Patents

Literature

42 results about "Instant potato" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Instant potato wrapper and processing method thereof

ActiveCN104621476AExtended storage timeGood rehydrationFood ingredient functionsFood preparationInstant potatoVegetable oil

The invention discloses an instant potato wrapper and a processing method thereof. The wrapper is prepared from the following raw materials: whole potato powder, wheat flour, a noodle improver, edible salt, konjac glucomannan, eggs, vital gluten, vegetable oil, dietary alkali, starch acetate and xanthan gum. The processing method comprises the following steps: (1) uniformly stirring the whole potato powder, wheat flour, konjac glucomannan, eggs, vital gluten, vegetable oil, starch acetate and xanthan gum, thereby obtaining the mixed raw materials; (2) adding the edible salt, the noodle improver and the dietary alkali into drinking water, stirring until the materials are completely dissolved, thereby obtaining an auxiliary material solution; (3) stirring the mixed raw materials and the auxiliary material solution together and making a dough; and (4) squeezing the kneaded dough, cooking, molding, shredding, shaking the shredded noodles to be loose, drying, cooling, performing vacuum packaging, thereby obtaining the instant potato wrapper. The instant potato wrapper prepared by the invention is rich in nutrition, is a non-fried food, can be eaten instantly and thus fast pace of life can be well met. Moreover, the wrapper is stable in quality, unlikely to go bad and simple in making process.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

Production method of instant potato rice noodles

InactiveCN107212254ARich in nutrientsImprove toughnessFood preservationFood shapingInstant potatoInstant noodle

The invention discloses a production method of instant potato rice noodles. According to the invention, whole potato flour is added into rice as a raw material for preparation. Prepared by a specific method, the instant potato rice noodles have rich nutrients, good toughness, fast rehydration, a low broken rate, and higher contents of protein, total sugar, insoluble dietary fibers and minerals of K and Ca than those of common instant rice noodles. The production method enriches nutrients of the instant rice noodles, and improves a sensual quality of the instant rice noodles at the same time. The instant potato rice noodles can not only enrich varieties of instant foods, but also increase varieties of potato staple food production so as to meet demands of modern metropolitan fast-paced people for health and fast food. The instant potato rice noodles prepared by the invention have better toughness, short time of rehydration and a low cooked broken rate. The production method enriches the nutrients of the instant rice noodles, and improves the sensual quality of the instant rice noodles at the same time.

Owner:贵州省生物技术研究所

Method for producing instant potato

InactiveCN101352225AAvoid churnHigh nutritional valueFruits/vegetable preservation by heatingFood preparationInstant potatoSolanum tuberosum

The invention provides a production method of an instant eating potato. The method comprises the steps that potatoes are selected, cleaned, dried until no bead on the surface of the potatoes, vacuum packing is carried out, then sterilization treatment follows, meanwhile, the potatoes are steamed, and the potatoes can be eaten after being unpacked. In the production method, the potatoes need not to be sliced, thus avoiding the loss of nutrients to the utmost extent; the instant eating potato is not fried, and the sterilization is carried out after the vacuum packing, therefore, the original flavor of the potatoes is maintained; the instant eating potato has the advantages of convenient eating, being nutritious and tasty, simple technology and convenient operation, which solves the problems that the potatoes are not easy for storage and inconvenient in eating, and provides an instant eating and nutritious potato product.

Owner:余朝昱 +1

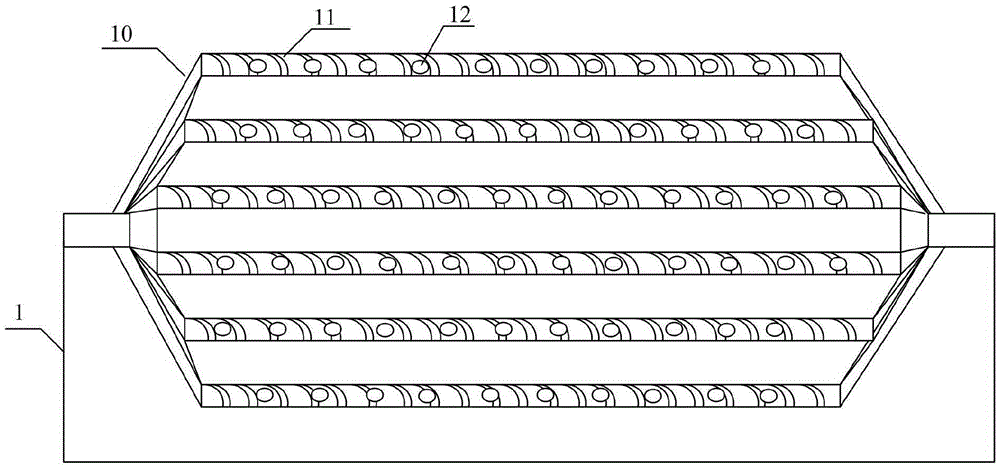

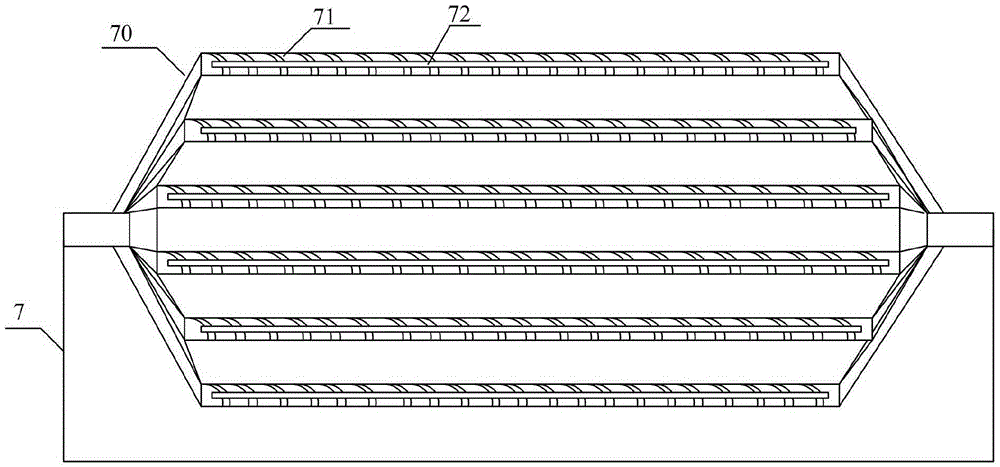

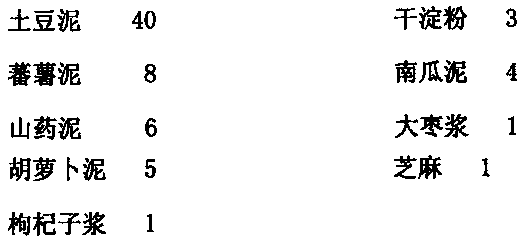

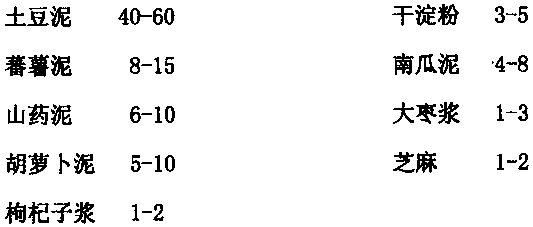

Instant potato cake and preparing method thereof

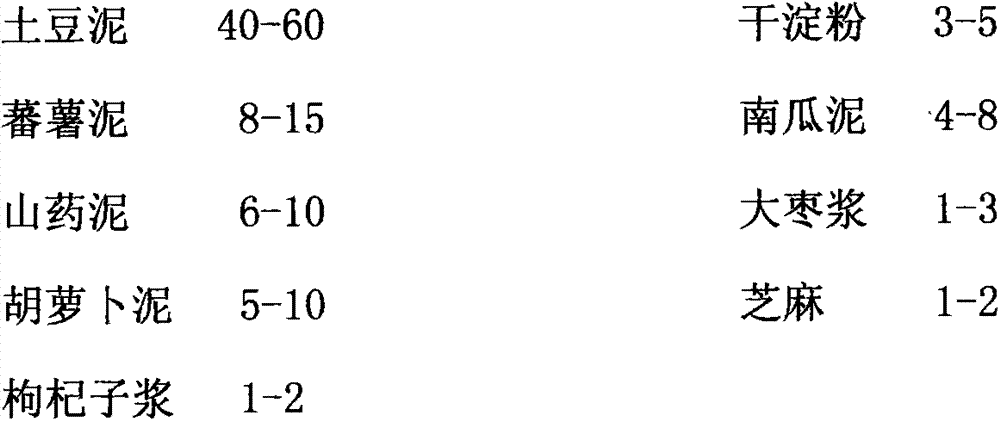

InactiveCN103478649AFull of nutritionEasy to eatFood ingredient functionsFood preparationSesamumInstant potato

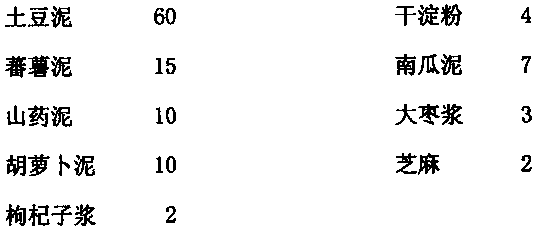

The invention relates to an instant potato cake, which includes the following raw materials in parts by weight: 40-60 parts of mashed potato, 8-15 parts of mashed sweet potato, 6-10 parts of mashed Chinese yam, 5-10 parts of carrot paste, 1-2 parts of barbary wolfberry fruit paste, 3-5 parts of dry starch, 4-8 parts of mashed pumpkin, 1-3 parts of fructus ziziphi jujubae paste and 1-2 parts of sesamum indicum. The preparing method for the potato cake includes the following steps: 1, preparing raw materials; 2, compounding and mixing the raw materials, 3, performing injection molding and forming; 4, heating and disinfecting at a high temperature, 5, packaging in the sterile and vacuum environment. The instant potato cake and the method are suitable for the preparation of nutritious, healthy and instant potato cakes using potatoes as the main raw material, the potato cake is delicious, nutritious, healthy and convenient to eat, and facilitates people's life and health, and application and sales volume of potatoes are enlarged; the preparing method is environment-friendly and sanitary.

Owner:陈建保

Instant potato flour and processing method thereof

InactiveCN105380175ARich tasteEasy to eatFood ingredient functionsProtein food ingredientsMonosodium glutamateSyzygium

The invention provides instant potato flour and a processing method thereof, and belongs to the field of deep processing of agricultural food. The instant potato flour comprises a bagged main ingredient bag, a nutrient bag and an additional bag. The main ingredient bag is made of raw mashed potatoes, sodium citrate and inositol. The nutrient bag is made of corn oligopeptide, walnut kernel powder, chlorella polypeptide powder and pilose asiabell root powder. The additional bag is made of salt, white granulated sugar, amomum kravanh, monosodium glutamate, syzygium aromaticum, dry shallot powder and dry caraway powder. The aim of making the raw mashed potatoes into an instant dissolved product and keeping nutrient ingredients basically unchanged is achieved, the varieties of potato products is increased, and a new path is provided for diversified development of potato food. The made instant potato flour contains multiple nutritional ingredients, and is rich in taste, convenient and flexible to eat and capable of meeting multiple needs of different people, and the healthcare effects of improving immunity, relieving fatigue, strengthening the spleen and tonifying the lung and the like are achieved if the instant mashed potato is eaten for a long time.

Owner:GANSU XIANGCAOFANG NATIVE PROD

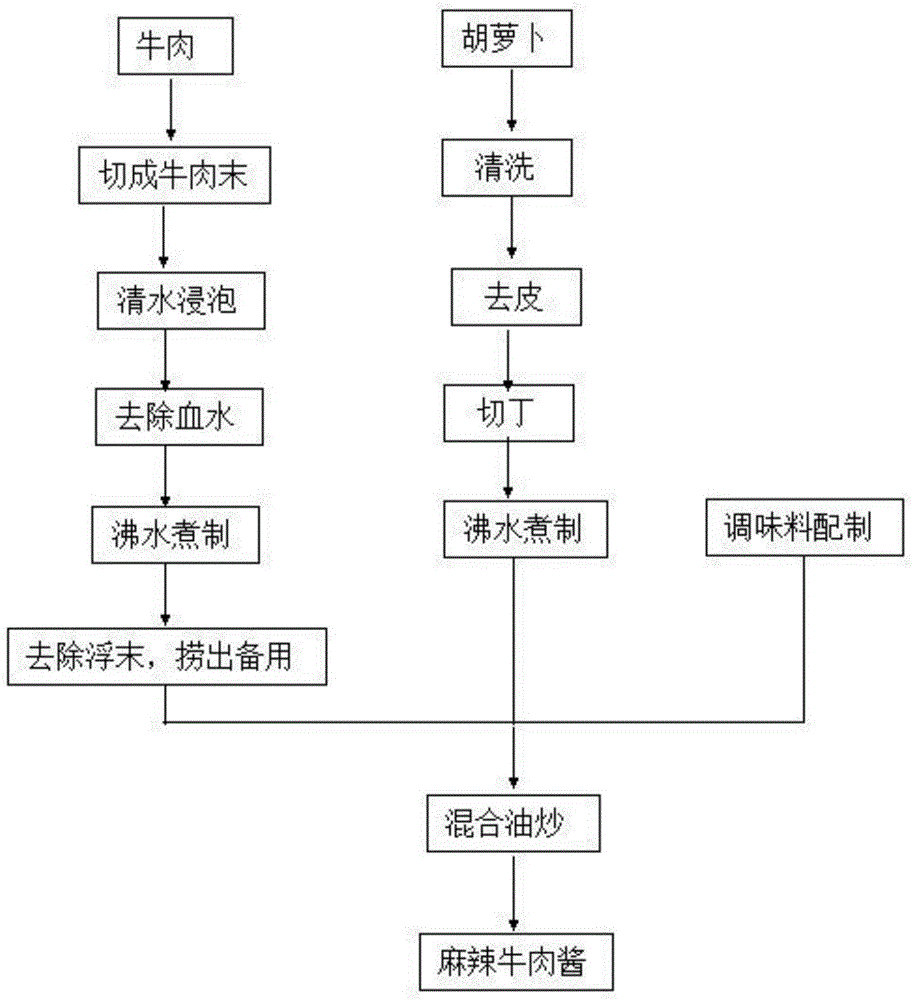

Spicy beef paste for instant potato noodles and preparation method of spicy beef paste

The invention discloses spicy beef paste for instant potato noodles and a preparation method of the spicy beef paste. The spicy beef paste comprises the following components in parts by weight: 33-53 parts of beef, 4-11 parts of carrots, 9-18 parts of Chinese prickly ash, 19-22 parts of chili, 6-11 parts of salt, 6-18 parts of white sugar, 6-11 parts of aginomoto, 45-65 parts of broad-bean sauce, 15-25 parts of cooking wine and 14-22 parts of soybean sauce. The preparation method comprises the following steps: cutting up the beef and boiling at 70-120 DEG C for 15-50 minutes; cutting the carrots into slices, grinding the Chinese prickly ash and the chili into powder to obtain the Chinese prickly ash powder and chili powder; and mixing the cooked ground beef, the sliced carrots, the Chinese prickly ash powder, the chili powder and other components in the spicy beef paste, and frying with oil, so as to obtain the spicy beef paste for the potato noodles. The spicy beef paste is spicy, palatable, balanced in nutrient, stable and uniform in sauce flavor, is especially suitable for being matched with the potato noodles, and can play a role in supplement with one another in flavor and nutrient.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Dehydrated instant potato product and low carbohydrate dehydrated instant potato product

The invention provides both regular and low-carbohydrate versions of a dehydrated instant potato product comprising from about 2% to about 25% of at least one texturizing agent. Inclusion of the texturizing agent provides a mashed potato product having improved texture and increased consumer acceptance when compared to other types of dehydrated instant potato products.

Owner:GENERAL MILLS INC

Method for preparing convenience food of sweet potato

An instant potato food with agreeable taste and high nutritive value is prepared from potato through removing impurities, washing, slicing, steaming, drying, shaping, and packing.

Owner:张居德

Preparation method of instant potato pellet

InactiveCN101773233ASolve storage problemsExtended storage timeFood preparationInstant potatoPreservative

The invention relates to a food preparation method, in particular to a preparation method of instant potato pellets, which comprises the following steps: cleaning potatoes, freezing the potatoes for 3-6 hours, soaking, thawing, extruding to dry, steaming, peeling, and crushing to prepare pellets, and then frying and vacuum packaging the pellets. The potato pellets prepared in the preparation method of the invention contain no preservative, and has the advantages of instant eating after bag opening, convenient, rapid and long-term storage time and no deterioration. Moreover, the potato pellets can be made into dishes without loss of nutrients, and solve the problem of storage in areas with the high yield of potatoes.

Owner:杨太平

Instant potato noodles and production method

InactiveCN107668485AImprove immunityIncrease creaminessFood dryingFood ingredient functionsInstant potatoSolanum tuberosum

The invention discloses instant potato noodles and a production method. The instant potato noodles are prepared from raw materials in parts by weight as follows: 100-130 parts of potatoes, 60-80 partsof table salt, 0.2-1 part of astragalus polysaccharide, 0.2-0.8 part of lycium barbarum polysaccharide, 0.2-0.5 part of a hawthorn fruit extract and 15-30 parts of a carrot extract. The production method of the instant potato noodles comprises five steps as follows: dough kneading, nitrogen cooking, vacuum frying, centrifugal oil removing and drying under reduced pressure. The prepared high-nutrition instant potato noodles have the advantages that the instant potato noodles taste smooth, nutrition can be absorbed easily, the fat content is low, the soaking time is short, the noodle cake cannot break easily, and the human immunity can be enhanced.

Owner:HEXI UNIV

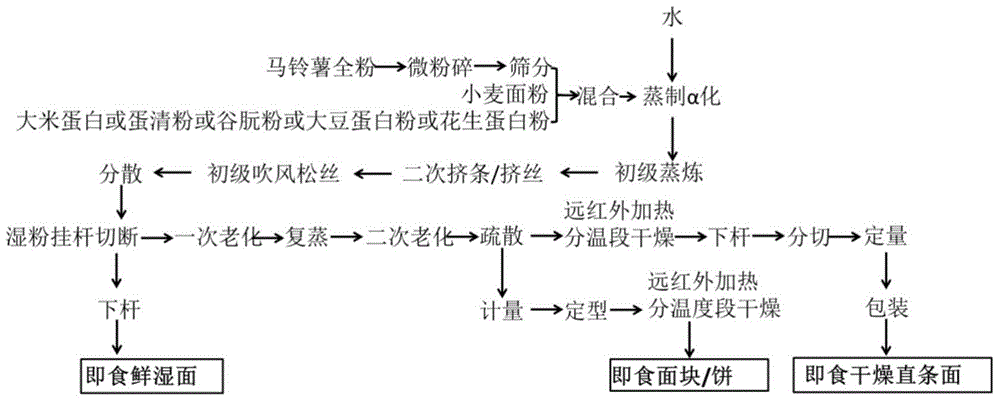

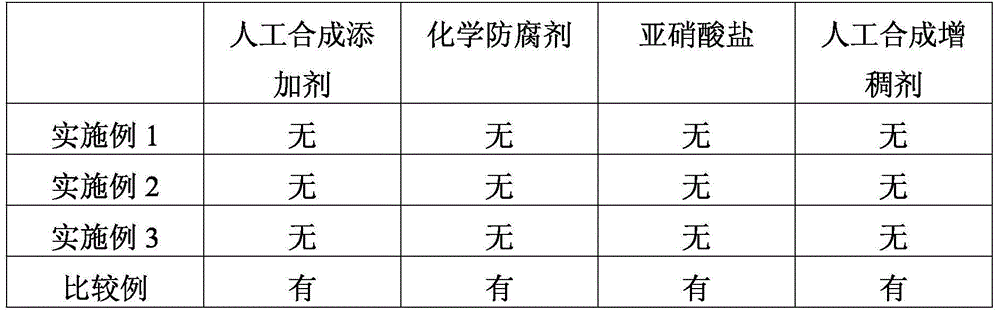

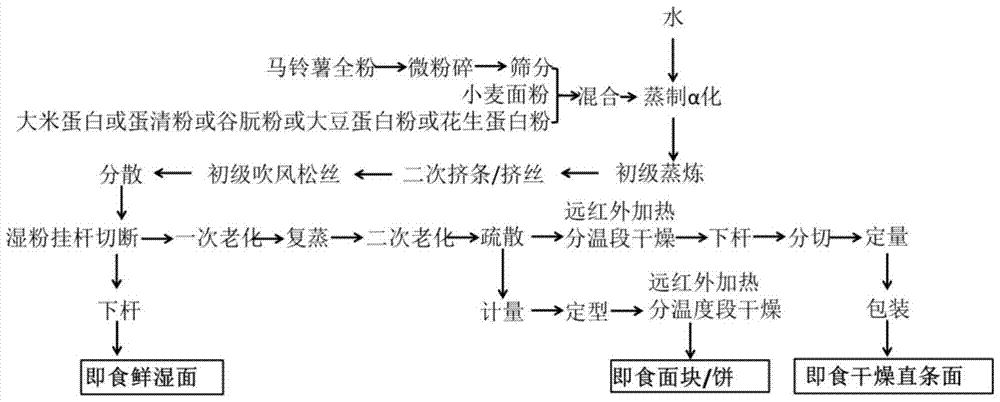

Alternating-type alpha gelatinization-aging processing method for instant potato noodle

The present invention discloses an alternating-type alpha gelatinization-aging processing method for an instant potato noodle. The processing method comprises the following steps: step 1, mixing and grinding 20-85 parts of mashed potato, 30-50 parts of wheat flour and 5-10 parts of protein powder calculated in parts by weight to make the fineness of the mixed powder less than 120 meshes; step 2, adding water (equivalent to 22-28% the weight of the mixed powder) into the mixed powder obtained in step 1, and then successively performing alpha gelatinization steaming, primary steaming and secondary extruding to obtain primary noodle with the temperature of the alpha gelatinization steaming of 95-105 DEG C, and the steaming time of 3-10 minutes, and the temperature of the primary steaming of 80-95 DEG C, and the steaming time of 10-30 seconds; step 3, conducting blowing and fluffing treatment on the primary noodle obtained in step 2 until the primary noodle is dispersed to obtain the instant fresh and wet noodle. The processing method enhances the instantiability, convenience and safety of potato products as staple food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

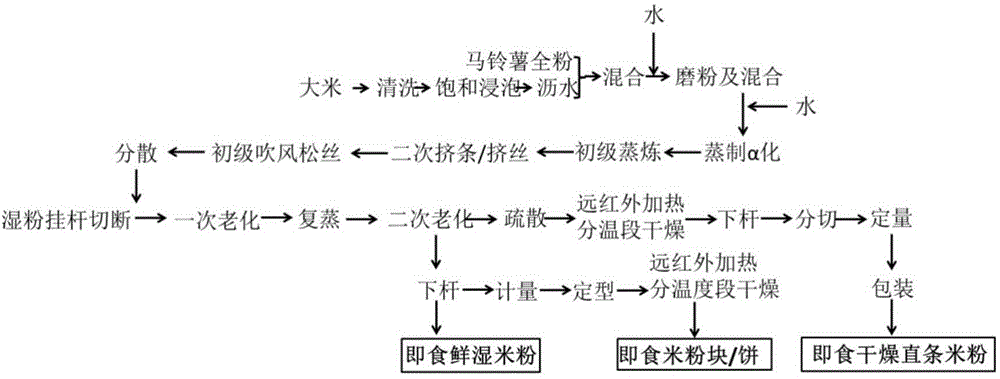

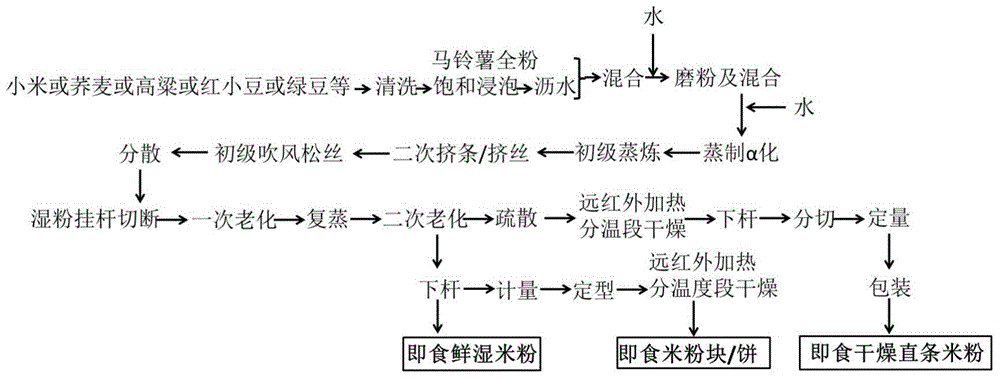

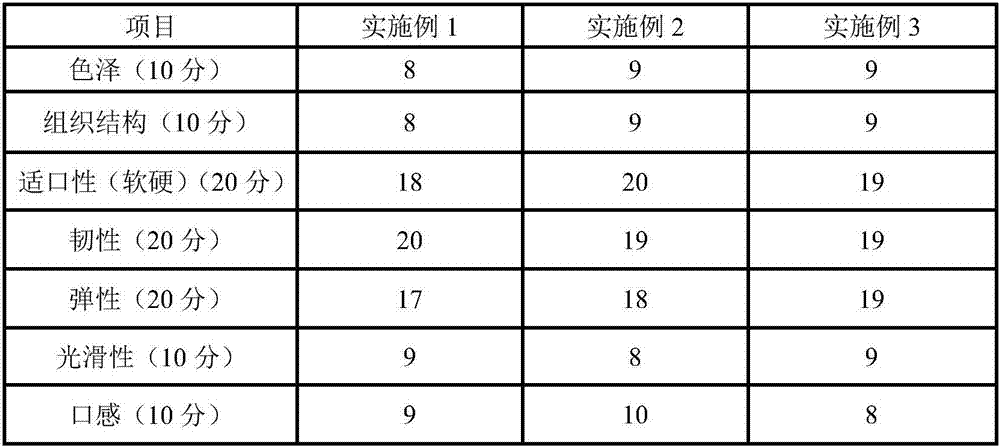

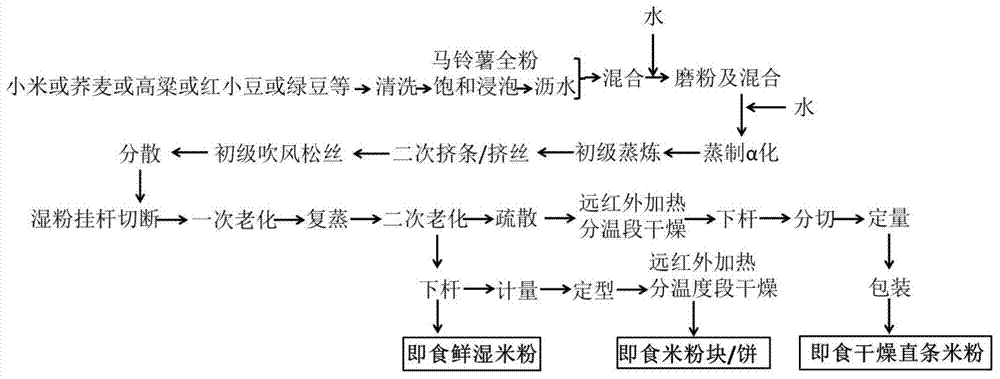

Alternating-type pregelatinization-retrogradation instant potato rice noodle processing method

The present invention discloses an alternating-type pregelatinization-retrogradation instant potato rice noodle processing method. The processing method comprises the following steps: step 1, mixing and grinding 15-85 parts of rice and 20-85 parts of potato whole powder; step 2, adding water (equivalent to 8-14% of the mixed powder by weight) into the mixed powder and successively conducting pregelatinization steaming, primary steaming and secondary extruding to obtain primary rice noodles, wherein a temperature of pregelatinization steaming is 96-106 DEG C and a steaming time is 2-8 minutes; step 3, conducting blowing and fluffing treatment on the primary rice noodles until the primary rice noodles are dispersed to obtain the semi-finished rice noodle products; and step 4, successively conducting primary retrogradation steaming and re-steaming and then conducting secondary retrogradation steaming on the semi-finished rice noodle products to obtain the instant fresh and wet rice noodles, wherein the primary retrogradation steaming temperature is 18-30 DEG C and the time is 6-14 hours, and the secondary retrogradation steaming temperature is 18-30 DEG C and the time is 2-6 hours. The technique enhances the instantiability, convenience and safety of potato products as staple food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

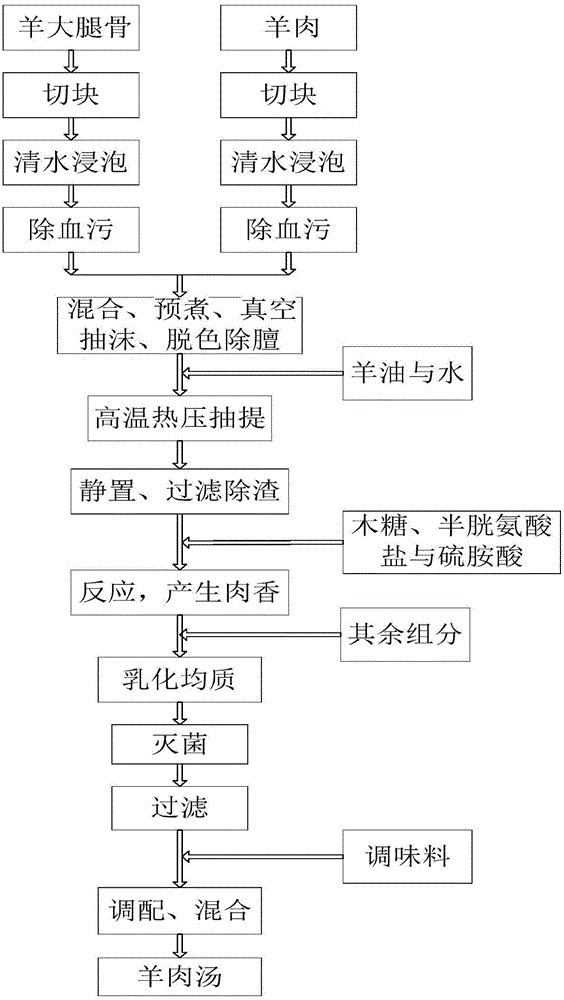

Mutton soup for instant potato noodle and preparation method for mutton soup

InactiveCN104643187AStrong fragranceHigh nutritional valueFood preparationNutritive valuesAmomum tsao-ko

The invention provides mutton soup for an instant potato noodle and a preparation method for the mutton soup. The mutton soup consists of the following components in parts by weight: 1500-2500 parts of sheep thigh bones, 1000-5000 parts of mutton, 100-500 parts of mutton fat, 4000-10000 parts of water, 70-250 parts of salts, 3-17 parts of Chinese prickly ash, 0.4-2 parts of fennel, 2-10 parts of anise, 0.05-0.35 part of white peppers, 0.1-1 part of clove, 0.2-1 part of cinnamon, 0.7-6 parts of dried ginger slices, 1-5 parts of amomum tsao-ko, 5-30 parts of pod peppers, 0.07-3 parts of cumin, 0.5-4 parts of netmeg, 0.5-3 parts of angelica roots, 5-15 parts of rhizoma kaempferiae, 0.5-2.5 parts of fructus amomi and 0.05-0.6 part of myrcia. The preparation process is simple and the prepared mutton soup has good fragrance, strong smell and a high nutritive value.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

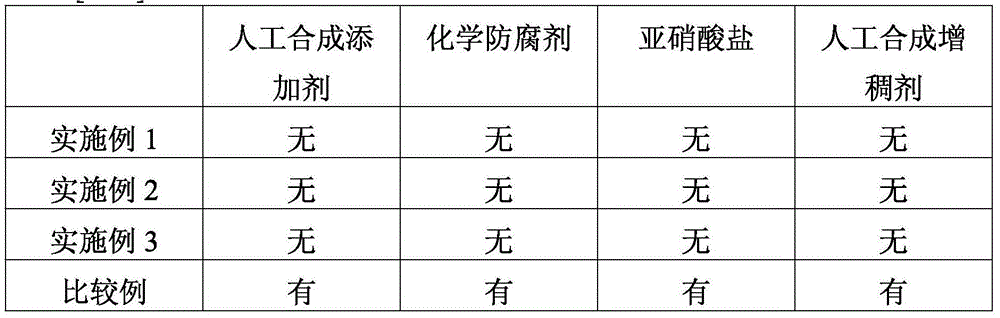

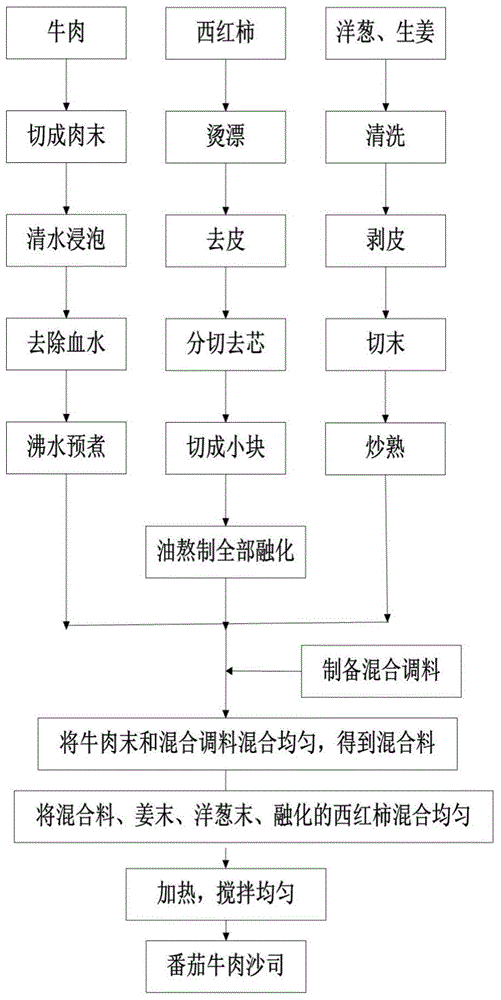

Tomato-beef sauce for instant potato noodles and preparation method for tomato-beef sauce

InactiveCN104687005ASimple preparation processSolve the single flavorFood preparationInstant potatoSweetness

The invention belongs to the field of food condiments and particularly relates to tomato-beef sauce for instant potato noodles and a preparation method for the tomato-beef sauce. The tomato-beef sauce for the instant potato noodles is prepared from the following raw materials in parts by weight: 37-47 parts of minced beef, 15-23 parts of tomato sauce, 5-15 parts of tomato sauce, 14-24 parts of tomatoes, 0.1-0.8 part of aginomoto, 0.1-0.8 part of chicken essence, 0.5-5.5 parts of chilli sauce, 0.3-1.2 parts of salts, 0.7-2.5 parts of edible oil, 1-7 parts of minced onion and 1-5 parts of fresh ginger powder, wherein 80g of the tomato-beef sauce for the instant potato noodles is mixed with 220g of the instant potato noodles to form the noodles with the sauce; after being eaten for a long time, the noodles with the sauce can meet various nutrient needs of people, so that the problem that the nutrient is single is avoided. The preparing formula of the tomato-beef sauce is fixed so that the unified product flavor is well guaranteed; the prepared tomato-beef sauce is strong in flavor, moderate in sourness and sweetness, and high in nutritional value. Besides, the preparation process is simple and can be used for industrial and large-scale production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Preparation method of hypoallergenic instant potato bean milk powder

ActiveCN107410502ASolve the problem of weak taste and poor satietyAllergenicity reductionMilk preparationFood ingredient functionsInstant potatoSolanum tuberosum

The invention discloses a preparation method of hypoallergenic instant potato bean milk powder, and belongs to the field of food processing. The method comprises the specific steps of making soybeans into soybean milk, performing enzymolysis on the soybean milk, performing glycosylation, then mixing the glycosylated material with potato juice, performing dialysis, adding milk powder, performing homogenizing and then performing spray drying so as to obtain the potato bean milk powder. The potato bean milk powder made by the method disclosed by the invention has the characteristics of being hypoallergenic, good in solubility, instant and the like, the quality guarantee period is greatly prolonged, and the potato bean milk powder is easy to store, transport and carry and convenient to eat, and has the efficacy of regulating the function of the stomach, regulating middle energizer, strengthening the spleen and replenishing qi.

Owner:黑龙江冰泉多多保健食品有限责任公司

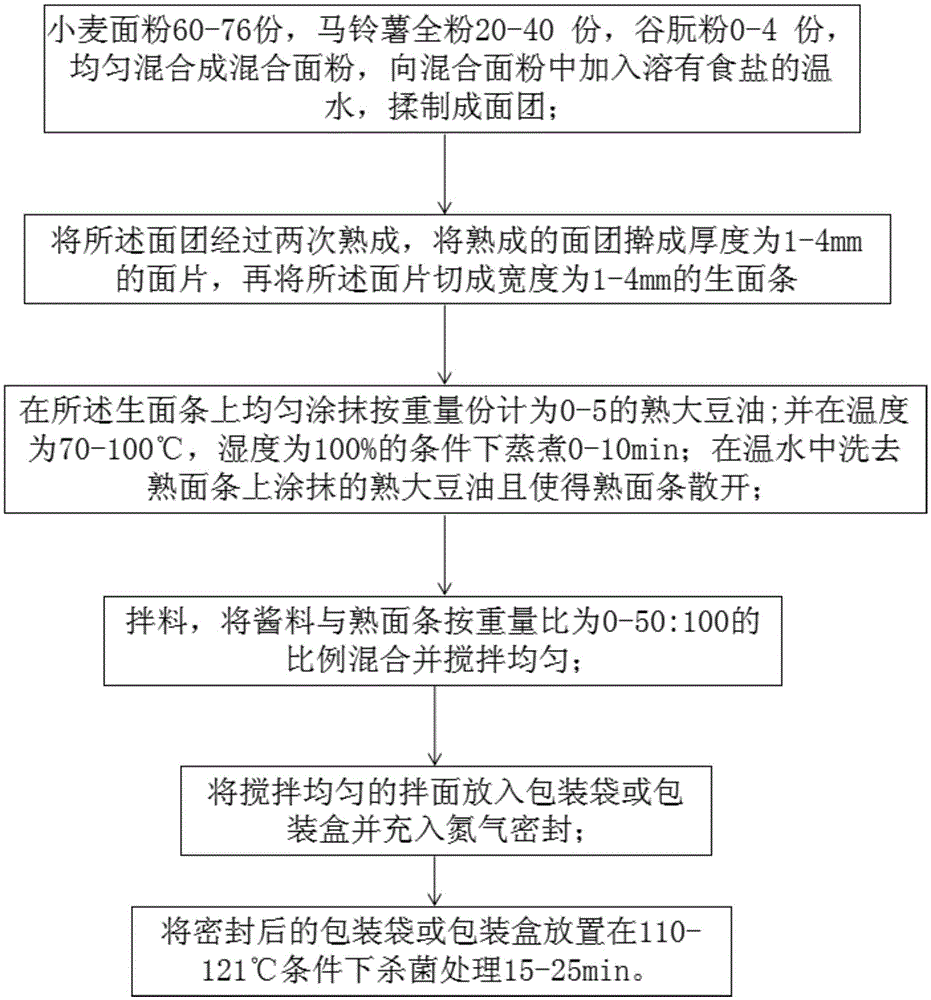

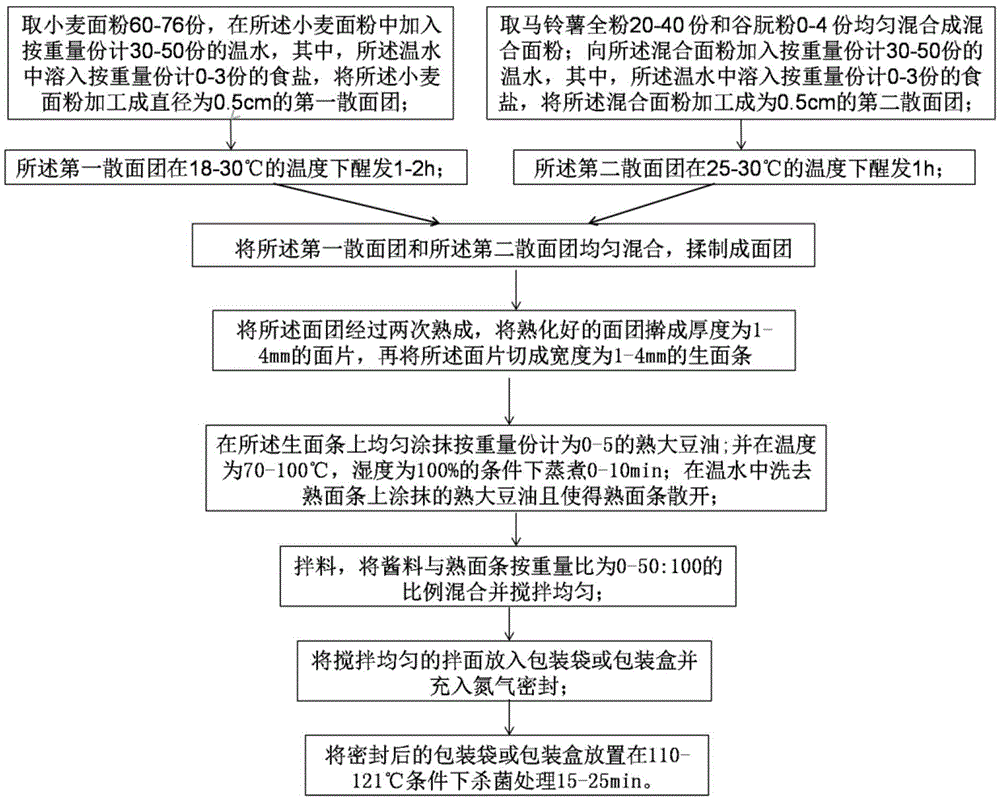

Normal-temperature instant potato stirred noodles and making method thereof

InactiveCN105614680AHigh in nutrientsRich varietyFood ingredient as mouthfeel improving agentInstant potatoNitrogen

The invention provides normal-temperature instant potato stirred noodles and a making method thereof. The making method comprises the following steps that 1, 60-76 parts of wheat flour, 20-40 parts of whole potato flour and 0-4 parts of gluten powder are taken by weight and kneaded into a dough; 2, the dough is prepared into raw noodles after being ripened for two times; 3, the raw noodles are steamed for 0-10 min on the conditions that the temperature is 70 DEG C-100 DEG C and the humidity is 100%; 4, material stirring is performed, wherein sauce and cooked noodles are mixed according to the weight ratio of (0-50):100 and stirred to be uniform; 5, the uniformly stirred noodles are put into a packing box or bag, nitrogen is introduced into the box or bag, and the box or bag is sealed; 6, the sealed packing box or bag is put at the temperature of 110 DEG C-121 DEG C to be sterilized for 15-25 min. The instant potato stirred noodles are rich in nutrition, good in mouthfeel, continuous and non-sticky.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

An alternating-type alpha gelatinization-aging processing method for instant potato and coarse cereal rice noodles

ActiveCN104814380AFull of nutritionFlexible processing technologyFood preparationInstant potatoFood flavor

The present invention discloses an alternating-type alpha gelatinization-aging processing method for instant potato and coarse cereal rice noodles comprising the following steps: Step 1, mixing and grinding 20-85 parts of coarse cereals and 15-80 parts of potato whole powder calculated in parts by weight to make the fineness of mixed powder less than 120 meshes; Step 2, adding water (equivalent to the weight of 8-14% of the mixed powder) into the mixed powder obtained in step 1, and followed by successively performing alpha gelatinization steaming, primary steaming and secondary extruding to obtain primary powder; Step 3, conducting blowing and fluffing treatment on the primary powder obtained in step 2 until the primary powder is dispersed to obtain semi-finished powder; Step 4, successively conducting primary aging steaming and re-steaming, and then secondary aging steaming on the semi-finished powder obtained in step 3, thereby obtaining the instant fresh and wet rice noodles. A production method for the instant potato and coarse cereal rice noodles richer in nutrition and varied in flavor is provided, and the production method are flexible in processing technology and convenient for mechanical processing development, and can achieve quantitative standardized production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Instant potato vegetarian sausage and production method thereof

InactiveCN107149109ARich categoryGuaranteed nutritional valueFood scienceBiotechnologyInstant potato

The invention discloses an instant potato vegetarian sausage and a production method thereof. Fresh potatoes are processed into fresh potato paste; then, the fresh potato paste and potato flour are compounded; the production cost is reduced; meanwhile, the nutrition value of the potato vegetarian sausage can be maintained, so that the product nutrition is comprehensive; the eating is convenient; the shelf life is long; the development trends of food nutrition, health, convenience and safety are met; meanwhile, the rich nutrition of the potatoes is combined with the special flavor of a conventional sausage, nutritional and healthy food with the unique mouthfeel is provided for customers; meanwhile, potato deep processing product categories are also enriched.

Owner:贵州省生物技术研究所 +1

Processing method of instant potato porridge

PendingCN114246297AFull of nutritionNutrition and healthFood ingredient functionsBiotechnologyInstant potato

The invention discloses a processing method of instant potato porridge, which comprises the following steps: removing surface impurities from sweet potatoes, potatoes, cassava and taros with the flour yield of more than or equal to 20%, and peeling under the steam pressure of 0.8 MPa; washing, and dicing within 30 minutes after washing to obtain potato dices; the diced potatoes are soaked in citric acid with the concentration being 0.4%, then fixation is conducted, and the steam temperature for fixation is not lower than 90 DEG C, so that the diced potatoes are steamed after fixation is completed for 8-12 min; the preparation method comprises the following steps: removing water, cooling to below 40 DEG C, crushing by a colloid mill with a sieve of more than 100 meshes to obtain mashed potatoes, crushing rice by a sieve of 60 meshes, uniformly mixing the crushed rice with the mashed potatoes, or drying the mashed potatoes, uniformly mixing whole potato flour and rice flour, carrying out extrusion molding at 115 DEG C, and carrying out normal-pressure airflow puffing treatment at 130 DEG C for 50 seconds to obtain the potato rice. The potato porridge prepared by the method disclosed by the invention has a meal replacement effect, can be industrially produced, is nutritional and healthy, can prevent diseases, and is rich in taste and convenient to eat.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

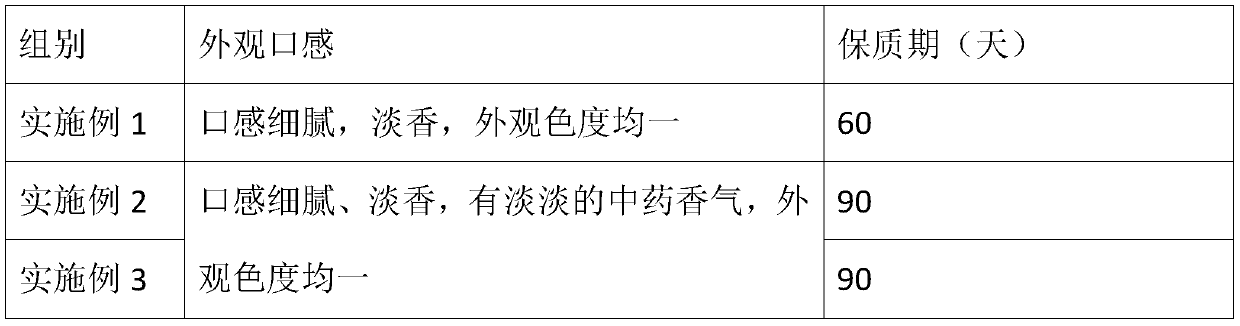

Instant potato processing method

ActiveCN105410765AGreat tasteStable tasteFood preservationNatural extract food ingredientsTemperature controlInstant potato

The present invention discloses an instant potato processing method which comprises the following steps: step 1, pretreating; step 2, color protecting; step 3, rinsing: the color protected raw materials are rinsed with pure water and / or traditional Chinese medicine nutrient solution to remove the color protecting liquid and / or primarily processed raw material added nutritional elements remaining on the surface of the raw materials, and the rinsing time is controlled at 0.5-1.5 hours; step four, vacuum bagging, the rinsed raw materials are packaged and evacuated and the vacuum degree is controlled at 0.05-0.2 Mpa to obtain a semi-finished product; and step five, heat sterilizing, the semi-finished product in the water is heated for 30-50 min, the temperature is controlled at 80 DEG C-95 DEG C, and at the same time, the pasteurization is simultaneously conducted to obtain the finished product. The instant potato processing method processed product is complete in color, flavor and taste, convenient and fast, short in production cycle, stable in color and luster, simple in operation, and low in production cost.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

Nutritional potato vermicelli and processing method thereof

The invention discloses an instant potato vermicelli and a making method thereof, and belongs to a pre-boiled noodle or a quickly cooked noodle food. The instant konjac vermicelli mainly comprises large potato flour, wheat flour, jade white potato flour and potato flour as main materials, and also comprises dry products of vegetables, mushrooms, fruits and meats as auxiliary materials. The making method comprises the following steps: carrying out peculiar smell removal treatment on jade white potatoes and potatoes, placing the large potato flour, wheat flour and auxiliary materials in a kneader, uniformly mixing the large potato flour, wheat flour and auxiliary materials, adding water, and uniformly stirring the obtained mixture and water to form a raw material; and sending the raw material into a self-cooking double cylinder vermicelli marker, and molding the potato vermicelli. The nutritional potato vermicelli contains various raw materials and abundant nutrients, and the diversified raw materials make the nutrient components of the raw materials complement to realize nutrition balance and improve the reasonability and the validity of food nutrient components, so the nutritional potato vermicelli plays a great role in the maintenance of the nutrition balance of human bodies and the healthiness and the long life of people.

Owner:张世禄

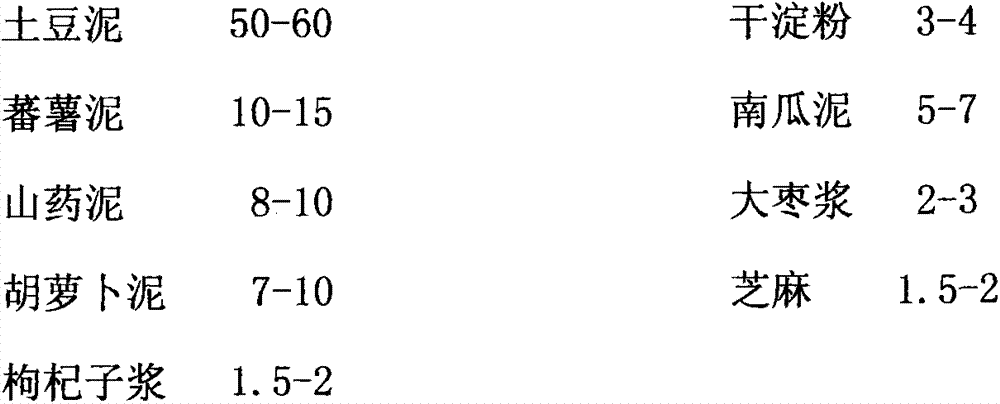

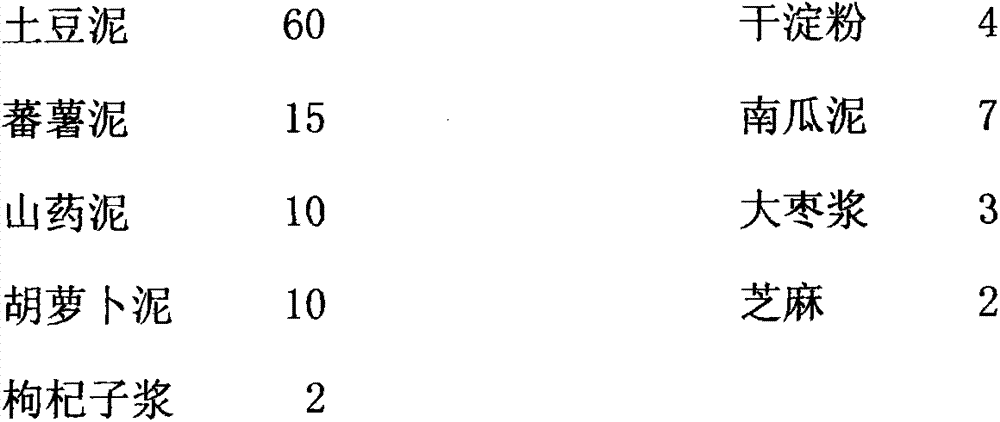

Instant potato cakes and making method thereof

The invention relates to instant potato cakes. The instant potato cakes comprise the following raw materials in parts by weight: 40-60 parts of mashed potatoes, 8-15 parts of mashed yams, 6-10 parts of mashed Chinese yams, 5-10 parts of mashed carrots, 1-2 parts of Chinese wolfberry fruit pulp, 3-5 parts of dry starch, 4-8 parts of mashed pumpkins, 1-3 parts of Chinese jujube pulp and 1-2 parts ofsesame seeds. A making method of the instant potato cakes comprises the following steps of 1, preparing raw materials; 2, mixing the prepared materials; 3, performing injection moulding and shaping;4, performing high-temperature heating for disinfection; and 5, performing bacteria-free vacuum packing. The making method is suitable for making nutritive, healthy and instant food potato cakes by using potatoes as main raw materials, and the instant potato cakes are delicious, nutritive, healthy, convenient to eat, convenient for living of people, and favorable for health of people. The use andthe sales volume of the potatoes are increased, and the making method is green and hygienic.

Owner:崔劲

Instant potato mosses and preparation method thereof

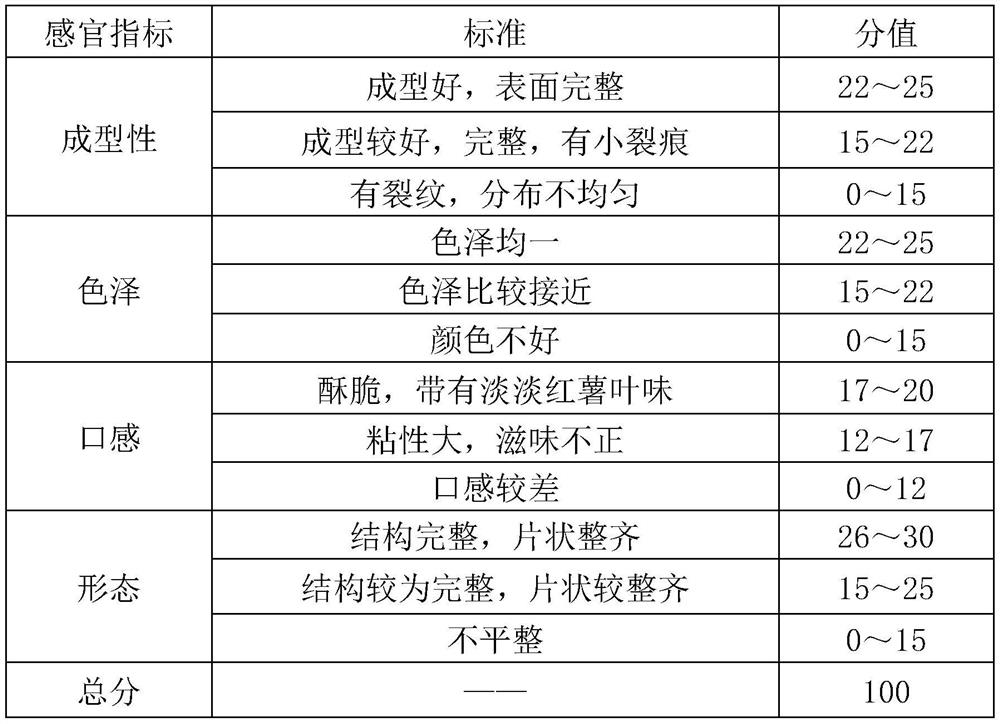

InactiveCN113331404ASolving non-stick problemsSolve the problem of sticky teethFood ingredient functionsBiotechnologyInstant potato

The invention provides instant potato mosses and a preparation method thereof. The instant potato mosses are prepared from the following raw materials in parts by weight: 100 parts of sweet potato leaves, 0.1-0.5 part of sodium alginate, 1-3 parts of edible soda, 0.3-0.8 part of white granulated sugar, 8.8-10.8 parts of fermented soy sauce, 2-10 parts of pure water and 0.7-2 parts of edible salt. The preparation method of the instant potato mosses comprises the following steps: S1, collecting; S2, selecting; S3, cleaning; S4, cutting into blocks; S5, blanching; S6, weighing; S7, stirring; S8, tabletting; S9, baking; and S10, packaging to obtain the instant potato mosses. The instant potato mosses provided by the invention are small in breeding risk, good in taste, low in cost and rich in nutrition, and the obtained product is excellent in taste, formability, color and form and does not stick to teeth.

Owner:宿州学院

A processing method of alternate α-aging and convenient instant potato noodles

The present invention discloses an alternating-type alpha gelatinization-aging processing method for an instant potato noodle. The processing method comprises the following steps: step 1, mixing and grinding 20-85 parts of mashed potato, 30-50 parts of wheat flour and 5-10 parts of protein powder calculated in parts by weight to make the fineness of the mixed powder less than 120 meshes; step 2, adding water (equivalent to 22-28% the weight of the mixed powder) into the mixed powder obtained in step 1, and then successively performing alpha gelatinization steaming, primary steaming and secondary extruding to obtain primary noodle with the temperature of the alpha gelatinization steaming of 95-105 DEG C, and the steaming time of 3-10 minutes, and the temperature of the primary steaming of 80-95 DEG C, and the steaming time of 10-30 seconds; step 3, conducting blowing and fluffing treatment on the primary noodle obtained in step 2 until the primary noodle is dispersed to obtain the instant fresh and wet noodle. The processing method enhances the instantiability, convenience and safety of potato products as staple food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Manufacturing method of instant potato zongzi

The present invention discloses a manufacturing method of instant potato zongzi. Fresh potatoes are used as a main material to wrap zongzi and a tradition of using glutinous rice as a main material toprepare the zongzi is changed. The obtained fresh potato zongzi preserves nutrient components of sweet potatoes, is rich in edible fibers, multi-vitamins, amino acids, calcium, potassium, phosphorus,magnesium and other nutrients, good in transparency, strong in glutinous property, not greasy after a long-term consumption, has effects on relaxing bowels, enriches varieties of the zongzi, gives people more choices, and is also very suitable for people with weak digestion ability or poor intestines and stomach.

Owner:饶有良

Instant potato and psyllium rice noodles and preparation method thereof

InactiveCN110839816AFully maintain nutrientsFull of nutritionFood shapingNatural extract food ingredientsBiotechnologyInstant potato

The invention provides instant potato and psyllium rice noodles. The instant potato and psyllium rice noodles are prepared from the following raw materials in parts by weight: 50-100 parts of fresh potatoes, 70-120 parts of rice, 15-25 parts of psyllium powder, 10-15 parts of a nutritional additives and 20-50 parts of water. The nutritional ingredients of the potatoes are fully maintained, the instant potato and psyllium rice noodles have the advantages of simplicity in process, good taste and rich nutrition, and the added psyllium has an effect of increasing satiety, so that weight loss can be realized.

Owner:曾四清

A kind of processing method of instant potato

ActiveCN105410765BGreat tasteStable tasteFood preservationNatural extract food ingredientsInstant potatoPasteurization

The present invention discloses an instant potato processing method which comprises the following steps: step 1, pretreating; step 2, color protecting; step 3, rinsing: the color protected raw materials are rinsed with pure water and / or traditional Chinese medicine nutrient solution to remove the color protecting liquid and / or primarily processed raw material added nutritional elements remaining on the surface of the raw materials, and the rinsing time is controlled at 0.5-1.5 hours; step four, vacuum bagging, the rinsed raw materials are packaged and evacuated and the vacuum degree is controlled at 0.05-0.2 Mpa to obtain a semi-finished product; and step five, heat sterilizing, the semi-finished product in the water is heated for 30-50 min, the temperature is controlled at 80 DEG C-95 DEG C, and at the same time, the pasteurization is simultaneously conducted to obtain the finished product. The instant potato processing method processed product is complete in color, flavor and taste, convenient and fast, short in production cycle, stable in color and luster, simple in operation, and low in production cost.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

A kind of processing method of alternating α-aging aging instant potato miscellaneous rice flour

ActiveCN104814380BFull of nutritionFlexible processing technologyFood scienceInstant potatoProcess engineering

The invention discloses a processing method of alternating α-aging-aging instant potato miscellaneous grain rice flour, which comprises the following steps: step 1, by weight parts, mixing 20-85 parts of miscellaneous grains and 15-80 parts of whole potato flour, Grinding, so that the fineness of the mixed powder is less than 120 mesh; step 2, adding water equivalent to 8-14% of the weight of the mixed powder to the mixed powder described in step 1, followed by alpha steaming, Primary steaming and secondary extrusion to obtain primary powder; step 3, the primary powder obtained in step 2 is blown and loosened until the primary powder is dispersed to obtain semi-finished powder; step 4, the semi-finished powder obtained in step 3 After one aging steaming and re-steaming in turn, the second aging steaming is carried out to obtain instant fresh wet rice noodles. The invention provides a production method of instant potato miscellaneous grain rice flour with richer nutrition and diversified taste, which has flexible processing technology, is convenient for mechanical processing, and can realize quantitative and standardized production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Making method of instant potato hot dry noodles high in resistant starch

InactiveCN109363072AReduced activityImprove digestion utilizationFood dryingFood ingredient functionsInstant potatoResistant starch

The invention discloses a making method of instant potato hot dry noodles high in resistant starch. The making method comprises the following steps of treating fresh potatoes to make mashed potatoes,mixing the mashed potatoes with high-gluten flour, treated wheat starch, treated buckwheat flour, treated oat flour, treated gordon euryale seed powder, treated taro meal, treated navy bean powder andtreated chickpea powder to obtain a mixture, adding edible salt, dietary alkali and water, and performing dough mixing; performing dough leavening, performing dough pressing, performing steam curingon the potato hot dry noodles formed through rolling, performing cooling treatment, and then performing microwave drying under reduced pressure, so that the potato hot dry noodles are obtained. Underthe premise that the flavor and the mouth feel of the potato hot dry noodles are maintained, the mashed potatoes are used as raw materials, and besides, various nutrient components are added, so thatthe content of digestion resistant starch in the potato hot dry noodles is increased, and besides, the product nutrient quality is improved. Nutrient and health care efficacy of products are given, requirements of consumers for nutrients and health of instant staple food products are met, and besides, the cost of the raw materials can be reduced.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

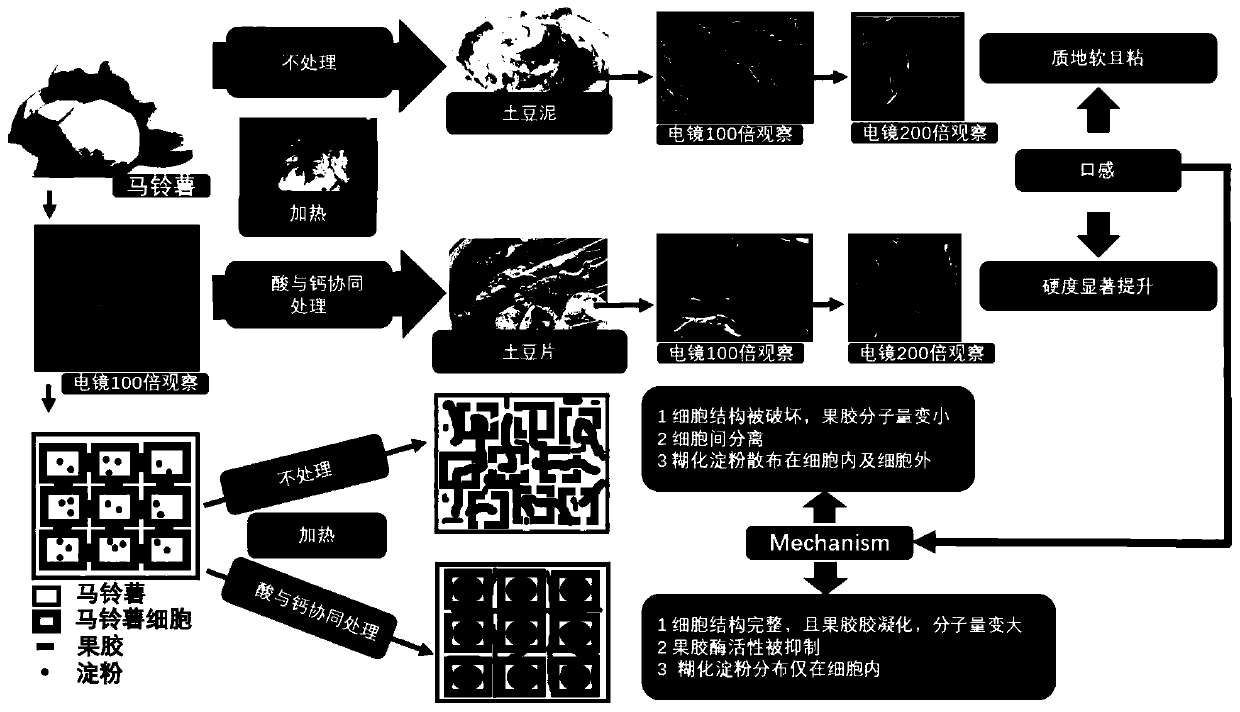

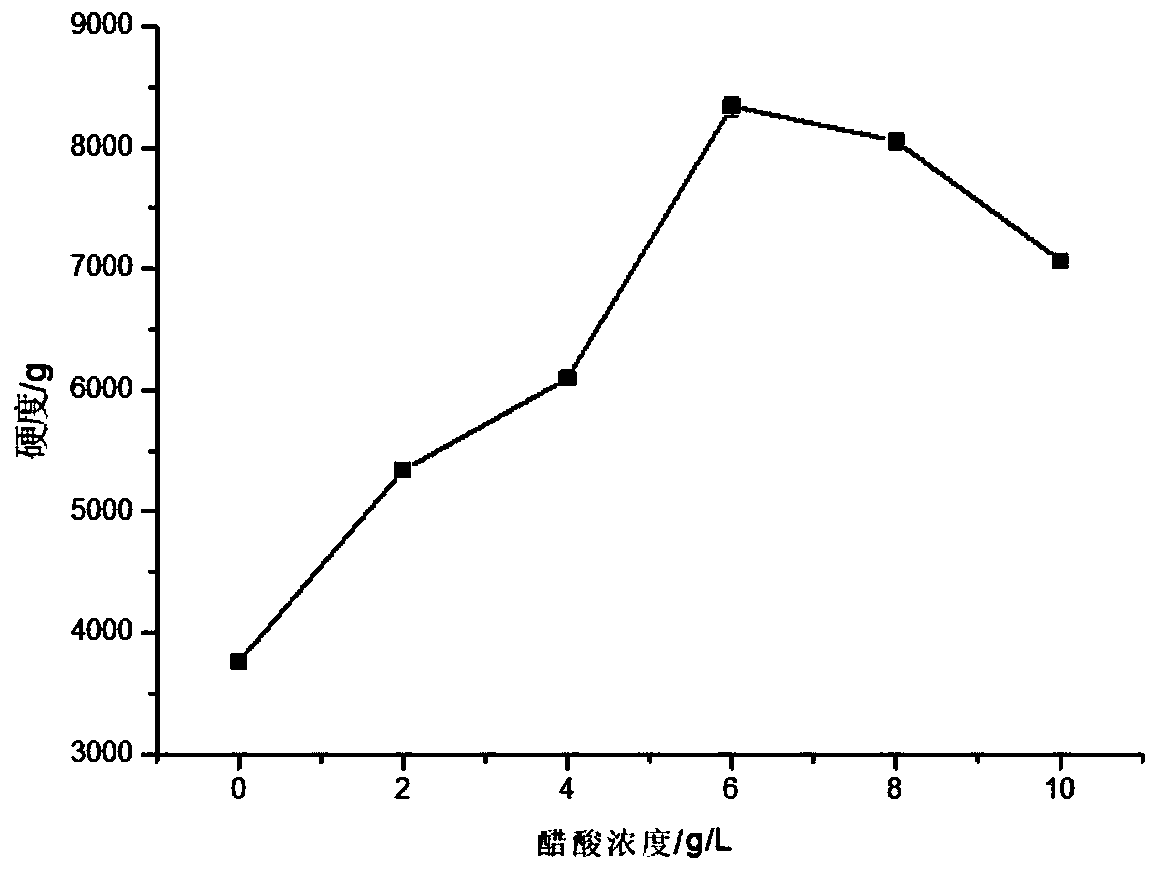

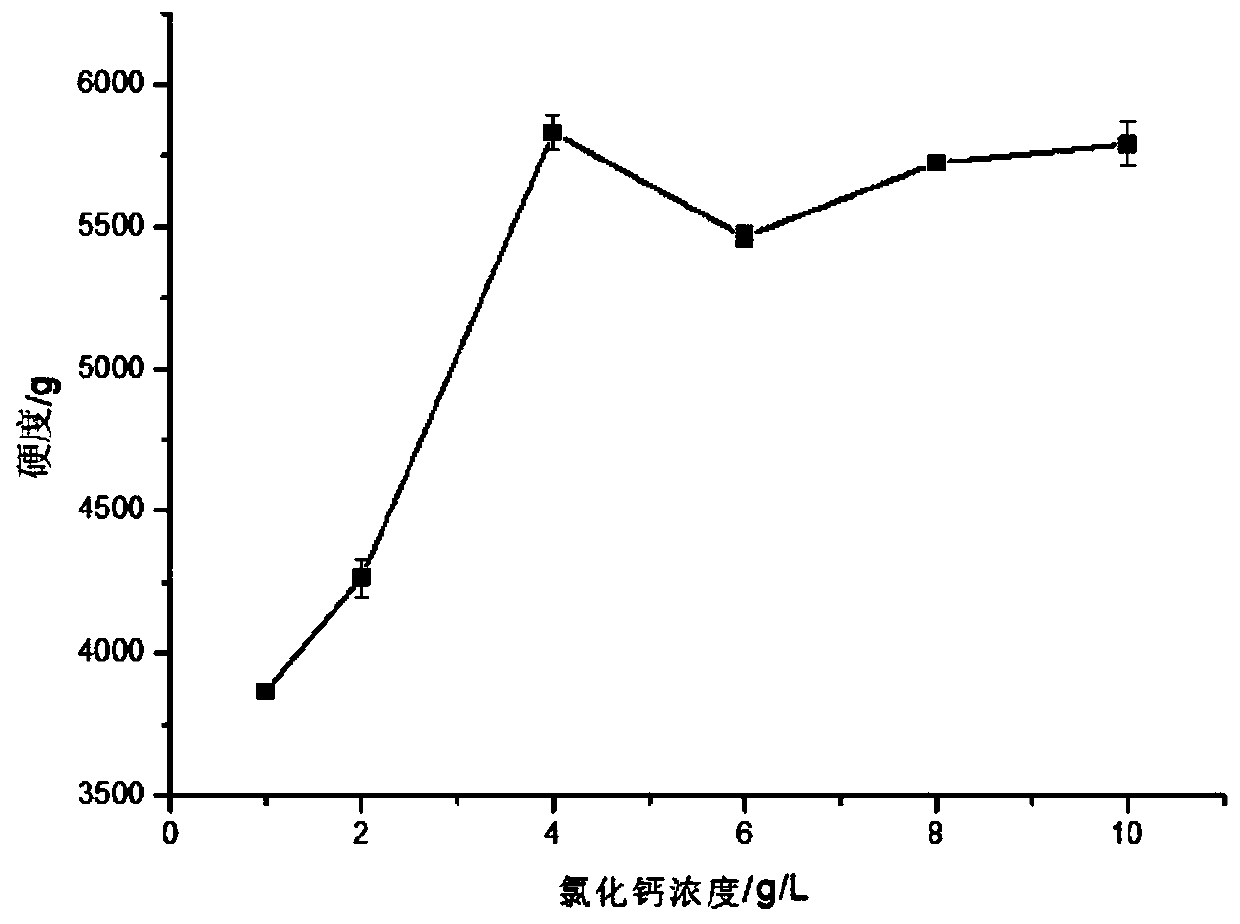

Hardness improving soaking agent and soaking treatment method for fresh-cut potatoes

InactiveCN110074180AImprove textural propertiesHigh hardnessFruit and vegetables preservationInstant potatoHardness

The invention discloses a hardness improving soaking agent and a soaking treatment method for fresh-cut potatoes. The soaking agent comprises an aqueous solution of an acid and a calcium salt. The inventors of the invention find that the synergistic treatment of potatoes with acid and calcium salt can improve the texture properties of the potatoes, improve the hardness of the fresh-cut potatoes after cooking; the mechanism is studied. By the experiments, types of the acid and calcium salt, and the best process formula are obtained, the problem of poor texture properties of the fresh-cut potatoes after cooking is solved, and a pre-treatment scheme is provided for the processing, storage and preservation of flavored instant potato chips.

Owner:ZUNYI NORMAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com