Patents

Literature

97results about How to "Improve textural properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano fishbone product as well as preparation method and application of nano fishbone product

ActiveCN103689664AAvoid problems such as corruptionAvoid uneven particle sizeFood preparationEmulsionHigh energy

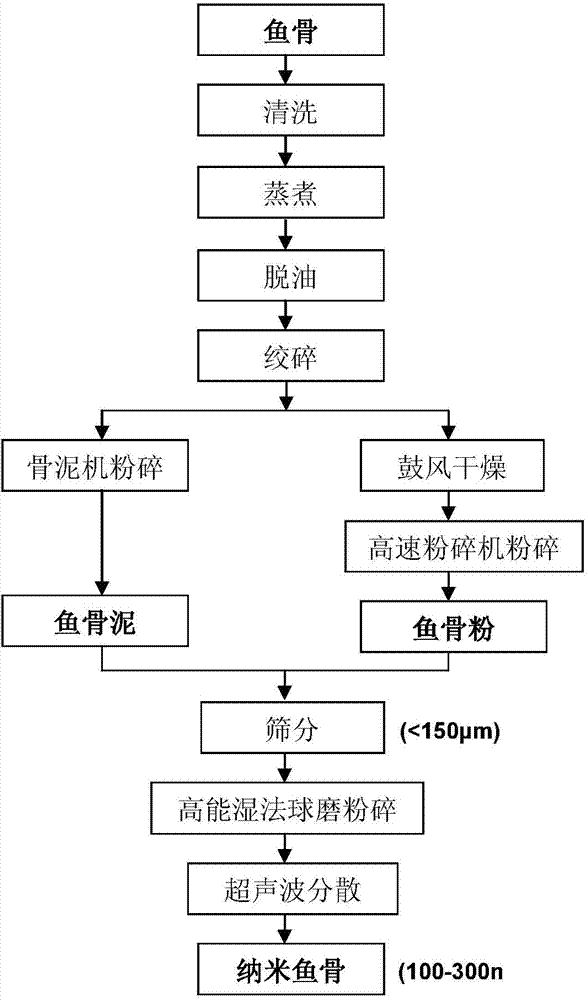

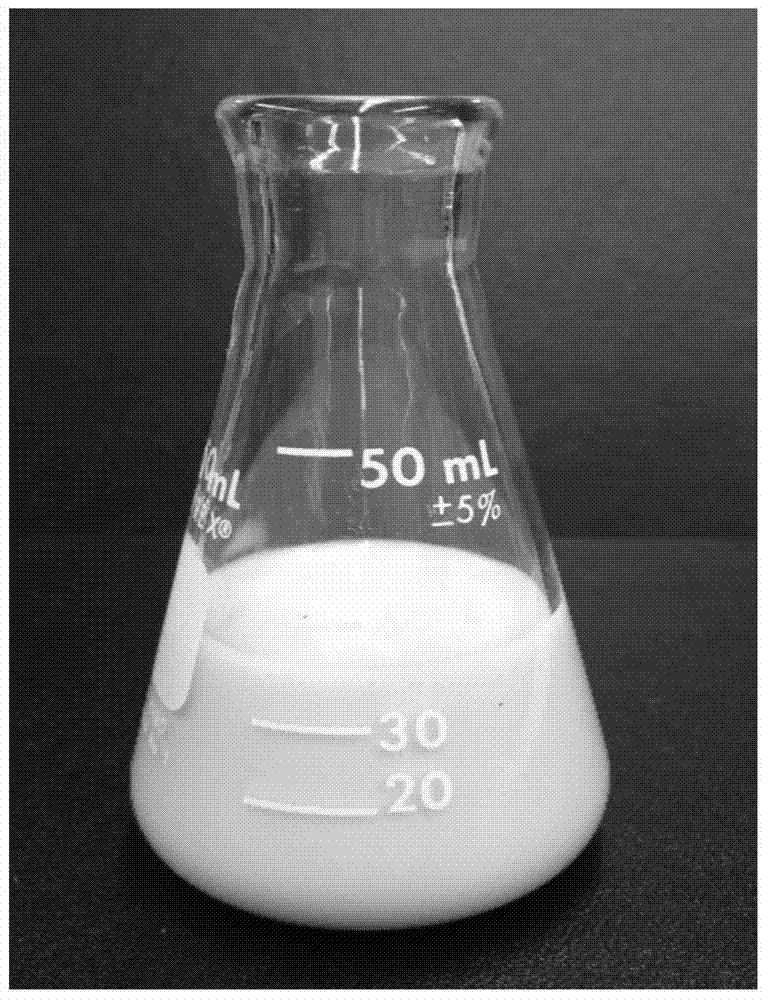

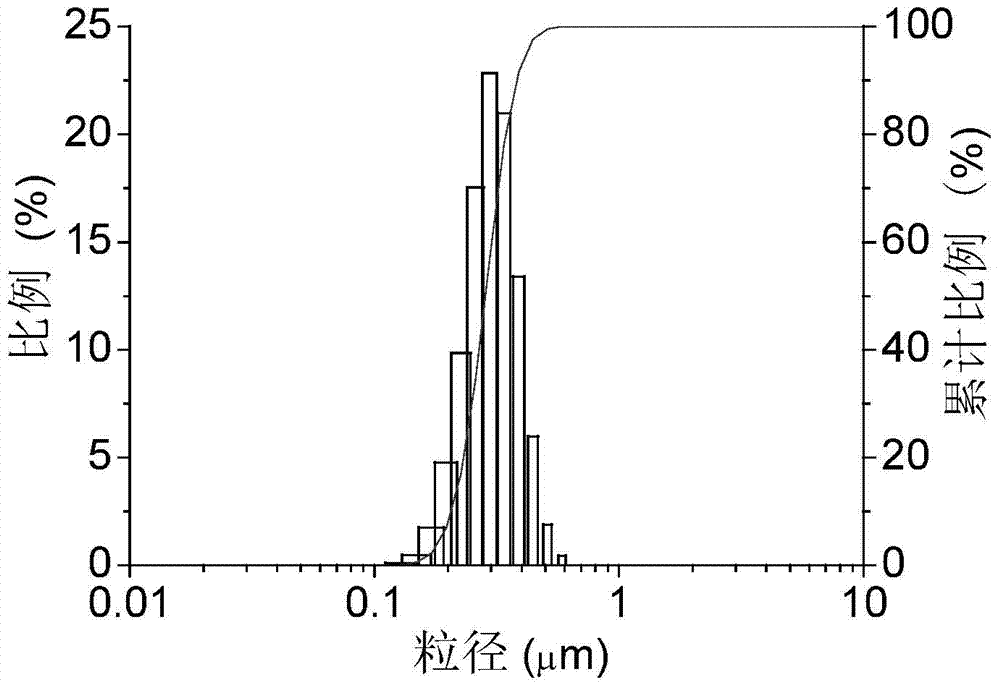

The invention discloses a nano fishbone product as well as a preparation method and application of the nano fishbone product, and belongs to the field of functional food. The preparation method of the nano fishbone product comprises the following steps of immersing cleaned fishbones in proper amount of water, stewing and softening the fishbones in a high-pressure digester, pouring out stewing liquid, adding water and rinsing, and draining off; breaking the fishbones with a meat grinder with the screen plate pore diameter of 2-10mm, drying, carrying out coarse grinding, and sieving by a 140-mesh sample separation sieve, thereby obtaining fishbone powder or fishbone paste with the particle size of less than 105 microns; and adding water into the fishbone powder or fishbone paste, regulating the water content of a dispersion liquid to 60-90%, and grinding by a high-energy ball mill at the speed of 2,000-3,000 rpm for 0.5-2 hours, wherein the size of the grinding medium is 0.5-5cm, and the filling content of the medium reaches 60%-80%. The nano fishbone product provided by the invention is emulsion which has no fishy smell, has the fishbone particle diameter of 100-300nm and has the calcium content of 30-50mg / g; the nano fishbone can be stably dispersed into the emulsion, has no gravel sense, and can be used for enhancing calcium in minced fish products and improving the texture property of the minced fish products.

Owner:湖北土老憨生态农业科技股份有限公司

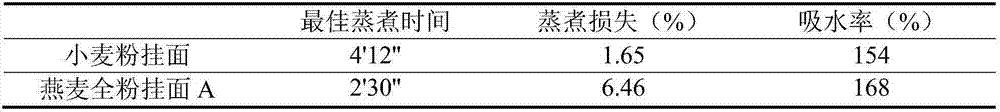

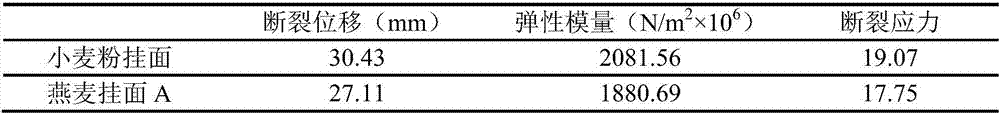

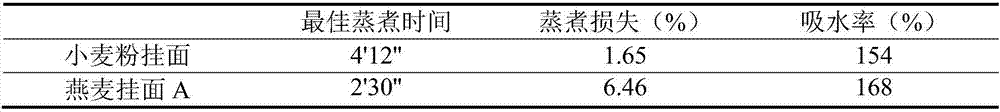

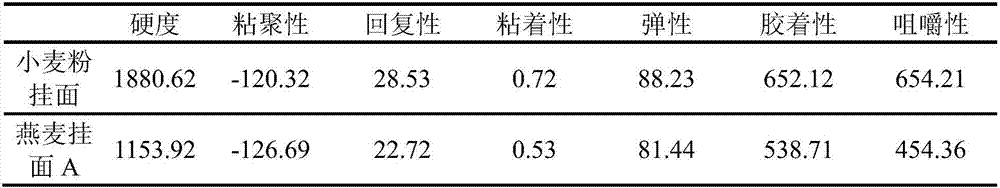

Whole-oat hypolipidemic functional fine dried noodle and production method thereof

InactiveCN106858316AIncrease the amount addedImprove digestion and absorption rateFood preservationInorganic compound food ingredientsSecondary hyperlipidemiaGluten

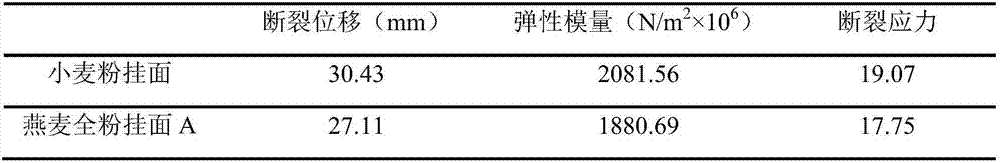

The invention provides a whole-oat hypolipidemic functional fine dried noodle and a production method thereof. According to the invention, the preprocessed whole oat flour is acquired according to the steps of preparing flour, stabilizing, pre-curing and finely smashing, and then the technologies, such as, formulation optimization, vacuum dough kneading and special rolling, are adopted for increasing the oat additive amount while guaranteeing the organoleptic quality of the fine dried noodle. The oat functional fine dried noodle is prepared from the following raw materials in parts by weight: 10-100 parts of preprocessed whole oat flour, 0-90 parts of wheat flour, 0-10 parts of high-activity gluten powder, 1-3 parts of salt, 0-3 parts of edible glue, 0-3 parts of soda and 0-3 parts of additional starch. According to the invention, under the condition of adding no any additives, 100% oat functional fine dried noodle product is produced, the quality is natural, the functional fine dried noodle belongs to dietary nutrition healthy food and has more obvious effects of reducing blood fat and restraining fat and an excellent staple food choice is supplied for the hyperlipidemia and obese patients.

Owner:KEMEN NOODLE MFG CO LTD

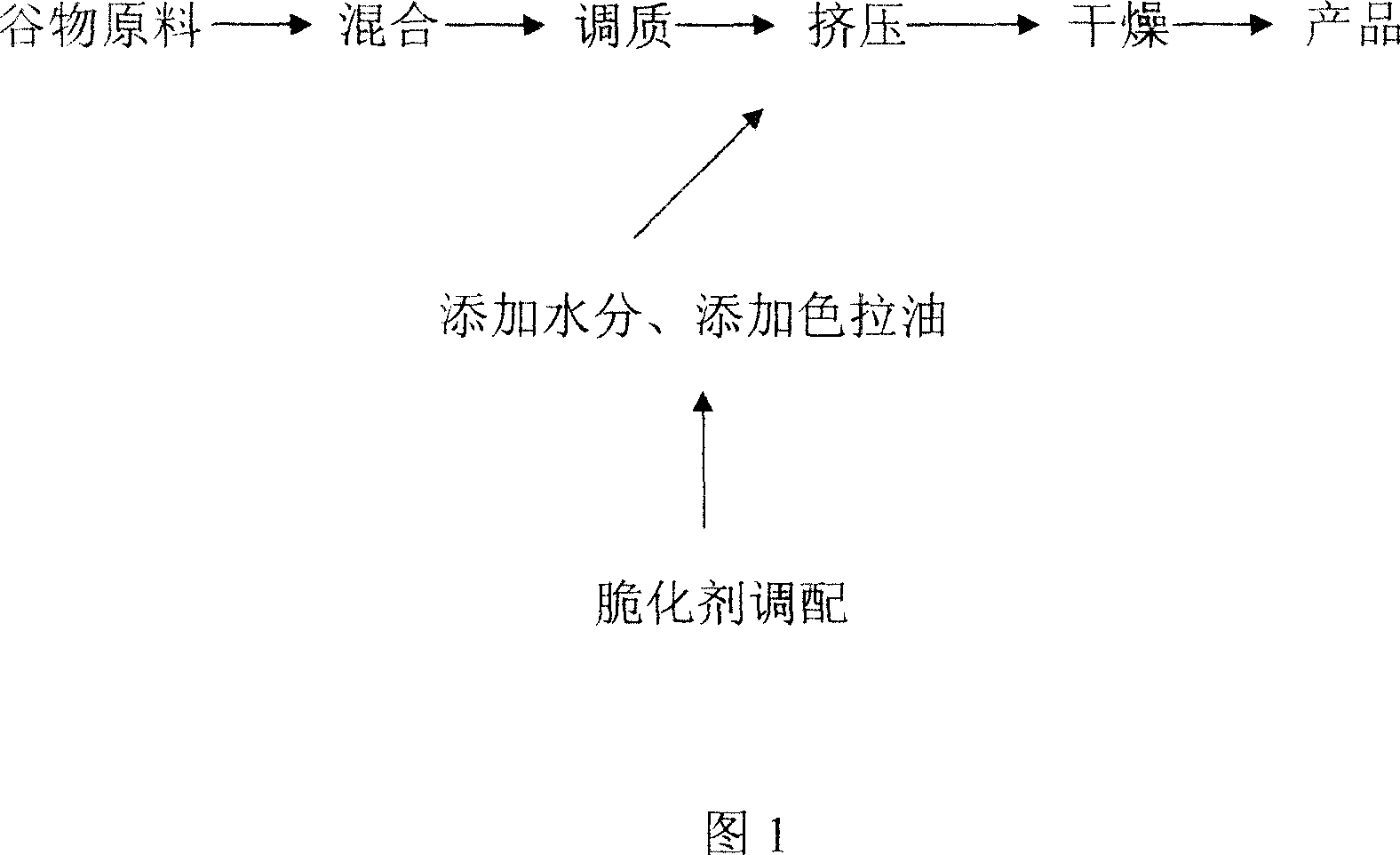

Method for producing breakfast food of slice shaped grain with excellent crisp property

InactiveCN100998386AImprove textural propertiesGood chewingFood preparationAdditive ingredientCow milk

Owner:JIANGNAN UNIV

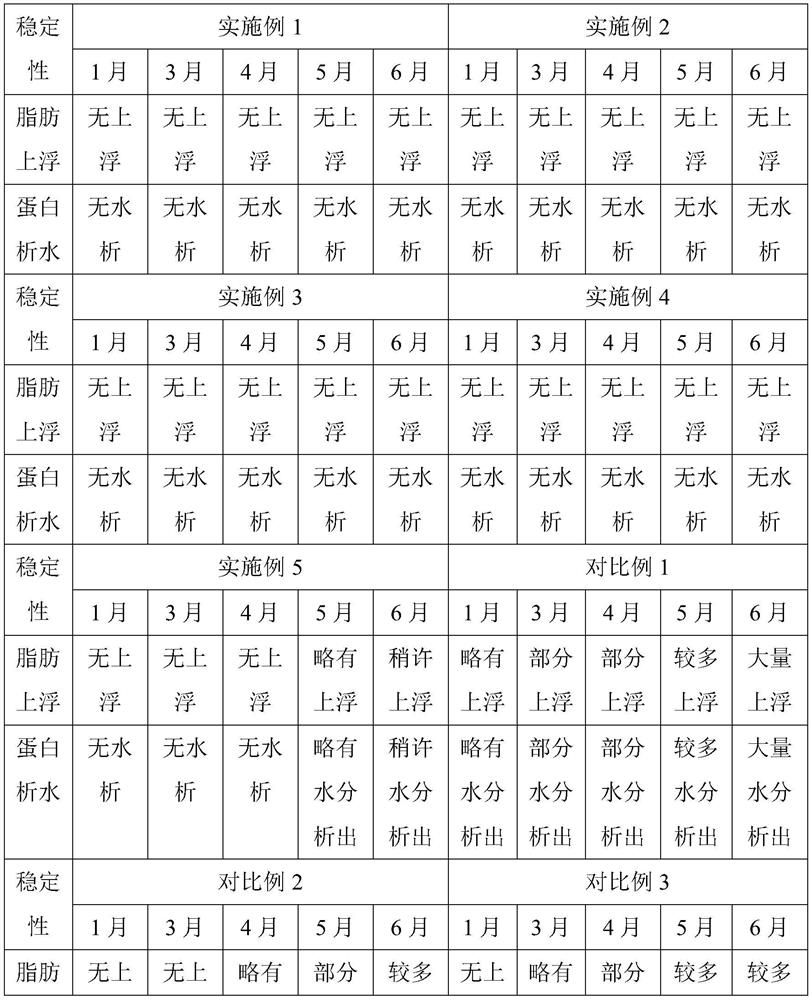

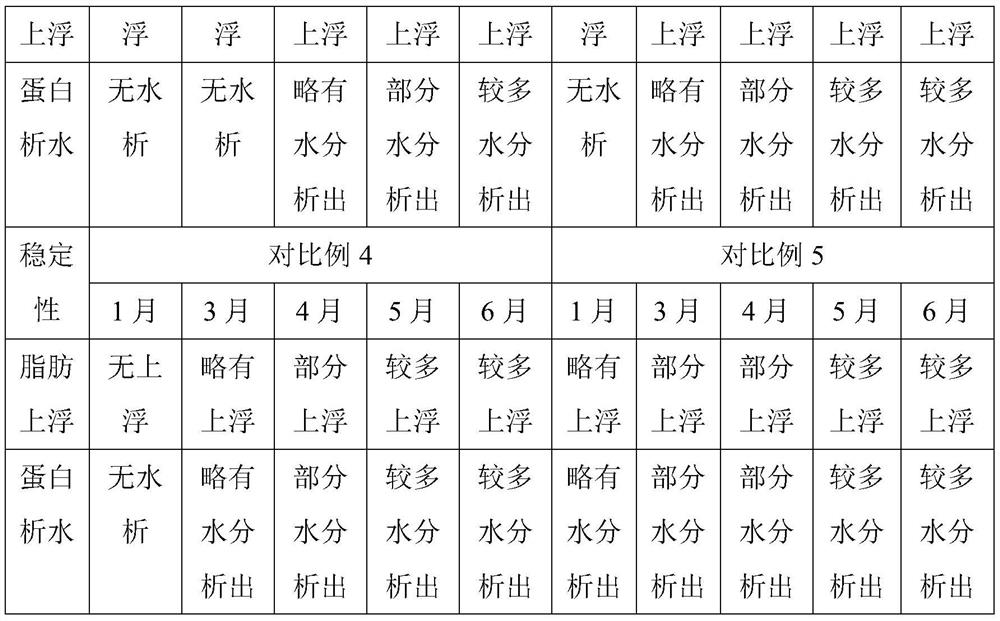

Plant-based fermented yoghourt and preparation method thereof

ActiveCN111919892AImprove textural propertiesImprove product qualityMilk preservationMilk substitutesBiotechnologyGellan gum

The invention relates to the field of yoghourt preparation, and particularly discloses plant-based fermented yoghourt and a preparation method thereof. The preparation method comprises the following steps of: primary burdening: a plant-based slurry is obtained after a plant fermentation base material is ground into thick liquid, a stabilizer A and a sweetening agent are added, and even mixing is conducted; pre-sterilization; fermentation; secondary burdening: a dissolved stabilizer B and a sweetening agent are added into the fermented fermentation liquor; acidity regulation; secondary sterilization; cooling; and packaging. The stabilizer A is prepared from the following raw materials: modified starch, agar, gellan gum and diacetyl tartaric acid ester of mono(di)glycerides; and the stabilizer B is selected from high-ester pectin. The invention also discloses the plant-based fermented yoghourt prepared by the preparation method. The pure plant-based fermented yoghourt has the advantagesthat the pure plant-based fermented yoghourt is provided, the obtained yoghourt is stored at normal temperature, the shelf life is prolonged to 6 months, the stability in the shelf life is guaranteed,the product quality is improved, and the blank of long shelf life of the current plant yoghourt at normal temperature is filled.

Owner:北京再益生物科技有限公司

Preparation method of coarse rice whole grain texture rice

InactiveCN102599411AImprove textural propertiesGood quality and stabilityFood preparationChemistryRelative humidity

The invention relates to a preparation method of coarse rice whole grain texture rice. A single screw extruder is adopted, and an improved extrusion technology is applied, so that coarse rice powder forms gel under the conditions of low temperature and high pressure, wherein the improved extrusion conditions are as follows: mixing and preheating are carried out in a first region at the temperature of 40-60 DEG C, extrusion transportation is carried out in a second region at the temperature of 50-70 DEG C, pregelatinization is carried out in a third region at the temperature of 95-115 DEG C, gelatinizing and cutting are carried out in a fourth region at the temperature of 75-95 DEG C and high pressure fusing is carried out in a fifth region at the temperature of 65-85 DEG C, and the rotating speed of a screw is 16-18rpm; cutting is carried out by virtue of a rotary cutter, pelletizing is carried out again, aging is carried out for 3-5 hours in a constant temperature constant humidity environment with the temperature of 35 minus or plus 5 DEG C and the relative humidity of 80+ / -5%, then drying is carried out at the temperature of 40-60 DEG C until the moisture content of the whole grain texture rice is 12-13%.edible quality of the prepared whole grain texture rice is greatly improved compared with the coarse rice raw material, the whole grain texture rice has good taste similar to high milled rice, and the storage stability of the whole grain texture rice is obviously improved compared with the coarse rice raw material.

Owner:NANCHANG UNIV

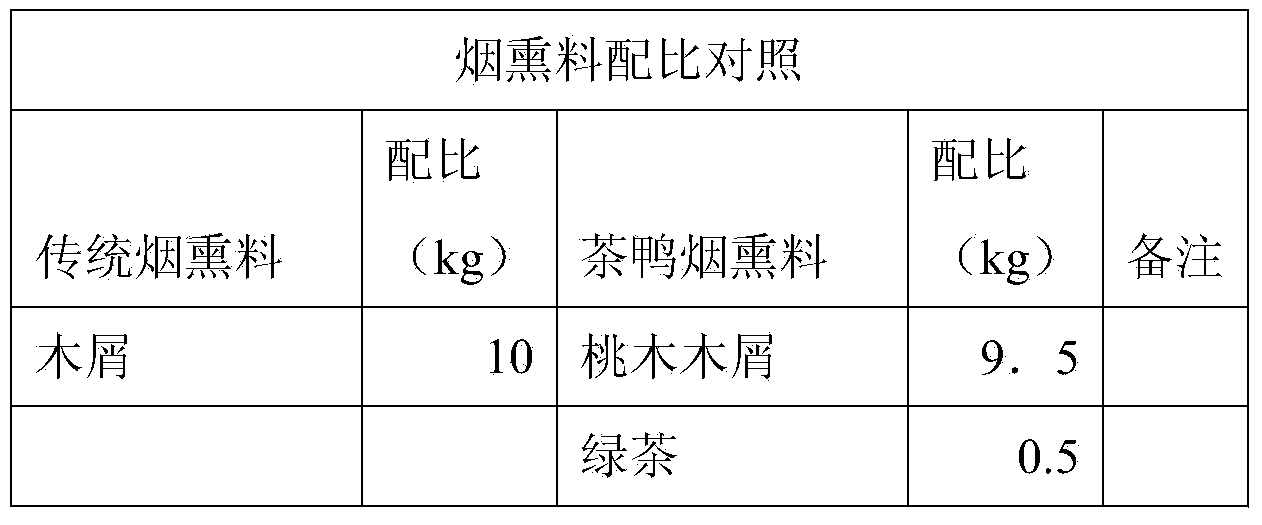

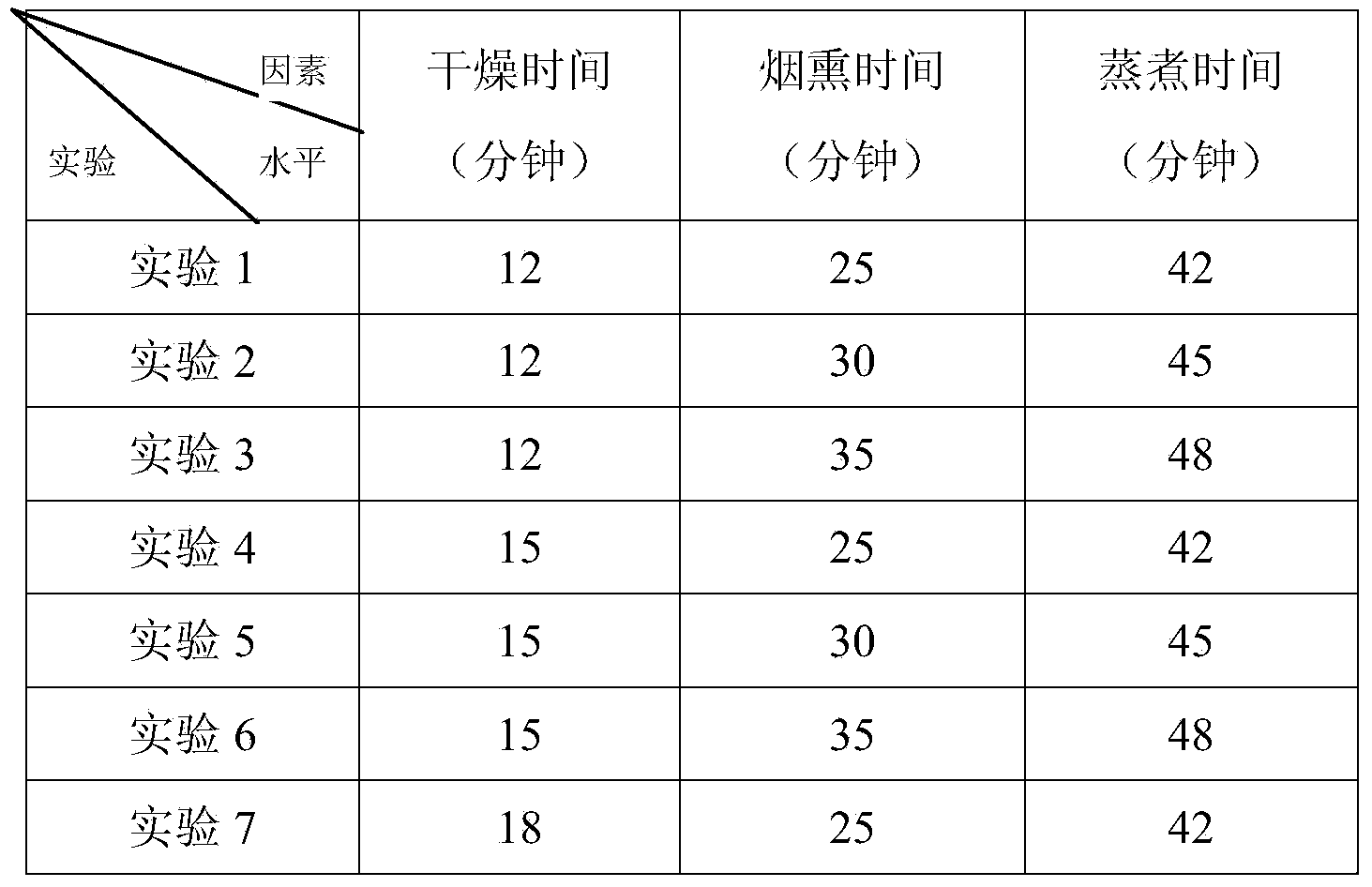

Production method of tea flavor type boiled salted duck

ActiveCN104223158AOvercome the defects of too heavy bottom flavor and insufficient flavorReduce churnFood ingredient as taste affecting agentFood ingredient as flavour affecting agentChemistryFlavor

The invention discloses a production method of a tea flavor type boiled salted duck. The method comprises the following steps: by taking a clean duck as a raw material, adding materials, namely white granulated sugar, table salt, anises and the like; and carrying out steps of dryly pickling, marinating again, smudging and cooking to obtain the tea flavor type boiled salted duck. The produced boiled salted duck has the characteristics of stable color and luster, light tea faint scent and compact tissues and the like due to a unique production process; and phenomena of a traditional sauce marinating process that salt and color are not stable, and the mouth feel and the tissues are diverged are avoided.

Owner:NANJING CHERRY DUCK IND

Method for producing bound trotters through artificial inoculation and fermentation

InactiveCN104997042AUnique flavorQuality improvementFood ingredient functionsFood preparationNutritive valuesReady to eat

The invention discloses a method for producing bound trotters through artificial inoculation and fermentation, and belongs to the technical field of food processing. The method comprises the following steps: preparing trotter skin; pretreating raw materials; pickling the pretreated raw materials at a low temperature; rolling and kneading the pickled raw materials; inoculating and fermenting the kneaded raw materials; encrusting the fermented raw materials, and bundling up the encrusted raw materials; marinating the bundled raw materials; cooling the marinated raw materials, and vacuum packing the cooled raw materials; and sterilizing the packed raw materials at high pressure, cooling the sterilized raw materials, packing the cooled raw materials in boxes, and warehousing the boxes. According to the method disclosed by the invention, a conventional processing method is combined with a microorganism fermentation technique, mixed bacteria species of bulgaricus milk bacillus, saccharomyces cerevisia or bulgaricus milk bacillus and staphylococcus carnosus are used for fermentation in a bacteria species mixing manner, so that a novel and convenient ready-to-eat health food is provided for society. The bound trotters processed by the method disclosed by the invention are unique in special flavor, deep red in color, loose in meat quality, high in nutrient value, easy to preserve, stable in quality, and high in edible safety, and effectively reduce the content of nitrite.

Owner:XUZHOU UNIV OF TECH

Production method of whole oat flour and production method of noodle preblending powder from whole oat flour

InactiveCN106942605AIncrease the amount addedImprove digestion and absorption rateFood ingredient as mouthfeel improving agentBlood sugarPolyphenol

The invention provides a production method of whole oat flour and a production method of noodle preblending powder from whole oat flour, and belongs to the field of processing of grains. The production method comprises the following steps of cleaning oat raw materials; preparing the whole oat flour; performing stabilization on the whole oat flour; precooking the stabilized whole oat flour; performing superfine comminution on the precooked whole oat flour so as to prepare the finished products of the whole oat flour; mixing the prepared whole oat flour with wheat flour, vital wheat gluten and the like to make preblending powder, wherein the formula of the preblending powder comprises the following components in parts by weight: 10-100 parts of pretreatment whole oat flour, 0-90 parts of wheat flour, 0-10 parts of high-activity gluten flour, and 0-3 parts of exogenous starch. The made whole oat flour and the preblending powder thereof completely reserve nutrient components of beta-glucan, pentosan, resistant starch, a dietary fiber polyphenol compound and the like in oat. The prepared whole oat flour and the preblending powder can be directly made into functional noodles with high whole oat flour content and other flour products under the condition that any additives are not added. The whole oat flour and the noodle preblending powder have the effects of reducing blood sugar and reducing blood fat.

Owner:KEMEN NOODLE MFG CO LTD

Processing method for quick-frozen fruit and vegetable slices

The invention discloses a processing method for quick-frozen fruit and vegetable slices. The processing method comprises the steps of raw material selection, cleaning, enzyme deactivation, slicing, quick freezing and packaging, wherein the enzyme deactivation is realized by a pulse magnetic field; the slicing is realized by high-pressure water cutting. According to the processing method, by the adoption of a non thermal treatment technology, the enzyme deactivation is realized by the pulse magnetic field, and the slicing is realized by high-pressure water cutting; therefore, the processed quick-frozen fruit and vegetable slices are higher in quality, and the processing efficiency is higher.

Owner:长沙星达知识产权服务有限公司

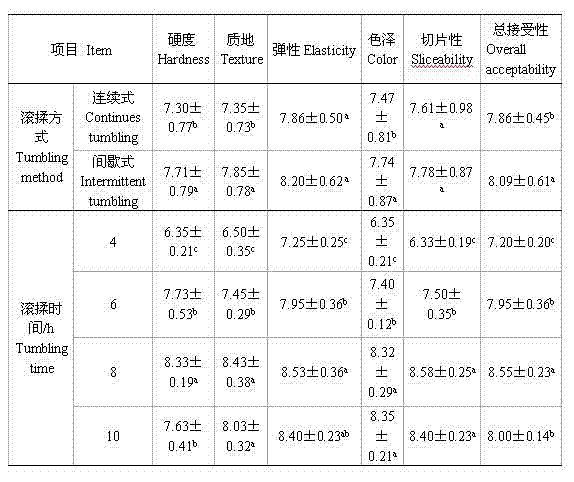

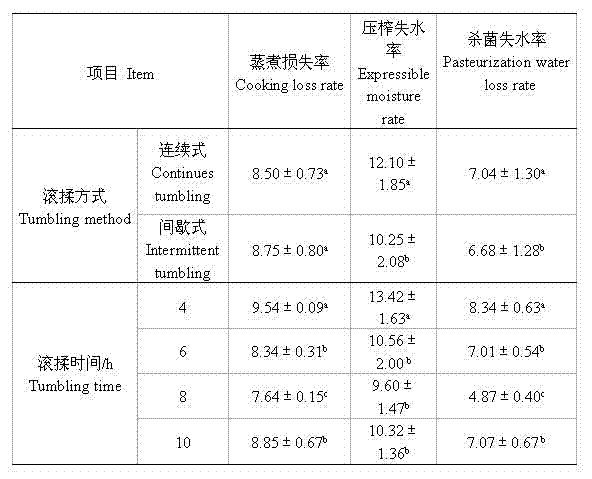

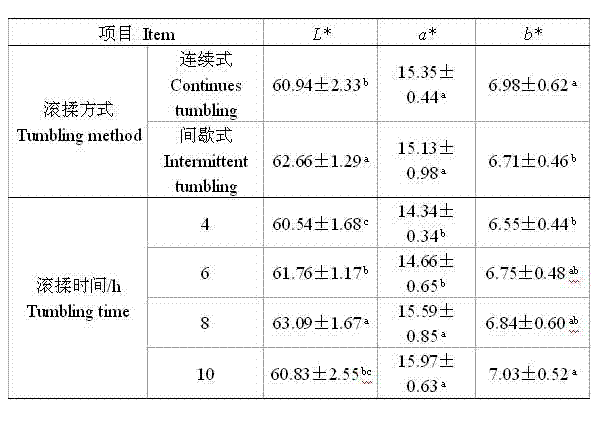

Processing method for improving quality of pork sliced ham

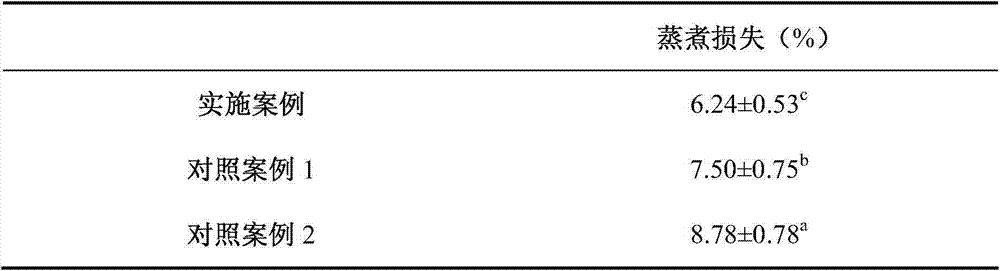

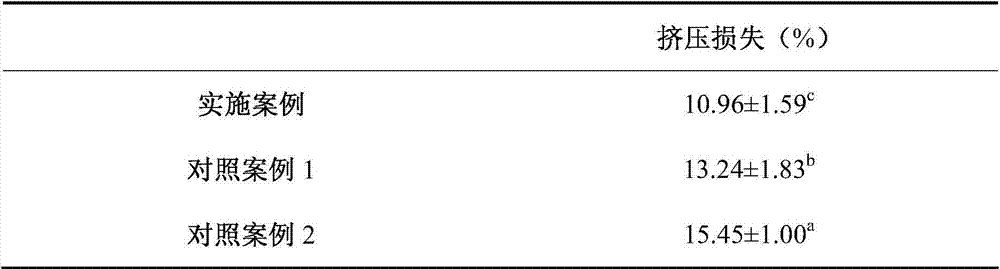

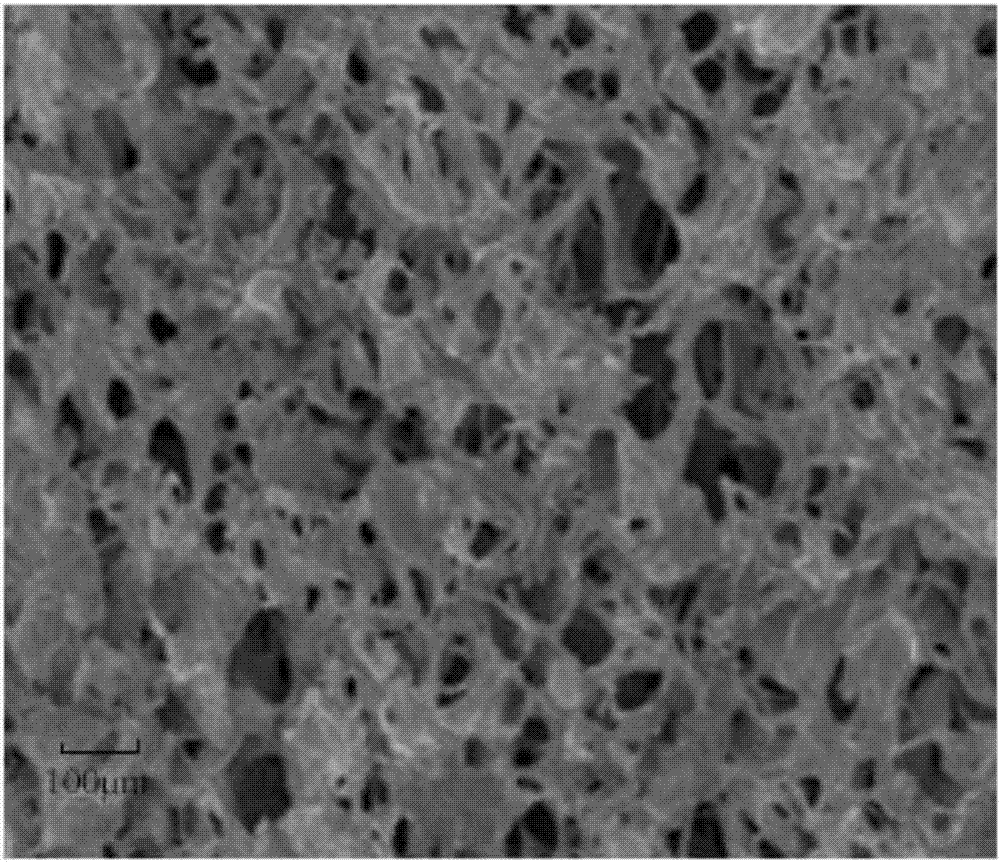

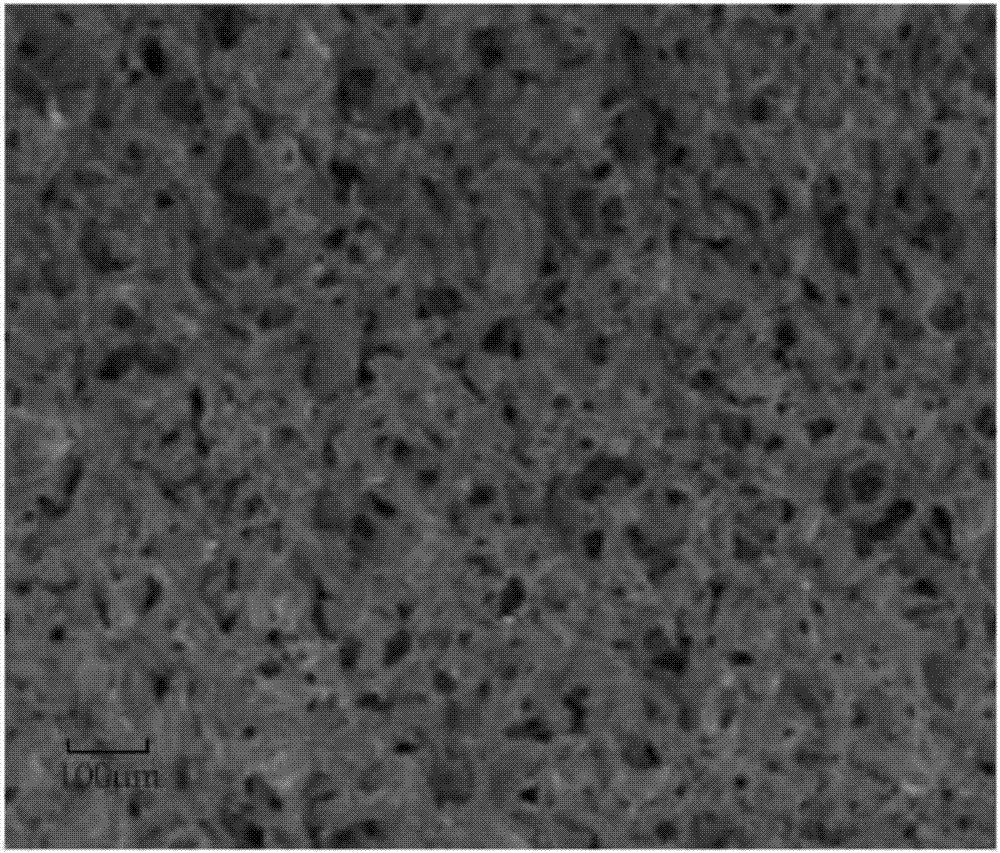

InactiveCN102754840AImprove textural propertiesFully efficient distributionFood preparationLoss rateDissolution

The invention discloses a processing method for improving quality of pork sliced ham. The processing method is characterized by comprising the steps of: thawing freezing-stored pork hindquarter, cutting, trimming, injecting, tenderizing, interval-tumbling for 6-10h, canning, smudging, steaming and cooking, cooling, slicing and vacuum-packaging. The pork sliced ham prepared by adopting the processing method has the characteristics of little steaming and cooking loss, small squeezing water loss rate and sterilization water loss rate, and good water holding capacity; and because the interval-tumbling process is carried out by adopting an aspiration tumbling mode under the conditions that meat loaves are in a vacuum state for a long time in a tumbling stage and a vacuum pump vacuumizes at intervals in a suspending stage, a preserving solution is more completely and effectively distributed in a muscle structure to be beneficial to the dissolution of salt soluble protein. Compared with the continuous tumbling mode, the interval-tumbling mode has the advantages that more salt soluble protein is generated, so that the binding among the meat loaves is facilitated; and during thermal processing, a stable protein gel structure is formed, thus the texture of the ham is improved.

Owner:NANJING YURUN FOOD

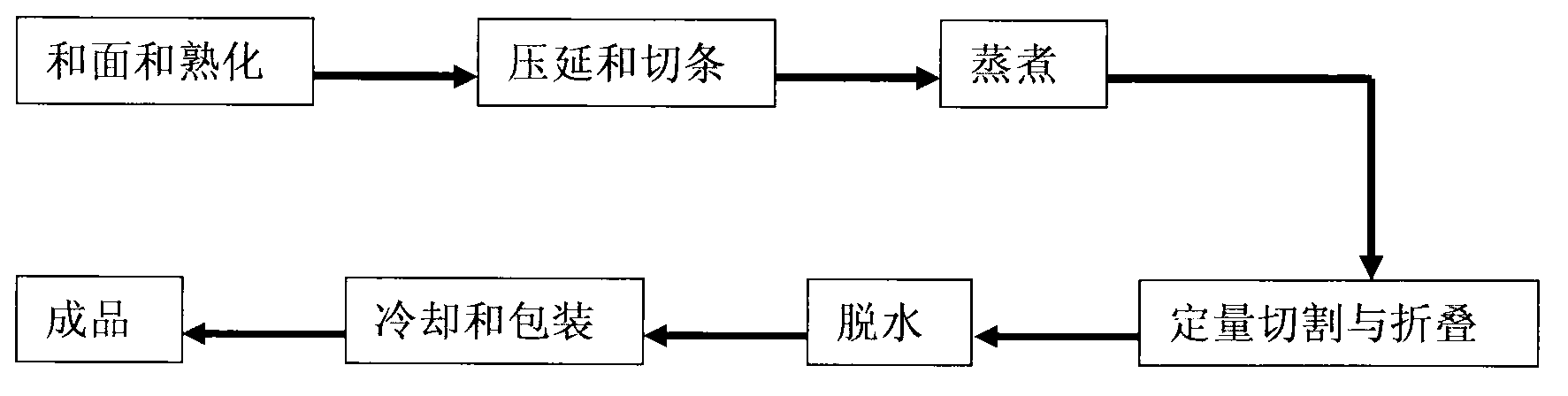

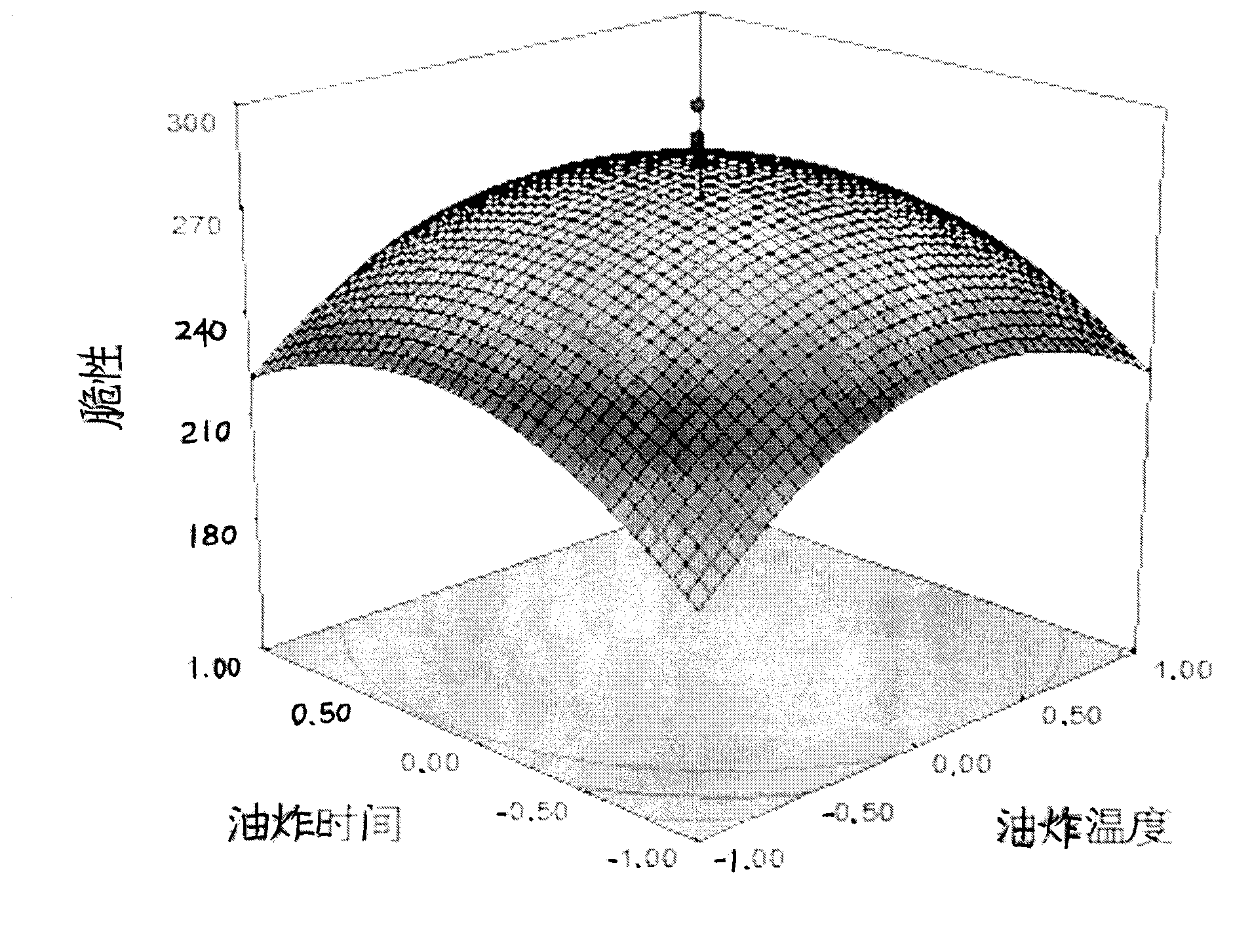

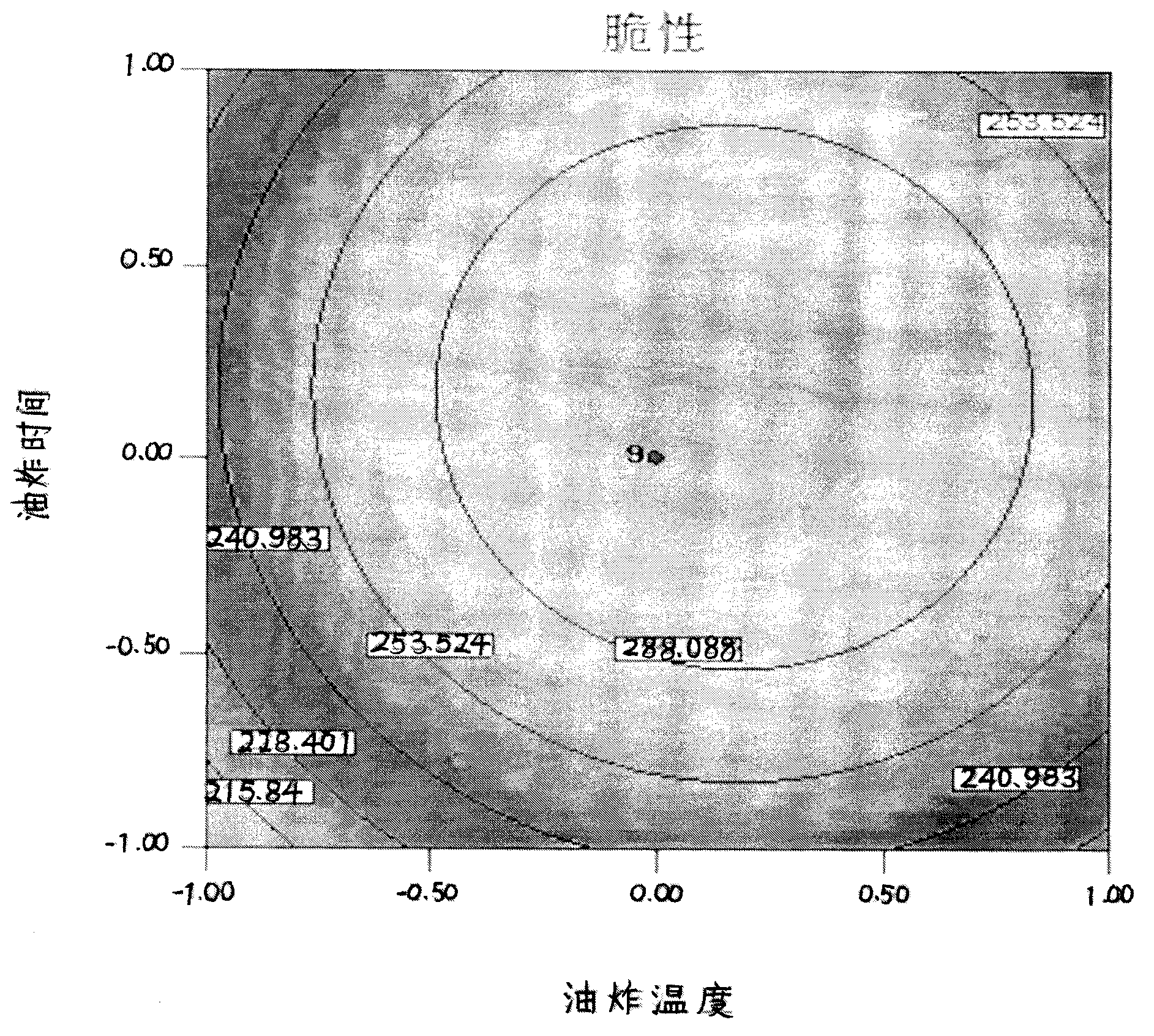

Preparation method of fried instant noodle with good brittleness and good brittleness keeping performance

InactiveCN103284071AGreat tasteImprove textural propertiesFood preparationUniform designSolid density

The invention discloses a preparation method of fried instant noodle with good brittleness and good brittleness keeping performance. The preparation method disclosed by the invention comprises the following steps of: selecting factors which obviously influence the texture of the fried instant noodle by the uniform design, researching the influence of each factor to the texture indexes of the fried instant noodle, such as the WAI (work ability index), the WSI, the volume density and the solid density, by a single factor experiment, confirming the values of the factors, and confirming the optimum preparation technology of the fried instant noodle through the response surface analysis. The brittleness and the brittleness keeping performance are taken as the indexes, and the optimum technology parameters are as follows: the frying temperature is 148 DEG C, the frying time is 62s, the water content is 50%, and the salt content is 1.8%. The preparation method disclosed by the invention can quickly and simply test the brittleness and the brittleness keeping performance of the processed instant noodle, and the fried instant noodle with good brittleness and good brittleness keeping performance processed by the preparation method has a wide and practical value.

Owner:XINJIANG UNIVERSITY

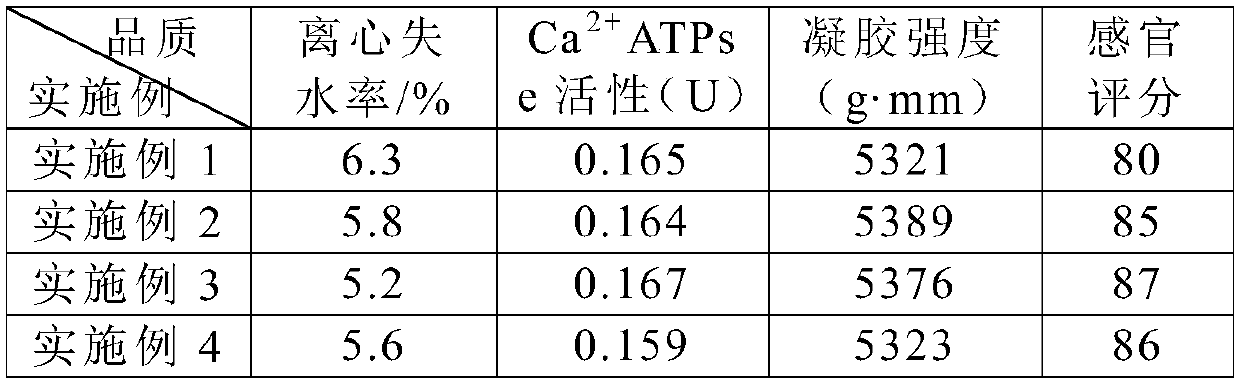

Method for improving texture properties of emulsified sausages at ultrahigh pressure

The invention discloses a method for improving the texture properties of emulsified sausages at an ultrahigh pressure. The method is composed of the following steps: removing the fats and fascia of raw meat, grinding by a meat grinder, and performing an ultrahigh-pressure treatment in certain conditions; mixing and chopping the samples after being subject to the ultrahigh-pressure treatment with salt, fats and ice water in a ratio, placing the mixture in a sausage stuffer, and stuffing by protein casings and boiling to obtain the emulsified sausages. According to the emulsified sausages prepared by using the method, the influence of the ultrahigh-pressure treatment on the colour of the samples can be reduced while the texture properties and water-retaining property are improved, thus improving the overall quality of the emulsified sausages.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Preparation method of ready-to-eat mushroom stem chips

ActiveCN107087786AImprove textural propertiesImprove palatabilityFood freezingFood dryingMaltodextrinEdible mushroom

The invention discloses a preparation method of ready-to-eat mushroom stem chips, and belongs to the technical field of deep processing of edible mushrooms. The method comprises the following steps of collecting raw materials namely mushroom stems, cleaning the collected mushroom stems, performing cutting from the middles of the cleaned mushroom stems, putting the cut mushroom stems in boiling water containing a seasoning bag, performing cooking, performing cooling, performing draining, then putting the drained mushroom stems in a maltodextrin solution containing preserving materials, performing auxiliary low-frequency ultrasonic wave impregnation, then putting the impregnated mushroom stems in a freezer, and performing prefreezing; and then transferring samples in a vacuum freeze drying machine, performing freeze drying according to a specific freezing curve, performing spraying with fat for seasoning, and then performing packaging. Compared with a conventional technology, the preparation method disclosed by the invention can improve the organoleptic quality of products, the defects that conventional deep-fried chips are high in oil yield, poor in color, hard in mouth feel, and the like are overcome, waste is turned into wealth, and an operable new way is provided for comprehensive utilization of the mushroom stems.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Method for improving frost crack resistance of dumpling wrappers

InactiveCN102726676AGood low temperature stabilityImprove frost resistanceFood preparationFrost crackCorn flour

The invention discloses a method for improving the frost crack resistance of dumpling wrappers. According to the method, a puffing technology is used to carry out extrusion puffing treatment on wheat flour, rice flour or corn flour to obtain modified pre-gelatinized cereal flour, and the cereal flour is added to dumpling flour according to a certain proportion. Dumplings made from the dumpling flour added with the puffed flour have the excellent qualities of strong frost crack resistance, boiling resistance, high transparency, toughness, good mouthfeel, easy digestion and the like, the puffedcereal flour added to the original wheat dumpling flour is healthy and safe, and has an edible effect equal to high-quality dumpling flour, and the production cost of quick-frozen dumpling flour is substantially reduced, so the quick-frozen dumpling flour is adapted to the popular consumption

Owner:HENAN UNIVERSITY OF TECHNOLOGY

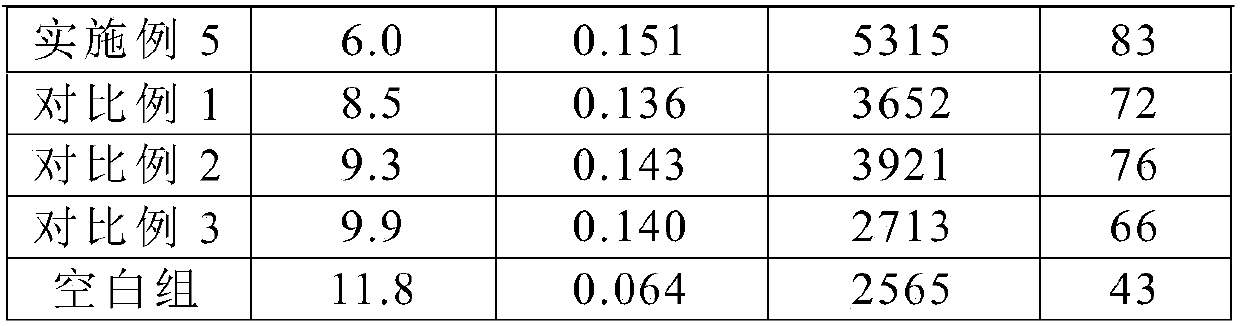

Anti-freeze fresh-keeping agent for frozen aquatic products

InactiveCN107744011AExtended shelf lifeReduce usageFood ingredient as anti-freezing agentMeat/fish preservation by coatingPhosphateArabinoxylan

The invention relates to an anti-freeze fresh-keeping agent for frozen aquatic products and belongs to the technical field of aquatic product processing. The anti-freeze fresh-keeping agent includes,by weight, 3.5-5.5 parts of araboxylan, 2.0-4.0 parts of alginate-derived oligosaccharides, 2.5-6.0 parts of modified soya bean protein powder, 0.15-0.3 parts of agar powder, 0.25-0.4 parts of alkaline phosphate, and 83.8-91.6 parts of water. The anti-freeze fresh-keeping agent is healthy and safe, has good fresh-keeping effect, can effectively alleviate defreezing loss of the frozen aquatic products, and improves texture properties and sensory quality of the frozen aquatic products.

Owner:舟山正品科技有限公司

High-dietary-fiber recombinant dried eggs and preparation method thereof

InactiveCN112021524ARealize high-value utilizationReduce manufacturing costFood scienceBiotechnologyAnimal science

The invention discloses high-dietary-fiber recombinant dried eggs and a preparation method thereof, and belongs to the technical field of dried egg manufacturing or food processing. The high-dietary-fiber recombinant dried eggs are prepared from egg white, salted egg white, resistant dextrin, edible gum and water as raw materials through mixing, degassing, modifying, molding, forming, baking, sterilizing and packaging. According to the method, the salted egg white and the egg white are compounded and modified, and the resistant dextrin is added, so that the high-dietary-fiber recombinant driedeggs with excellent flavor and taste are prepared, the efficient value-added utilization of the salted egg white is realized, the colors and varieties of dried egg products are enriched, and nutritional and healthy convenient leisure foods are provided for consumers.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Processing method of freeze-drying yak meat

PendingCN106071914AImprove textural propertiesHas a bactericidal effectFood freezingMeat/fish preservationFiberFreeze-drying

The invention discloses a processing method of freeze-drying yak meat. The processing method of the freeze-drying yak meat comprises the steps: selecting yak meat passing inspection and quarantine, separating the yak meat according to parts, selecting meat loaf of a processing part, cutting the meat loaf into meat slices in a direction vertical to muscle fibers, placing the cut meat slices under ultrahigh pressure to process, freezing the yak meat slices at low temperature, performing vacuum freeze drying on the yak meat slices at vacuum cold trap temperature, putting the freeze-drying yak meat slices into plastic bags, performing vacuum package on the plastic bags containing the freeze-drying yak meat slices to form slice shapes, putting the packed plastic bags into external packages, storing and selling. Products prepared by the processing method provided by the invention have high nutrition and healthcare values, special taste, convenience in eating and long guarantee period, are easy to store and transport, and are a product form fully exerting the highland yak meat featured resource.

Owner:QINGHAI ACAD OF ANIMAL SCI & VETERINARY MEDICINE

Stomach invigorating bread and making method thereof

InactiveCN105475423AEasy to absorb waterImprove water holding capacityDough treatmentModified nutritive productsSucroseSaccharum

The invention discloses stomach invigorating bread which is prepared from, by weight, 400-410 parts of wheat flour, 4-5 parts of salt, 6-7 parts of yeast, 10-11 parts of cane sugar, 12-13 parts of shortening, 10-11 parts of Chinese yam, 10-12 parts of sticky rice, 8-9 parts of hawthorn fruits, 1-2 parts of endothelium corneum gigeriae galli, 2-3 parts of poria cocos, 1-2 parts of dried orange peel, 2-3 parts of amomum, 10-11 parts of dried honey powder, 3-3.2 parts of beta-cyclodextrine and 0.3-0.4 parts of allicin. According to the bread, the dried honey powder replaces part of cane sugar, improves the water-holding capacity of the bread and has an inhibition function on starch retrogradation. Meanwhile, the specific volume of the bread can be increased through the dried honey powder, so that the color of the bread is darkened, the texture property becomes better, mildew can be inhibited by adding allicin, the shelf life of the bread is prolonged, and the bread can invigorate the stomach.

Owner:王梅

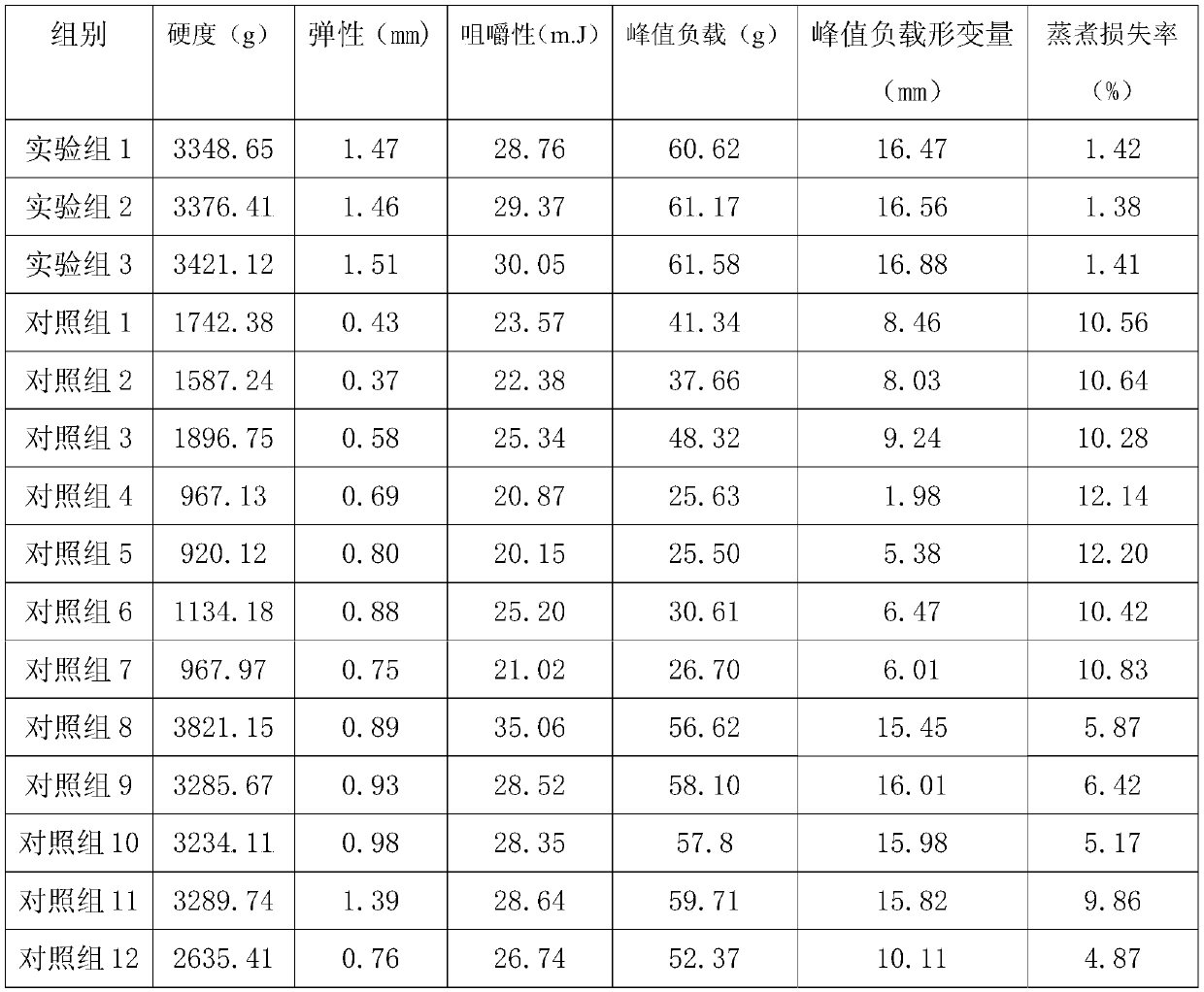

Potato dried rice noodles and preparation method thereof

The invention belongs to the technical field of food processing, and particularly discloses potato dried rice noodles and a preparation method thereof. The preparation method of the potato dried ricenoodles comprises the following steps of (1) preparing rice pulp: soaking rice, and performing grinding to obtain the rice pulp; (2) performing pulp material mixing: mixing the rice pulp with potato whole powder; (3) performing standing with a compounding modifier: mixing the mixed rice pulp with the compounding modifier, and performing standing, wherein the compounding modifier consists of guar gum, xanthogen, low-acyl gellan gum, disodium hydrogen phosphate, distilled glyceryl monostearate, vital wheat gluten and edible corn starch; (4) performing extrusion shaping; (5) performing ageing intwo stages; (6) flushing rice powder and performing compaction; and (7) performing low-temperature middle-humidity 6-stage baking. The invention further provides the potato dried rice noodles. The preparation method of the potato dried rice noodles is simple to operate, industrial production is easy, and the prepared potato dried rice noodles are smooth, complete, low in noodle breaking rate and bending rate, short in rehydration time and high in quality.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Production method of lactic acid bacteria fermented tied pig leg meat with the addition of zymolytic bone paste

InactiveCN105124610AHigh in collagenGreat tasteSugar food ingredientsFood ingredient functionsLow temperature curingHigh pressure

The present invention discloses a production method of lactic acid bacteria fermented tied pig leg meat with the addition of zymolytic bone paste. The method comprises the following steps: preparing raw materials including pigskin, pig leg meat, and fat meat; preparing zymolytic bone paste and cooked pigskin shreds; performing low-temperature curing; performing rolling; inoculating lactic acid bacteria for fermentation; wrapping fillings in pigskin, and performing tying; stewing the tied pig leg meat in a marinade; performing cooling, shaping and vacuum packaging; and performing high-pressure sterilizing, cooling and boxing and putting the end products in storage. The method combines the traditional processing method, enzyme engineering technology and microbial fermentation technology, and uses the lactic acid bacteria for fermentation, thereby providing a convenient and instant food with a new taste for the society; and the produced tied pig leg meat is unique in flavor, red in color and luster, delicious and appetizing in taste, soft in meat texture, high in calcium contents, richer in nutrition, easy to preserve, stable in quality and high in edible safety, and effectively reduces nitrite contents.

Owner:XUZHOU UNIV OF TECH

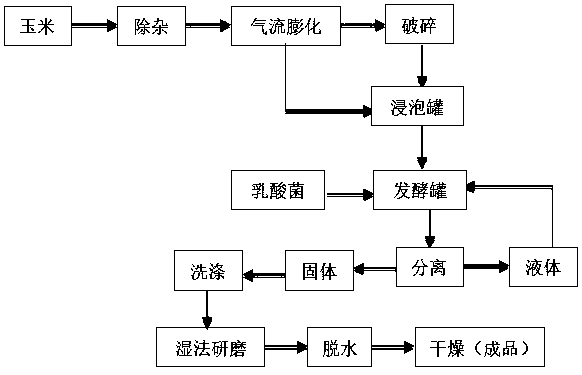

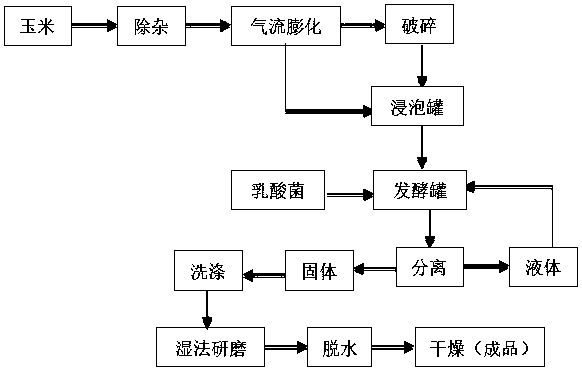

Wet method for producing whole corn flour

The invention discloses a wet method for producing whole corn flour, comprising: step 1, puffing the corn through an airflow puffing technology after removing the impurities; step 2, partially crushing the puffed corn into big corn particles, mixing with the remaining puffed whole corn, and blanching with hot water; step 3, cooling the corn, adding with sodium percarbonate and soaking the corn; step 4: washing the corn with clean water to neutral, placing the corn in a fermentation tank, and adding with lactic acid bacteria to ferment; step 5: performing the solid and liquid separation after fermentation, washing the corn with water and grinding the corn into corn flour by wet method to obtain the whole corn flour after dehydrating and drying the slurry. The method can make all the components of the corn into flour without any by-products, the obtained corn flour retains all the nutrition of the corn and has good processing performance. The food processed with the corn flour has good taste, rich nutrition, and the method has simple production process and is suitable for industrial production.

Owner:HARBIN INST OF TECH

Barley green juice noodles and preparation method thereof

ActiveCN107712619AImprove food qualityImprove toughnessFood ingredient as mouthfeel improving agentRaw materialWheat flour

The invention provides barley green juice noodles and belongs to the technical field of noodles and preparation of the noodles. The barley green juice noodles contain the following raw materials in parts by weight: 100 parts of wheat flour, 0.5-3 parts of barley green juice powder, 40-50 parts of water and 0.1-0.5 part of an improving agent. The barley green juice noodles and the preparation method thereof provided by the invention have the benefits that the noodles take the wheat flour as a raw material, and the barley green juice powder and the improving agent are added for compounding, so that the eating quality of the noodles is improved, and the noodles are better in toughness, resistant to boil, hard to break, good in mouth feeling and richer in nutrition; the barley green juice powder as the raw material is made of barley young wheat leaves and has the efficacies of detoxifying, removing dampness, beautifying and the like; the adding quantity of the improving agent is less, andthrough the reasonable use of the improving agent, the toughness, the elasticity, the cohesiveness and the like of the noodles are obviously improved, so that the eating quality of the noodles is better.

Owner:HENAN INST OF SCI & TECH

Processing method of instant small-particle pork blood ball

InactiveCN104543019AGood molding effectRealize industrial productionCheese manufactureIce waterGlutaminase

The invention provides a preparation method of an instant small-particle pork blood ball. The preparation method comprises the following steps: by taking soybean isolate protein, pork blood, salad oil, ice water and transglutaminase as main raw materials, chopping and uniformly mixing the materials at a high speed; preparing small-particle balls by using a ball molding machine; performing gel-molding of the balls at a low temperature by utilizing the gel characteristics of the soybean isolate protein and the protein crosslinking characteristics of the transglutaminase; drying the molded balls, smudging, packaging in vacuum and sterilizing at a high temperature to obtain a finished product. The pork blood ball prepared by the method disclosed by the invention is strong in flavor, rich in nutrients, good in product structure, crisp and tasty in taste and capable of bearing 121 DEG C high-temperature sterilization. The preparation method of the pork blood ball can realize instant and large-scale production of the pork blood ball.

Owner:HUNAN HUADE FOOD GRP

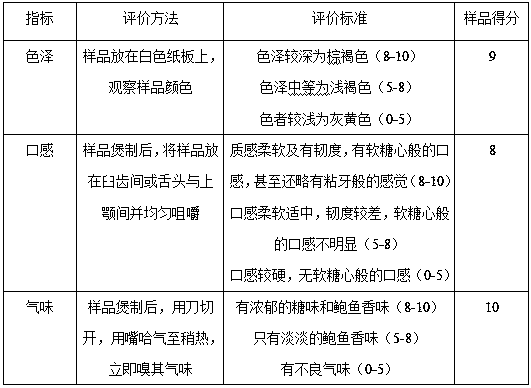

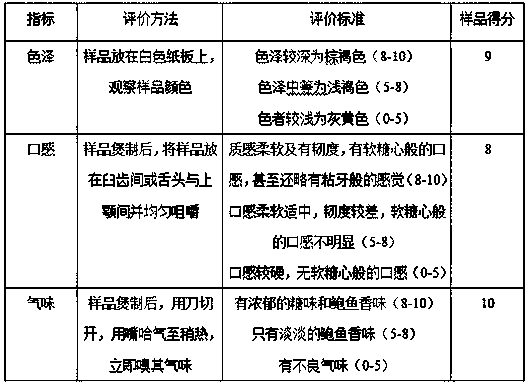

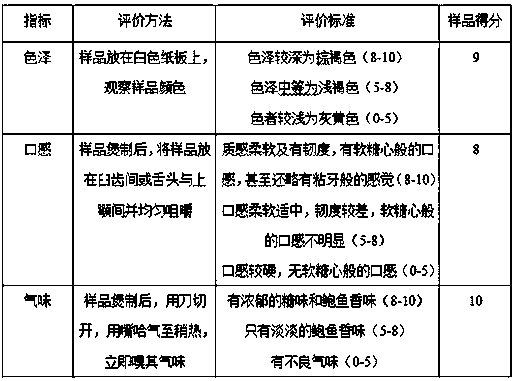

Preparation method of semifluid-center dried abalone

InactiveCN109363110AEasy to controlNot easy to influenceFood dryingFood ingredient as mouthfeel improving agentDark brown colorBiology

The invention discloses a preparation method of semifluid-center dried abalone and particularly relates to the technical field of abalone preparation. According to the method, a finished product is obtained through abalone selection, shell removal and meat taking, scrubbing, gelling treatment, precooking, pre-drying and primary tempering, setting, internal organ removal and trimming, air drying and secondary tempering, fermentation and storage. The method is not susceptible to the environment and weather, can control the temperature and humidity accurately and guarantee the sanitary conditionand is energy saving and environmentally friendly. The semifluid-center dried abalone obtained by the preparation method has darker brown color, soft texture and toughness, tastes like soft sweet cores, even tastes slightly sticky to the teeth and has the characteristics of strong sweet aroma and abalone fragrance.

Owner:福建海鳞源食品开发有限公司

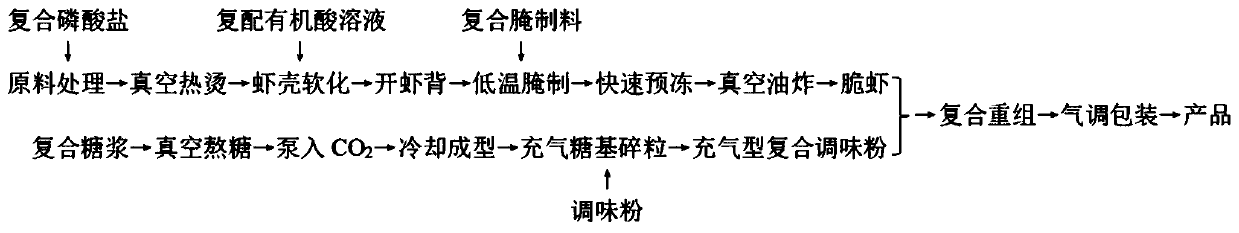

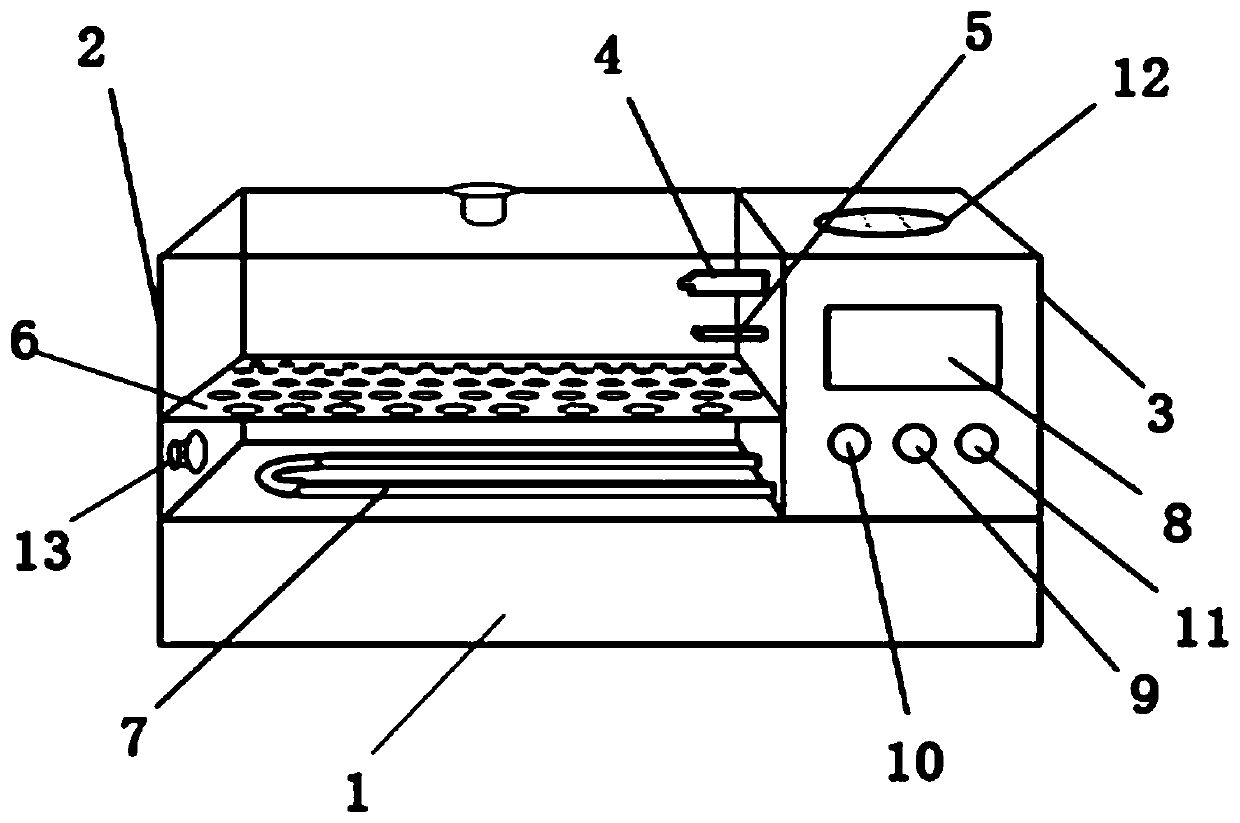

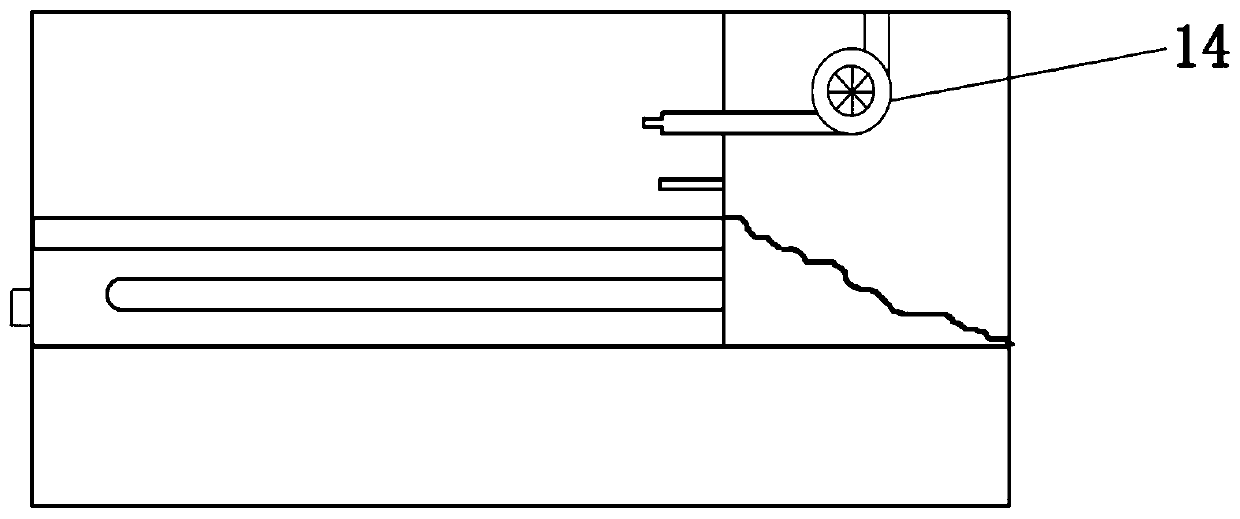

Production method of interesting ready-to-eat leisure jumping shrimps

PendingCN110604272AImprove physical and chemical qualityOrganizational structure is completeFood scienceFlavorReady to eat

The invention discloses a production method of interesting ready-to-eat leisure jumping shrimps. Through soft green processing techniques of performing vacuum low-heat blanching, softening shrimp shells, performing vacuum low-temperature preserving, performing quick pre-freezing, performing vacuum deep-frying and the like, crisp type dehydrated dried shrimps are prepared; through a high-pressure shaping technique and a three-dimensional uniform mixing technique, inflation type composite seasoning powder is prepared; and then recombination and shaping are performed, so that the inflation type composite seasoning powder is inlaid into crisp shrimps of which the backs are split, and the interesting ready-to-eat jump shrimp leisure foods are produced. According to the production method disclosed by the invention, running off of nutritive components of the prawns can be effectively reduced, and physical and chemical quality of products are improved; deep-frying dehydrating treatment is performed under vacuum low-heat condition, so that the flavor and the nutritional quality of the products are better; a plurality of treatment processes are all performed under the vacuum condition, so that the organoleptic quality and nutrients of the products are reserved better; and the production method disclosed by the invention has the characteristics that the technique is green and friendly, nutrients are efficiently reserved, the mouth feel experience is unique, and the production cost is controllable, and consumption hobby of nutritive healthy leisure interesting modern foods can be met.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

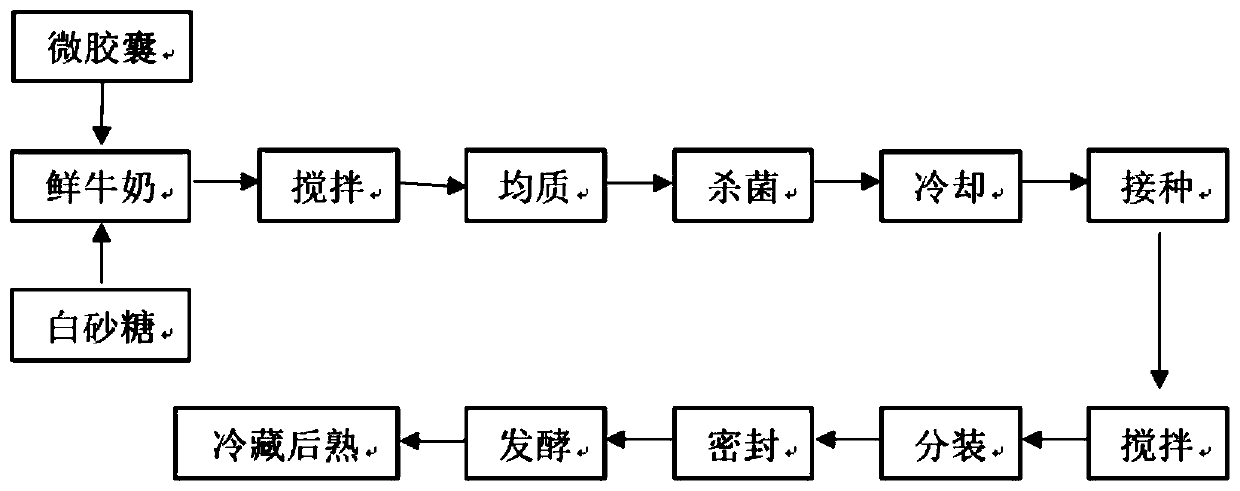

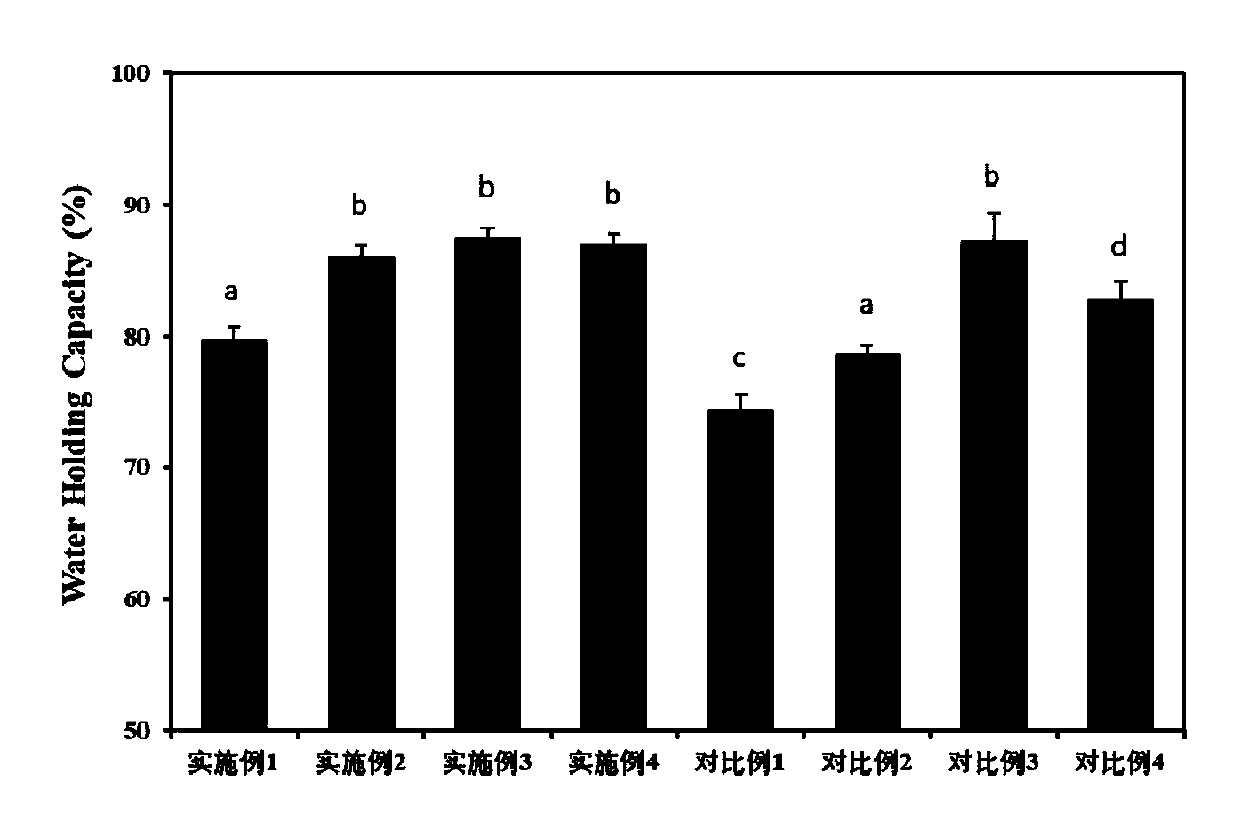

Yoghourt containing essential oil microcapsules

PendingCN110999967APrevent whey precipitationImprove water holding capacityMilk preparationOther dairy technologyMouthfeelEssence oil

The invention discloses yoghourt containing essential oil microcapsules, and belongs to the field of food processing. The yoghourt disclosed by the invention is set yoghourt prepared by taking fresh milk as a main raw material, adding microcapsules loaded with natural plant essential oil, and carrying out homogenizing, sterilizing, inoculating and fermenting. The yoghourt provided by the inventionis free of any thickening agent and can prevent whey from being separated out, the water-holding capacity of the yoghourt is increased, the texture characteristics of the yoghourt is improved, and the yoghourt is set yoghourt which is safe, reliable and long in storage life. In addition, the yoghourt is endowed with better aroma and taste, the nutritional value and additional value of the yoghourt are improved, and the yoghourt has a greater market potential.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

Ultrahigh-pressure production technology of natural sausage casings

InactiveCN106561784AEnsure safetyAchieve sterilization effectAnimal intestine cleaningNatrual gut chemical treatmentWork in processChemistry

Owner:YANGZHOU UNIV

Glutinous rice healthy food and preparation method thereof

The invention discloses a glutinous rice healthyfood and a preparation method thereof. The preparation method of the glutinous rice healthyfood comprises the following steps: I, soaking; II, ozone treatment; III, steaming; and IV, molding. The prepared glutinous rice healthy food is soft and glutinous in taste, convenient to store, free of preservatives and other additives, green and healthy.

Owner:宁波北仑戌鸿农业科技有限公司

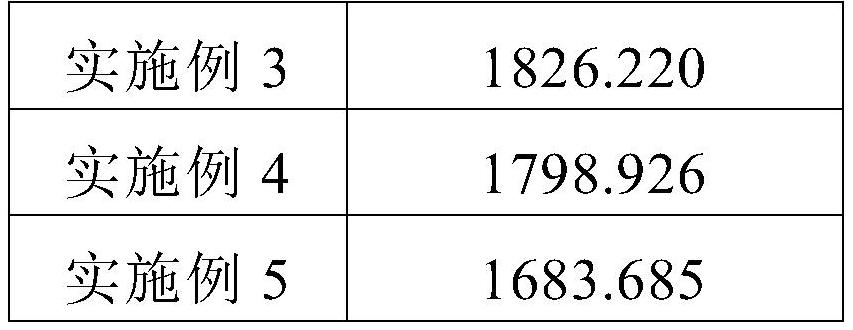

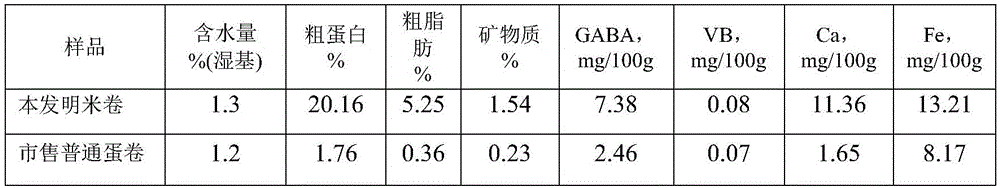

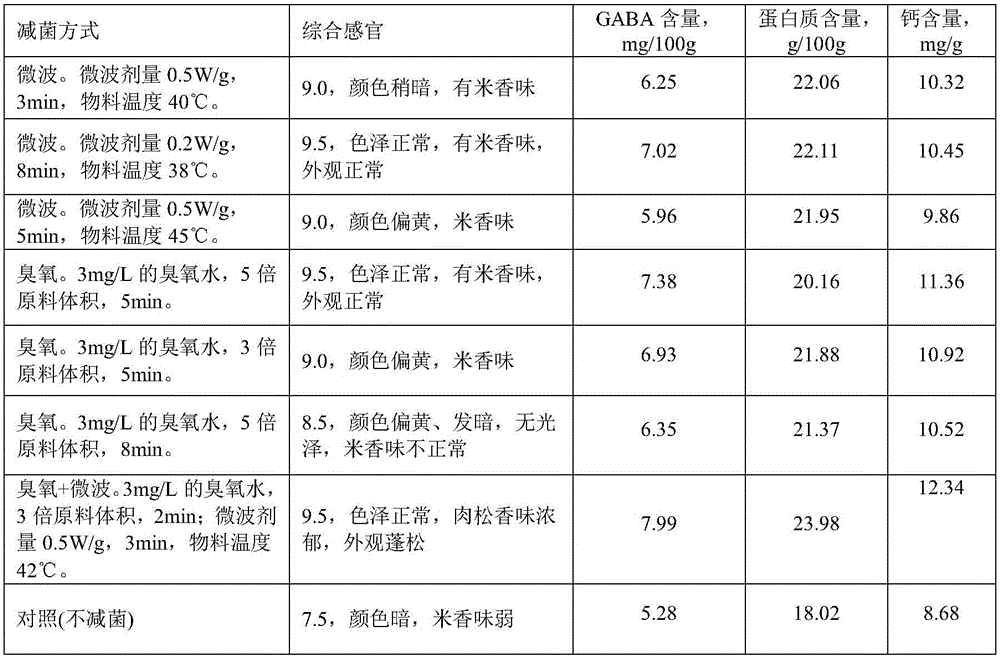

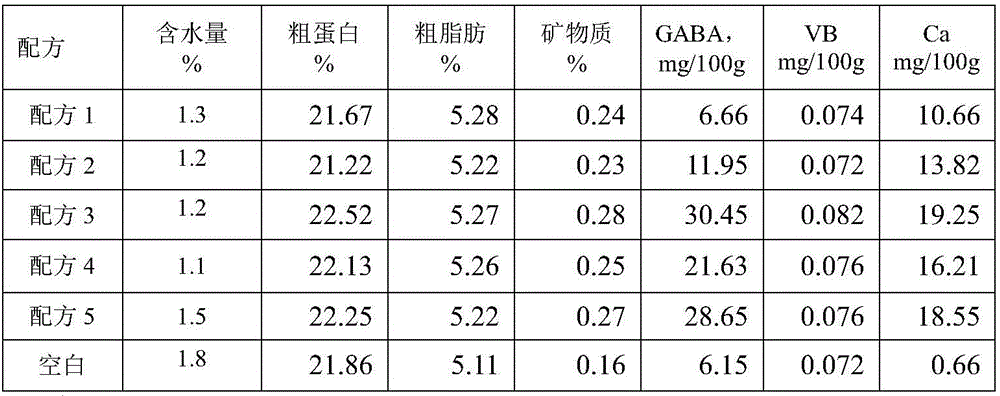

High-gamma-aminobutyric acid high-protein high-calcium nutritional rice roll and manufacturing method thereof

InactiveCN106036484ANutritional diversityImprove pasting effectFood ingredient as mouthfeel improving agentFiberMonoglyceride

The invention belongs to the field of food processing and relates to a high-gamma-aminobutyric acid high-protein high-calcium nutritional rice roll and a manufacturing method thereof. The rice roll comprises, by weight parts, 100 parts of cereal, 0.2-20 parts of glutamic acid, 0.2-5 parts of dietary fiber, 0.2-2 parts of vitamin C, 1-20 parts of calcium lactate, 1-20 parts of sugar, 0.5-1 part of salt, 0.2-20 parts of GABA, 1-10 parts of egg white powder, 1-30 parts of high gluten flour, 1-8 parts of wheat gluten, 0.5-5 parts of butter, 0.5-2 parts of vegetable oil, 0.2-2 parts of monoglyceride, 0.1-2 parts of starch octenyl succinate and 1-10 parts of nano bone calcium. The method for manufacturing the rice roll comprises the steps of cereal bacterial reduction treatment, infiltration sprouting, mixing and roll manufacturing, wherein bacterial reduction comprises ozone and microwave bacterial reduction. The nutritional rice roll is high in nutrient reinforcement efficiency and nutritional ingredient content, good in sensory quality and favorable for absorption by the human body.

Owner:HUAZHONG AGRI UNIV +1

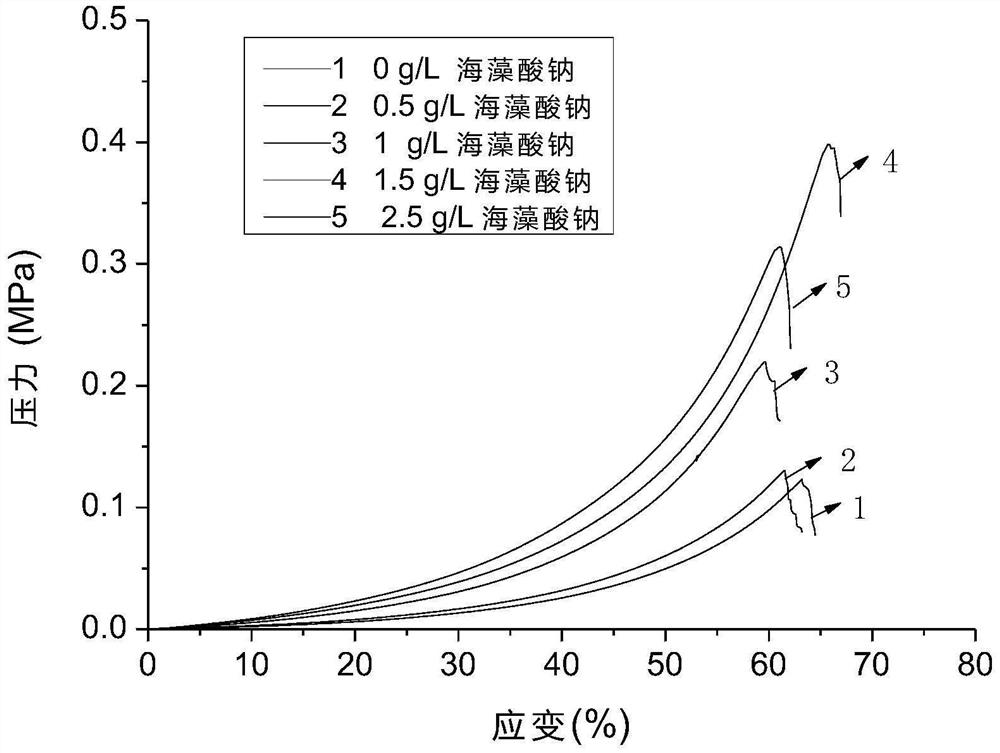

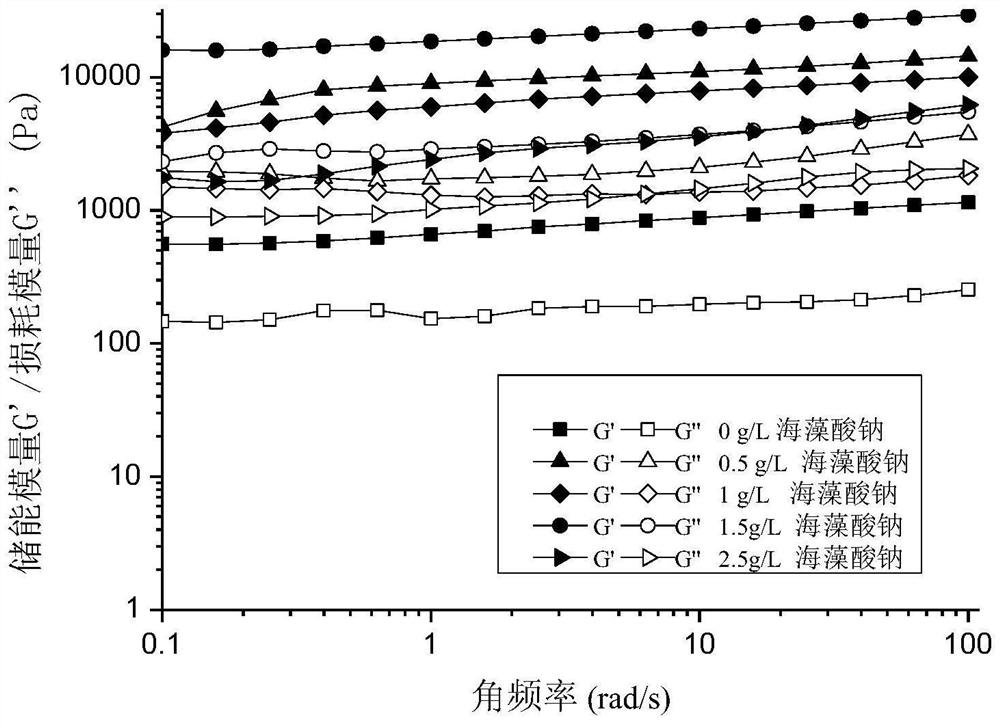

Double-network pea protein hydrogel with high freeze-thaw stability and preparation method thereof

ActiveCN114027392AKeep shapeIncrease elasticityVegetable proteins working-upPea proteinPolysaccharide

The invention discloses a double-network pea protein hydrogel with high freeze-thaw stability and a preparation method thereof, and belongs to the field of food. The preparation method of the double-network pea protein hydrogel comprises the following steps: (1) dispersing pea protein in water, and fully hydrating to obtain a pea protein suspension; (2) adding polysaccharide into the pea protein suspension, and uniformly mixing to obtain a pea protein-polysaccharide mixed solution; (3) adding a glutamine transaminase solution into the pea protein-polysaccharide mixed solution, uniformly mixing, pouring into a mold, and heating and cross-linking to obtain pea protein hydrogel containing a first protein cross-linked network; and (4) dipping the pea protein hydrogel containing the first protein cross-linked network in a metal ion solution, taking out, and washing to obtain the dual-network pea protein hydrogel. The double-network pea protein hydrogel has good mechanical property, rheological property, mechanical strength, texture property and freeze-thaw stability.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com