Plant-based fermented yoghourt and preparation method thereof

A plant-based, yogurt technology, applied in the direction of dairy products, milk preservation, milk substitutes, etc., can solve problems such as gaps, achieve long shelf life, improve product quality and texture properties, and extend shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

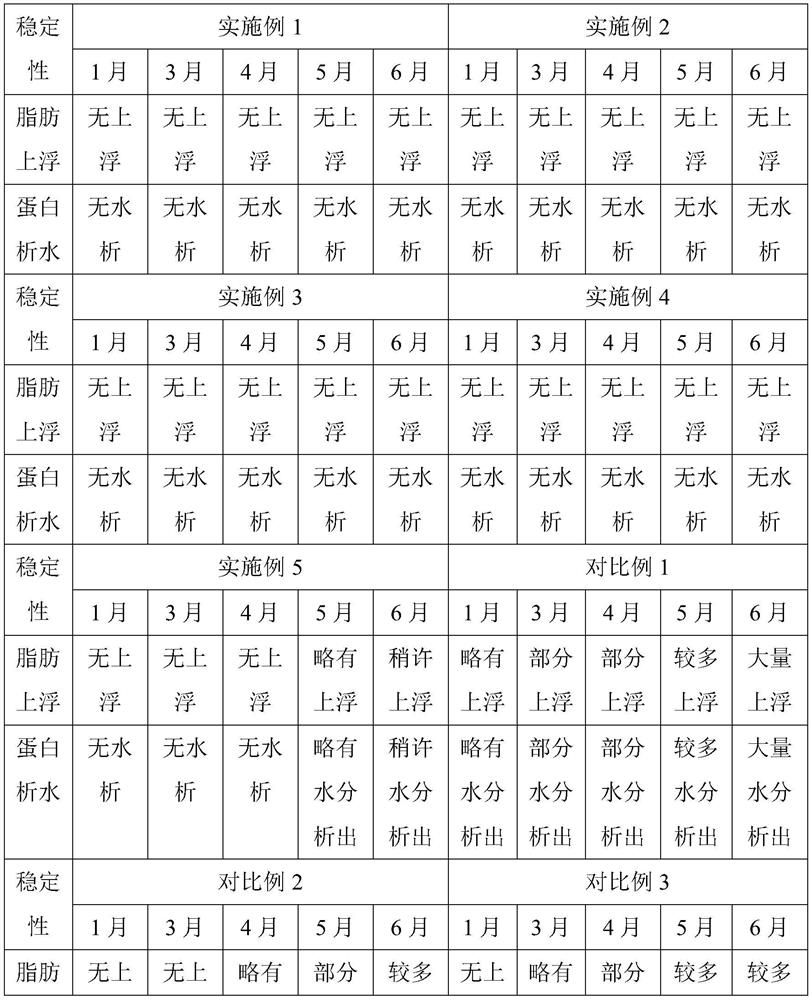

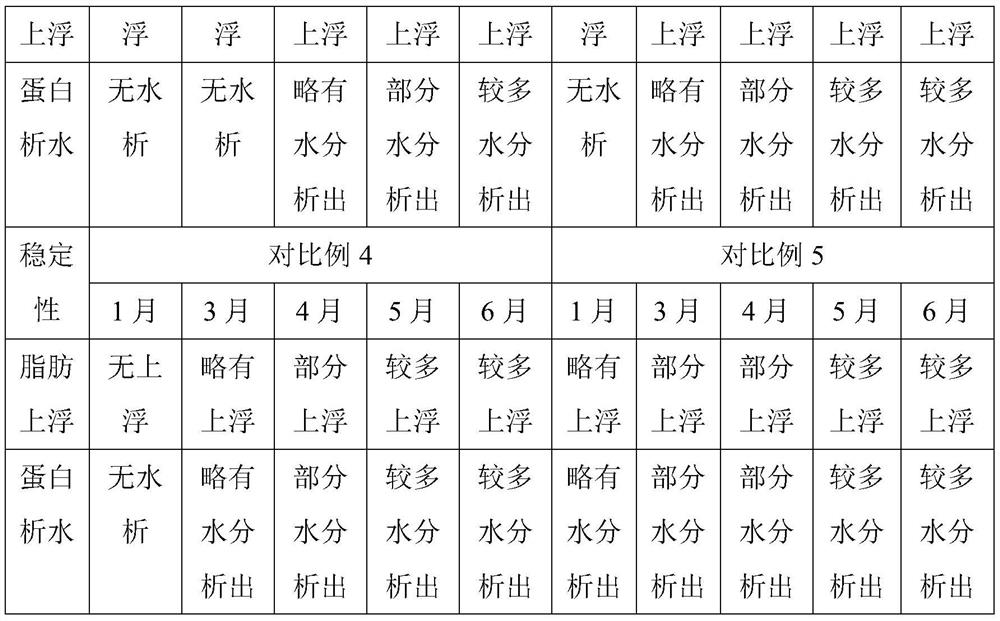

Examples

preparation example Construction

[0040] In view of the fact that the vegetable yogurt on the market is a low-temperature short-term preservation type, the application provides a preparation method for obtaining a normal-temperature long-term preservation type plant-based fermented yogurt, which includes the following steps:

[0041] Initial batching: after refining the plant fermentation base material to obtain a plant-based slurry, add 30-60wt% of the total amount of plant-based slurry to preheat to 40-75°C, add stabilizer A and sweetener, mix evenly, Then add the remaining plant-based slurry, which can be supplemented with water at last to obtain 100 parts by weight of the mixture, wherein the plant-based slurry is selected from soybean residue-free soybean milk obtained after dehulled soybeans are refined, and in one embodiment, the whole soybean The protein content in the residue-free soybean milk is 4.0%, and the fat content is 1.8%, and the protein content in the mixture obtained after the initial batching...

Embodiment 1

[0055] A method for preparing plant-based fermented yogurt, comprising the following steps:

[0056] Initial ingredients: grind the dehulled soybeans to obtain whole bean dregs-free soymilk, add 30wt% whole bean dregs-free soymilk, preheat to 60°C, add 1kg modified starch, 0.1kg agar, 0.03kg high acyl gellan Glue, 0.05kg diacetyl tartrate mono-diglyceride, 5kg white sugar and 4kg coconut milk, mix evenly, then add the remaining whole bean dregs-free soy milk, add water to obtain a 100kg mixture, the total amount of whole bean dregs-free soy milk added is 88kg , the modified starch is selected from hydroxypropyl distarch phosphate;

[0057] Pre-sterilization: Preheat the mixture obtained from the first batching to 60°C for homogenization. The homogenization adopts a two-stage step method. The first stage of homogenization is carried out at a pressure of 200bar, and the second stage of homogenization is carried out at a pressure of 50bar. After completion, the mixture is pasteu...

Embodiment 2

[0063] A method for preparing plant-based fermented yoghurt, which is carried out according to the method in Example 1, the difference is that: initial ingredients: dehulled soybeans are ground to obtain whole bean dregs-free soybean milk, and a total amount of 30 wt% whole bean dregs-free soybean milk is added Soybean milk, preheated to 45°C, add 1.5kg of modified starch, 0.2kg of agar, 0.04kg of gellan gum, 0.1kg of diacetyl tartaric acid mono-diglycerides, 6kg of white sugar and 8kg of coconut milk, mix well, and then add the remaining whole Bean dregs-free soy milk, add water to get 100kg of mixture, the total amount of whole bean dregs-free soy milk is 70 kg, and the modified starch is hydroxypropyl distarch phosphate;

[0064] Pre-sterilization: Preheat the mixture obtained from the first batching to 50°C for homogenization. The homogenization adopts a two-stage step method. The first stage of homogenization is carried out at a pressure of 180bar, and the second stage of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com