Wet method for producing whole corn flour

A technology of whole corn flour and production method, which is applied in the field of grain processing, can solve the problems of poor taste and poor processing performance of corn flour, and achieve the effects of benefiting national health, improving scalability, and enriching dining tables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

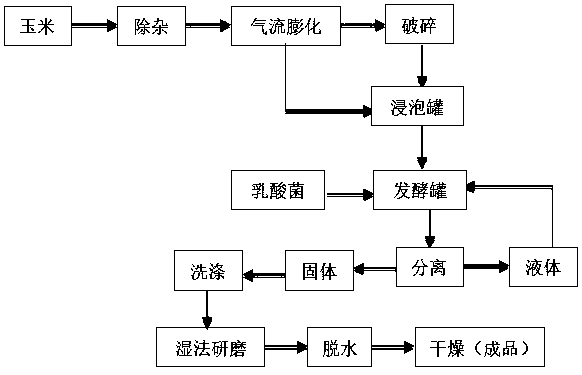

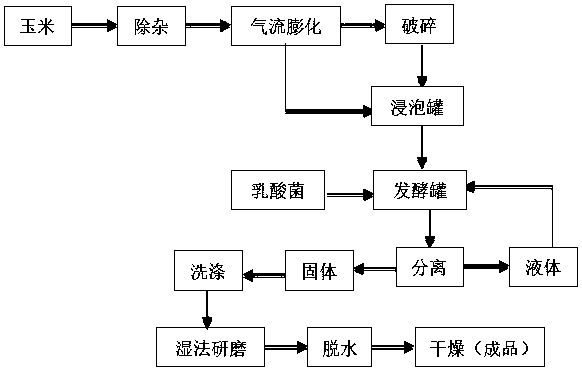

[0016] The invention provides a method for producing wet corn whole meal, such as figure 1 As shown, the method includes the following steps:

[0017] (1) Corn pretreatment

[0018] Send corn kernels with moisture content ≤ 14% without mildew to the magnetic separator and stone remover through the bucket elevator to remove iron, stone and other sundries, and then pass through a 6-8 mesh fine vibrating screen and a 4-mesh coarse screen , sifting out sandy soil smaller than corn kernels and corn cob particles larger than corn kernels, etc., and the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com