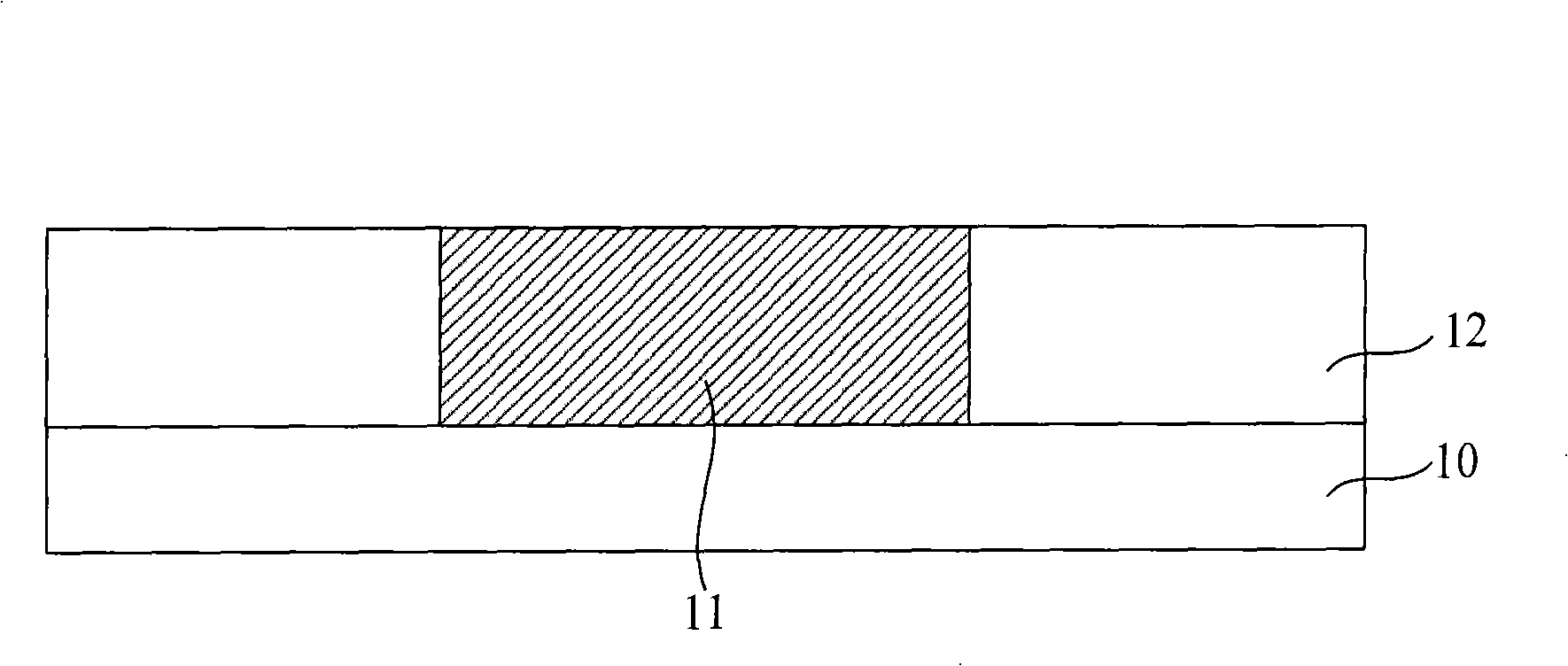

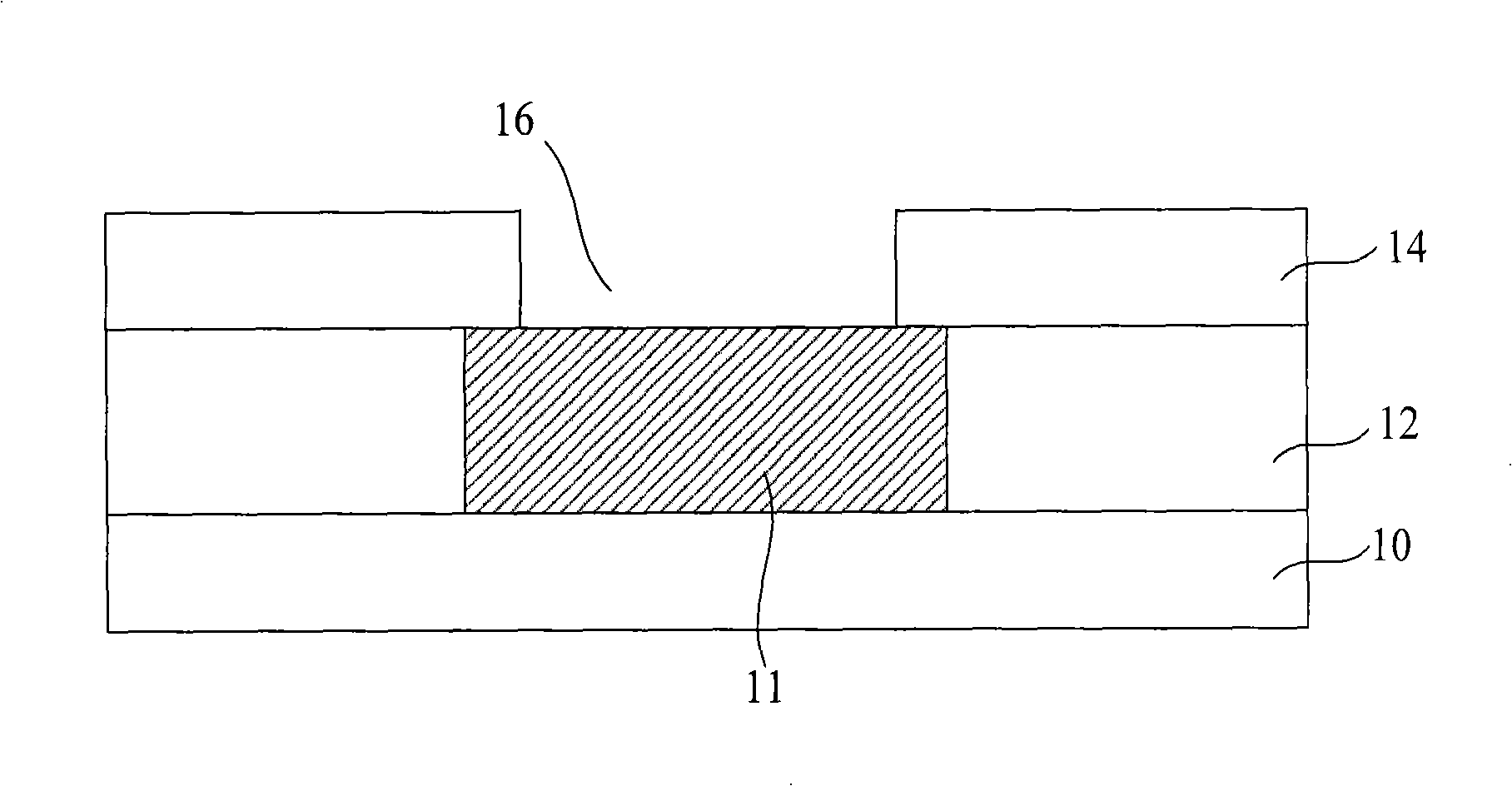

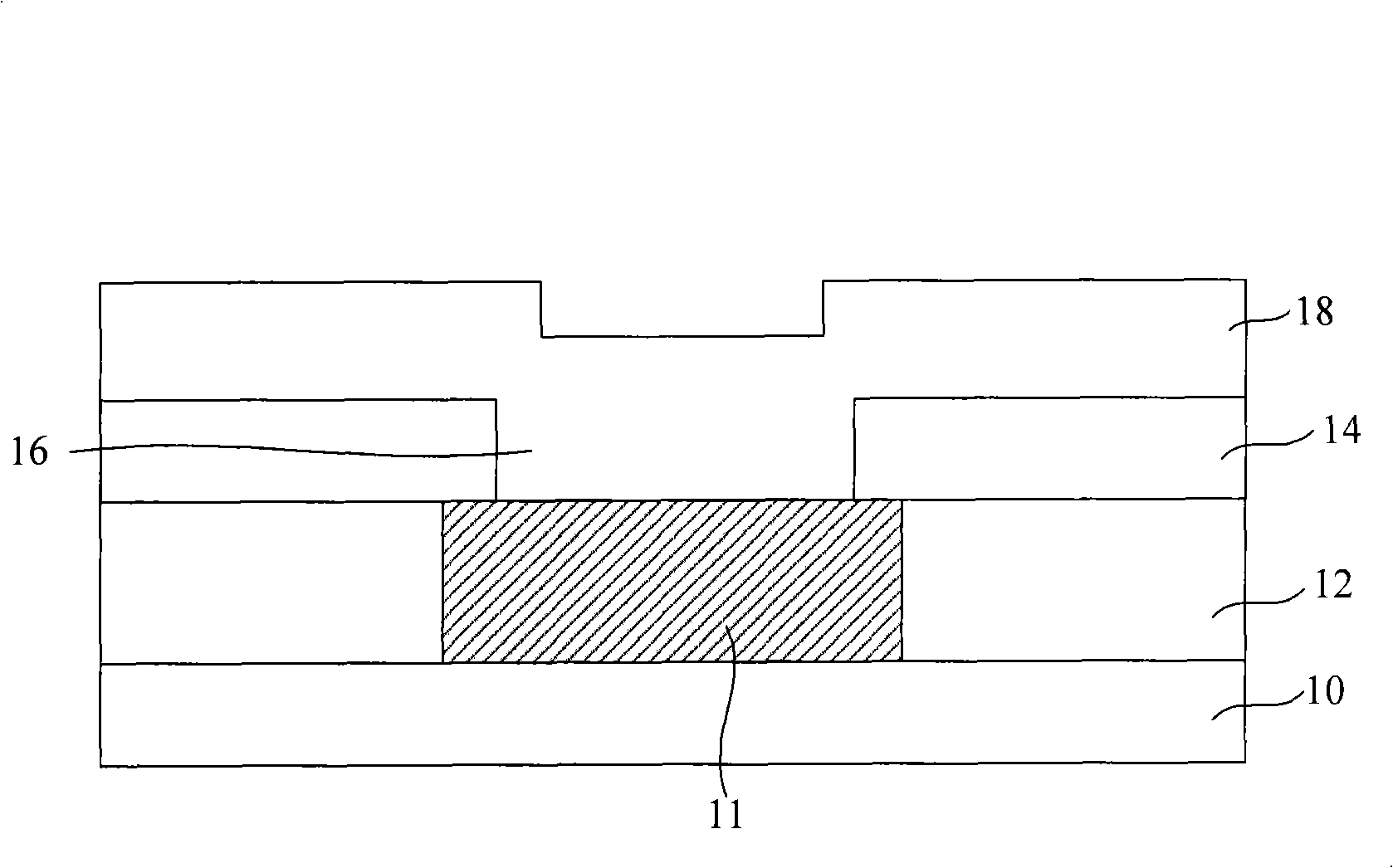

Method for manufacturing semiconductor device

InactiveCN101303987AWon't hurtEnhance binding strengthSolid-state devicesSemiconductor/solid-state device manufacturingResistHydrofluoric acid

The invention relates to a manufacturing method for a semiconductor device, which provides a semiconductor structure. The semiconductor structure is provided with an aluminum welding pad; a passivation layer is arranged on the semiconductor structure and the aluminum welding pad; a photo resist layer is formed on the passivation layer and is schematized to form an opening pattern; the passivation layer on the bottom of the opening pattern is etched and an opening is formed in the passivation layer; the photo resist layer is removed; the bottom and side walls of the opening are washed by aqueous solution containing sulphuric acid and oxyful; the bottom and side walls of the opening are further washed by aqueous solution containing hydrofluoric acid and ammonia. The method can eliminate polymers generated in the process of etching the passivation layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

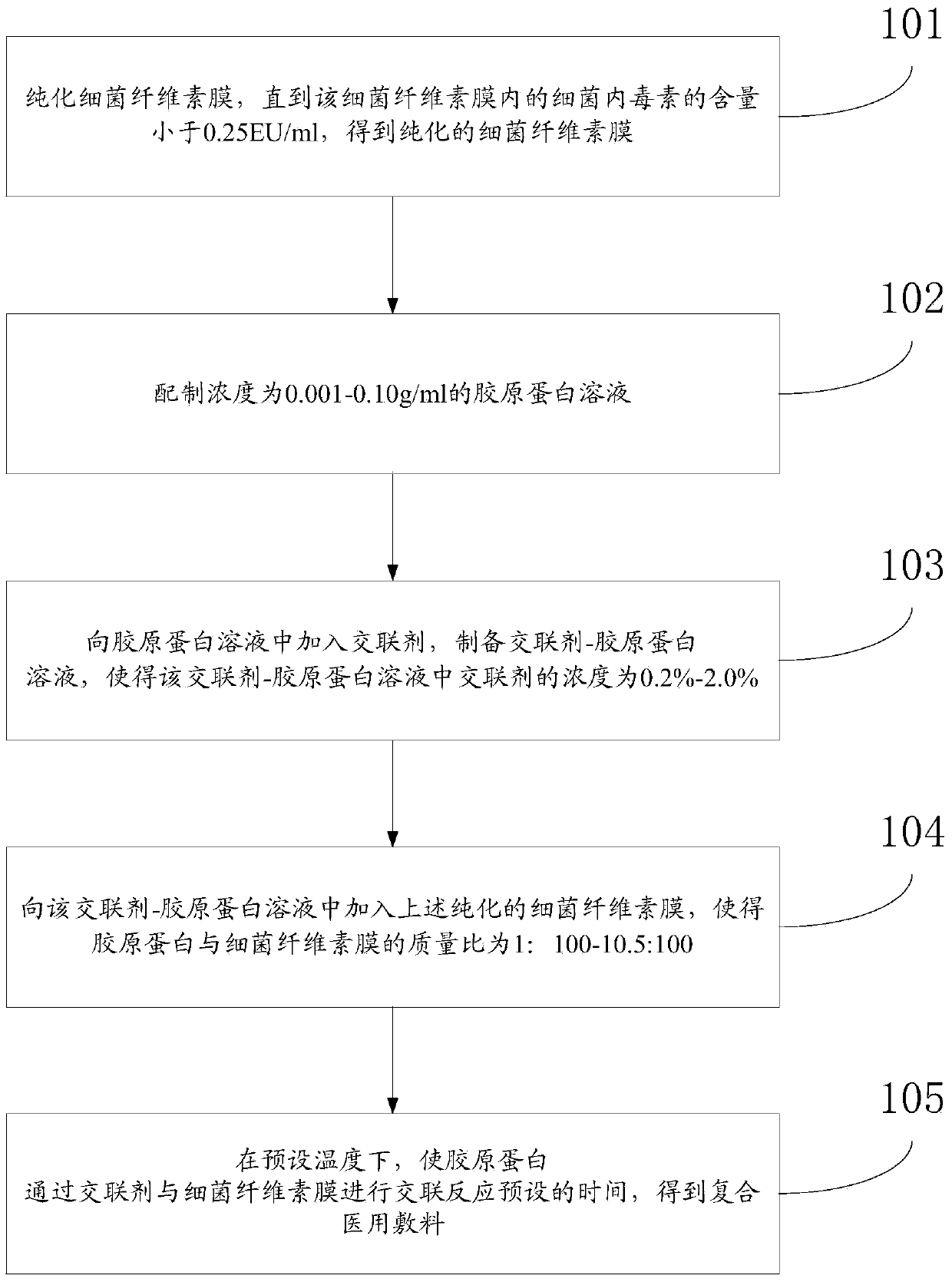

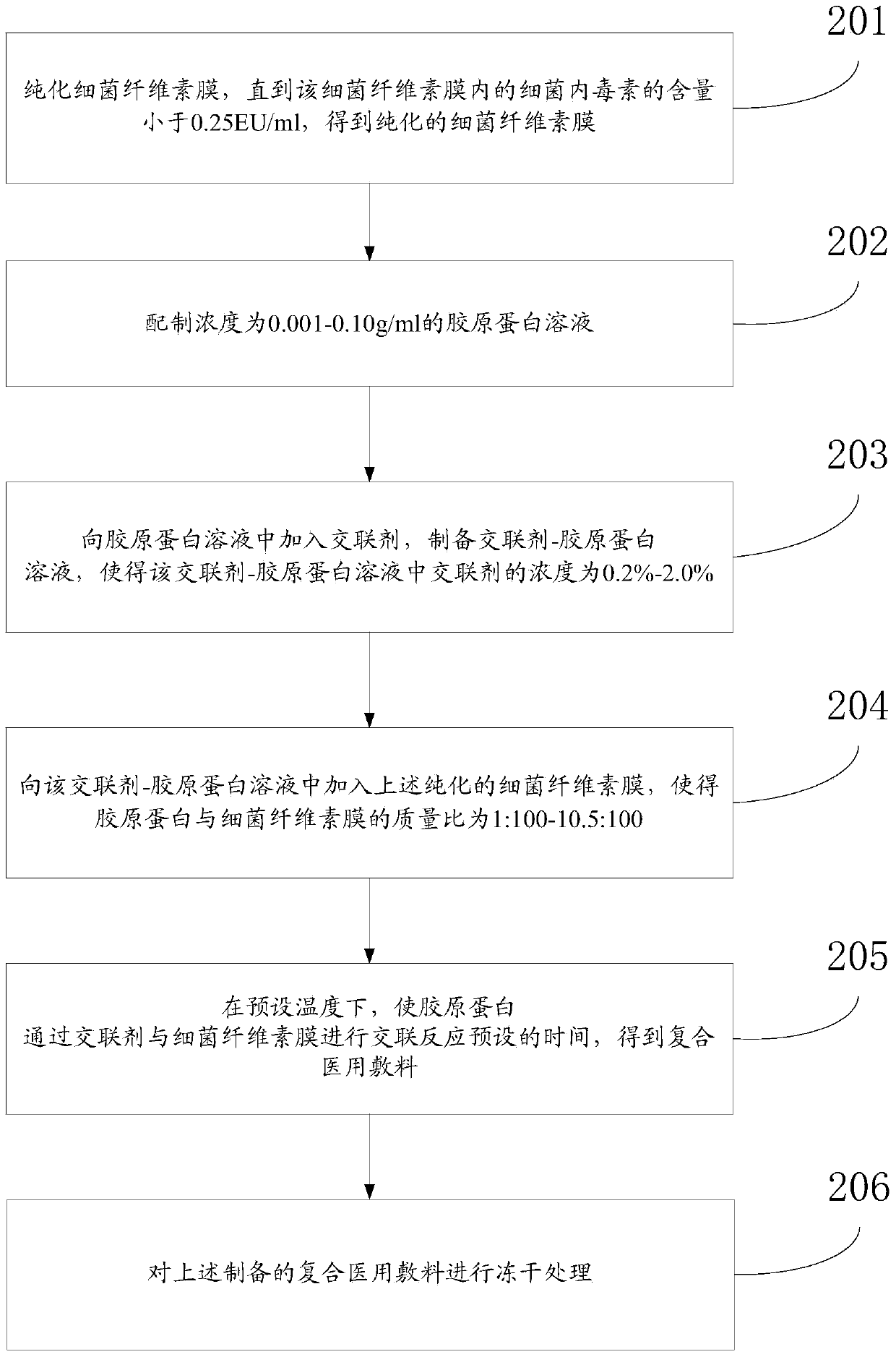

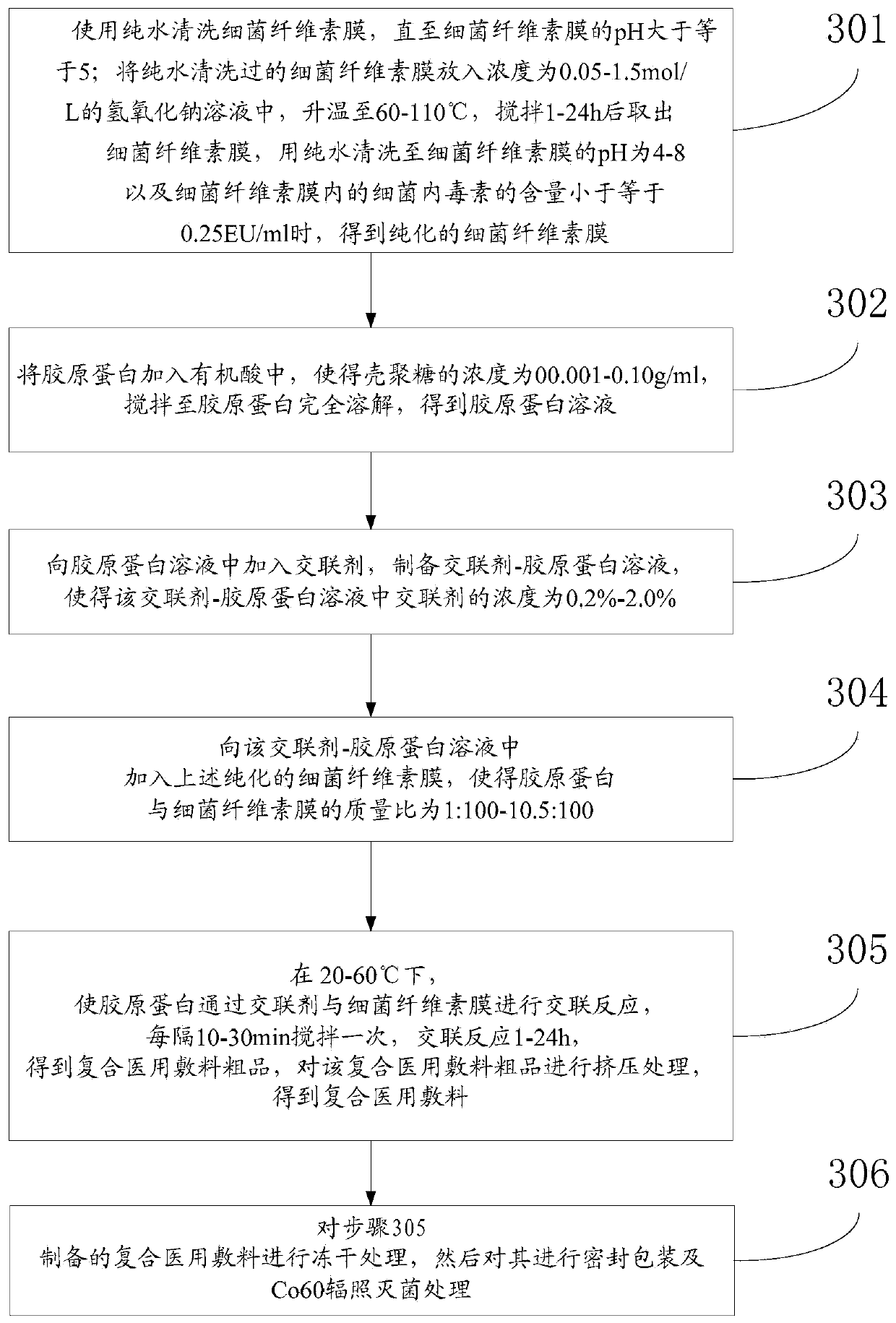

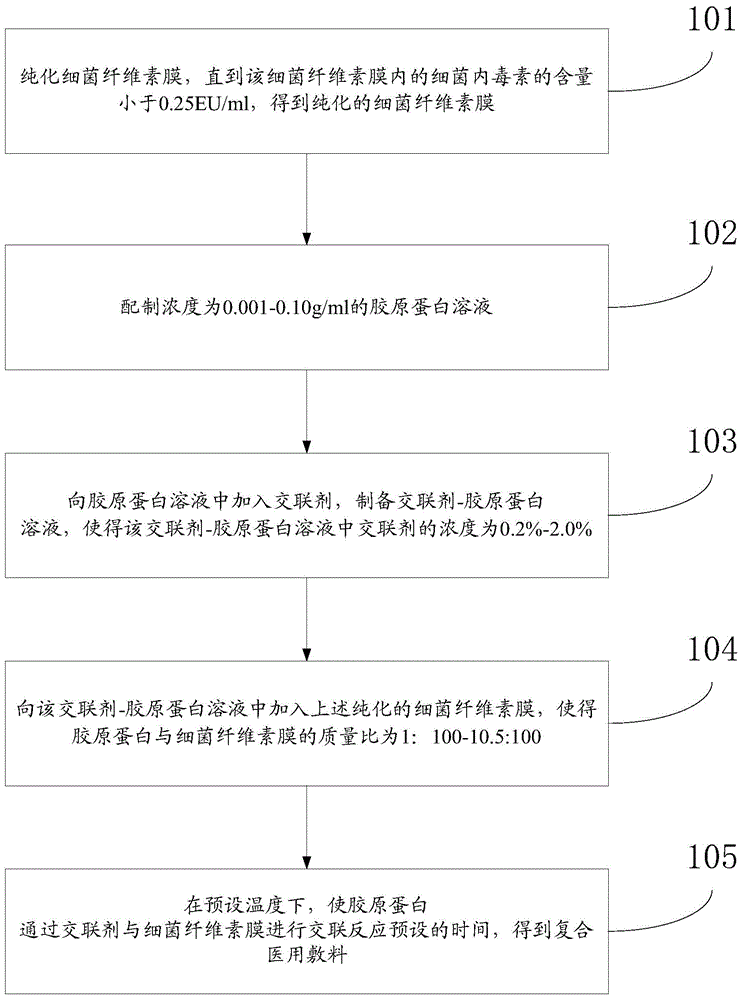

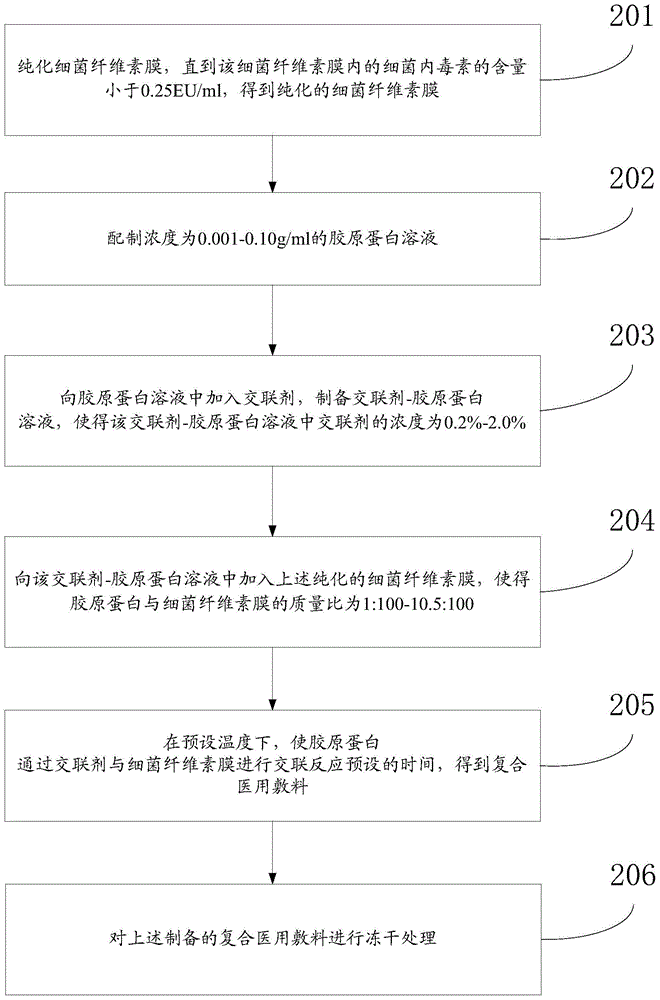

Compound medical dressing and preparation method thereof

ActiveCN103990172ALong-lasting and stable performanceIncrease loadAbsorbent padsBandagesOrganic chemistryProtein C

The invention discloses a compound medical dressing and a preparation method thereof, belonging to the field of compound medical dressings. The compound medical dressing comprises bacterial cellulose membranes, collagens and crosslinking agents, wherein the collagens are crosslinked on the bacterial cellulose membranes via the crosslinking agents. The preparation method comprises the steps of adding the purified bacterial cellulose membranes to a collagen solution containing the crosslinking agents and enabling the bacterial cellulose membranes and the collagens to carry out crosslinking reaction, thus obtaining the compound medical dressing. The loads of the collagens on the bacterial cellulose membranes and the loading stability of the collagens are improved by using the crosslinking agents, so that the properties of the prepared compound medical dressing are more lasting and stable. The method is simple, is easy to operate and has relatively high practicability.

Owner:BEIJING DINGHAN HENGHAI BIOLOGICAL TECH DEV

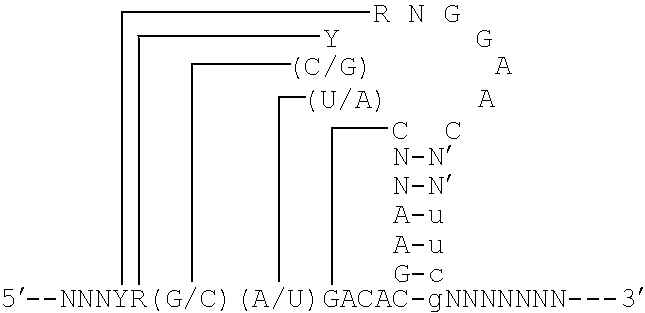

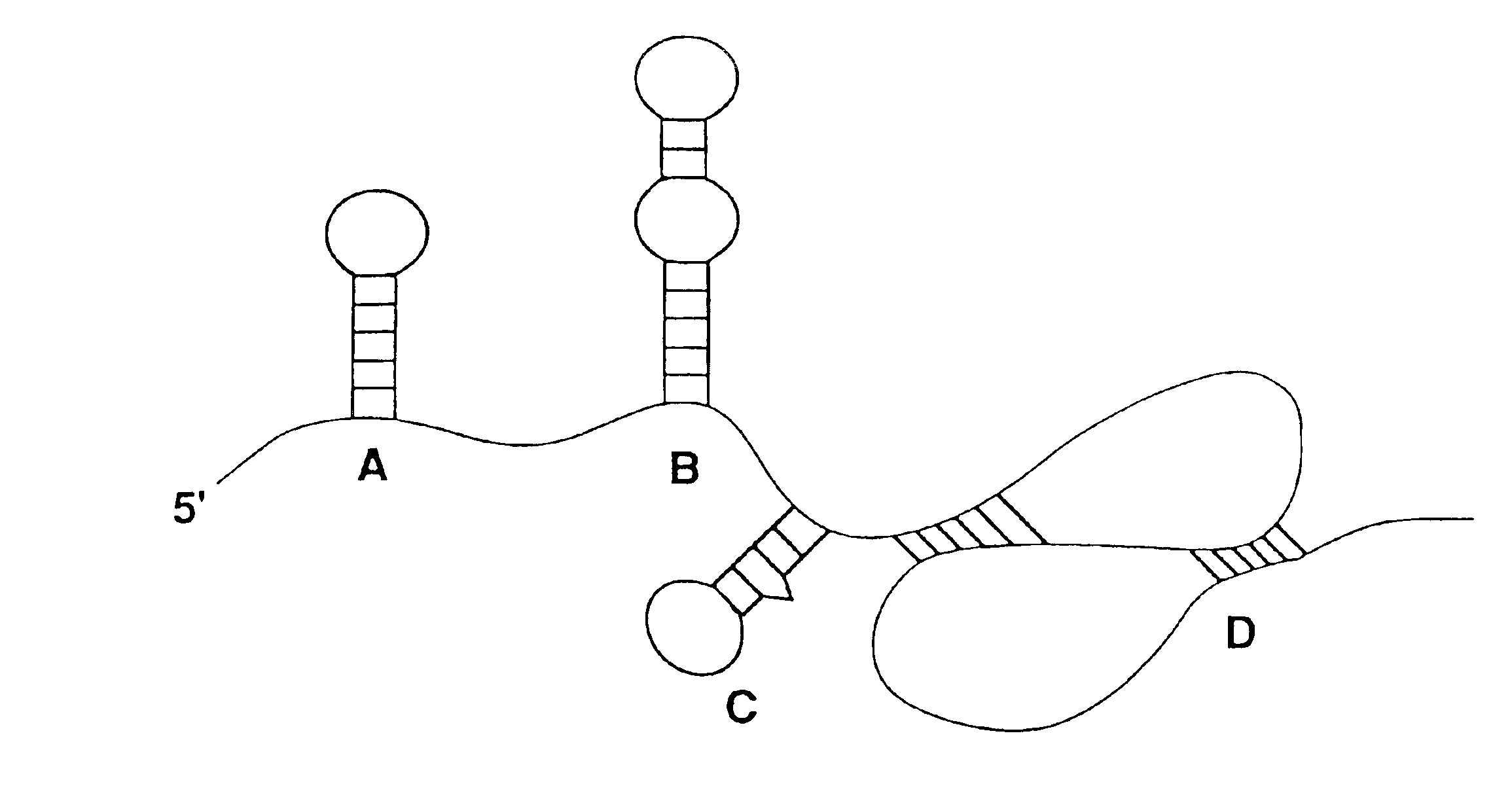

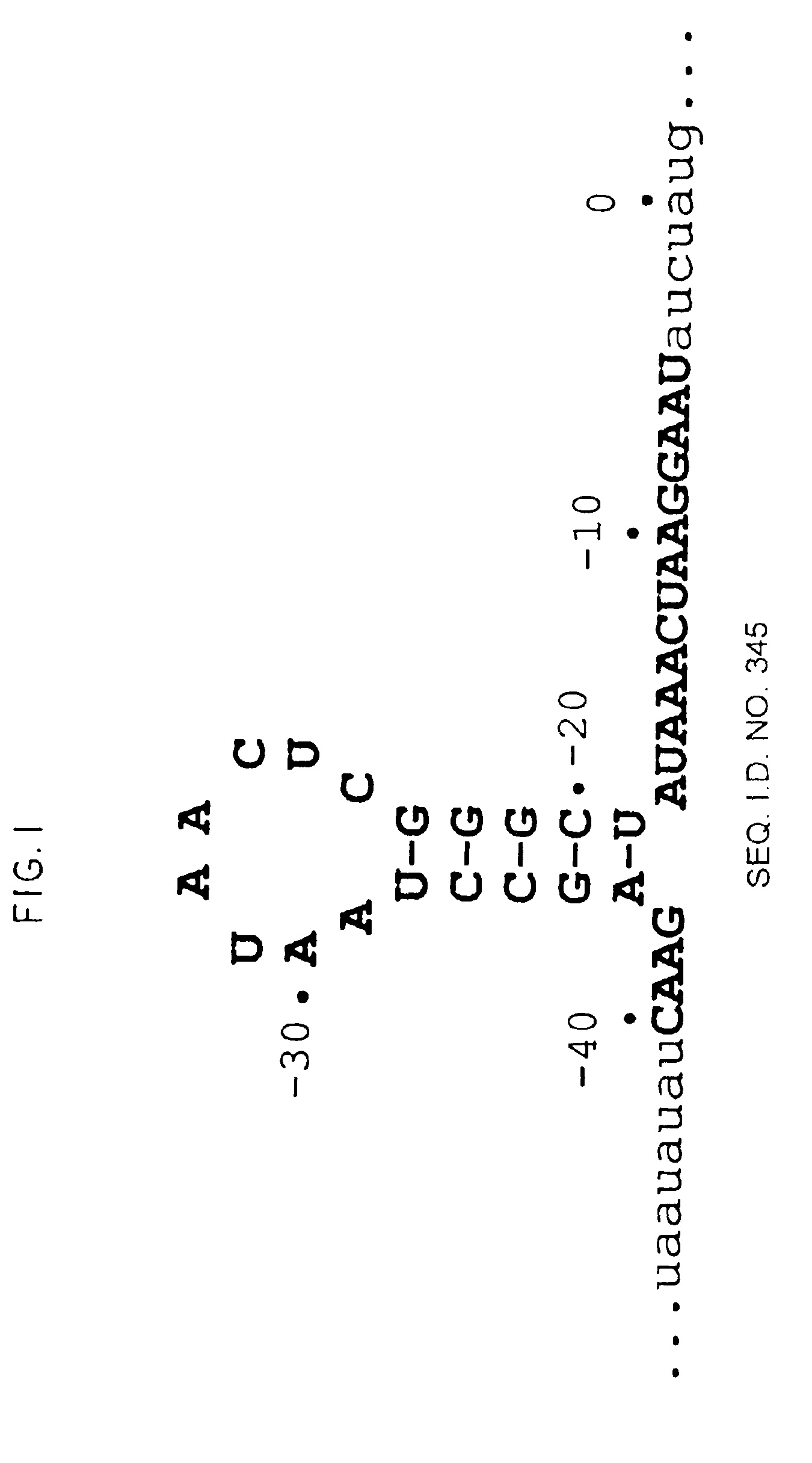

Nucleic acid ligand binding site identification

InactiveUS6933116B2Easy to combineEfficient use ofPeptide/protein ingredientsOrganic chemistry methodsBinding siteBiology

This invention comprises nucleic acid ligand for use as a diagnostic reagent for detecting the presence or absence of a target molecule in a sample, and a diagnostic reagent to measure the amount of a target molecule in a sample. In a preferred embodiment the nucleic acid ligands are identified by the method of the invention referred to as the Systematic Evolution of Ligands by EXponential enrichment (SELEX), wherein a candidate mixture of nucleic acids are iteratively enriched in high affinity nucleic acids and amplified by further partitioning.

Owner:GILEAD SCI INC

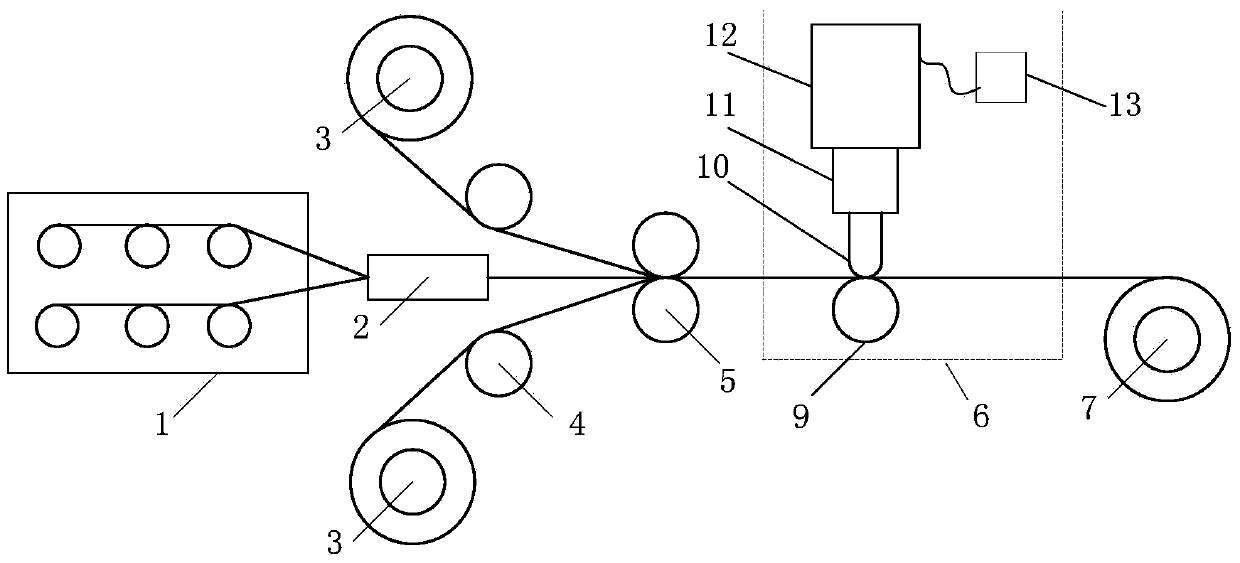

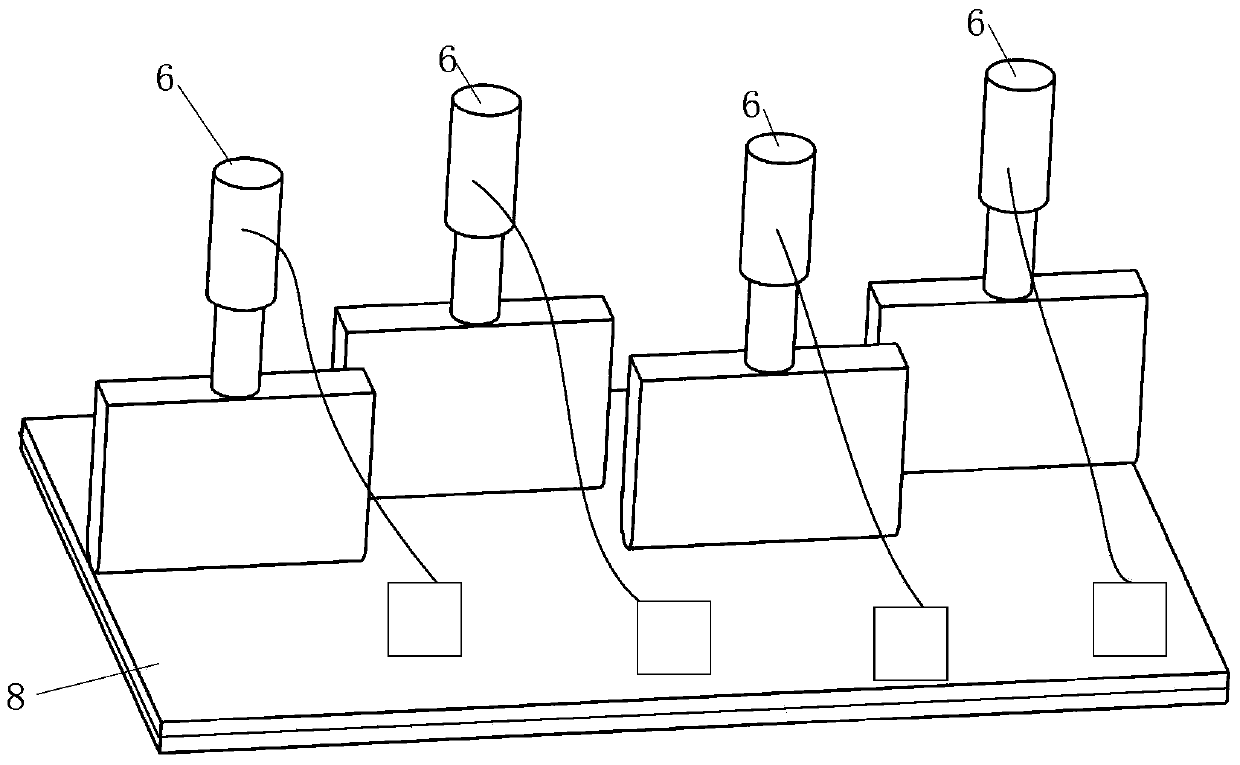

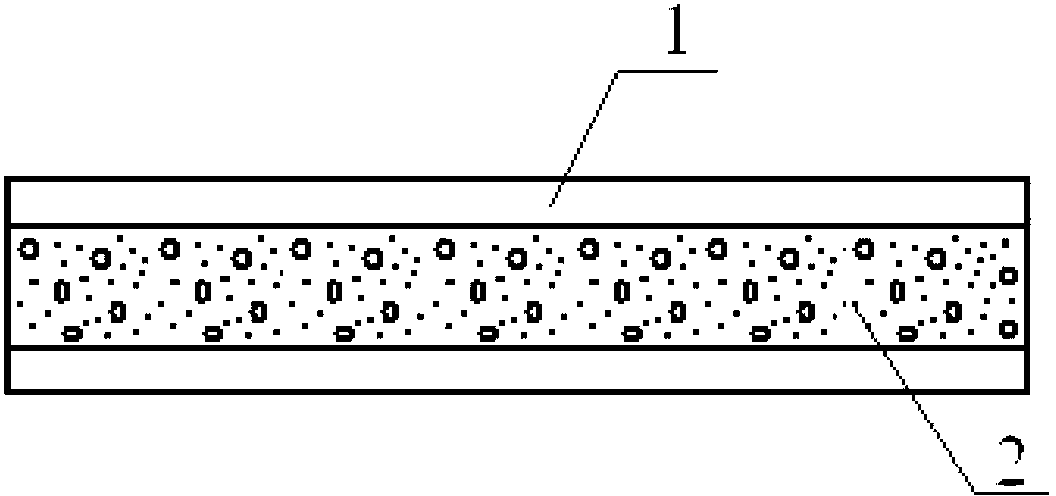

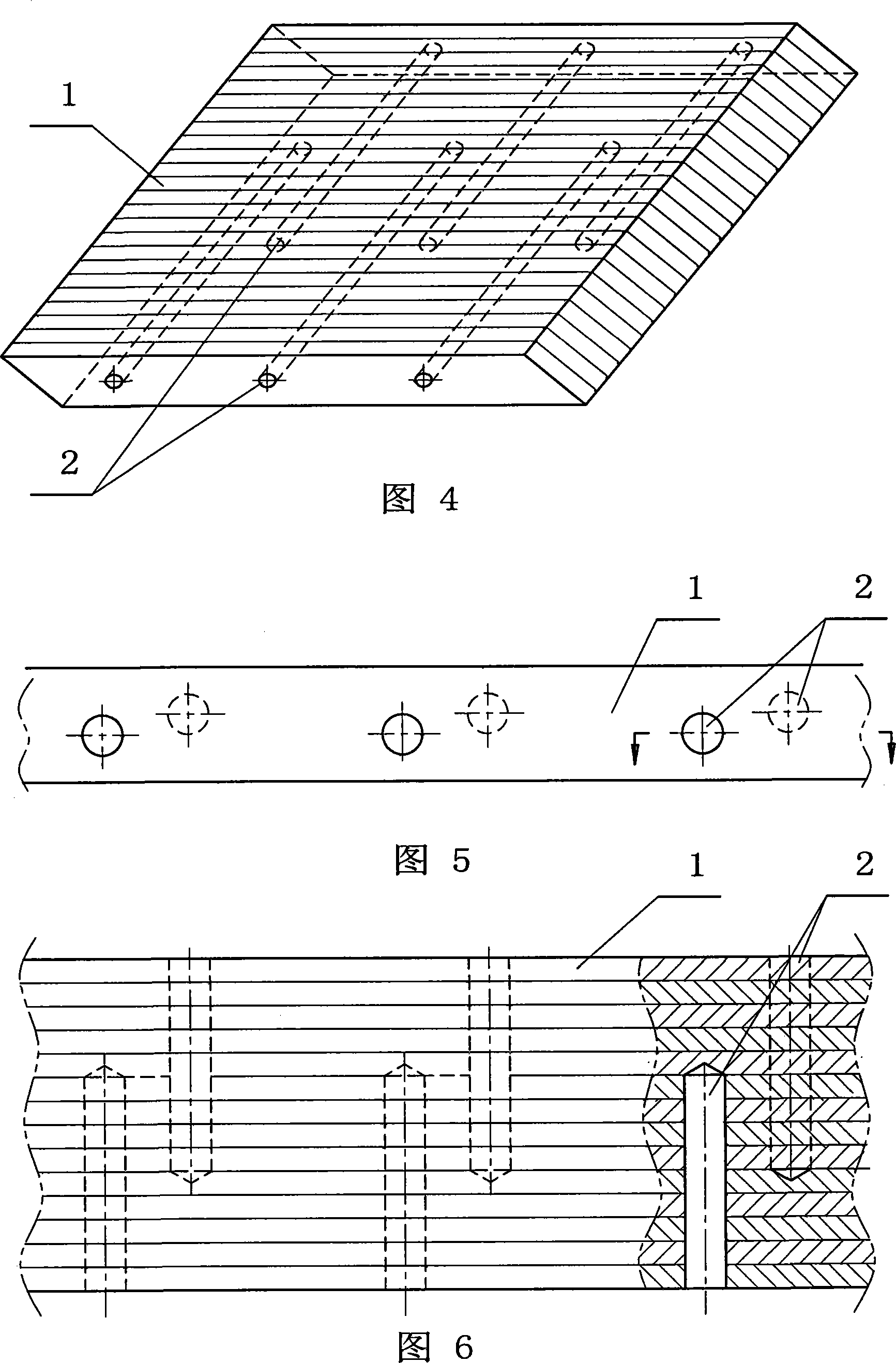

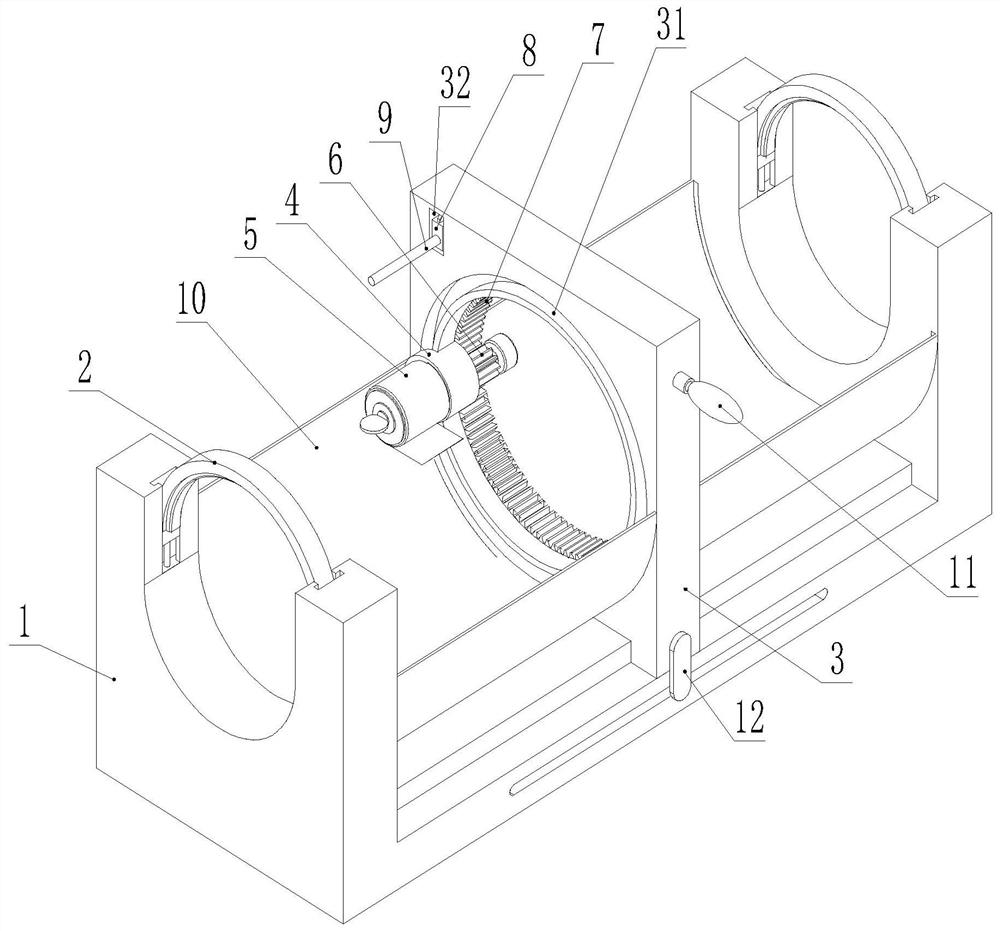

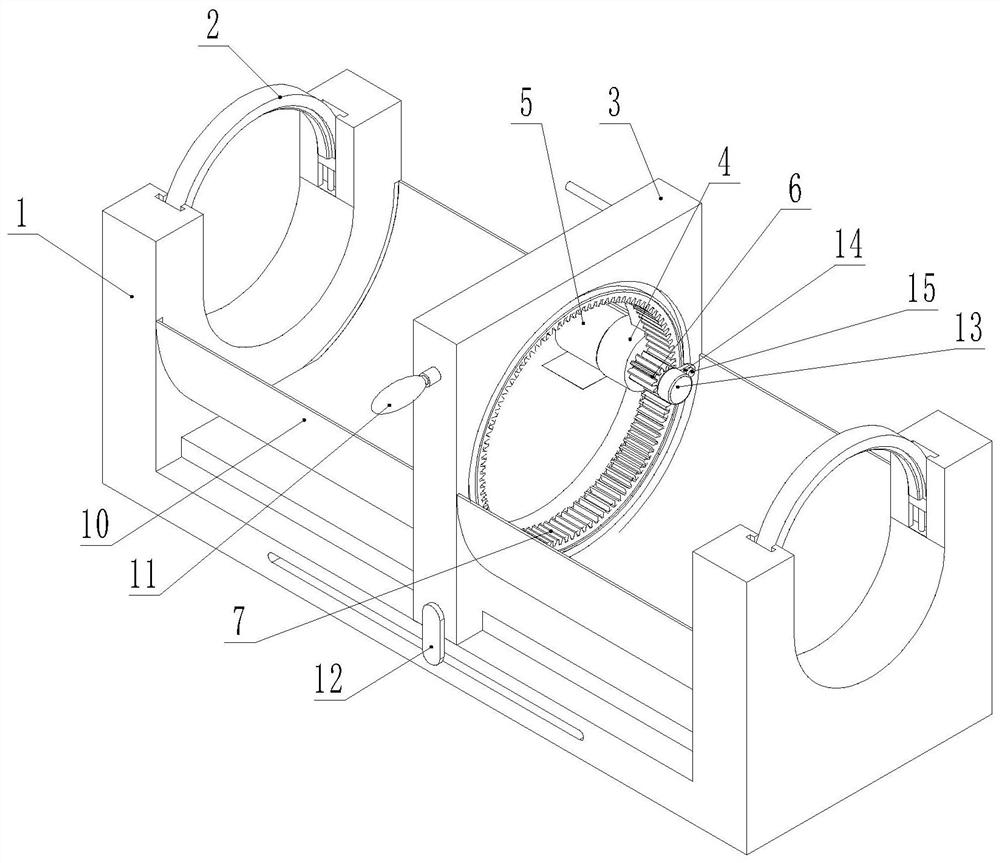

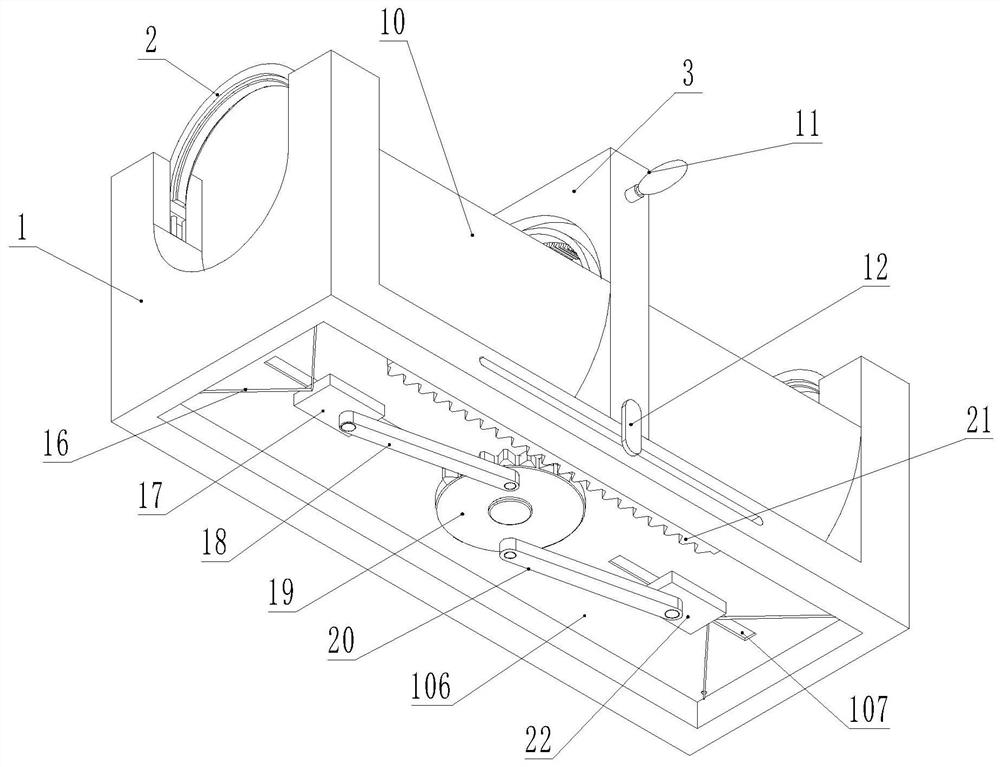

Method and device for improving permeability and homogeneity of resin and reducing pores of prepreg tape

The invention relates to a method and a device for improving permeability and homogeneity of resin and reducing pores of a prepreg tape. The method comprises the steps of firstly rolling for attaching resin adhesive films to the prepreg tape integrated by fiber bundles by a hot pressing roller so as to allow resin to permeate into the prepreg tape preliminarily; and then assisting in pressing through supersonic vibration by a supersonic vibration compressing device so as to obtain the prepreg tape with good permeability and homogeneity of resin and few pores. The device comprises a bundle integrating device for integrating fiber bundles into the prepreg tape, resin adhesive film rolls are arranged at two sides of the bundle integrating device, and the hot pressing roller for rolling for attaching the resin adhesive films at the upper side and the lower side of the prepreg tape to the prepreg tape, the supersonic vibration compressing device for assisting in pressing the rolled attached prepreg tape through supersonic vibration, and a winding device for winding the prepreg tape pressed by supersonic vibration are sequentially arranged in the outlet direction of the bundle integrating device. The method can effectively improve the permeability and the distribution homogeneity of resin in the prepreg tape and overcome the defect of pores in the prepreg tape so as to greatly improve the quality of the prepreg tape.

Owner:XI AN JIAOTONG UNIV

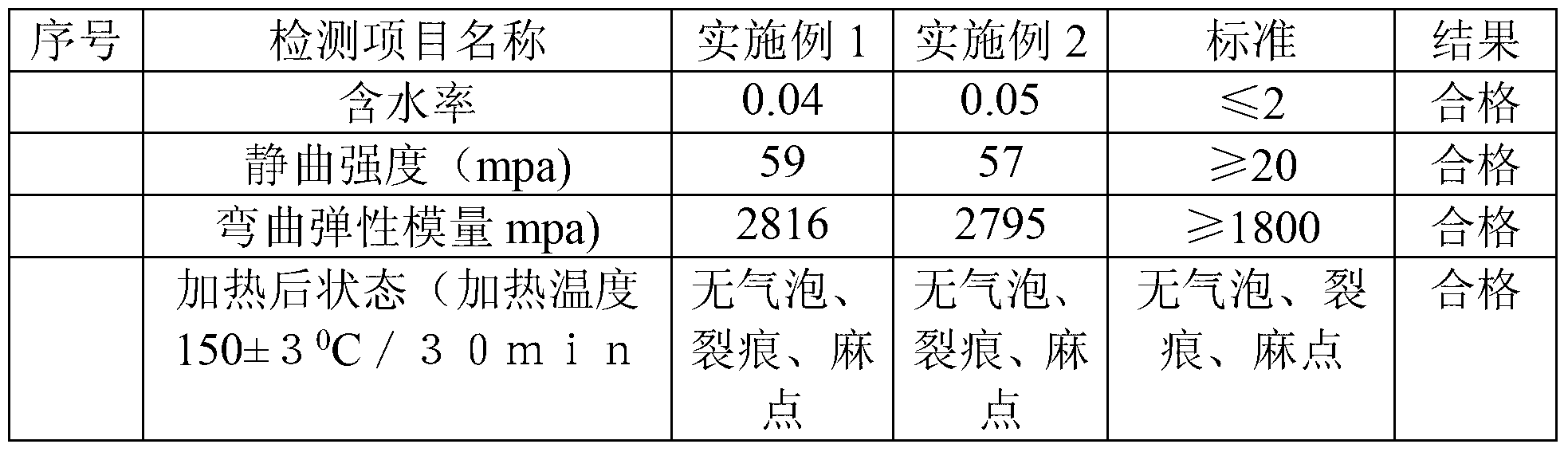

Special-shaped panel prepared from thermoplastic plastics filled with mixture of wheat straw fibers and powder coal ash as well as preparation method of special-shaped panel

InactiveCN103252952AEliminate pollutionSave resourcesSynthetic resin layered productsThermoplasticFiber

The invention discloses a PVC (polyvinyl chloride) production and decoration special-shaped panel filled with regenerated powder coal ash and wheat straw. A core layer of the PVC special-shaped panel is prepared by taking PVC resin, power coal ash and wheat straw broken powder materials with auxiliary raw materials as filling materials, and the core layer wraps a hard PVC layer so as to form a combined special-shaped panel. The invention also discloses a preparation method of the special-shaped panel prepared from thermoplastic plastics filled with the mixture of wheat straw fibers and powder coal ash. According to the technical scheme provided by the invention, wood material consumption is reduced, and the aims of environment protection and resource conservation are achieved; the special-shaped panel prepared by adopting the preparation method achieves the same using and decoration effects with the special-shaped panel prepared in the prior art.

Owner:HUAINAN YIXING PLASTIC PROD

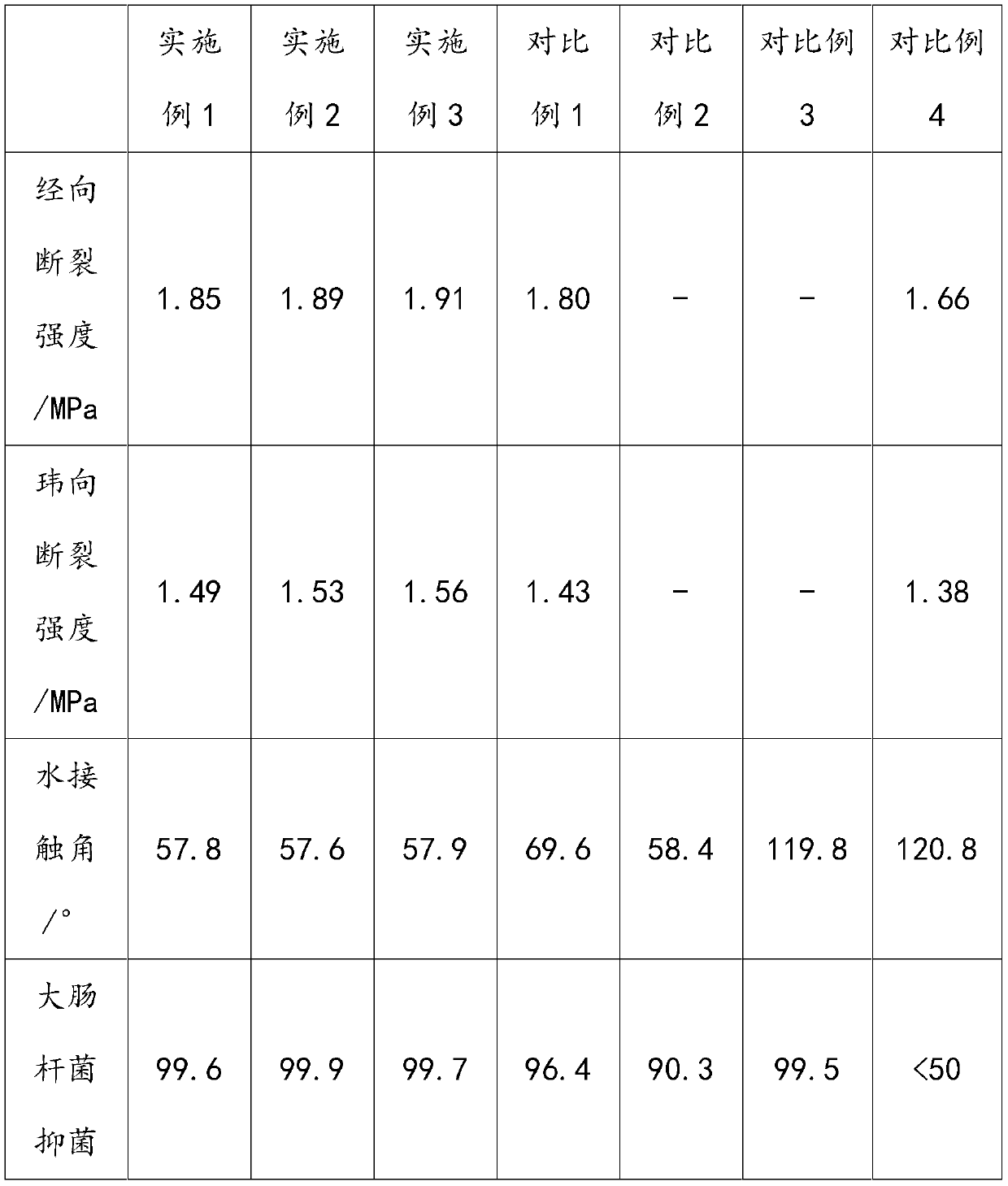

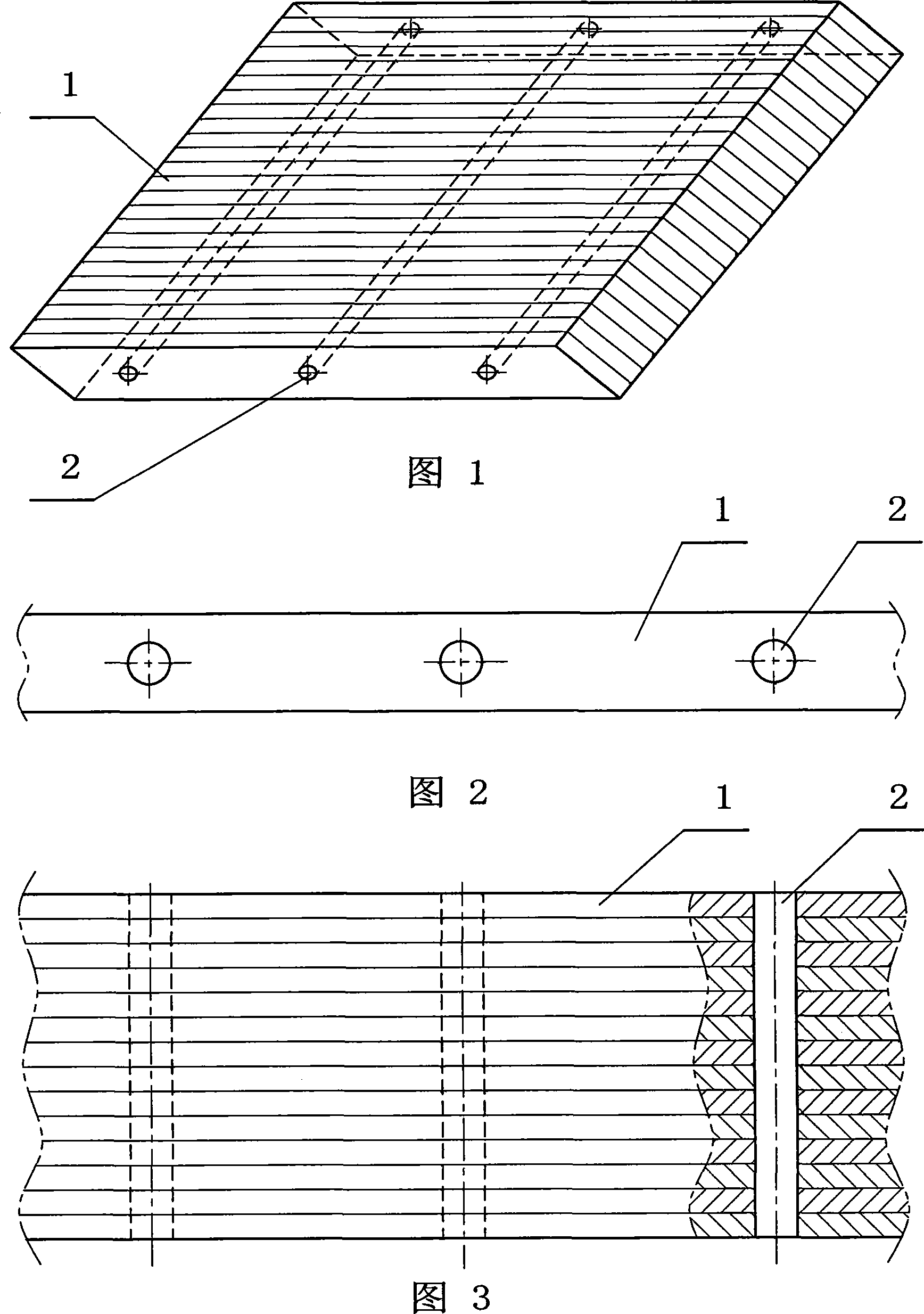

Preparation method of antibacterial non-woven fabric

InactiveCN111364246AEvenly distributedStable antibacterial activityStain/soil resistant fibresBiochemical fibre treatmentElastomerPolymer science

The invention discloses a preparation method of an antibacterial non-woven fabric. The preparation method comprises the following steps that 1, the antibacterial non-woven fabric is prepared from thefollowing raw materials of, in parts by weight, 90-100 parts of PET, 8-10 parts of glycidyl methacrylate grafted polyolefin elastomer and 3-4 parts of modified chitosan; S2, a copolymer is prepared from the PET and the modified chitosan; S3, electrostatic spinning is performed on the copolymer to prepare base cloth; S4, the surface of the base cloth is modified; S5, an antibacterial base cloth isprepared; and S6, surface hydrophilic modification is carried out. According to the preparation method of the antibacterial non-woven fabric, the modified chitosan is added into the raw material, thechitosan is uniformly distributed in the PET matrix, so that the base cloth has good antibacterial performance, quaternary ammonium salt antibacterial treatment is performed on the surface of the basecloth, the antibacterial performance is further improved, and the two reinforcing modes have high washing resistance, so that the non-woven fabric has lasting antibacterial performance; the anti-pollution capability is improved by improving the hydrophilic performance of the non-woven fabric; and the obtained non-woven fabric has wide application value in the field of sewage disposal.

Owner:新昌县高纤纺织有限公司

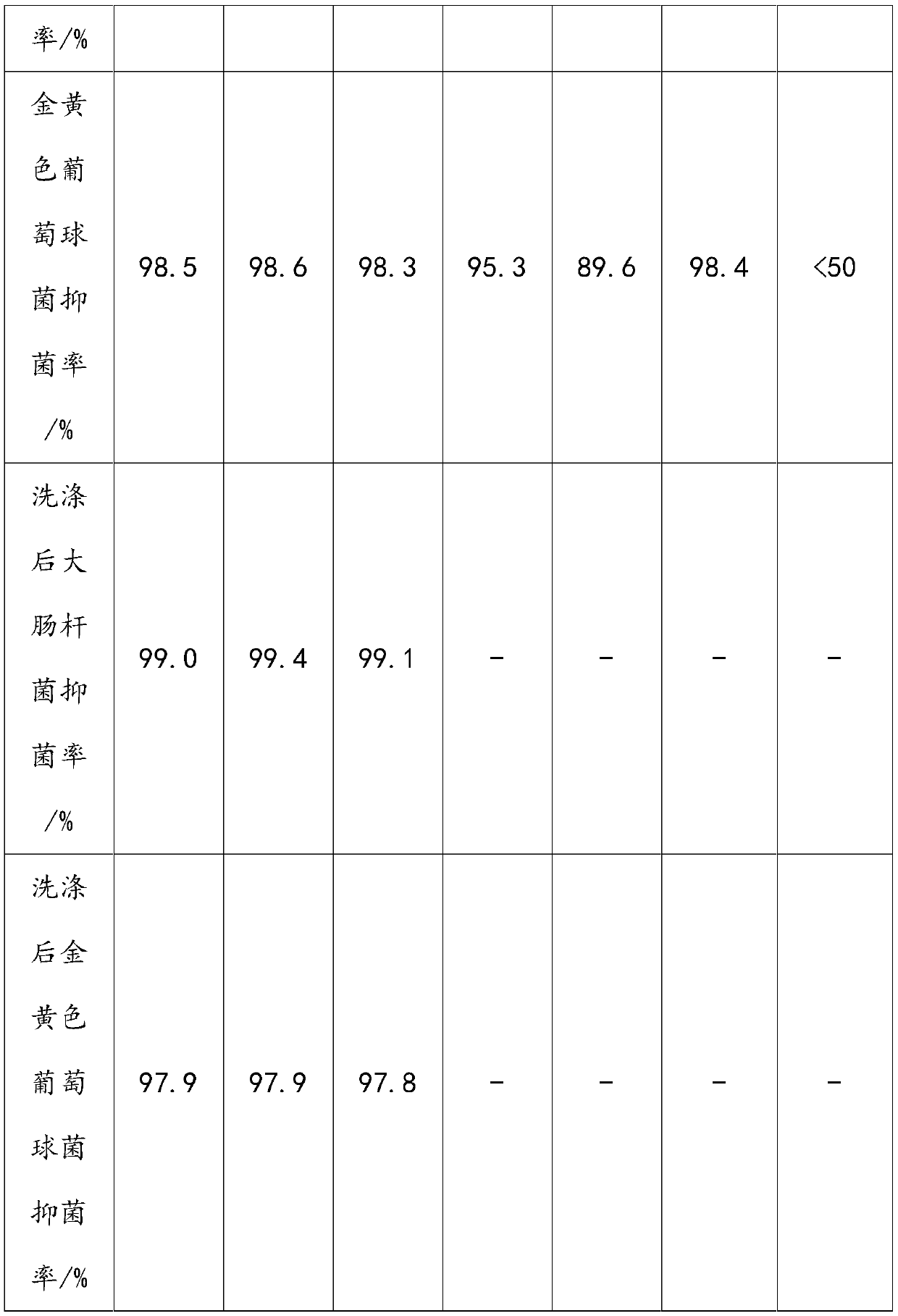

Composition for preparing oil-proof and easy-to-clean paint, related paint, paint preparation method and cupboard board preparation method

ActiveCN109504263AHigh electronegativityStrong bond energyAntifouling/underwater paintsPaints with biocidesPolymer scienceHardness

The invention discloses a composition for preparing oil-proof and easy-to-clean paint, related paint, a paint preparation method and a cupboard board preparation method. The composition for preparingthe oil-proof and easy-to-clean paint is prepared from resin raw materials and a perfluoropolymer system; the resin raw materials include fluorination modified resin and mixed solvents; the perfluoropolymer system includes macromolecular perfluoropolymers with the molecular weight of 30000-100000, medium-molecular perfluoropolymers with the molecular weight of 5000-30000 and micromolecular perfluoropolymers with the molecular weight of 1000-5000. The oil-proof and easy-to-clean paint prepared by the preparation method has the advantages of good hydrophobic and oleophobic effect, high wear resistance, high adhesion to paint layers or coatings on the surfaces of wood boards, high hardness, high wear resistance, and high hydrophobic and oleophobic durability.

Owner:JOMOO KITCHEN & BATHROOM

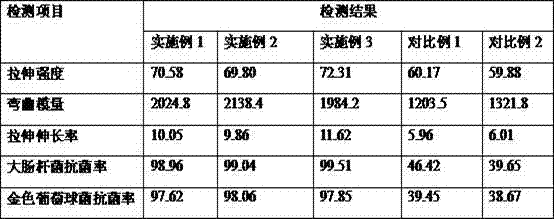

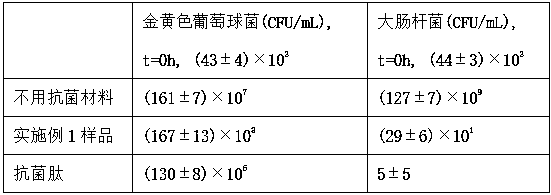

Graphene crystal composite polylactic acid antibacterial material and preparation method thereof

The invention belongs to the field of high molecular materials, and particularly relates to a modified graphene polylactic acid antibacterial composite material and a preparation method of the composite material. An antibacterial mixture used in the composite material comprises nano silver and nano titanium oxide, and nano zinc oxide capable of improving the optical activity of nano titanium oxide is added, so that an antibacterial property is greatly improved, a nature is more stable, and antibacterial action is more persistent. The composite material fully exerts antibacterial properties of nano silver and nano titanium oxide and a mechanical characteristic of a graphene material, so that a mechanical property of the material is improved under the condition that an antibacterial effect is maximized; and the preparation method is mild in technological condition, and is suitable for industrial production.

Owner:江苏苏沃尚新材料科技有限公司

Fireproof mud used for power cable and preparation method thereof

The invention discloses fireproof mud used for installation of a power cable, and belongs to the technical field of fireproof mud. The fireproof mud is composed of, by weight, the raw materials of 25-28 parts of condensed polycyclic aromatic hydrocarbon resin, 15-20 parts of epoxy resin, 8-10 parts of chlorinated paraffin, 14-18 parts of clay, 11-13 parts of porcelain clay powder, 7-9 parts of perlite, 6-9 parts of quartz sand, 5-7 parts of bauxite chamotte, 2-4 parts of magnesium hydroxide, 6-8 parts of tributyl citrate, 4-6 parts of ethylene glycol, 7-9 parts of ammonium phosphate, 2-4 parts of antioxidant, 1-2 parts of anti-corrosion agent and 1-3 parts of antistatic agent. The invention further discloses a preparation method of the fireproof mud used for installation of the power cable. The fireproof mud is easy to prepare, environmentally friendly, low in pollution and good in durability, and has the effects of good fire resistance, corrosion resistance, water resistance and static resistance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

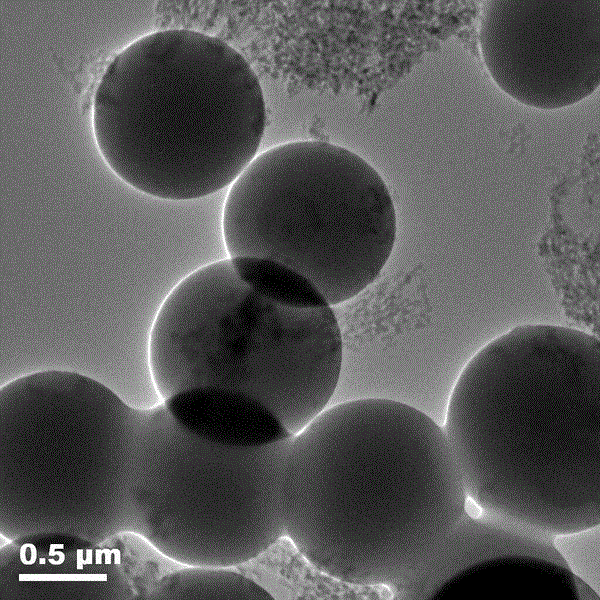

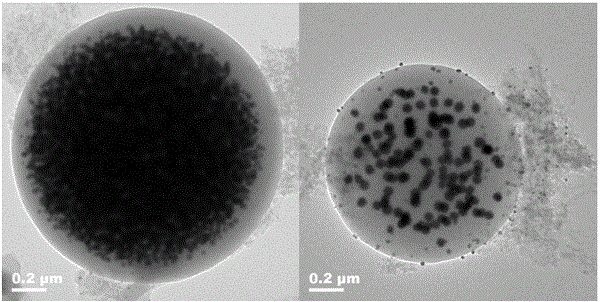

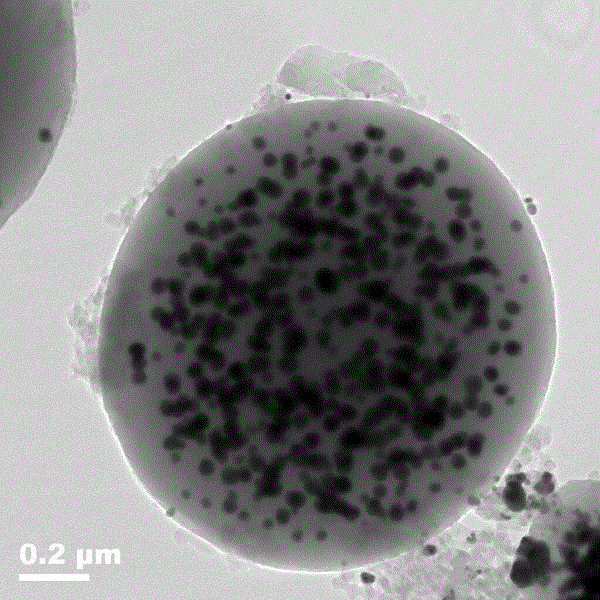

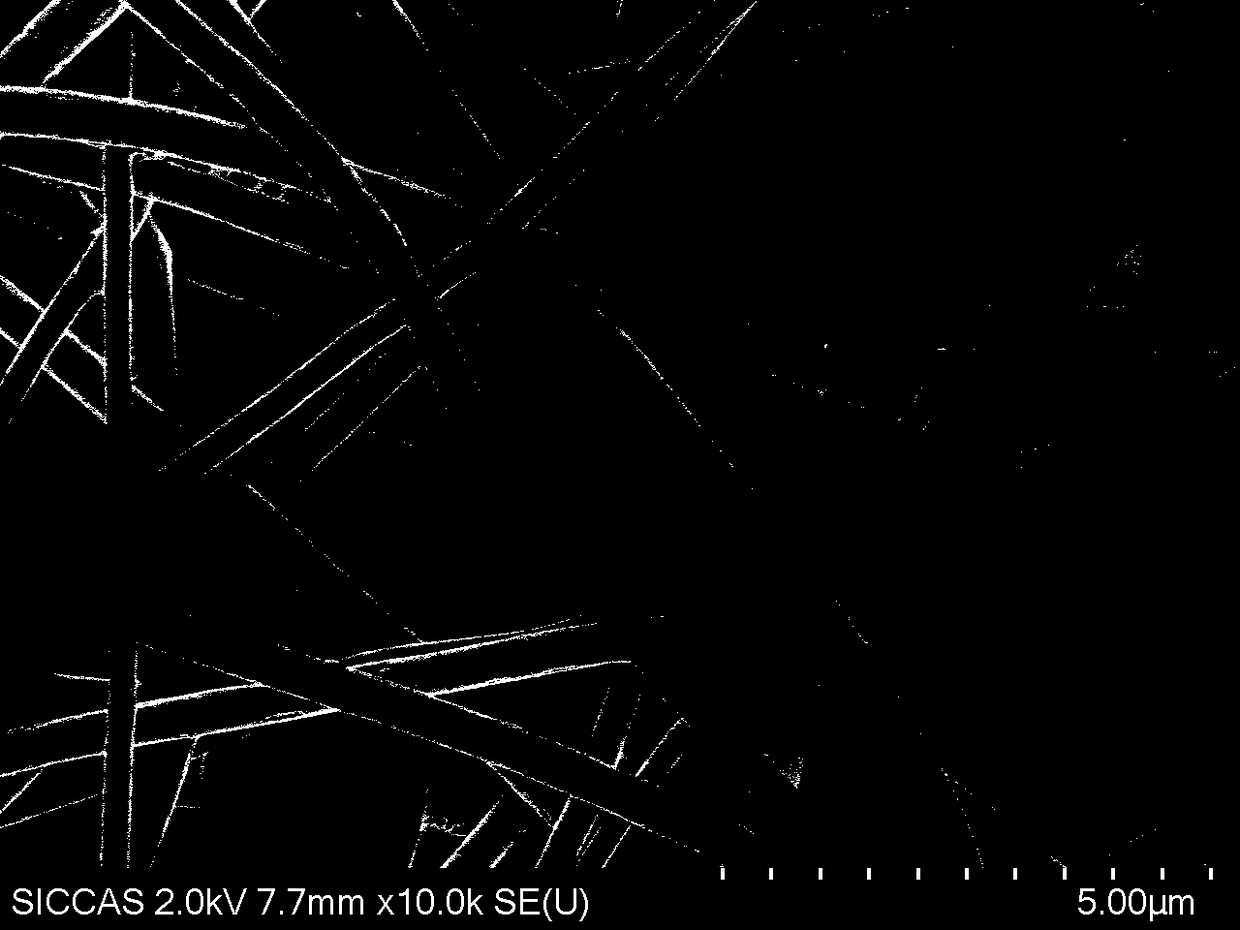

Silver nanoparticle-embedded carbon microsphere preparation method

The invention relates to a silver nanoparticle-embedded carbon microsphere preparation method. The method is characterized in that oil-tea camellia shells are uniformly dispersed in water, then are subjected to a hydrothermal reaction to obtain the hydro-thermal carbon microspheres, then the carbon microspheres are added in a silver nitrate solution, and the silver nanoparticle-embedded carbon microspheres can be obtained through a solvothermal reaction. The method process is simple, no toxic organic reagent is introduced into a preparation process, silver-carrying amount of the prepared carbon microspheres is large, and the silver nano particles have good dispersion and can be sealed in the carbon microspheres. The silver nanoparticle-embedded carbon microspheres are hopeful to be widely used as a water-purification processing agent, an air filtering agent, and a catalyst and an electrode material.

Owner:NANCHANG HANGKONG UNIVERSITY

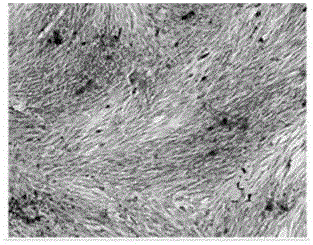

Composite membrane for guided bone regeneration and preparation method of composite membrane

InactiveCN109125812AGood biocompatibilityHigh mechanical strengthTissue regenerationNon-woven fabricsWound healingCell adhesion

The invention discloses a composite membrane for guided bone regeneration and a preparation method of the composite membrane. The preparation method of the composite membrane includes the operation steps: treating pig jejuna by a mechanical method to obtain small intestinal submucosa; performing multilayer horizontal-vertical overlapping after processes such as acid, decontaminant and alkali treatment to obtain a compact layer; uniformly spinning prepared collagen solution on the compact layer by an electrospinning technique, and performing compounding and vacuum freeze-drying to obtain the composite membrane. The composite membrane prepared by the method has excellent biocompatibility and bioactivity and is easily absorbed by tissues, the compact layer in a structure can selectively stopsoft tissues from growing into a bone defect area, a loose layer is of a loose porous structure and large in specific surface area by the aid of the electrospinning technique, combination of two membranes, cell adhesion and growing into pores are facilitated, new tissue regeneration can be supported by the aid of bioactive factors or medicines, and wound healing is promoted. By combination, the composite membrane achieves excellent mechanical performance and can keep a regeneration space stable within a certain time.

Owner:上海白衣缘生物工程有限公司

Preparation method of silicon negative electrode material of lithium ion battery

InactiveCN108417784AEnhance binding strengthGuaranteed normal transmissionCell electrodesSecondary cellsPotassiumCopper nitrate

Disclosed is a preparation method of a silicon negative electrode material of a lithium ion battery. The preparation method comprises the following steps of (1) putting cleaned silicon powder into a mixed solution of metal salt and HF to be subjected to deposition treatment; and (2) finally, performing oxidization treatment on the surface metal modified silicon powder to form an oxide layer on thesurfaces, not covered with metal particles, of the silicon particles, wherein metal salt is silver nitrate, gold potassium chloride, potassium hexachloroplatinate or copper nitrate. By virtue of thepreparation method, conductivity of silicon powder can be improved, the combination strength between silicon particles and a binder can be reinforced, and the cycle performance of the silicon negativeelectrode material can be greatly improved; and in addition, the preparation method is simple in process, low in cost, very suitable for large-scale industrial production and expected to accelerate development of the silicon-based negative electrode material of the lithium ion battery.

Owner:NANCHANG UNIV

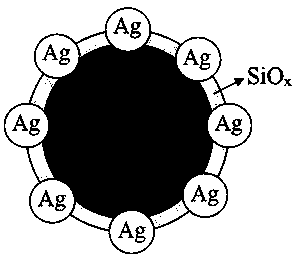

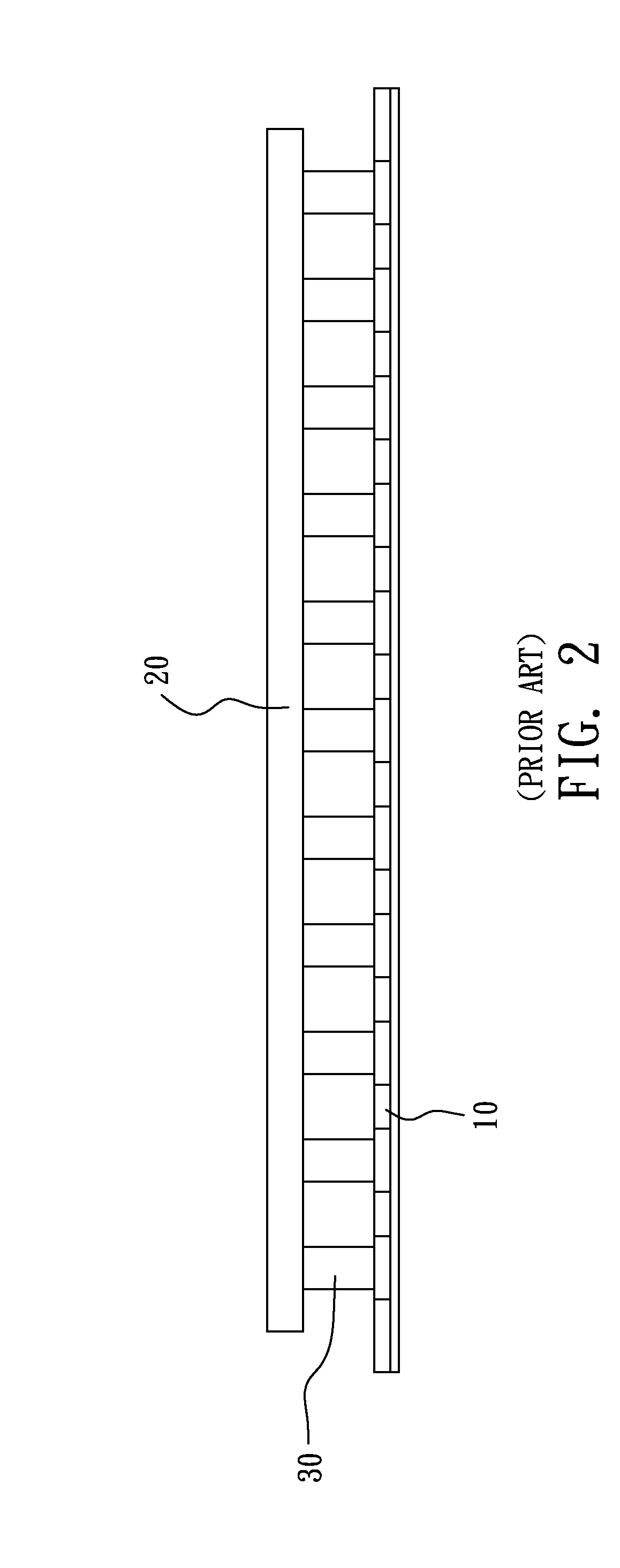

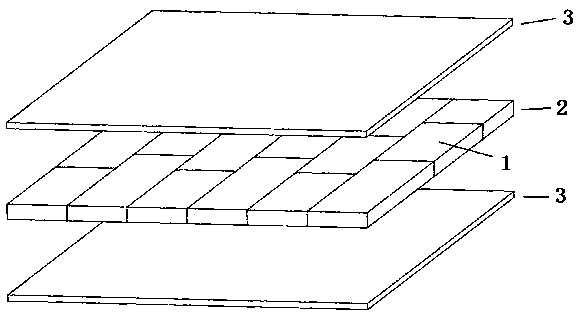

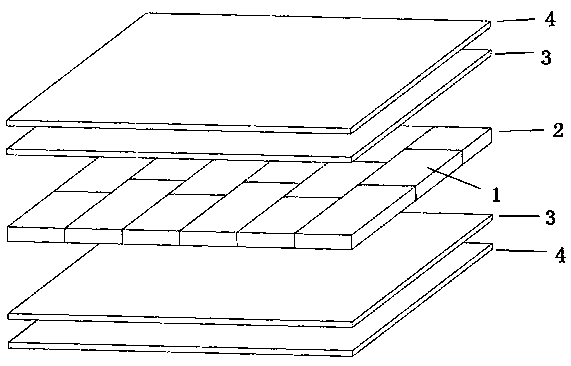

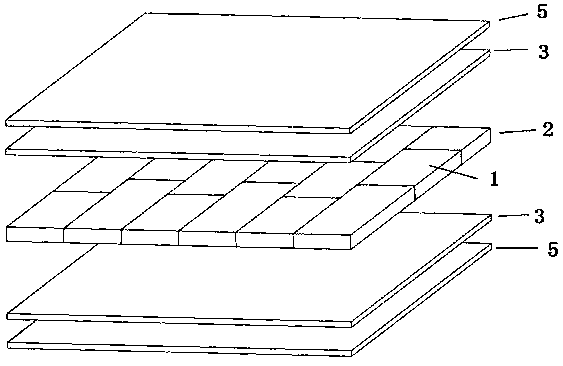

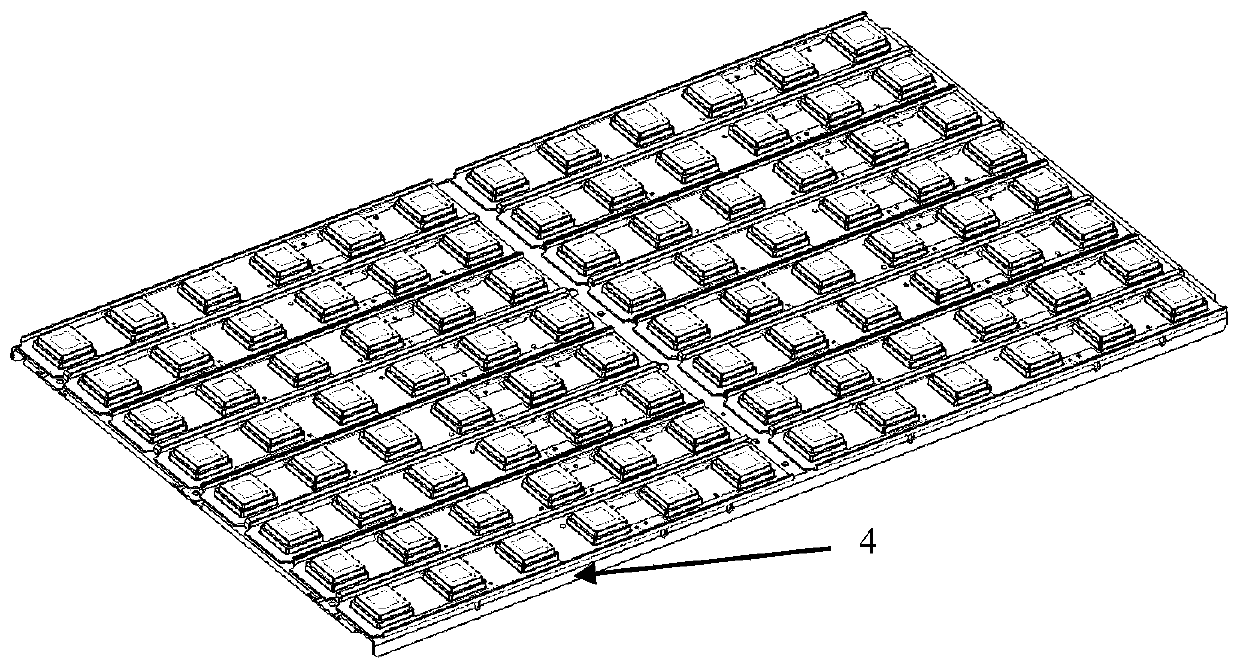

Deformation-resisting laminated stickiness bamboo wood board

InactiveCN101134327AHigh strengthEnhance binding strengthWood veneer joiningWood layered productsWood veneerKeel

The deformation resisting laminated and adhered bamboo and wood board consists of bamboo sheets and wood sheets laminated and adhered in the direction perpendicular to the board plane. It has through holes and / or blind holes in the direction perpendicular to the board plane and bolting rods inside the holes to combine the bamboo sheets and wood sheets and enhance the combination strength, and the bolting rods serve as keel to raise the strength of the laminated and adhered bamboo and wood board and to resist the transverse deformation effectively.

Owner:赵斌

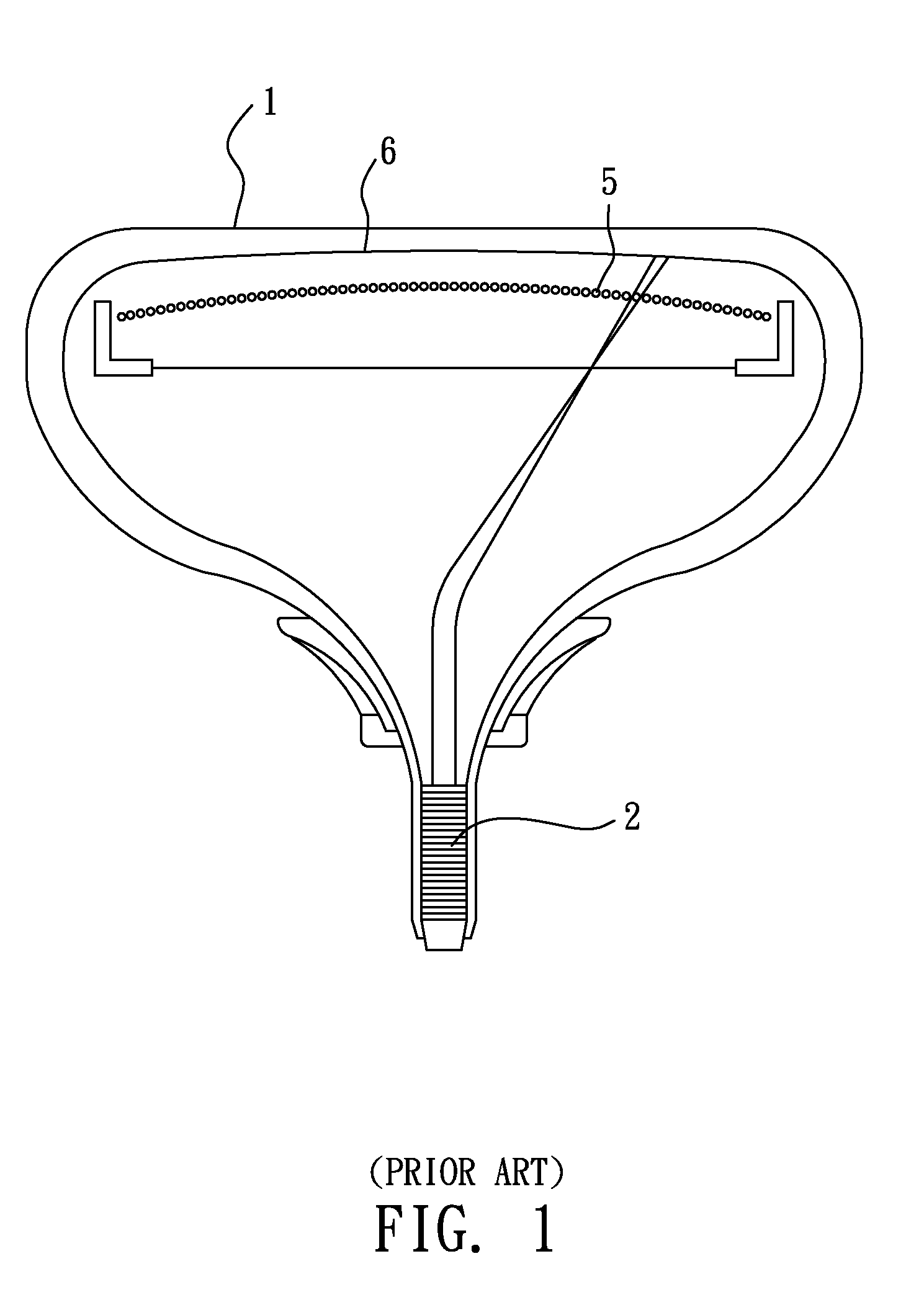

Trichromatic field-emission display and phosphors thereof

InactiveUS20100039022A1Improve luminanceEnhance binding strengthDischarge tube luminescnet screensCathode ray tubes/electron beam tubesRare-earth elementElectric field

A trichromatic field-emission display is disclosed to include a cathode plate, three cathode electroluminescent phosphor screens and an anode plate, the anode plate having a transparent oxide thin film bonded to the photo gate electrode thereof, electron sources emitted by the photo gate electrode of the cathode plate striking the cathode electroluminescent phosphor screens to cause change of the electric field in the gap between the cathode plate and the anode plate. The cathode electroluminescent phosphor screens are made of an excitable rare earth element, assuring high stability and uniformity of luminous brightness when excited by an electron beam.

Owner:LO WEI HUNG

Instant potato noodles and production method

InactiveCN107668485AImprove immunityIncrease creaminessFood dryingFood ingredient functionsInstant potatoSolanum tuberosum

The invention discloses instant potato noodles and a production method. The instant potato noodles are prepared from raw materials in parts by weight as follows: 100-130 parts of potatoes, 60-80 partsof table salt, 0.2-1 part of astragalus polysaccharide, 0.2-0.8 part of lycium barbarum polysaccharide, 0.2-0.5 part of a hawthorn fruit extract and 15-30 parts of a carrot extract. The production method of the instant potato noodles comprises five steps as follows: dough kneading, nitrogen cooking, vacuum frying, centrifugal oil removing and drying under reduced pressure. The prepared high-nutrition instant potato noodles have the advantages that the instant potato noodles taste smooth, nutrition can be absorbed easily, the fat content is low, the soaking time is short, the noodle cake cannot break easily, and the human immunity can be enhanced.

Owner:HEXI UNIV

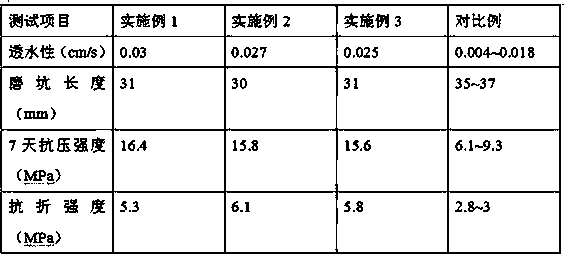

Method for preparing water permeable bricks based on coal gangue

The invention discloses a method for preparing water permeable bricks based on coal gangue, belonging to the field of water permeable bricks. According to the method, the coal gangue having adhesive property is melted at the high temperature in the carbon dioxide atmosphere; under the action of high temperature, the formed sodium metaaluminate reacts with carbon dioxide, so that sodium hydrogen carbonate is produced; sodium hydrogen carbonate is further decomposed by heat so as to produce sodium carbonate, and pore-forming is carried out, so that the porosity is increased; furthermore, the adsorbed lignin, cellulose and the like are thermally decomposed, so that the pores are protected; then, particles and cryolite powder are added, mixed and calcined, and the melting point of the mixtureis lowered by means of the cryolite powder; in a calcining process, a serpentine structure is destroyed, and magnesium-like olivine is formed, so that the porosity is increased, and the strength is improved; furthermore, silica in the calcined product reacts with the sodium carbonate so as to form sodium silicate, so that the bonding strength between the substances is improved, and the compressionresistance and the breaking strength are improved. The method solves the problems of high production cost and low compressive strength of the existing water permeable bricks.

Owner:方建波

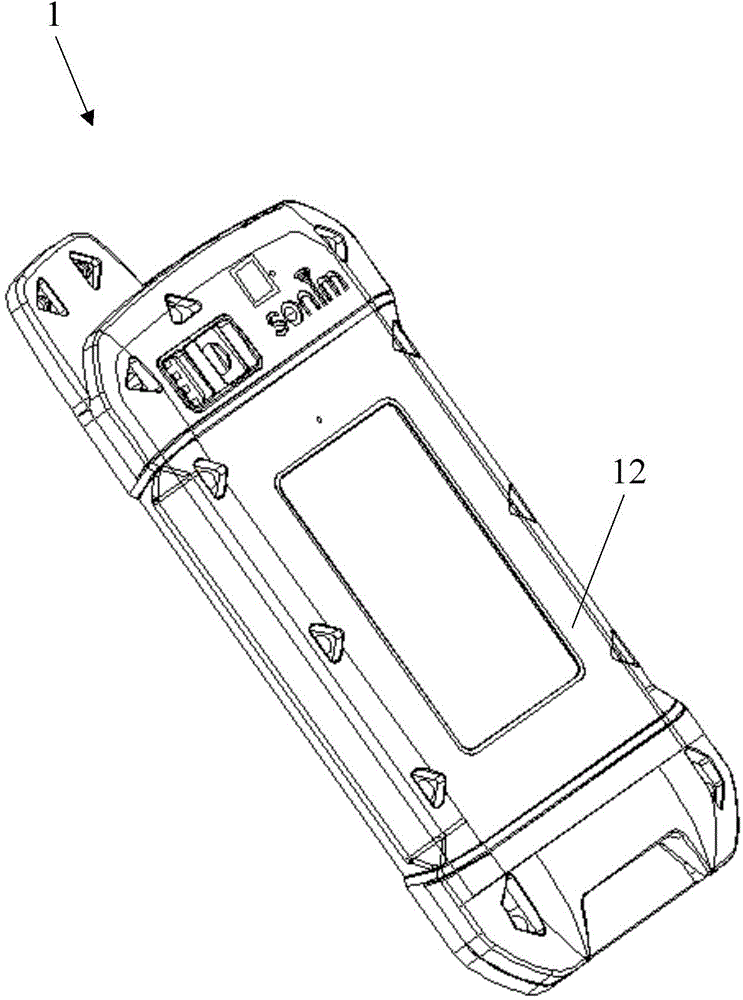

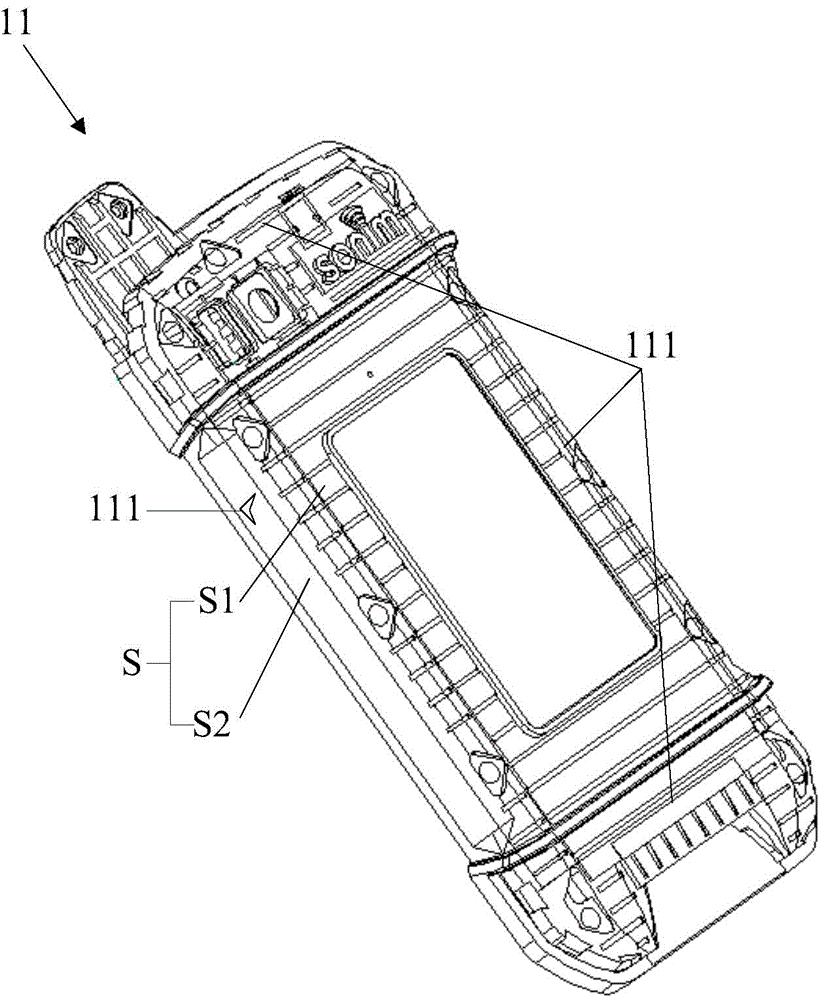

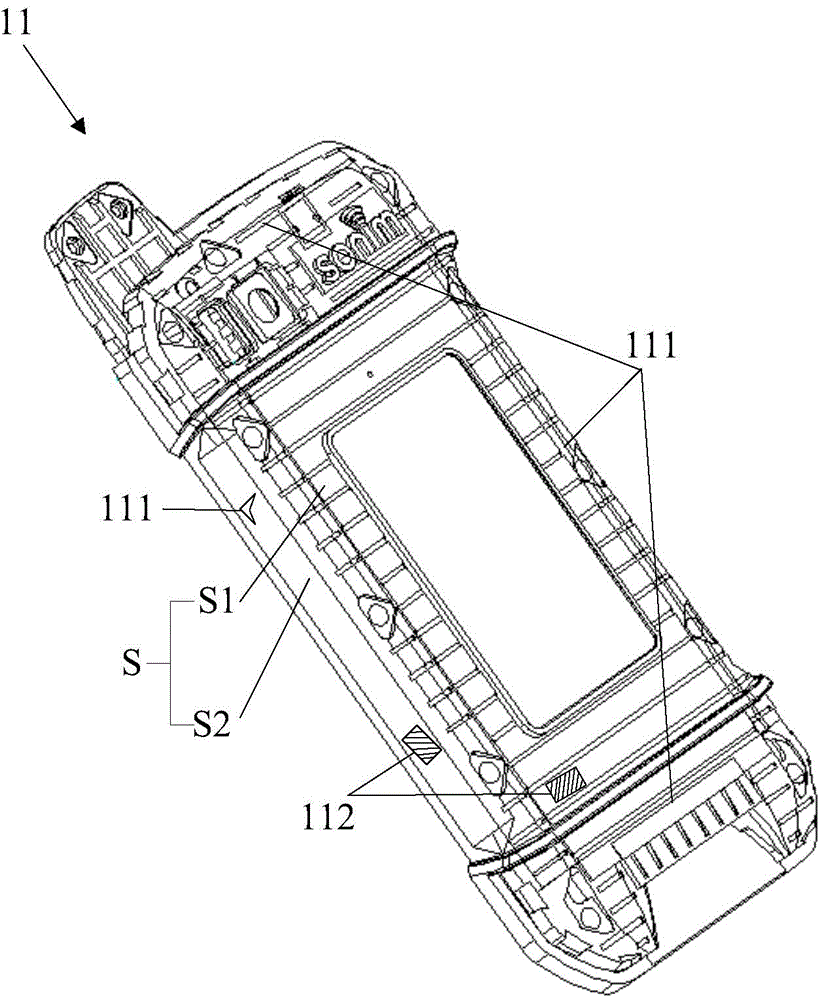

Double-shot injection moulding shell and injection mold

InactiveCN105984076AImprove bindingIncrease binding areaTelephone set constructionsEngineeringInjection moulding

The invention relates to structural design of a shell and discloses a double-shot injection moulding shell and an injection mold. The double-shot injection moulding shell comprises a first plastic layer and a second plastic layer combined with each other, wherein a first combining surface of the first plastic layer is provided with at least one first convex block; a second combining surface of the second plastic layer is provided with a first concave groove corresponding to the first convex block; the first plastic layer and the second plastic layer are combined through the first combining surface and the second combining surface; the first convex block is tightly embedded in the first concave groove. Therefore, the combining area of the two plastic layers of the double-shot injection moulding shell is increased to enable the combination of the two plastic layers to be firmer and prevent the two plastic layers from stripping.

Owner:SHANGHAI SIMCOM LTD

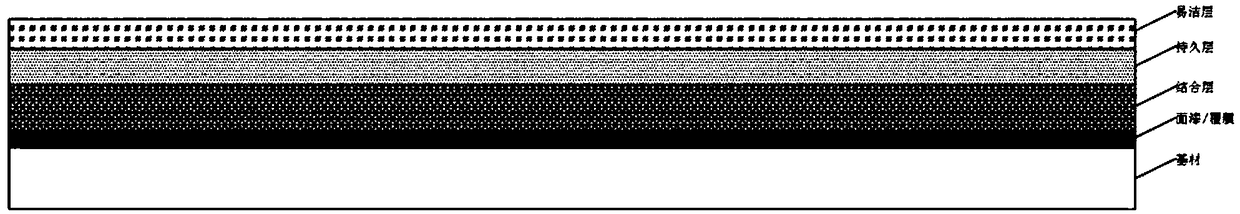

Porous alumina/titanium dioxide-based polylactic acid-modified composite fabric with nano-pillar array structure and preparation method thereof

ActiveCN108410332AGood film formingImprove adhesionAnodisationTextiles and paperPhosphoric acidTetrahydrofuran

The invention provides a porous alumina / titanium dioxide-based polylactic acid-modified composite fabric with a nano-pillar array structure and a preparation method thereof. The specific preparation method is as follows: a pretreated aluminum sheet as an anode undergoes anode oxidation twice with a titanium plate as a cathode and phosphoric acid solution and chromic acid solution as electrolytes,the acid solution and oxide film of the surface of the aluminum sheet are cleaned off, and thereby a porous anodal alumina film is obtained; nano-titanium dioxide sol is added into tetrahydrofuran, L-lactic acid and stannous octoate catalyst are respectively added, and after heating for reaction, the solution and polylactic acid solution are uniformly mixed, so that titanium dioxide-modified polylactic acid solution is obtained; the porous anodal alumina film is immersed into the titanium dioxide-modified polylactic acid solution and oscillated under microwaves, the solution is applied on thesurface of a textile, and after a film is formed by curing under room temperature, the microimprinting technique is utilized to form a nano-pillar array on the surface of the film, so that the porousalumina / titanium dioxide-based polylactic acid-modified composite fabric with a nano-pillar array structure is prepared.

Owner:SHENZHEN ELLASSAY FASHION CO LTD

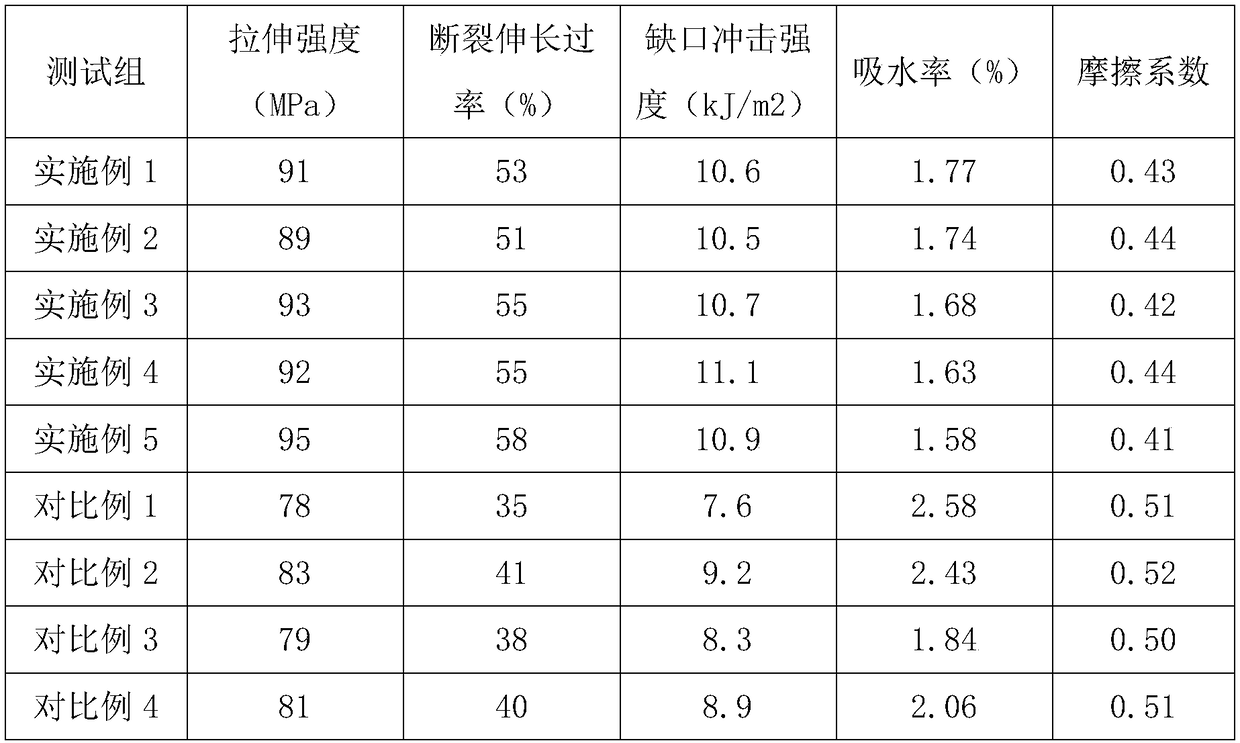

Preparation method for modified polyamide composite material

The invention discloses a preparation method for a modified polyamide composite material, which relates to the field of novel polyamide materials. The preparation method comprises the following steps:preparation of maleic anhydride-grafted polyphenyl ether; surface treatment of graphene oxide; preparation of modified graphene oxide; preparation of polyphenyl ether-grafted graphene oxide; and preparation of modified polyamide composite material. According to the preparation method disclosed by the invention, by grafting polyphenyl ether onto the graphene oxide to modify polyamide, the grapheneoxide grafted onto the polyphenyl ether is highly compatible with the polyamide, the binding force is high, and the tensile strength and mechanical impact resistance of the composite material can beeffectively increased, and moreover, the water absorption and friction coefficient of the composite material can be effectively decreased.

Owner:安徽菲扬新材料有限公司

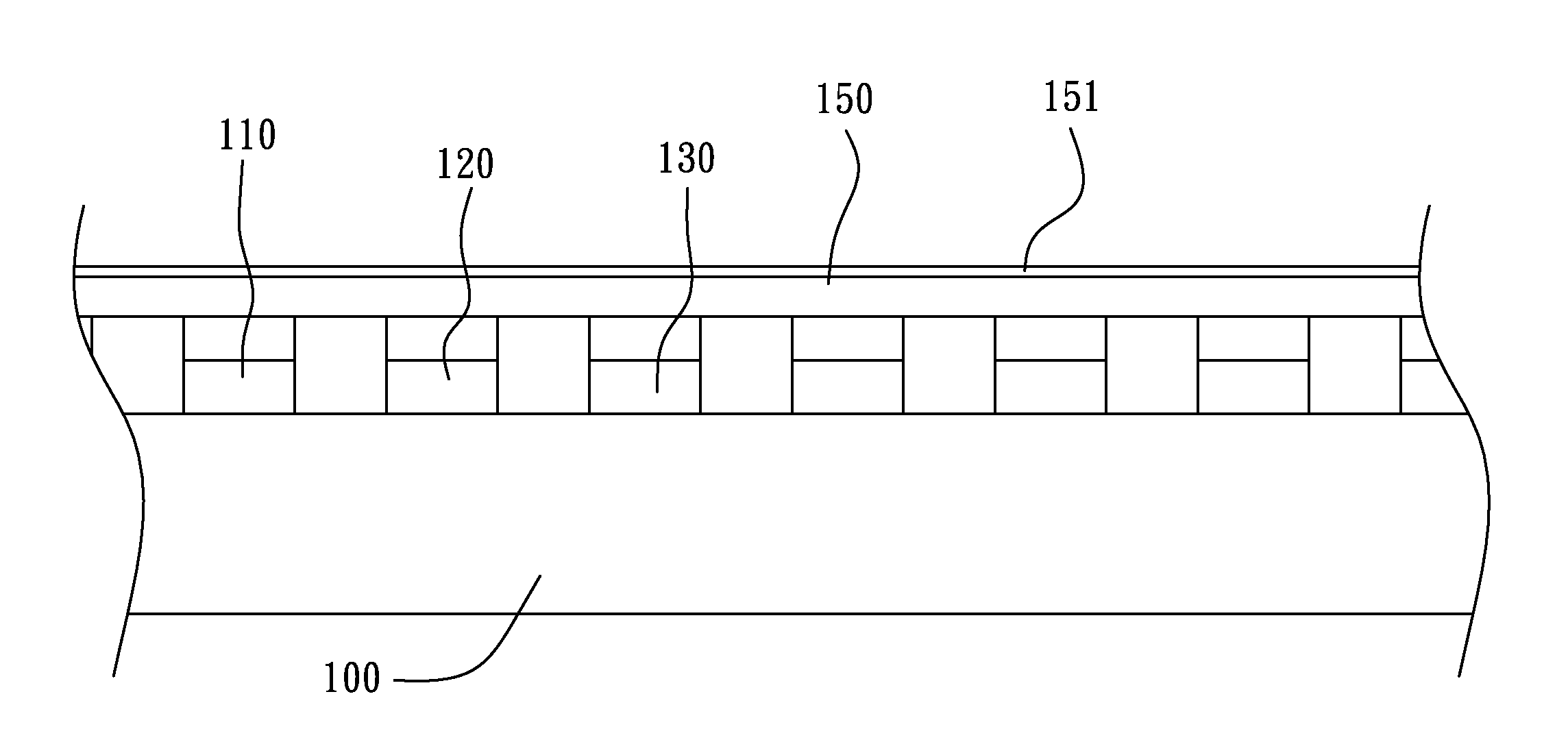

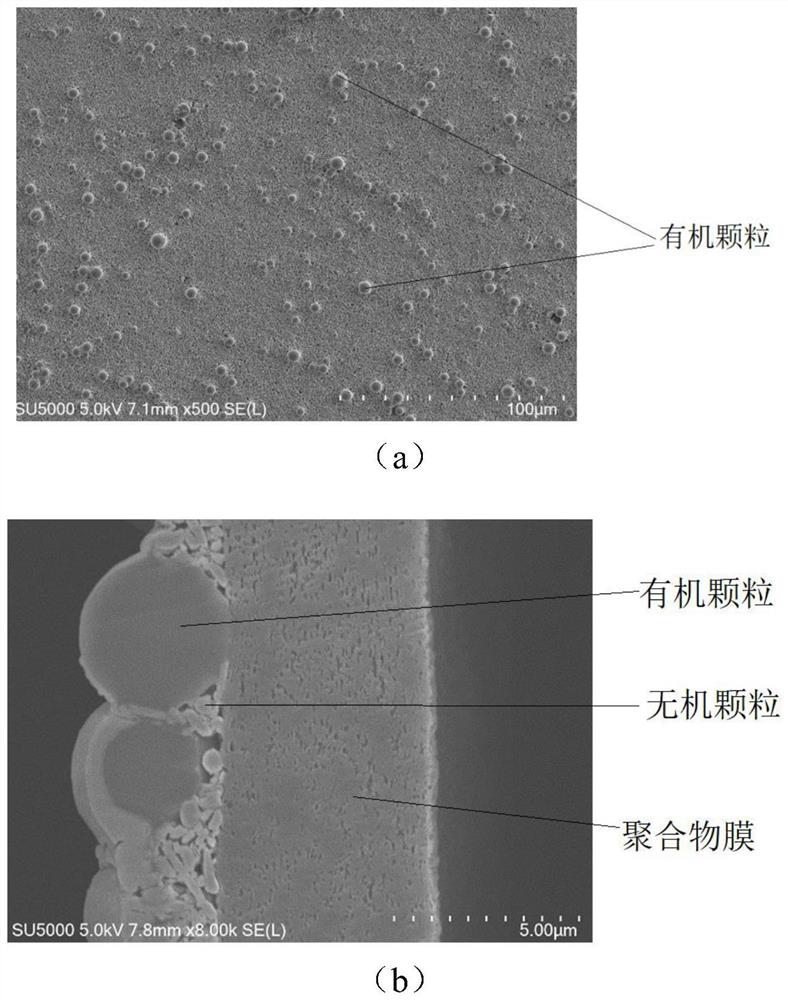

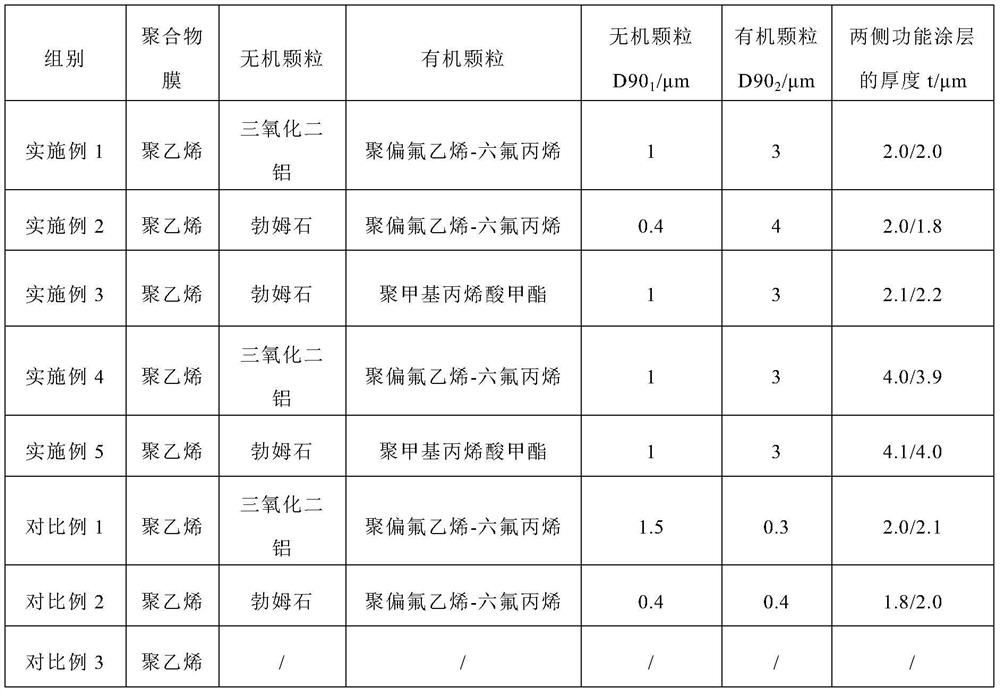

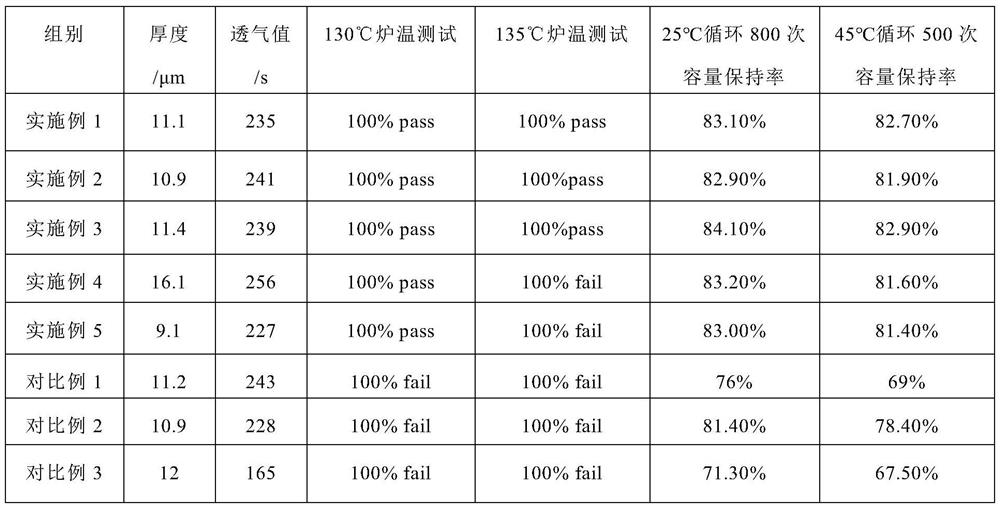

Composite membrane and electrochemical device

PendingCN114361717AHigh strengthImprove structural stabilitySecondary cellsCell component detailsHigh energyElectrochemistry

The invention provides a composite diaphragm and an electrochemical device, the composite diaphragm comprises a polymer film and a functional coating arranged on at least one surface of the polymer film, and the functional coating comprises inorganic particles and organic particles; the particle size D901 of the inorganic particles and the particle size D902 of the organic particles meet the following conditions: 0.01 * D902 < = D901 < = 0.5 * D902, and D901 is the particle size of the inorganic particles reaching 90% of the volume accumulation from the small particle size side in the volume-based particle size distribution, and D902 is the particle size of the organic particles reaching 90% of the volume accumulation from the small particle size side in the volume-based particle size distribution. D902 is that in volume-based particle size distribution, the particle size of the organic particles reaches 90% of volume accumulation from the small particle size side. The composite diaphragm has excellent heat-resistant shrinkage performance and interface bonding performance, and can give consideration to high energy density and high safety of an electrochemical device when being applied to the electrochemical device.

Owner:ZHUHAI COSMX BATTERY CO LTD

Preparation method of electromagnetic shielding biological material and antimagnetic plate prepared by preparation method

ActiveCN110708942AAbundant resourcesIncrease storage capacityMagnetic/electric field screeningWood veneer joiningCarbonizationPulp and paper industry

The invention discloses a preparation method of an electromagnetic shielding biological material. The preparation method comprises the following steps: step 1, cutting moso bamboo into bamboo chips; step 2, soaking in a sodium hydroxide solution with the concentration of 20% for 2 hours; step 3, continuously soaking in a sodium hydroxide solution with the concentration of 3%-10% for 16-24 hours; step 4, crushing the bamboos by using a crusher, and then putting the crushed bamboos into a dry distillation kiln to prepare bamboo charcoal; step 5, after carbonization, mixing the prepared bamboo charcoal with an analytically pure ferric nitrate solution by adopting a vacuum pressure impregnation process to prepare a bamboo charcoal / ferric nitrate compound; and step 6, carrying out secondary carbonization on the bamboo charcoal / ferric nitrate compound, crushing, and screening to obtain the carbon powder. Bamboo blocks are selected to be processed into bamboo powder to prepare bamboo charcoal, so that the unit surface area is increased, the contact area with a hot gas medium in a dry distillation kiln is increased, the energy consumption is low, the production efficiency is high, the charring reaction is sufficient, and the final charcoal yield, the charcoal yield, the bamboo charcoal graphitization degree and the conductivity are improved.

Owner:SHENZHEN SONGBOYU TIMBERING

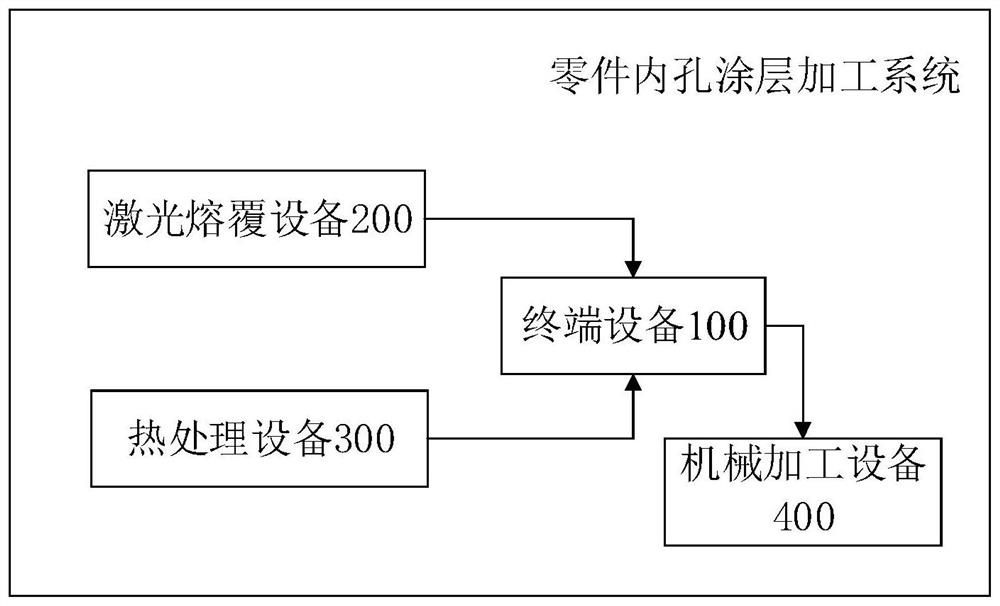

Part inner hole coating machining method and system, and device

PendingCN111979540AReduced risk of deformation or even crackingEnhance binding strengthMetallic material coating processesCommunication interfaceTerminal equipment

The invention discloses a part inner hole coating machining method and system, and a device, relates to the technical field of laser additive manufacturing, and is used for machining a coating in an inner hole of a part, so that the service life of the part can be prolonged. The part inner hole coating machining method comprises the following steps: providing a prefabricated part with a hole structure; according to the coating cladding strategy, controlling a laser cladding device to form the coating in the hole structure of the prefabricated part, so that a part blank is obtained, wherein thecoating cladding strategy is determined by the structural parameters of the hole structure; and controlling a heat treatment device to carry out heat treatment on the part blank. The terminal devicecomprises a processor and a communication interface, so that the part inner hole coating machining method can be realized. The part inner hole coating machining method provided by the invention is used for preparing the wear-resistant coating of the inner hole.

Owner:天津辉锐激光科技有限公司

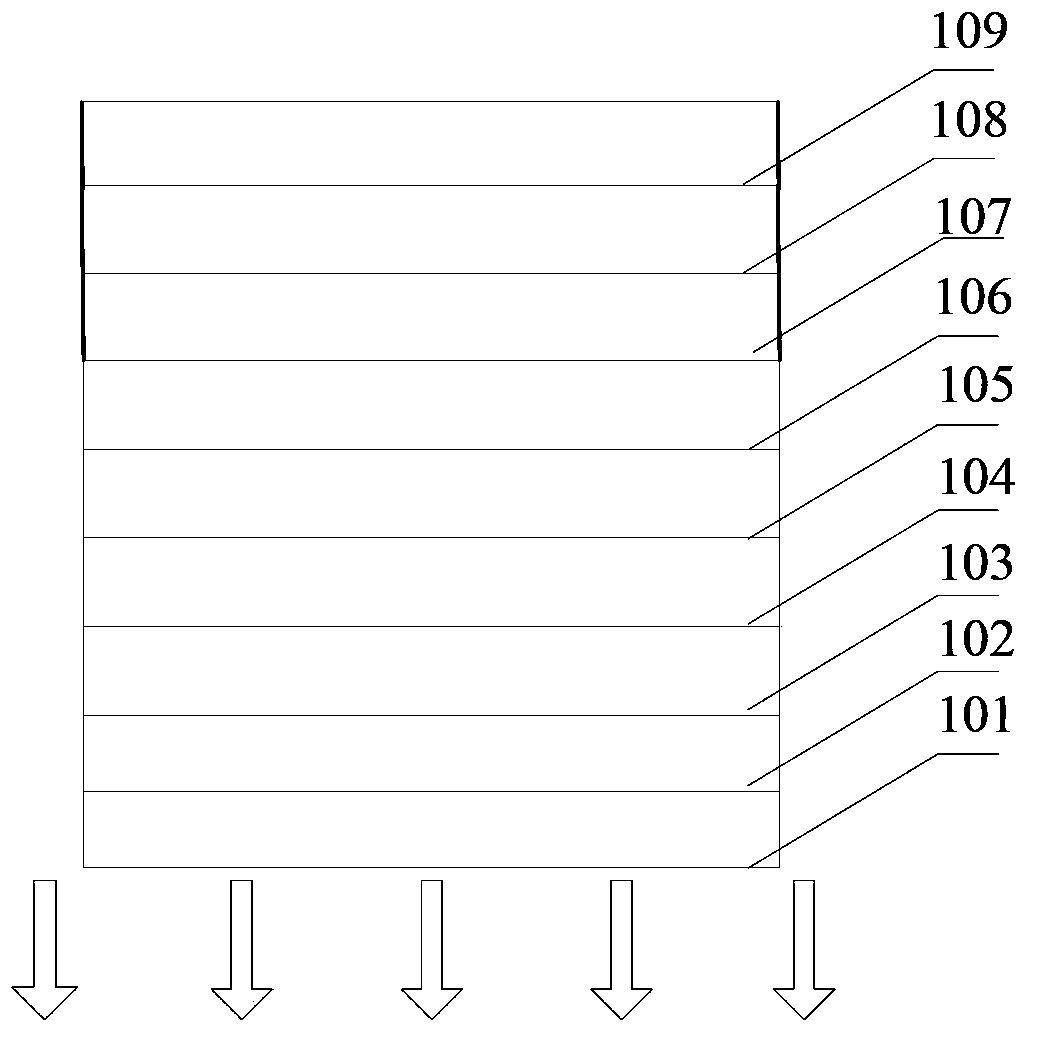

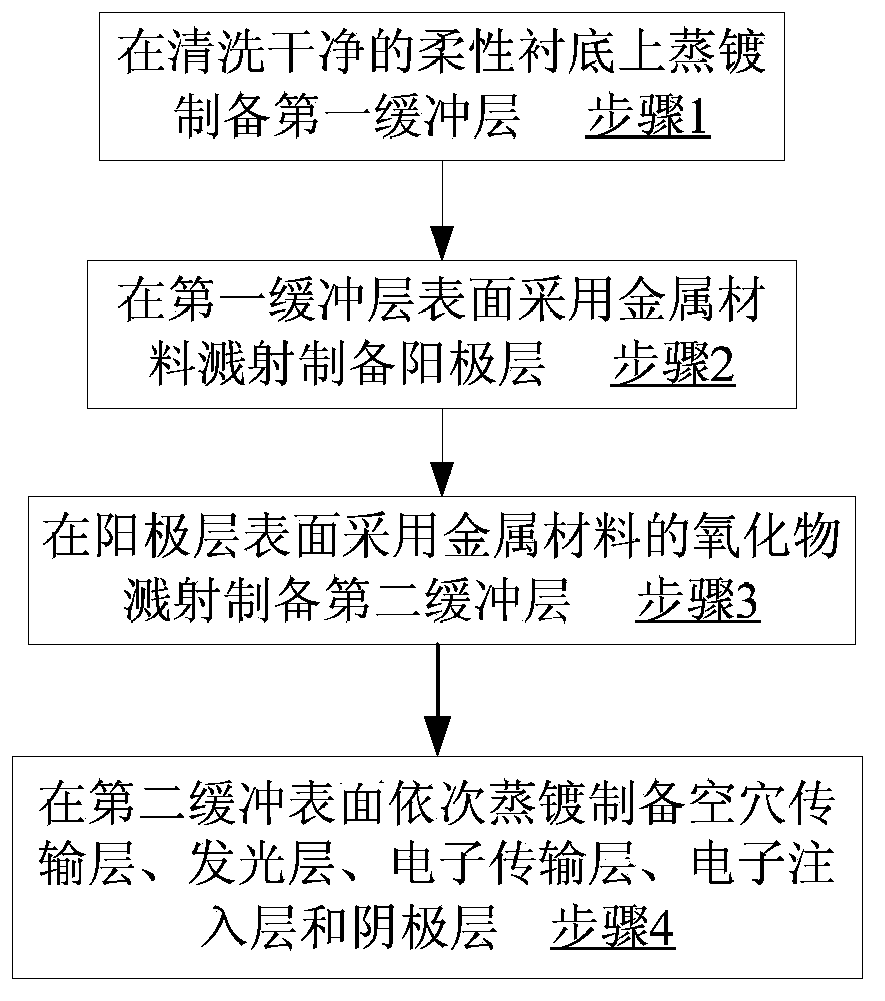

Flexible organic light emitting diode and method for manufacturing same

InactiveCN103545446AReduce surface resistanceAvoid sheddingFinal product manufactureSolid-state devicesFlexible organic light-emitting diodeSilicon monoxide

The invention discloses a flexible organic light emitting diode and a method for manufacturing the same. The flexible organic light emitting diode comprises a flexible substrate, an anode layer, a second buffer layer, a hole transport layer, a light emitting layer, an electron transport layer, an electron injection layer and a cathode layer which are sequentially stacked on one another. The anode layer is made of metal materials, and a first buffer layer which is used for increasing binding force between the flexible substrate and the anode layer is further arranged between the flexible substrate and the anode layer and is made of silicon monoxide, zirconium dioxide or titanium dioxide. The flexible organic light emitting diode and the method have the advantages that the anode layer is made of the metal materials, so that surface resistance of the anode layer can be reduced; the first buffer layer is arranged between the anode layer and the flexible substrate and can increase the binding force between the flexible substrate and the anode layer, so that the anode layer can be prevented from dropping off from the flexible substrate, and the light emitting stability of the finally manufactured light emitting diode can be improved; a process for manufacturing the flexible organic light emitting diode is simple and is easy to implement.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

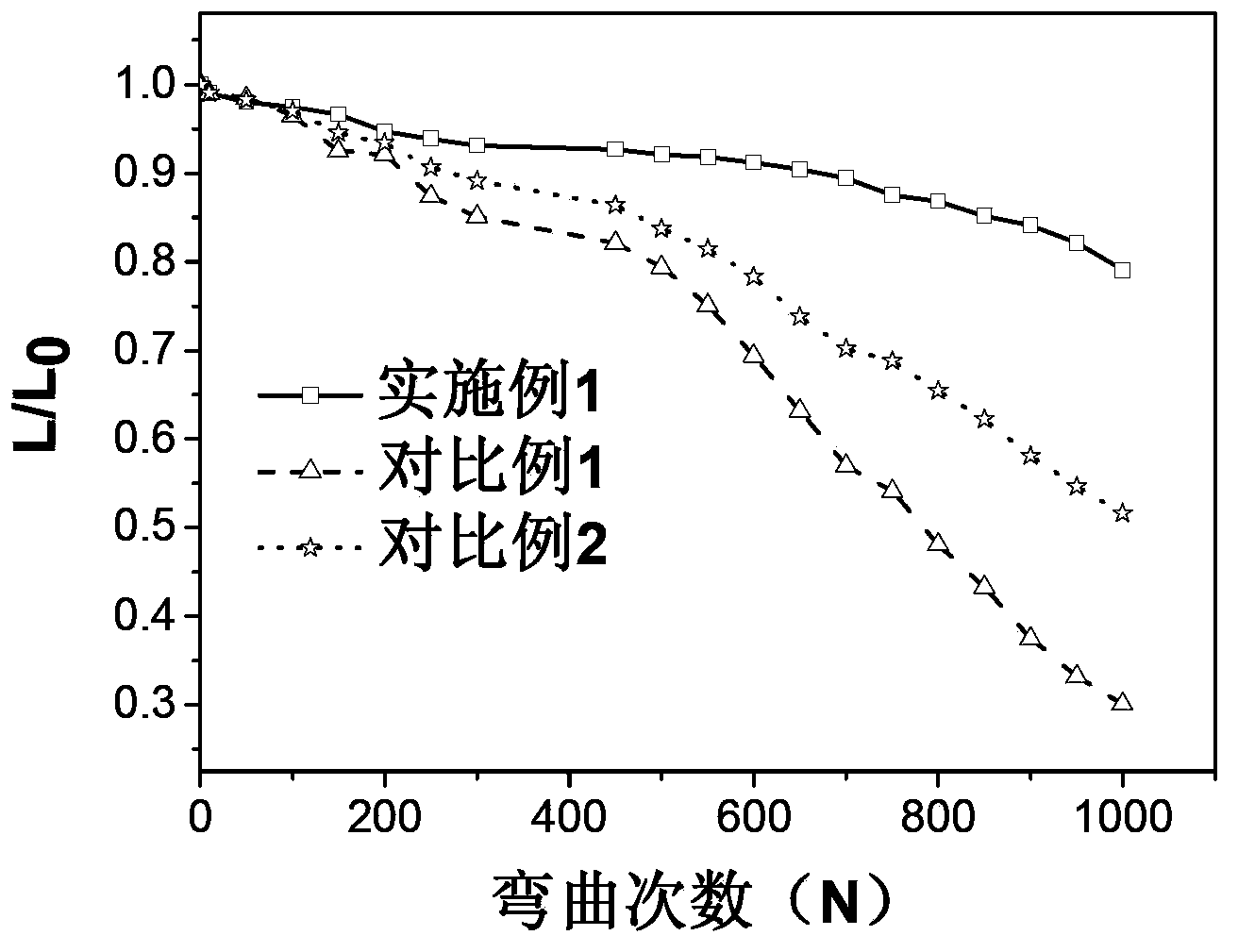

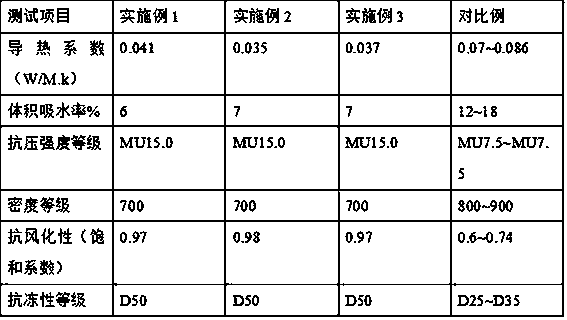

Preparation method for composite thermal-insulation brick

The invention discloses a preparation method for a composite thermal-insulation brick, and belongs to the field of thermal-insulation bricks. According to the method provided by the invention, wheat straw is used as an adding raw material to reduce the production costs, bamboo residues are supplemented, and the bamboo residues are utilized to increase the mechanical properties of the wheat straw and the antibacterial performance of the wheat straw; low-temperature micro carbonization is performed by utilizing the difference of carbonization temperatures of the bamboo residues and the wheat straw to make carbonization incomplete, in the carbonization process, colloid and other substances in the wheat straw are decomposed to increase pores, at the same time, the activated bamboo residue powder is embedded into the wheat straw, then the powder and an additive are mixed, substances in the additive are adsorbed through a carbide, and the additive is supported into the pores; and metal ionsin the added particles are adsorbed by utilizing properties of sodium phytate and sodium pyrophosphate, and the generated pores are filled, so that the porosity is reduced, and the weathering resistance is improved. The method provided by the invention solves the problems that a current thermal-insulation brick has low compressive strength and poor weathering resistance, thereby having poor durability and short service life.

Owner:闫博文

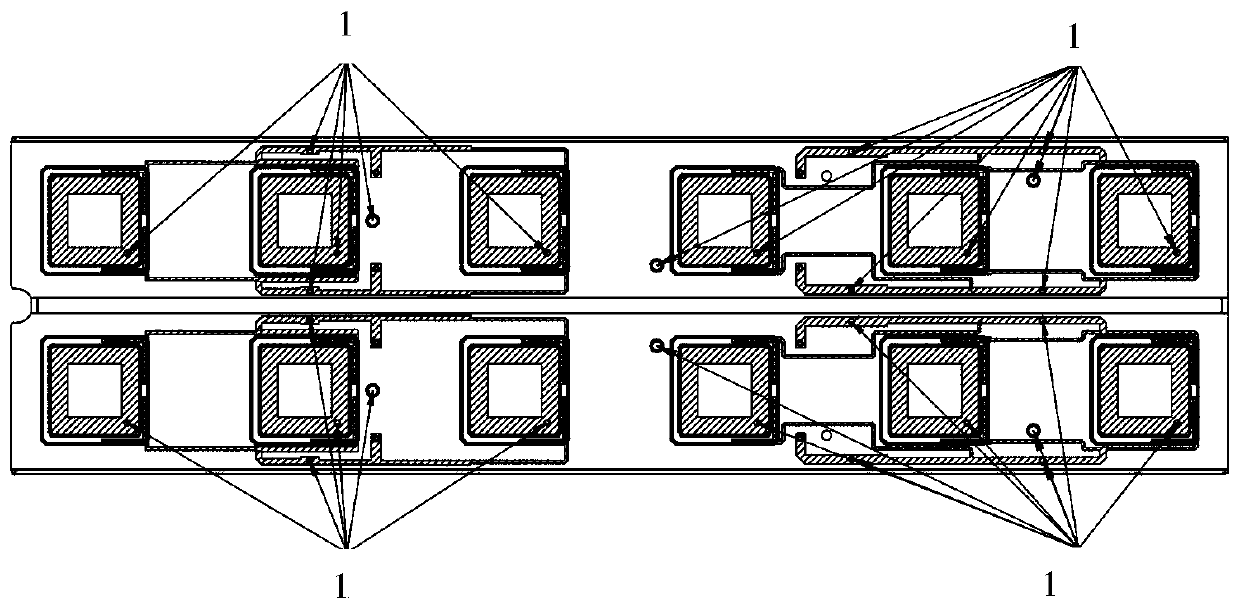

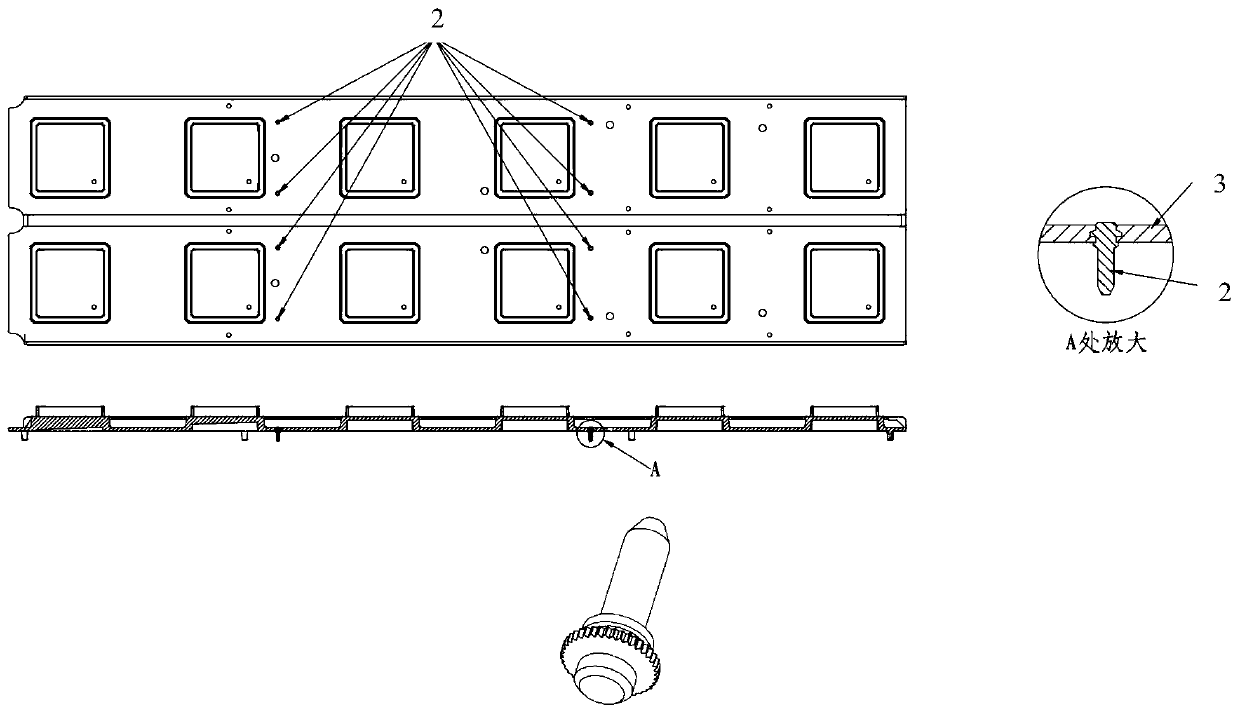

Antenna oscillator and manufacturing method thereof

ActiveCN111355022AEnhance binding strengthManufacturing method optimization and improvementAntenna supports/mountingsRadiating elements structural formsStructural engineeringAntenna element

Owner:深圳慧联达科技有限公司

A hemostatic auxiliary device for vascular surgery nursing

The invention discloses a hemostasis auxiliary device for vascular surgery nursing, relates to the technical field of medical appliances, and comprises a base, the base is composed of a horizontal plate and fixed blocks arranged at both ends of the horizontal plate, and a U-shaped groove is opened on the fixed block horizontally, and the U-shaped groove There is a U-shaped block inside, and the two ends of the U-shaped block are slidingly connected with the side wall of the U-shaped groove; there is a sliding support on the horizontal plate in the middle of the base, and there is a round hole in the middle of the sliding support, and a fixed seat is provided on the sliding support , the fixed seat moves in a circle along the edge of the round hole opened in the middle of the sliding support, and a reel is arranged on the side end surface of the fixed seat away from the sliding support, and the reel is wrapped with gauze for hemostasis, and the reel is connected with the damping round bar for damping rotation. By driving the fixing seat to make a circular motion along the patient's limbs, automatic winding of gauze is realized, which is convenient and quick to operate, saves the time of medical staff, improves work efficiency, and increases the strength of gauze binding.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

Electrode active material, electrode and energy storage device including the same, and method of preparing the electrode active material

ActiveUS20160344023A1Enhance binding strengthHigh bonding strengthMaterial nanotechnologyChemical electrode manufacturingNanometreEnergy storage

Owner:SAMSUNG ELECTRONICS CO LTD

A kind of composite medical dressing and preparation method thereof

ActiveCN103990172BLong-lasting and stable performanceIncrease loadAbsorbent padsBandagesBacterial celluloseEgg white

The invention discloses a compound medical dressing and a preparation method thereof, belonging to the field of compound medical dressings. The compound medical dressing comprises bacterial cellulose membranes, collagens and crosslinking agents, wherein the collagens are crosslinked on the bacterial cellulose membranes via the crosslinking agents. The preparation method comprises the steps of adding the purified bacterial cellulose membranes to a collagen solution containing the crosslinking agents and enabling the bacterial cellulose membranes and the collagens to carry out crosslinking reaction, thus obtaining the compound medical dressing. The loads of the collagens on the bacterial cellulose membranes and the loading stability of the collagens are improved by using the crosslinking agents, so that the properties of the prepared compound medical dressing are more lasting and stable. The method is simple, is easy to operate and has relatively high practicability.

Owner:BEIJING DINGHAN HENGHAI BIOLOGICAL TECH DEV

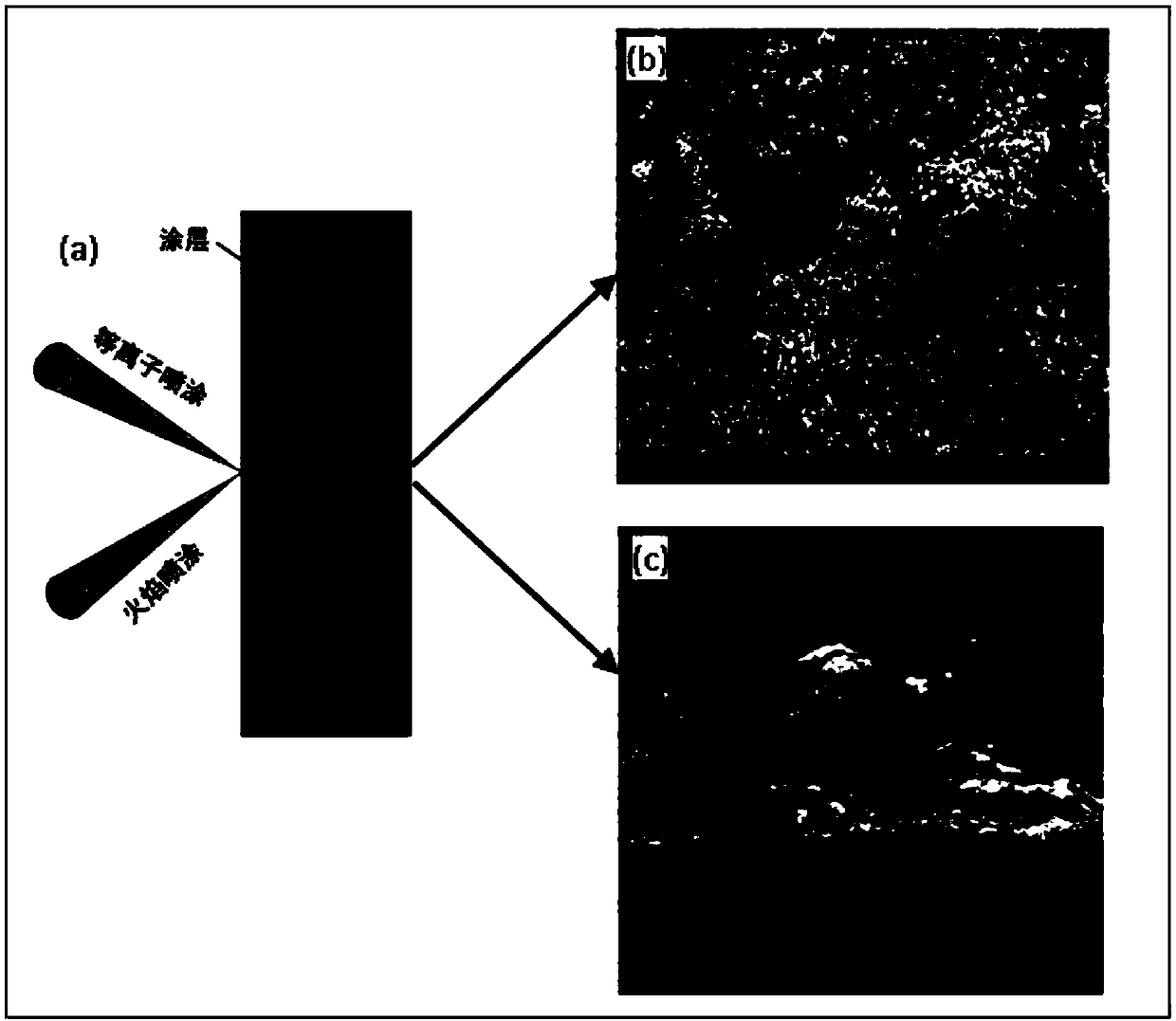

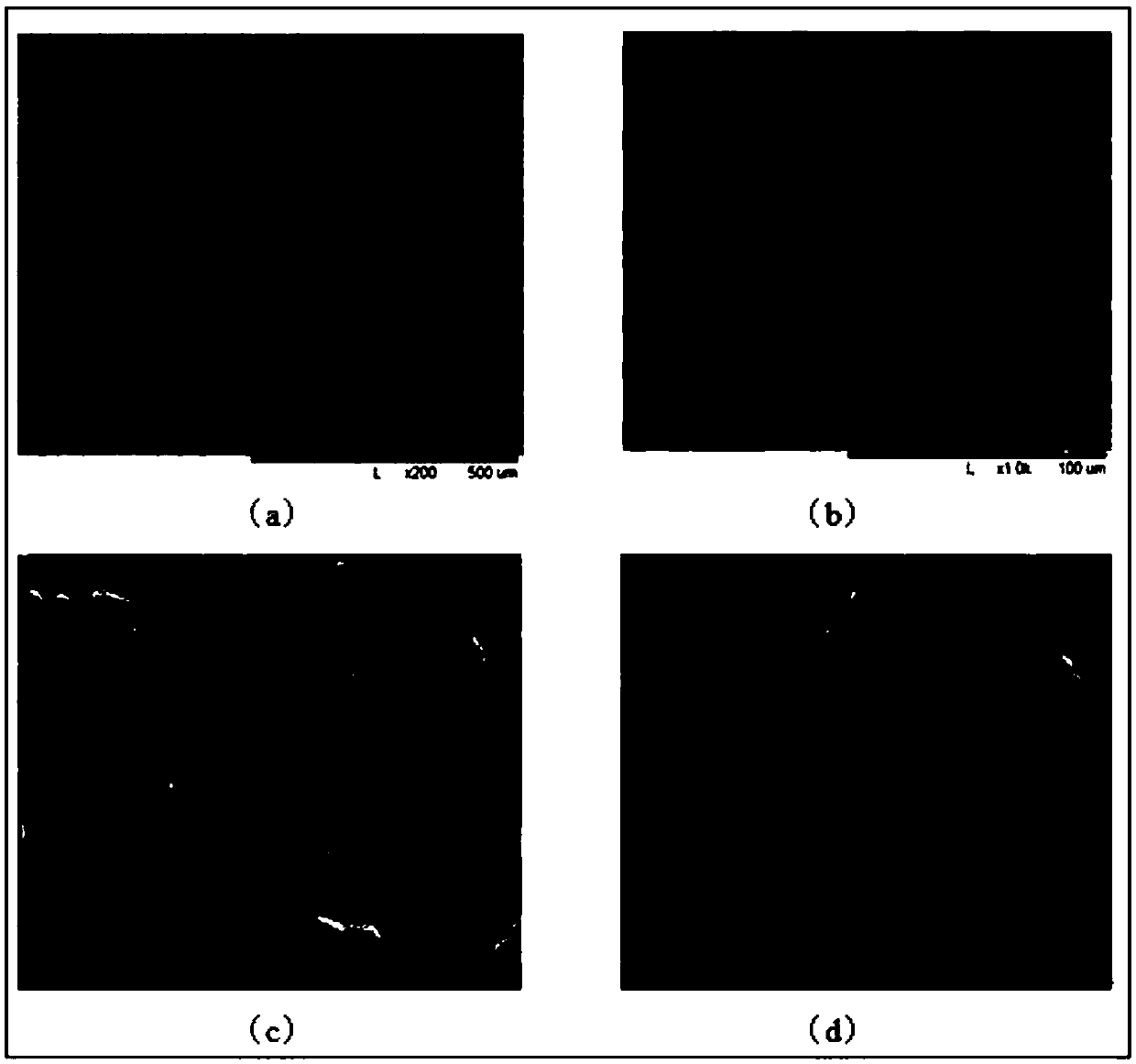

High-performance ceramic coating and preparing method thereof

InactiveCN108330427AImprove densification performanceReduce porosityMolten spray coatingCeramic coatingMetallurgy

The invention relates to the technical field of material surface treatment, in particular to a high-performance ceramic coating and a preparing method thereof. According to the method, micron ceramicpowder and nano ceramic powder serve as raw materials, the plasma spraying and flame spraying combined manner is adopted, and a high-performance ceramic coating is formed on the surface of a base body; and according to the plasma spraying and flame spraying combined manner, plasma spraying and flame spraying are formed at a time. The high-performance ceramic coating with the micron / nano coupling effect is prepared through combination of the two spraying technologies. The high-performance ceramic coating and the preparing method thereof have the beneficial effects that a large number of holes in the micron ceramic powder coating are reduced, the holes are filled with the nano ceramic powder, and accordingly density of the coating is improved; the difficult problems that the nano ceramic powder is difficult to convey and prone to ablation are solved; due to the combination action of the micron nano powder and the nano ceramic powder, the bonding strength of the ceramic coating is enhanced; and the strength and tenacity of the coating are improved, and the purpose of improving the abrasion resisting performance of the coating is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

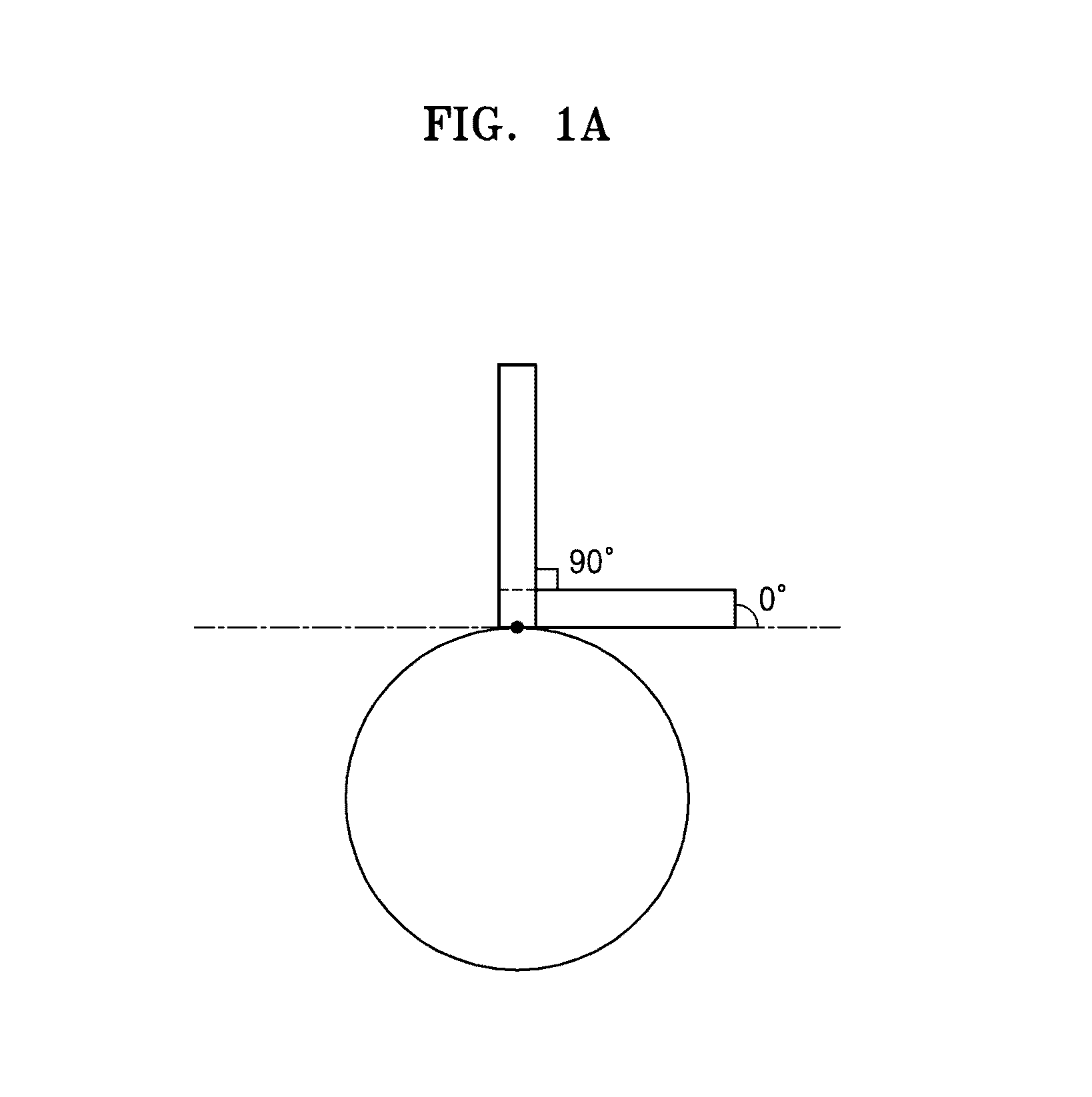

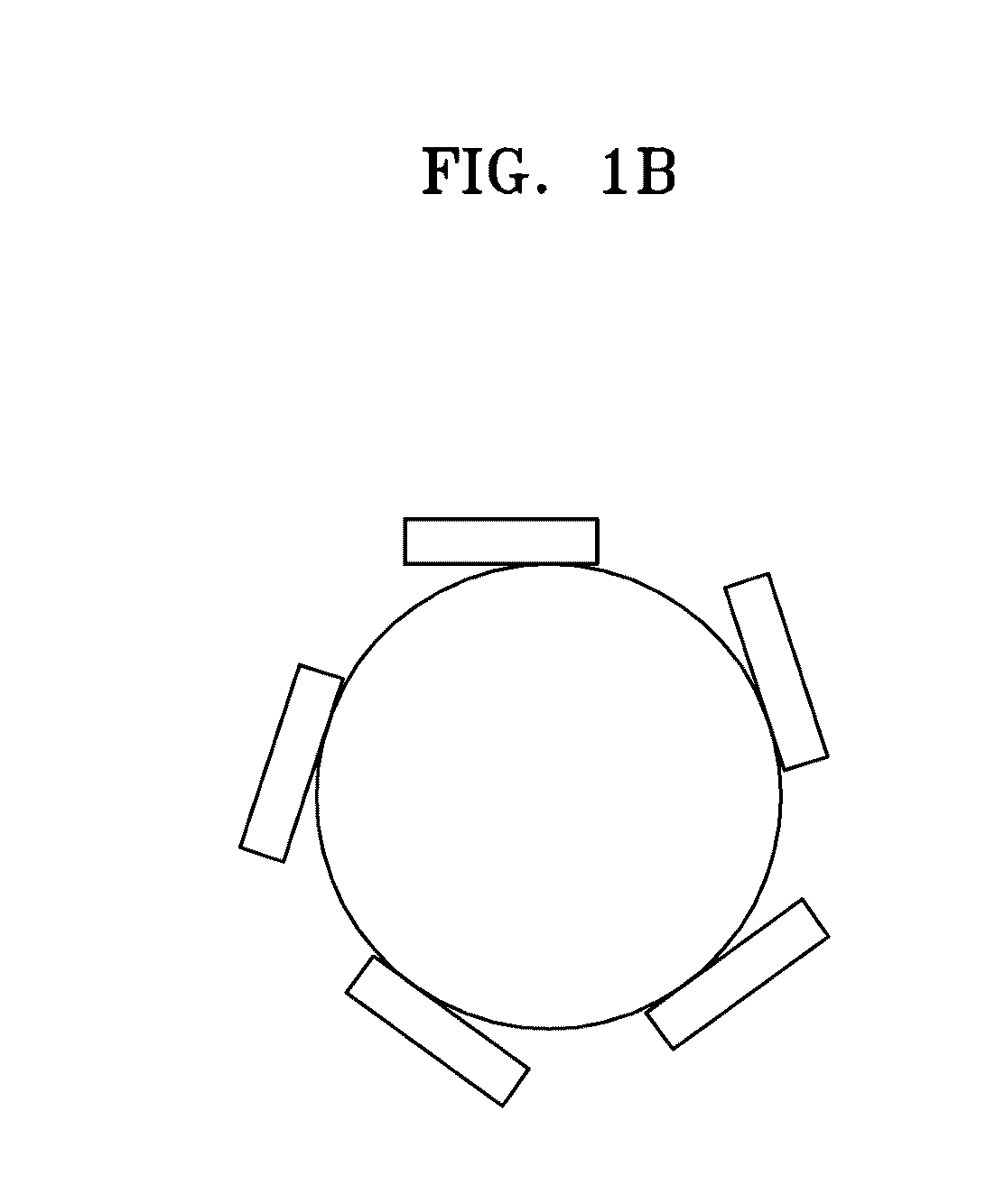

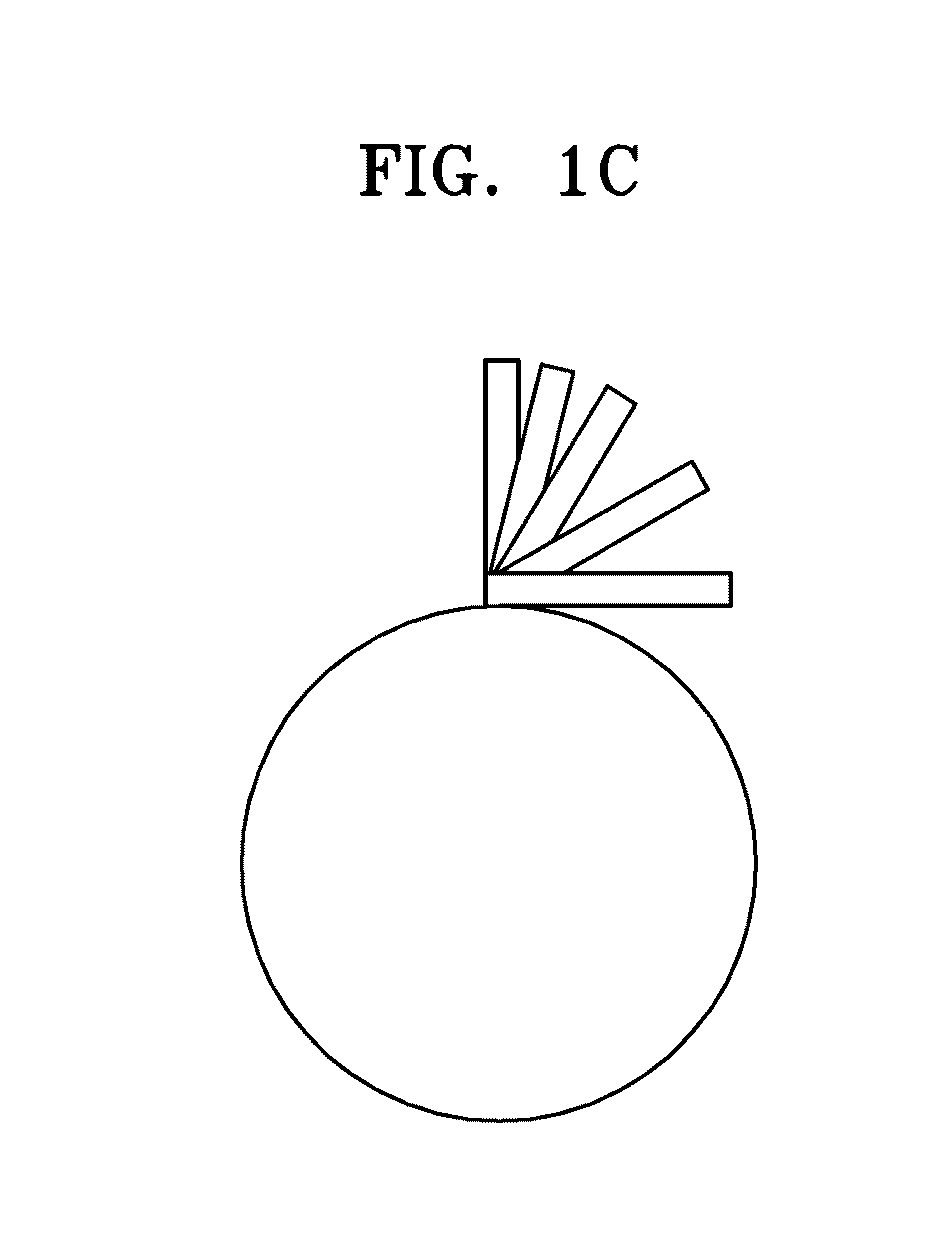

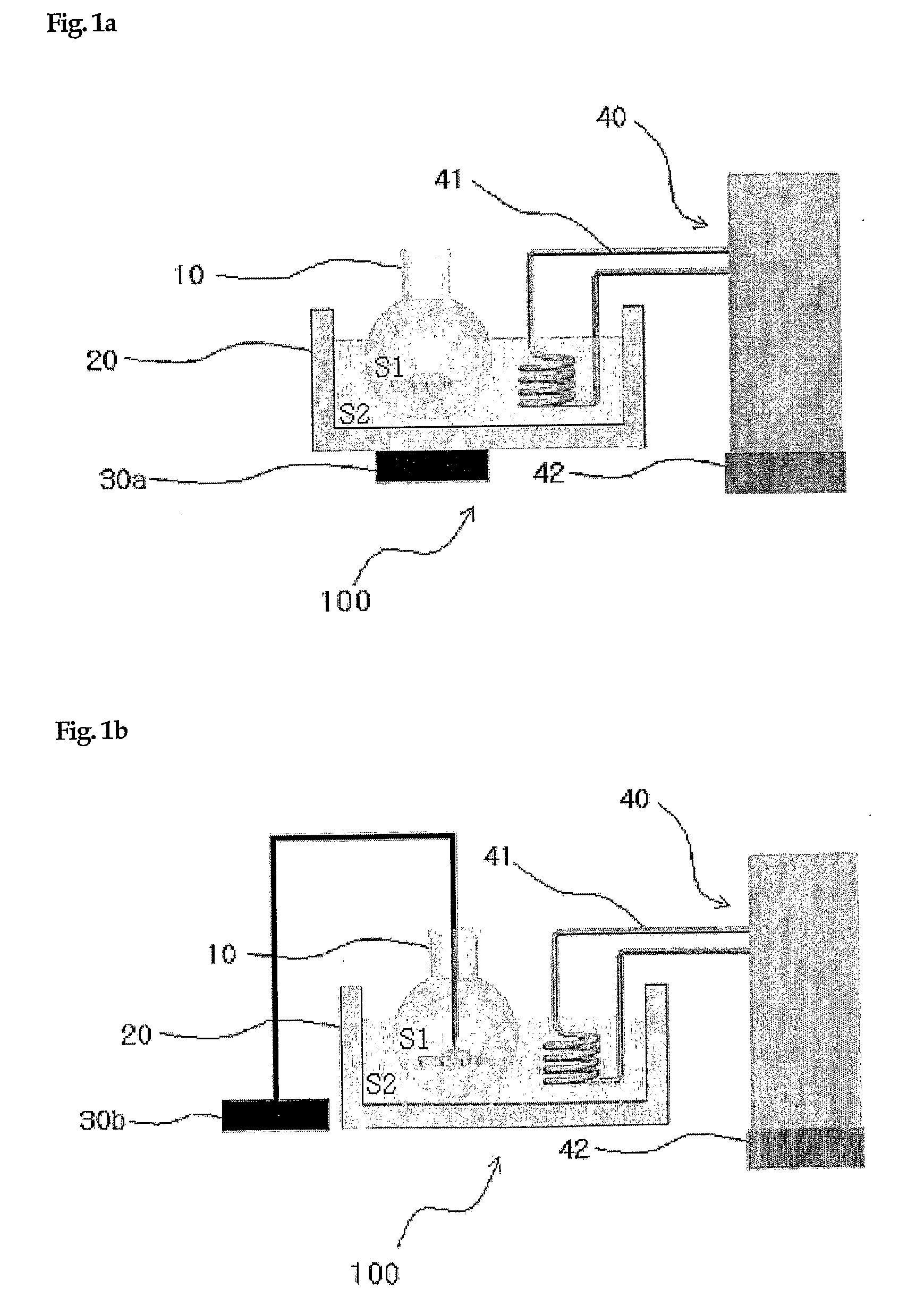

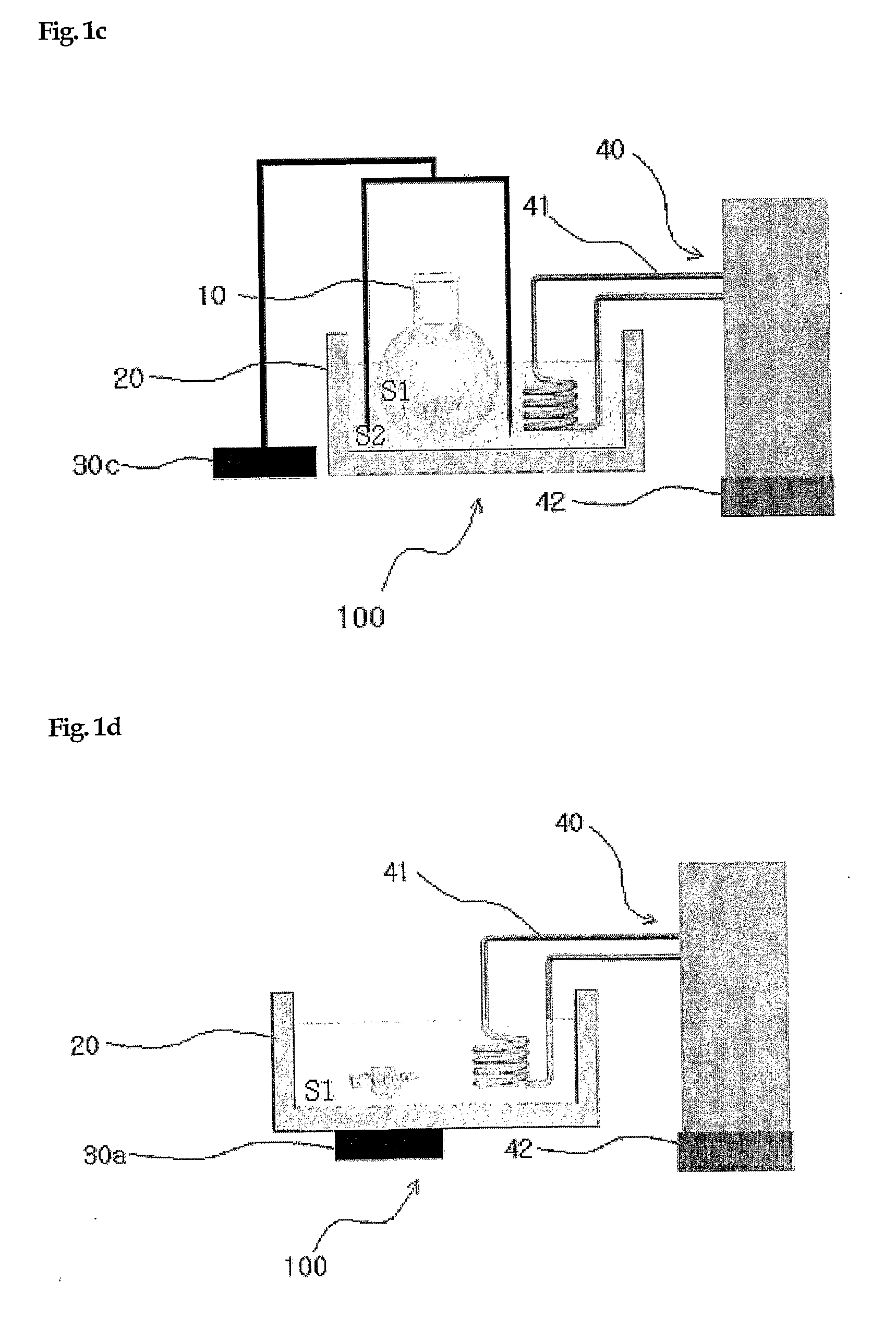

Method of Preparing Substrates - Molecular Sieve Layers Complex Using Ultrasound and Apparatuses Used Therein

InactiveUS20080254969A1Weaken energyShorten the timeMolecular sieve catalystsNanosensorsMolecular sieveCoupling

The present invention relates to a method for preparing substrate-molecular sieve layer complex by vising ultra-sound and apparatuses used therein, more particularly to a method for preparing substrate-molecular sieve layer complex by combining substrate, coupling compound and molecular sieve particle, wherein covalent, ionic, coordinate or hydrogen bond between a substrate and a coupling compound; molecular sieve particle and coupling compound; coupling compounds; coupling compound and intermediate coupling compound is induced by using 15 KHz-100 MHz of ultrasound instead of simple reflux to combine substrate and molecular sieve particles by various processes, further to reduce time and energy, to retain high binding velocity, binding strength, binding intensity and density remarkably, to attach molecular sieve particle uniformly onto all substrates combined with coupling compound selectively, even though substrate with coupling compound and substrate without coupling compound exist together; and apparatuses installed therein, which can improve to produce substrate-molecular sieve layer complex ina large scale.

Owner:IND UNIV COOP FOUND SOGANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com