Instant potato processing method

A processing method and raw material technology, applied in the field of instant potato processing, can solve the problems of food safety issues that need to be verified, the loss of fresh nutrition is not large, and the loss of nutrients, so as to reduce direct contact and secondary pollution, and facilitate digestion , Long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

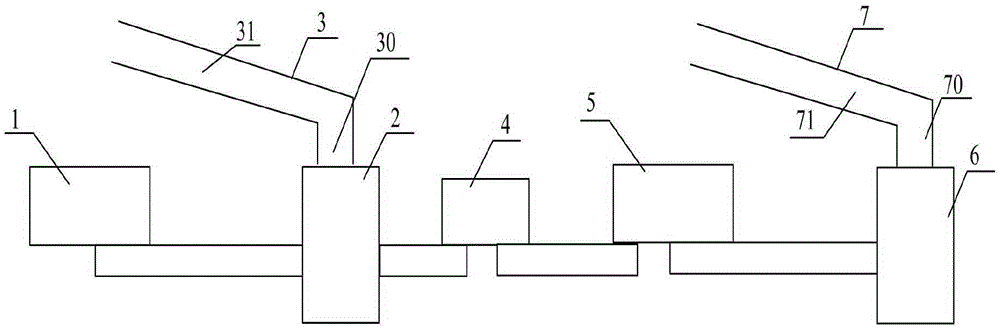

[0060] The processing method of instant potato is as follows:

[0061] Step 1, preprocessing

[0062] Fresh potatoes are graded and accepted according to the requirements of processing special varieties, and fresh potatoes with rotten and insect eyes are removed. It is best to select fresh potatoes with uniform size, smooth skin, no insect eyes, and no rotten scars, and then wash them with a squirrel cage potato washing machine. The surface of the fresh potatoes is silt, and the uncleaned ones are picked out and returned to the previous cleaning process, and the cleaned fresh potatoes are sent to the steam peeling machine, steam peeled for 2 minutes under the steam pressure of 0.5MPa, and the peeled potatoes are peeled again. The finished fresh potatoes are transported to the potato washing machine for cleaning, and then transported to the selection platform to remove the fresh potatoes and impurities that cannot enter the next process, such as those with insect eyes and rot, ...

Embodiment 2

[0072] The processing method of instant potato is as follows:

[0073] Step 1, preprocessing

[0074] Fresh potatoes are graded and accepted according to the requirements of processing special varieties, and fresh potatoes with rotten and insect eyes are removed. It is best to select fresh potatoes with uniform size, smooth skin, no insect eyes, and no rotten scars, and then wash them with a squirrel cage potato washing machine. The surface of the fresh potatoes is silt, and the uncleaned ones are picked out and returned to the previous cleaning process, and the cleaned fresh potatoes are sent to the steam peeling machine, steam peeled under the steam pressure of 0.5MPa for 5 minutes, and the peeled potatoes are peeled again. The final fresh potatoes are transported to the potato washing machine for cleaning, and then transported to the selection platform to remove the fresh potatoes and impurities that cannot enter the next process such as worm eyes and rot, and pick out the fr...

Embodiment 3

[0084] The processing method of instant potato is as follows:

[0085] Step 1, preprocessing

[0086] Fresh potatoes are graded and accepted according to the requirements of processing special varieties, and fresh potatoes with rotten and insect eyes are removed. It is best to select fresh potatoes with uniform size, smooth skin, no insect eyes, and no rotten scars, and then wash them with a squirrel cage potato washing machine. The surface of the fresh potatoes is silt, and the uncleaned ones are picked out and returned to the previous cleaning process, and the cleaned fresh potatoes are sent to the steam peeling machine, steam peeled under the steam pressure of 0.8MPa for 3 minutes, and the peeled potatoes are peeled again. The final fresh potatoes are transported to the potato washing machine for cleaning, and then transported to the selection platform to remove the fresh potatoes and impurities that cannot enter the next process such as worm eyes and rot, and pick out the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com