Patents

Literature

136results about How to "Improve pasting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing cassava starch octenyl succinate by sub-gelatinization technology

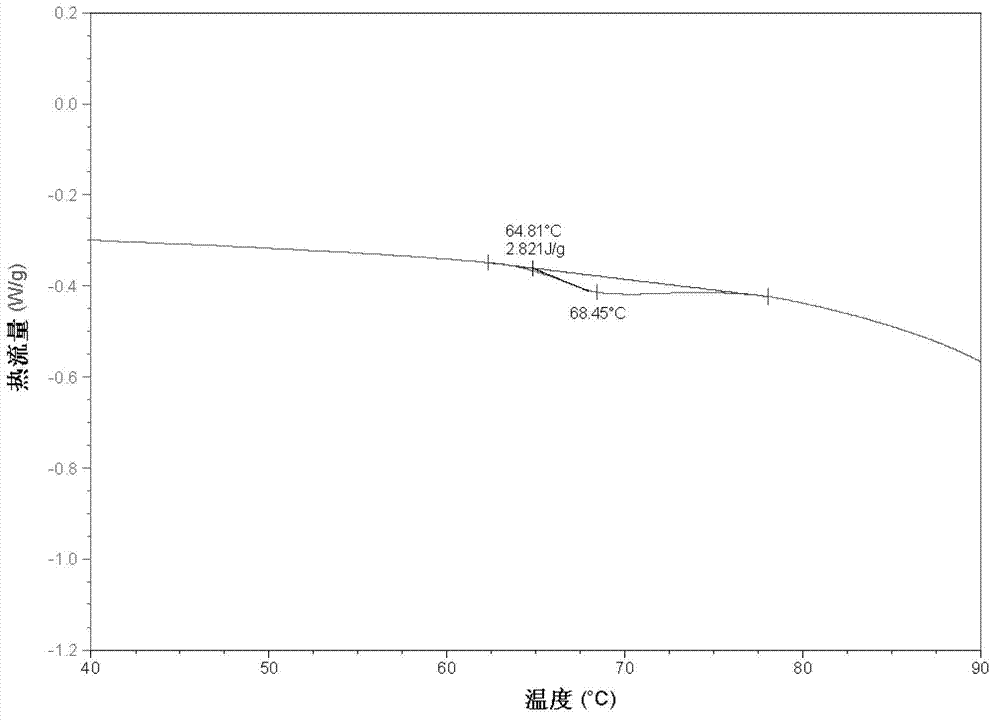

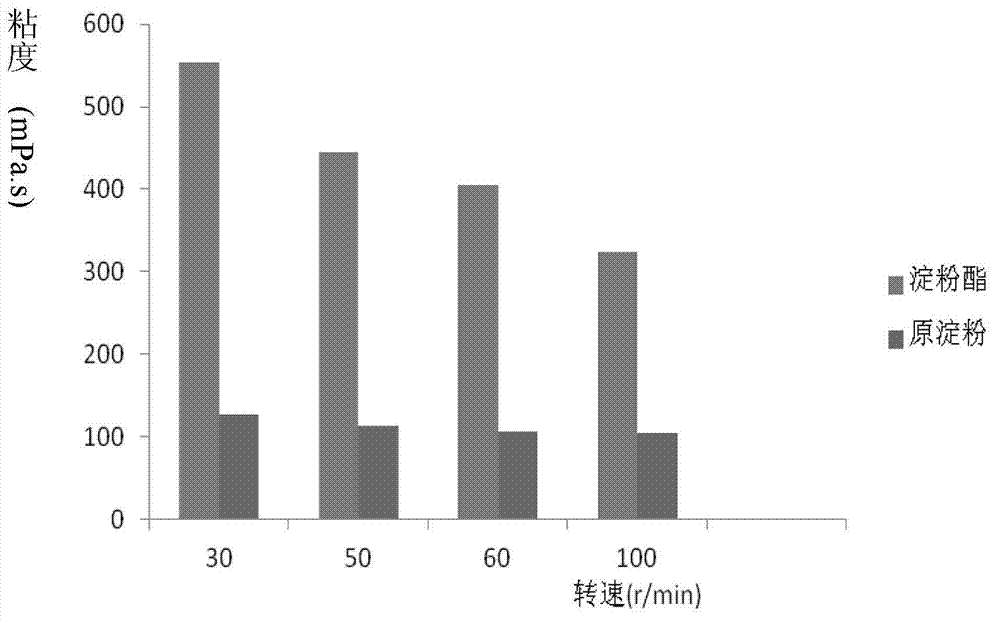

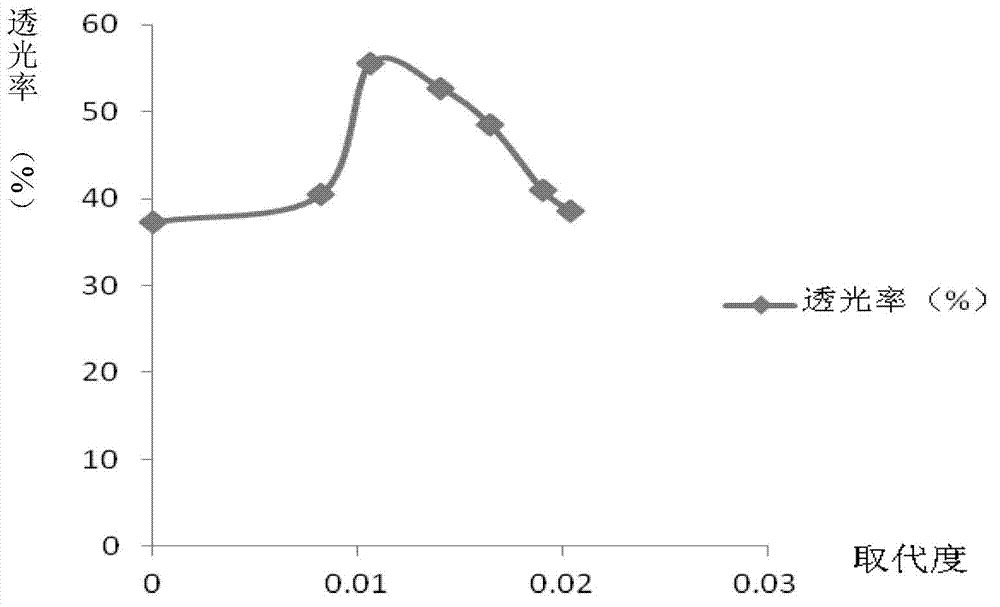

The invention provides a method for preparing cassava starch octenyl succinate by a sub-gelatinization technology. The method comprises the following steps of: adding cassava starch into an ethanol solution with concentration of 45-65% by volume; gelatinizing at 60-85 DEG C for 1-3 hours while stirring to obtain sub-gelatinized cassava starch emulsion; in a condition with pH value of 7.2-9.2, adding the octenyl succinic anhydride diluted by an organic solvent into the sub-gelatinized cassava starch emulsion to enable esterification reaction; and processing the reaction product to obtain the cassava starch octenyl succinate. According to the method provided by the invention, the raw materials are widely available, and the cost is low; moreover, the technology is simple, the gelatinization degree of starch is proper, the esterification reaction is uniform, and the reaction efficiency is high; and the prepared cassava modified starch has high esterification substation degree and relatively good transparency, thickening property and emulsifying property.

Owner:ZHEJIANG UNIV

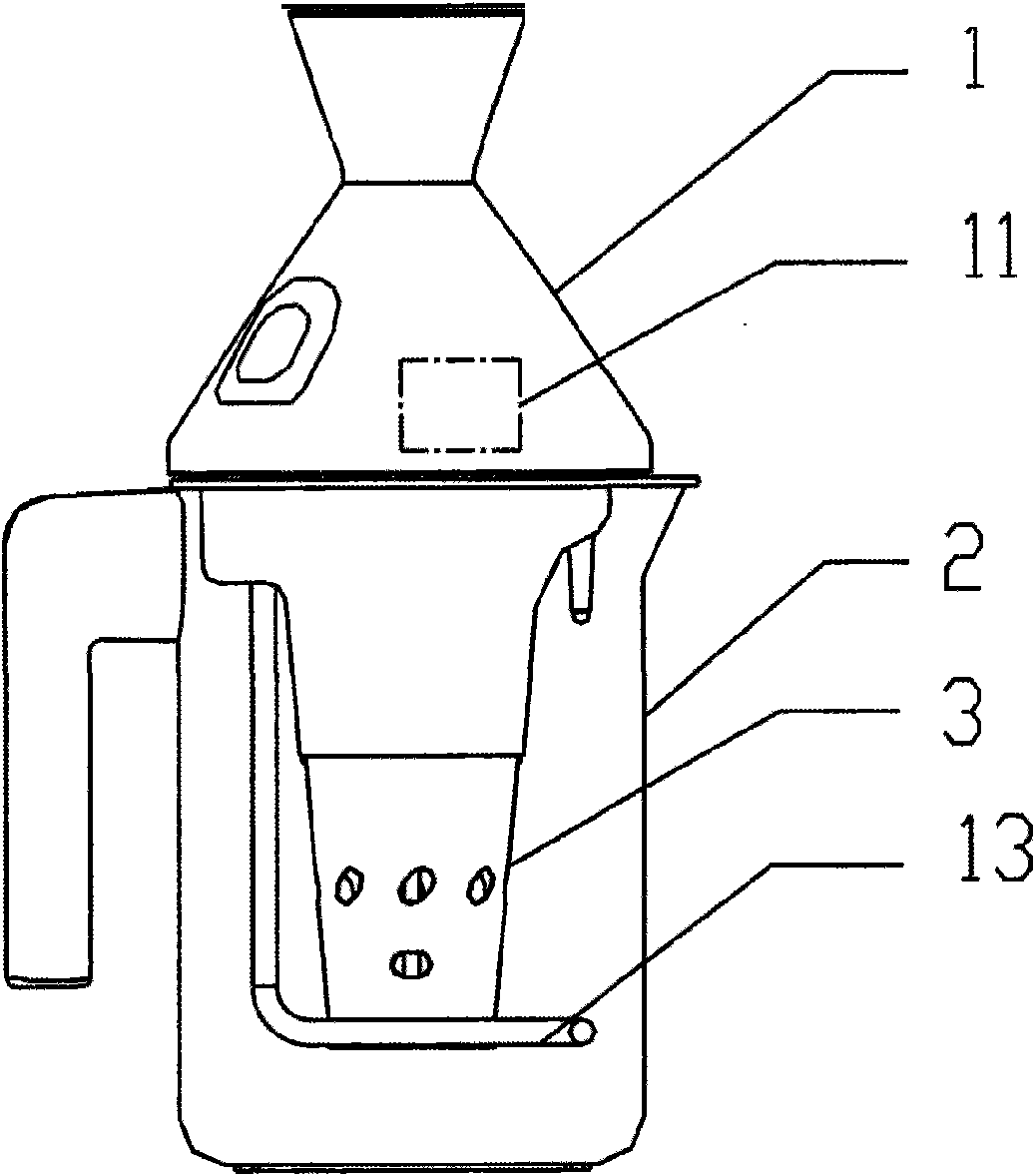

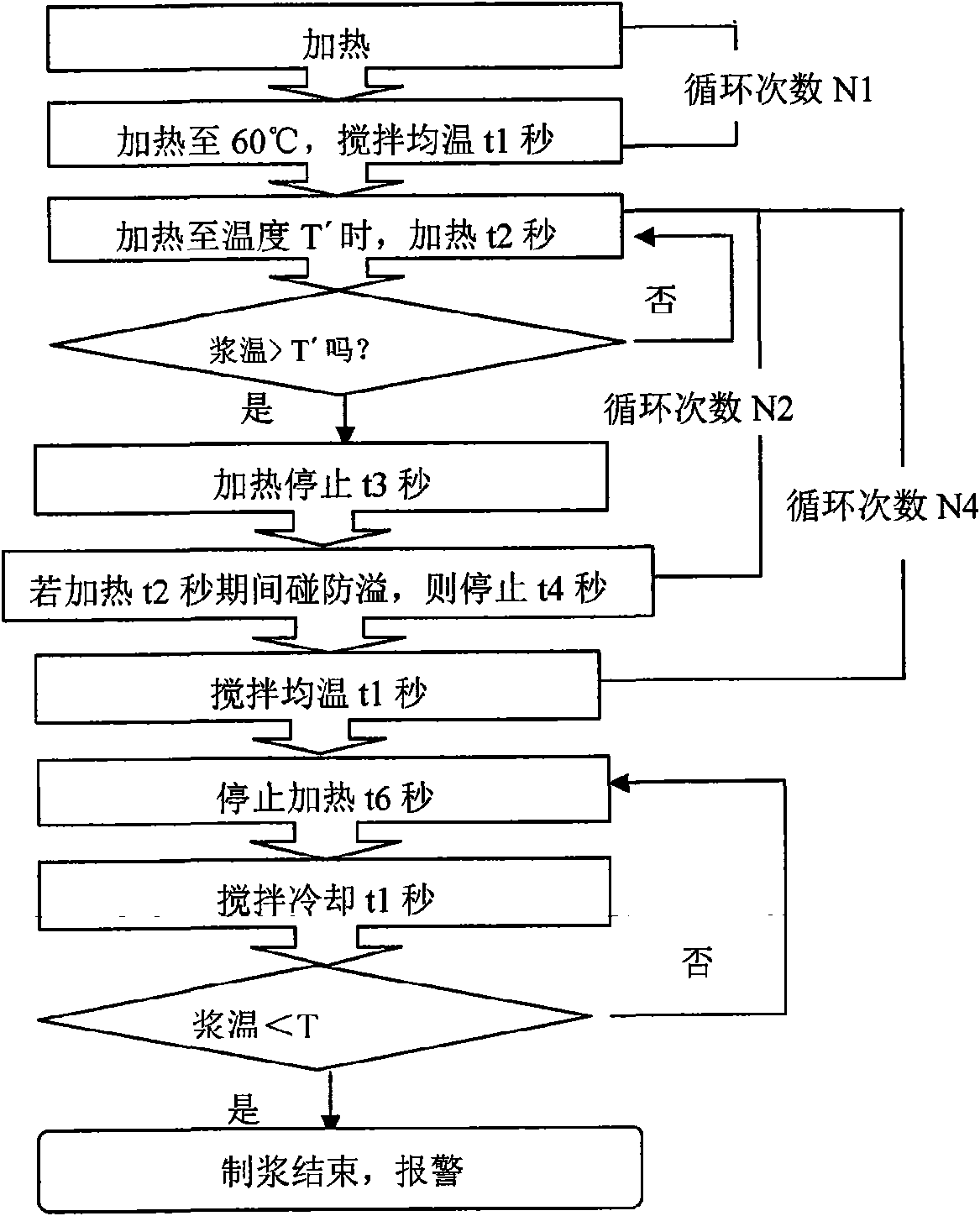

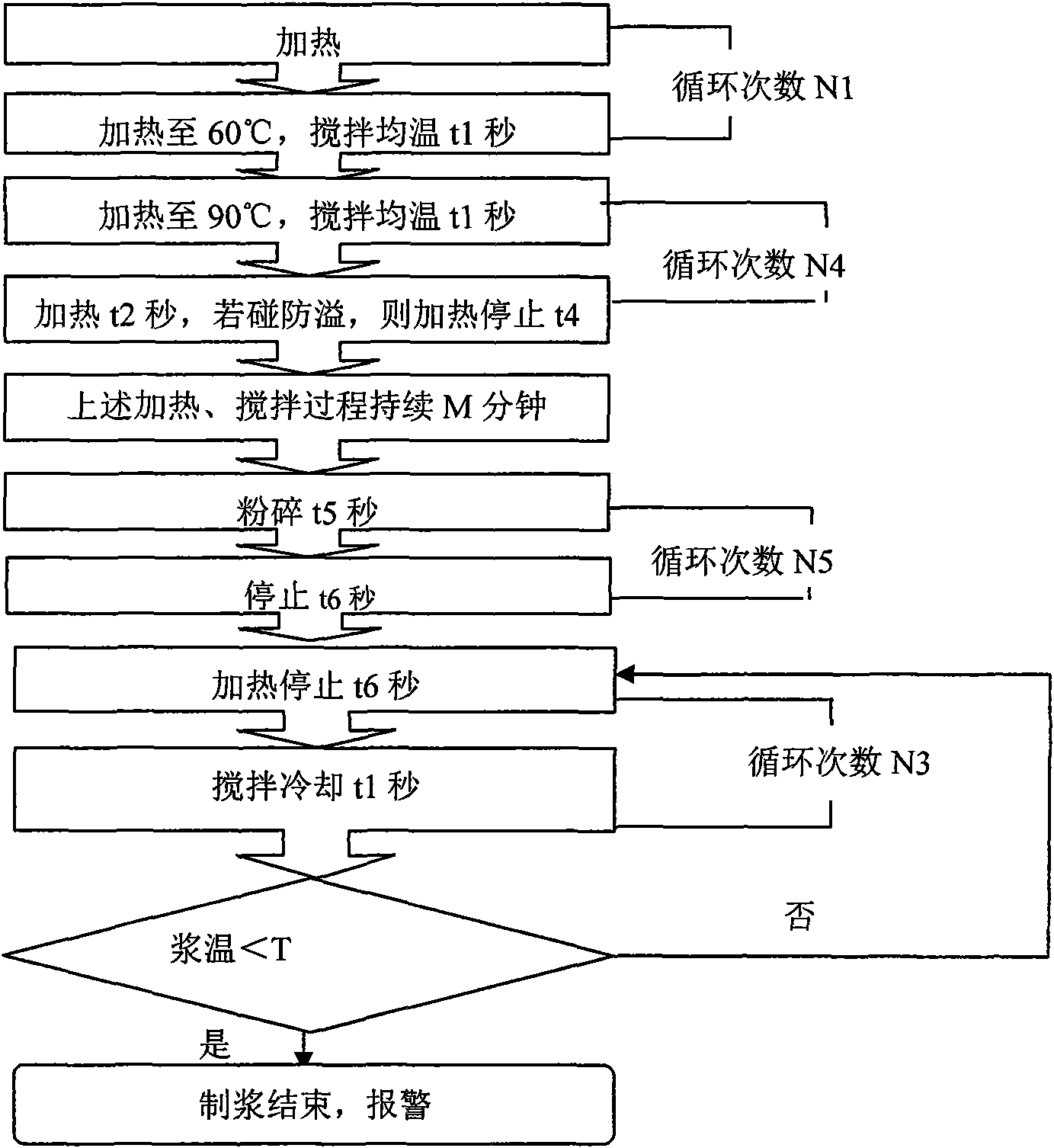

Method for preparing rice milk and soybean milk maker thereof

ActiveCN101579074AImprove pasting effectGreat tasteBeverage vesselsFood preparationKitchen utensilsEngineering

The invention relates to a food processing method for kitchenware, in particular to a method for preparing rice milk by a soybean milk maker, which at least comprises the following steps: (a) a boiling step, namely heating water and materials held in a cup body of the soybean milk maker until the materials are boiled, and entering the next step; and (b) a pasting step, namely stopping the heating, stirring the materials by cutter blades driven by a motor until the temperature of the milk fluid mixed by the materials and the water is reduced to a pasting temperature T. The soybean milk maker realizing the method for preparing the rice milk comprises a handpiece, the cup body, a heating device, a grinding device, the motor and a circuit control panel, and is characterized in that: the working procedure for preparing milk by the soybean milk maker comprises any method for preparing the rice milk in claims 1-9. The invention provides a method for preparing the rice milk and a soybean milk maker realizing the method. When the method and the soybean milk maker are adopted to prepare the rice milk, the boiled rice milk is difficultly layered, has good pasting effect and is difficult to paste a tube.

Owner:JOYOUNG CO LTD

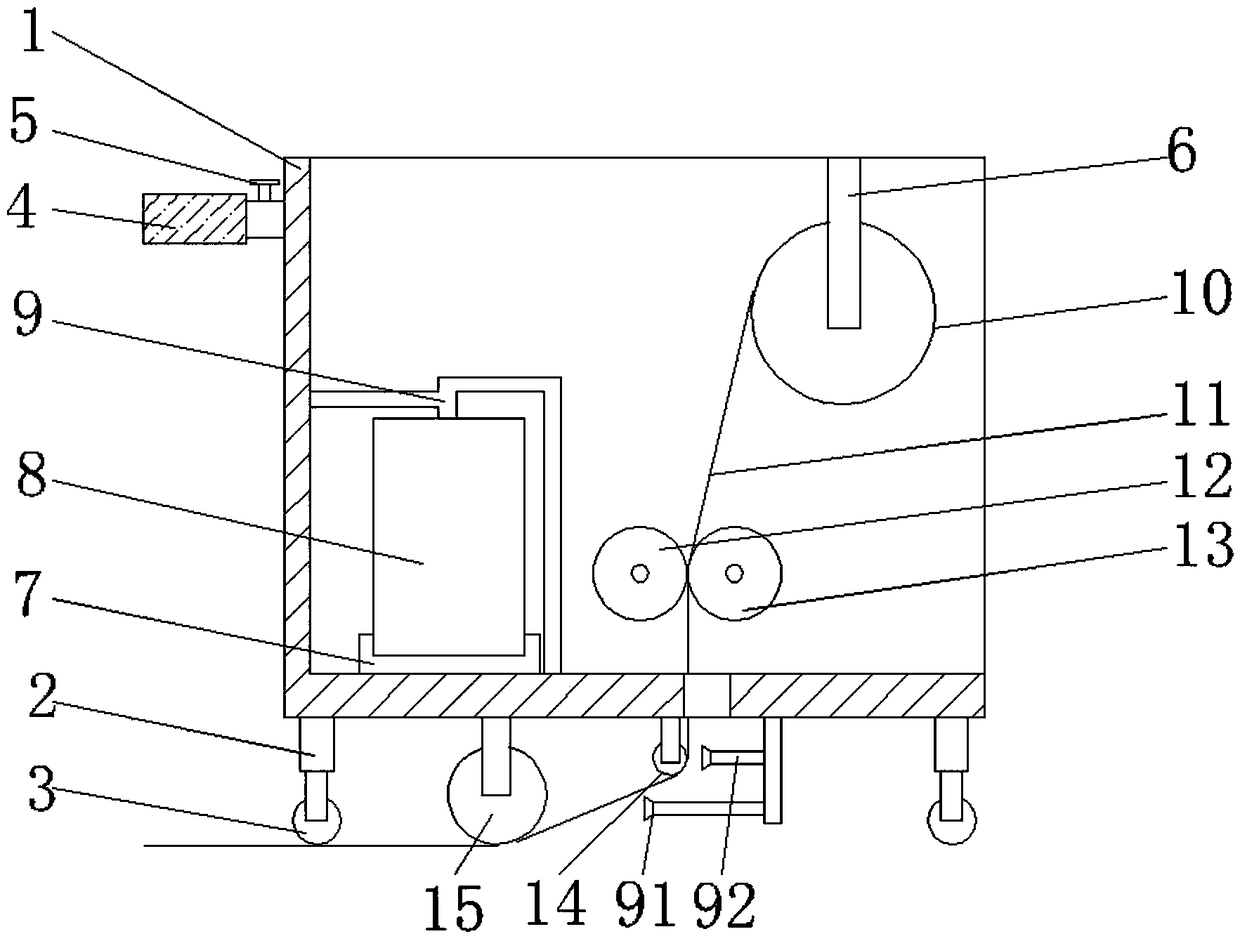

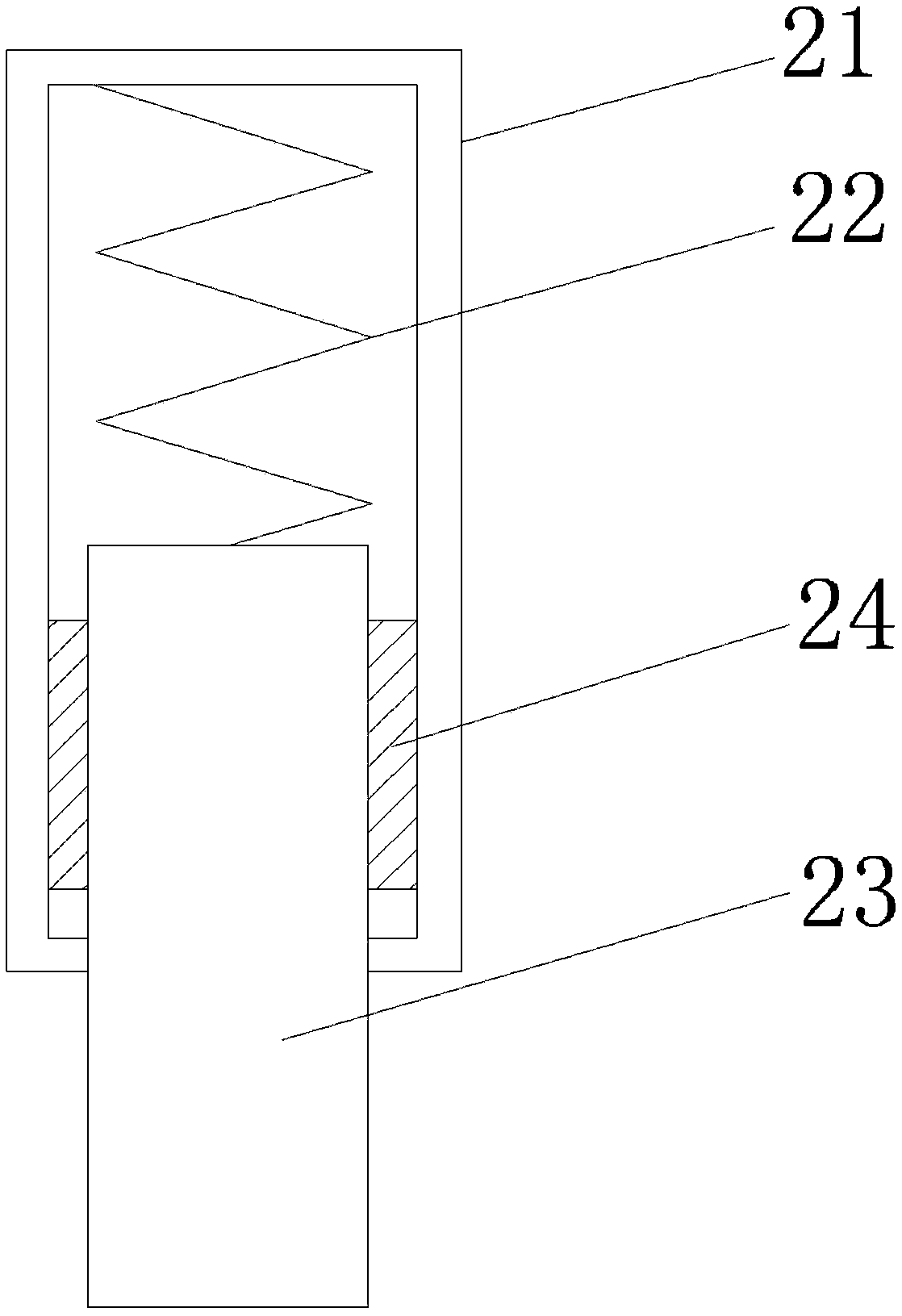

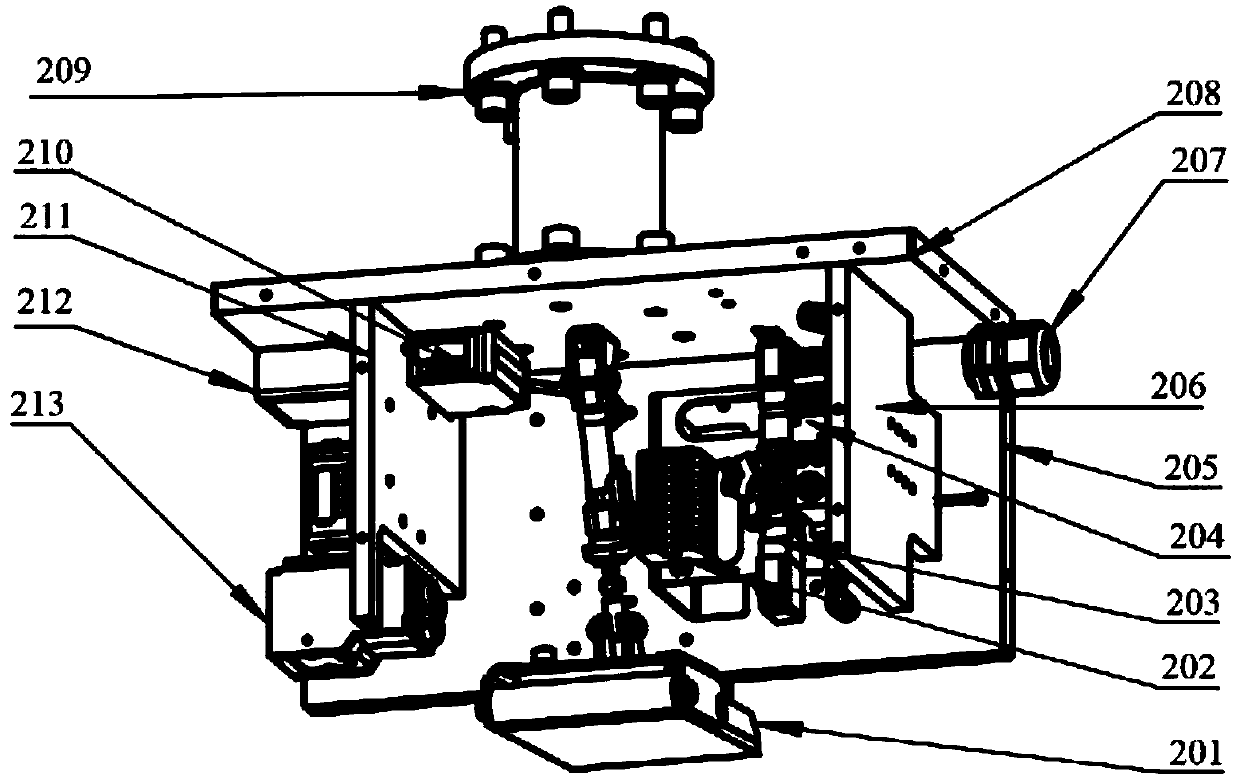

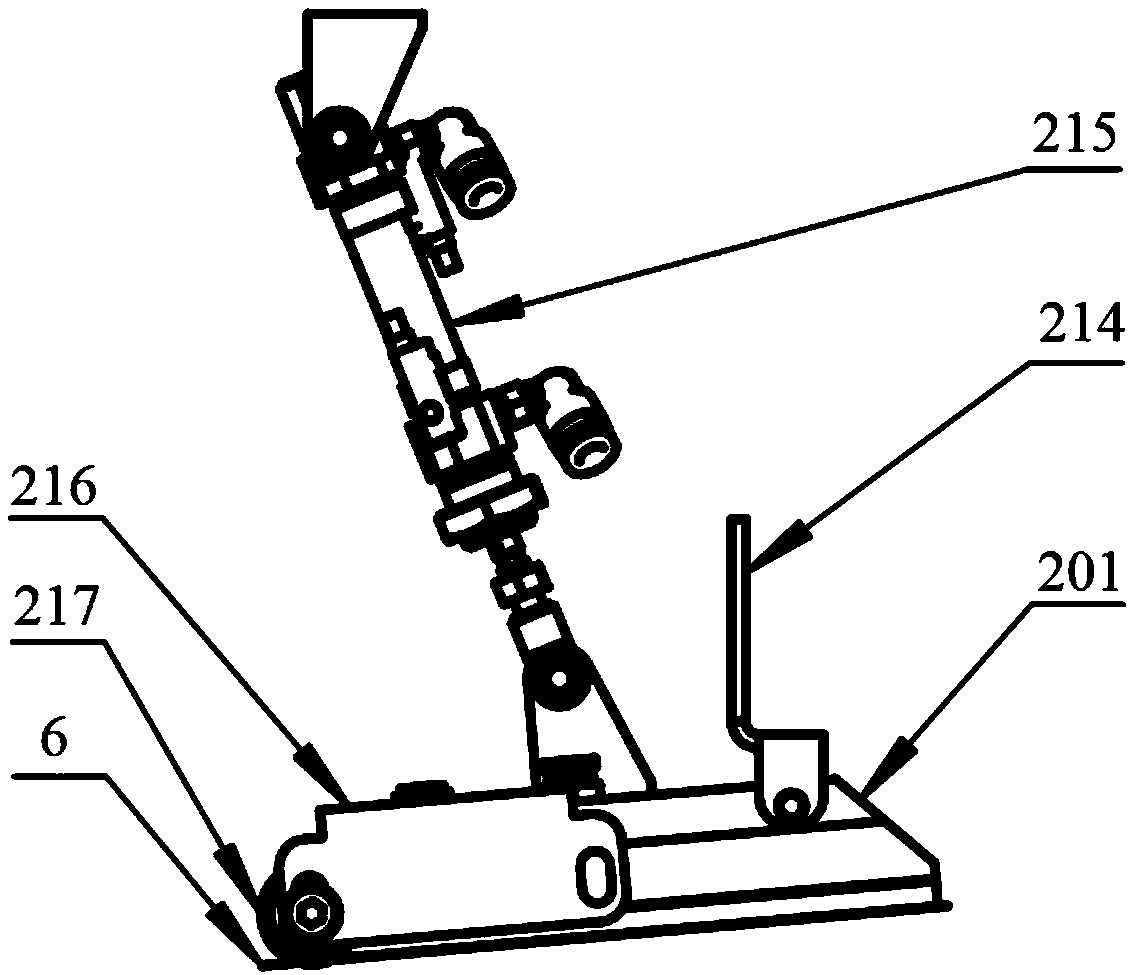

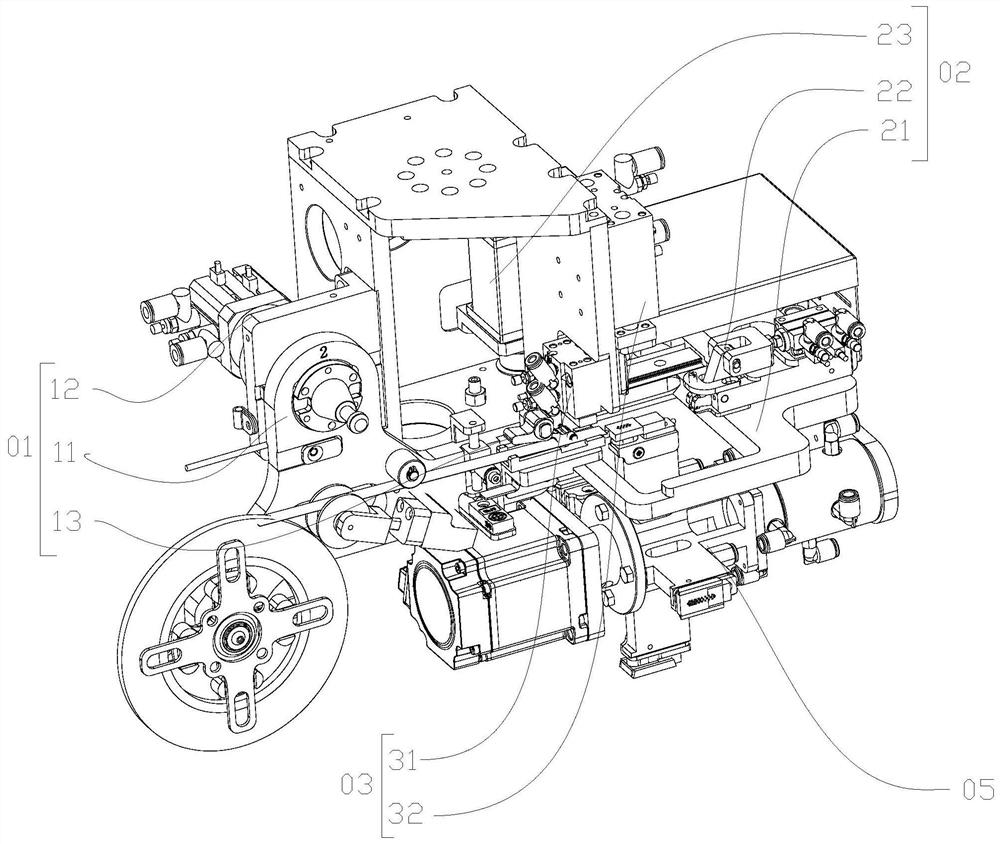

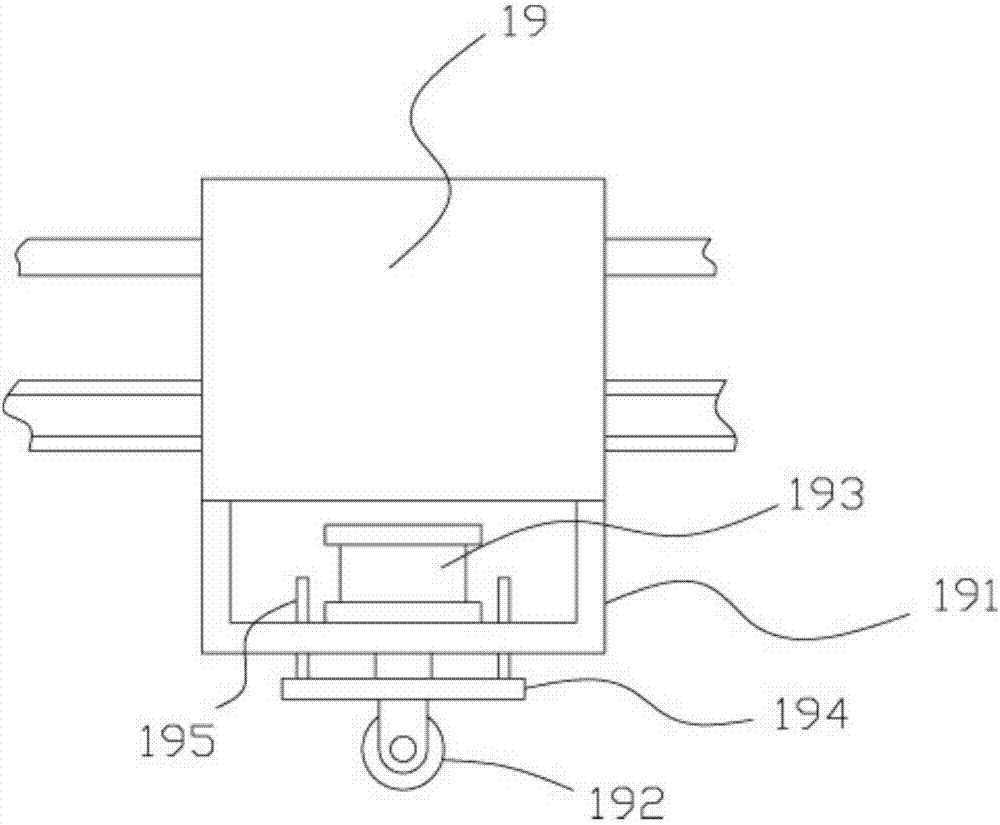

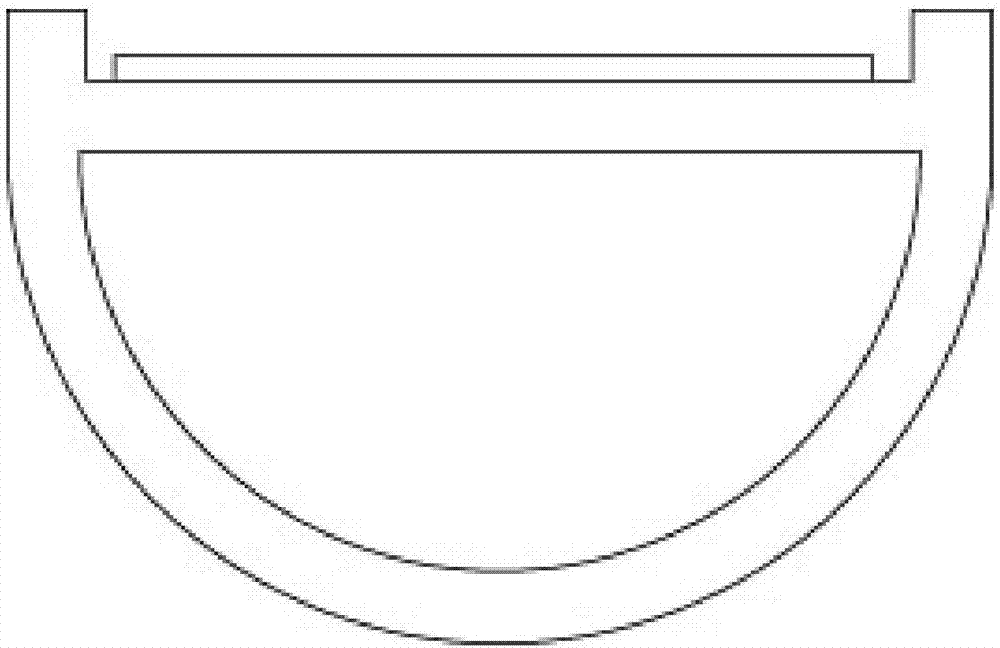

Laying device for waterproof coiled material

The invention discloses a laying device for a waterproof coiled material. The laying device comprises a box body, a heating device and a laying pressing device; damping rods are mounted at the four corners of the bottom end of the box body, sliding wheels are mounted at the bottom ends of the damping rods, a handle is arranged at the upper end of the outer wall of the left side of the box body, and an adjusting valve is arranged on the handle; sliding grooves are symmetrically formed in the front inner wall and the rear inner wall of the box body; the heating device comprises a U-shaped base,a fuel gas tank and a fuel gas pipeline; the U-shaped base is fixed to a bottom plate of the box body, the fuel gas pipeline stretches out of the fuel gas tank, one end of the fuel gas pipeline is connected with the adjusting valve, and the other end of the fuel gas pipeline stretches out of the bottom plate of the box body and is provided with a preheating spraying nozzle and a heating spraying nozzle; and the laying pressing device comprises a first winding roller, the waterproof coiled material, a second winding roller, a third winding roller, a flat-laying roller and a pressing roller. Thelaying device has the advantages that the stability of the laying device is good, the pasting effect of the waterproof coiled material is good, construction manpower is reduced, and the constructionefficiency is improved.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

Nutritious noodle rich in glutinous wheat flour

InactiveCN103330135AHigh total starch contentReduce amylose contentFood preparationAdditive ingredientTriticum turgidum

The invention discloses a nutritious noodle rich in glutinous wheat flour, and more specifically relates to a product of grain processing. The nutritious noodle comprises, by mass, 47 to 87% of common wheat flour and 10 to 50% of glutinous wheat flour as main ingredients, 0.2 to 1.5% of konjac fine powder and sodium alginate as auxiliary ingredients, and 0.3 to 1.5% of salt as an ingredient. The nutritious noodle is prepared by following steps: purified water in proportional quantity is added in a mixture of the ingredients above, wherein the mass ratio of the ingredients to purified water is 100:32-35; the mixture is kneaded into dough, and then is cured, rolled and pressed, cut into strips and shaped, and dried, so as to obtain the ultrathin nutritious noodle with a thickness of 0.5 to 0.6mm. The innovation of the main ingredients and the ratio of the nutrients are reasonable; the noodle is rich in nutrient, has excellent viscoelasticity, soft and tenacity mouthfeels, and is easy to cook; broken rate is low; and it only takes 1.5 to 2.5min to cook the noodle.

Owner:HUBEI BAIDIAN IND

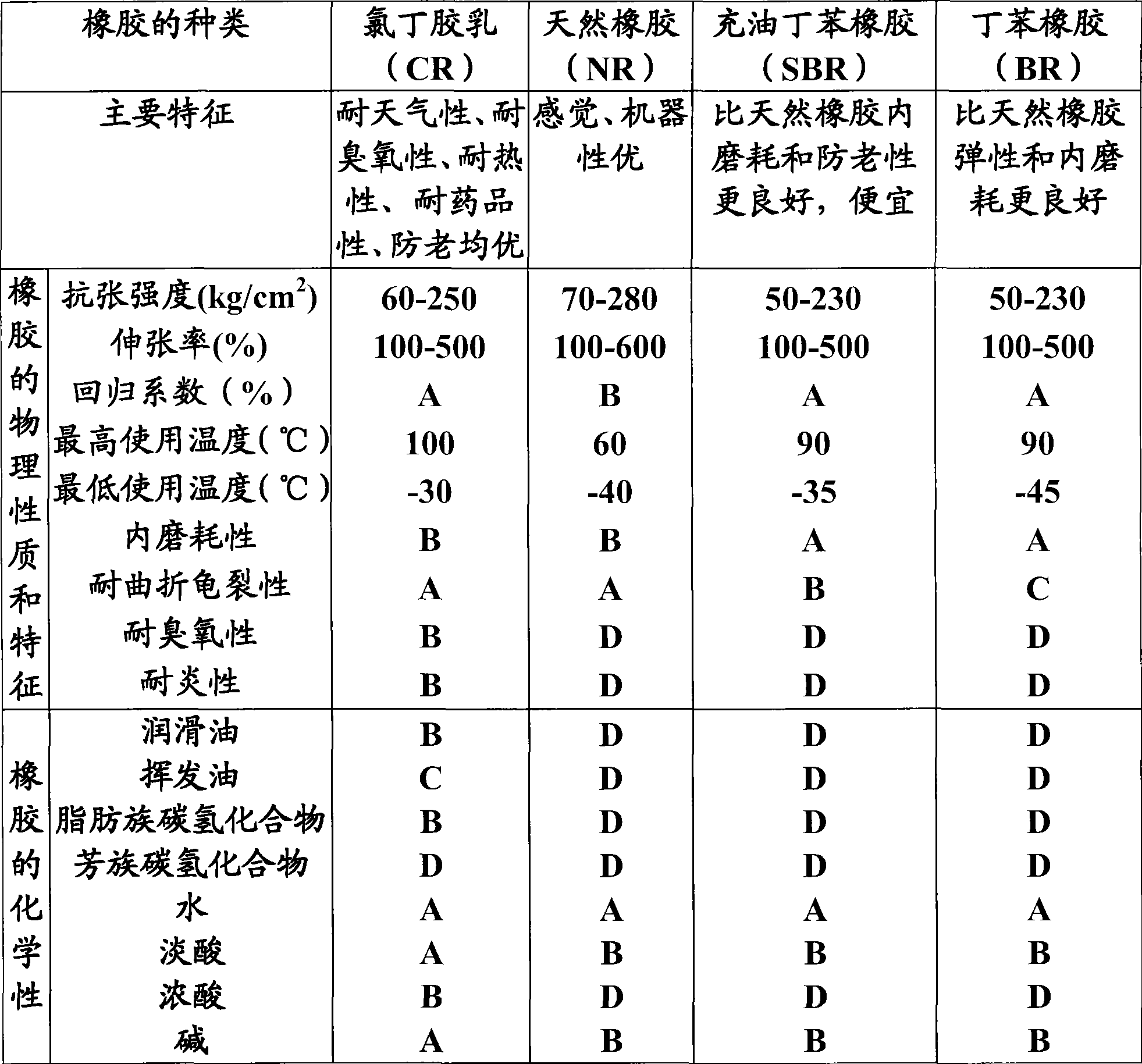

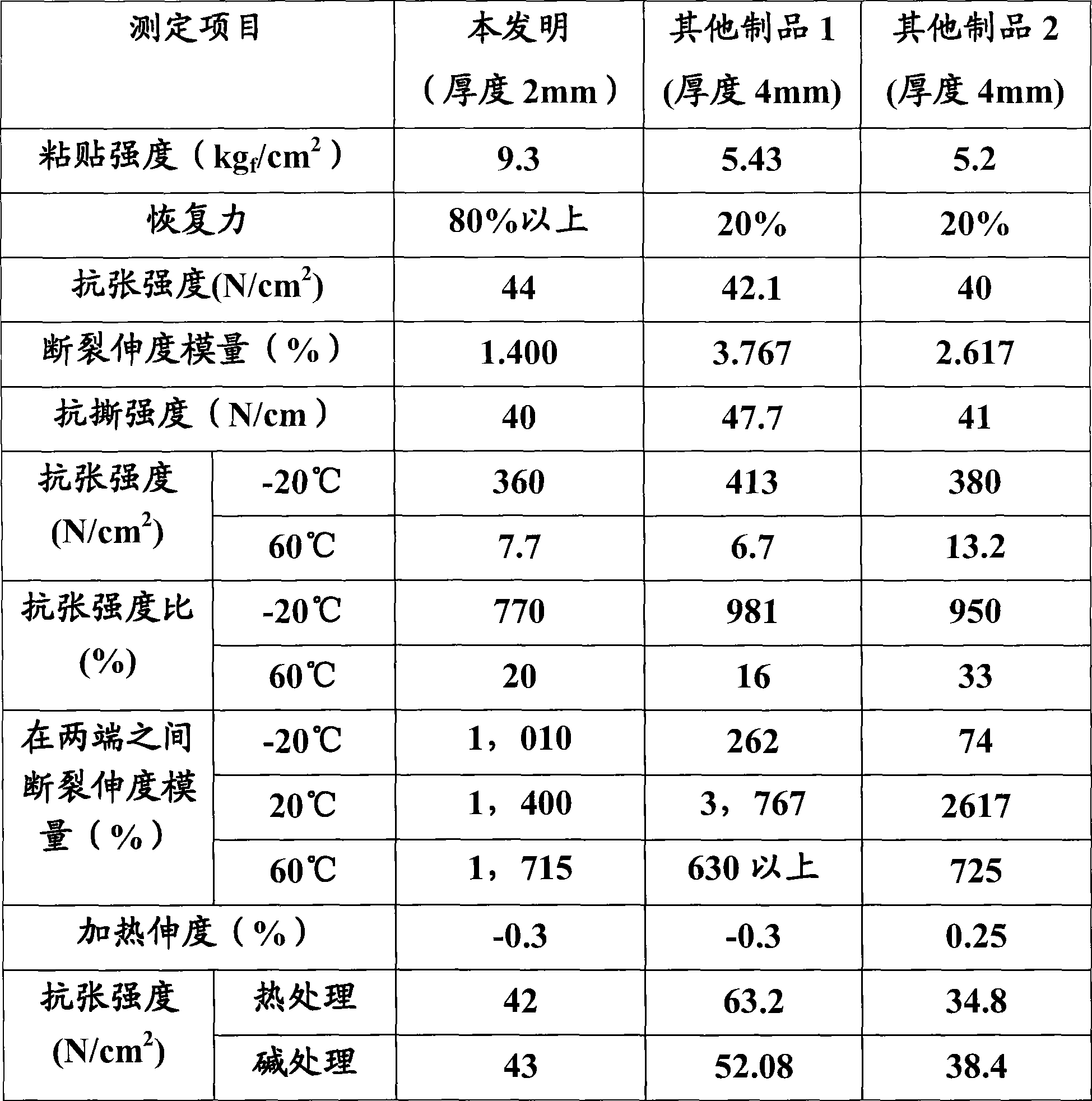

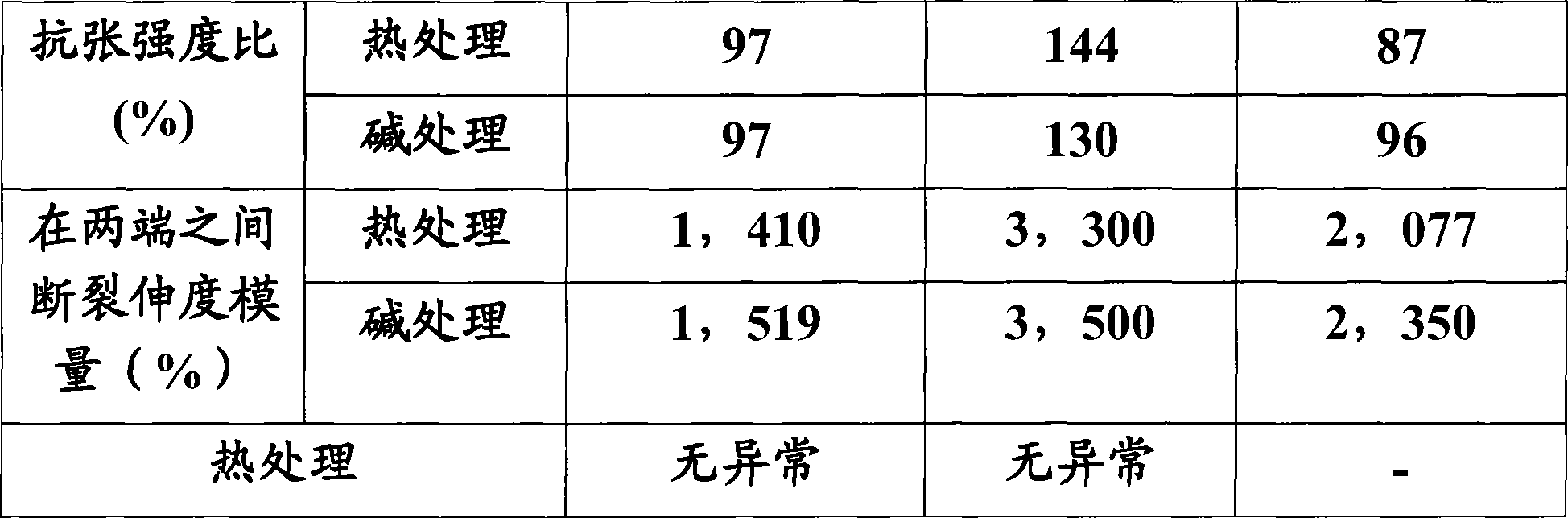

Waterproofing compound and construction method using the compound

ActiveCN101545305AHigh viscosityImprove recovery effectCovering/liningsBuild-up roofsNeopreneCold resistance

The invention provides a waterproof composition and configuration and construction method thereof. The waterproof composition is an asphalt waterproof composition using liquid rubber, having high restoring force, cold resistance and adhesiveness. Based on 100 parts of neoprene latex by weight, 100 parts of neoprene latex, 160 to 240 parts of oil-extended styrene buadiene rubber, 160 to 240 parts of carboxylic styrene butadiene rubber, 90 to 1600 parts of emulsified asphalt and 2 to 100 parts of additive by weight are mixed so as to provide the waterproof composition with the pH value of 7 to 12.

Owner:SPACE +1

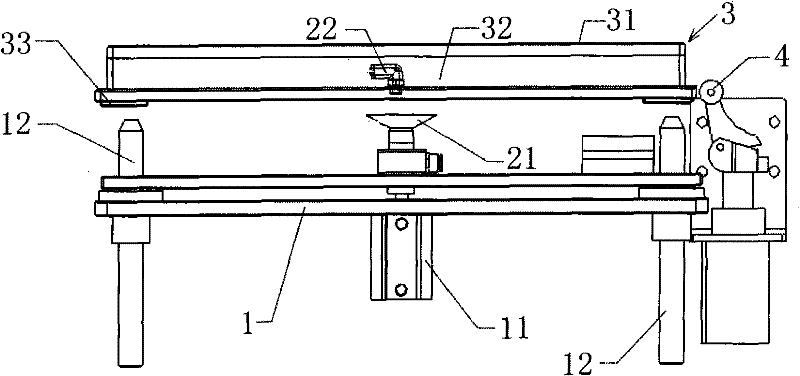

Full automatic plane labeling machine

ActiveCN106586161AImprove label sticking effectImprove pasting effectLabelling machinesEngineeringPaper tape

The invention discloses a full automatic plane labeling machine which comprises a rack. A main supporting plate is fixed on the rear portion of a top plate of the rack; a total groove is formed in the top face of the top plate of the rack; conveying driving rollers are hinged to the left end and the right end of the total groove; a conveyer belt is connected on the two conveying driving rollers in a tensioning mode; a conveying motor is fixed on the front wall face of the right end of the top plate of the rack; and an output shaft of the conveying motor stretches into the total groove and is connected with connecting shaft portions of one ends of the conveying driving rollers through a coupling. A first connecting block is fixed on the front wall face of the left end of the main supporting plate; a first proximity switch is fixed on the first connecting block; and the induction end of the first proximity switch is arranged vertically downward and faces the top face of the conveyer belt. According to the full automatic plane labeling machine, the products to be stuck can be automatically conveyed, automatic counting and positioning are completed to realize automatic label sticking, the tension degree of paper tape conveying can be adjusted, meanwhile, a paper tape of a label rolling cylinder can be guaranteed to be separated from a label, and the label sticking effect is improved.

Owner:桐城市建设投资发展有限责任公司

Steel coil labelling method

The invention discloses a steel coil labelling method which adopts labelling equipment. The steel coil labelling method comprises the following steps: S1, picking up labels through the labelling equipment; and S2, pasting the picked-up labels onto steel coils through the labelling equipment. The steel coil labelling method disclosed by the invention adopts special labelling equipment, can reliablyaccomplish pick-up and pasting of labels, can improve working efficiency of labelling the steel coils, is stable and reliable in work, is high in a labelling success rate, and improves the pasting effect of labelling the steel coils.

Owner:ANHUI MA STEEL AUTOMATION INFORMATION TECH

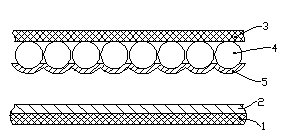

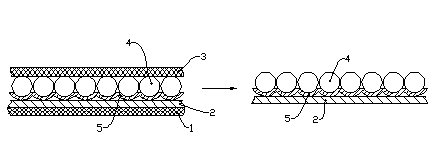

Manufacturing method of high-strength type reflection film

InactiveCN103105637ASimple preparation processFlat coatingLaminationLamination apparatusSizingMaterials science

The invention relates to a manufacturing method of a high-strength type reflection film. The manufacturing method of the high-strength type reflection film includes the following steps: step a, a bonding layer is coated on the surface of a first vase material; step b, a bead establishing layer is formed on the surface of a second base material with pressure-sensitive adhesive, and a reflection layer is plated on the surface of the outer side of glass beads of the bead establishing layer; step c, a light reflecting layer formed by the bonding layer, the reflection layer and the glass beads is formed; step d, embossing is carried out on the back face of the bonding layer through a hot-press embossing roller, and therefore partial of the bonding layer is pressed to form square protruded ribs, and transparent surface material is connected with tops of the protruded ribs; step e, after the bonding layer is embossed, a supporting layer is sprayed on the back of the bonding layer so as to form a plane; and step f, the pressure-sensitive adhesive is evenly coated on the back of the supporting layer, and release materials are covered on the pressure-sensitive adhesive. According to the manufacturing method of the high-strength type reflection film, the smooth supporting layer can be acquired, coating of the pressure-sensitive adhesive can be smooth and uniform, bonding effect is good, and sizing material can be saved.

Owner:JIANGSU TST NEW MATERIALS SCI & TECH

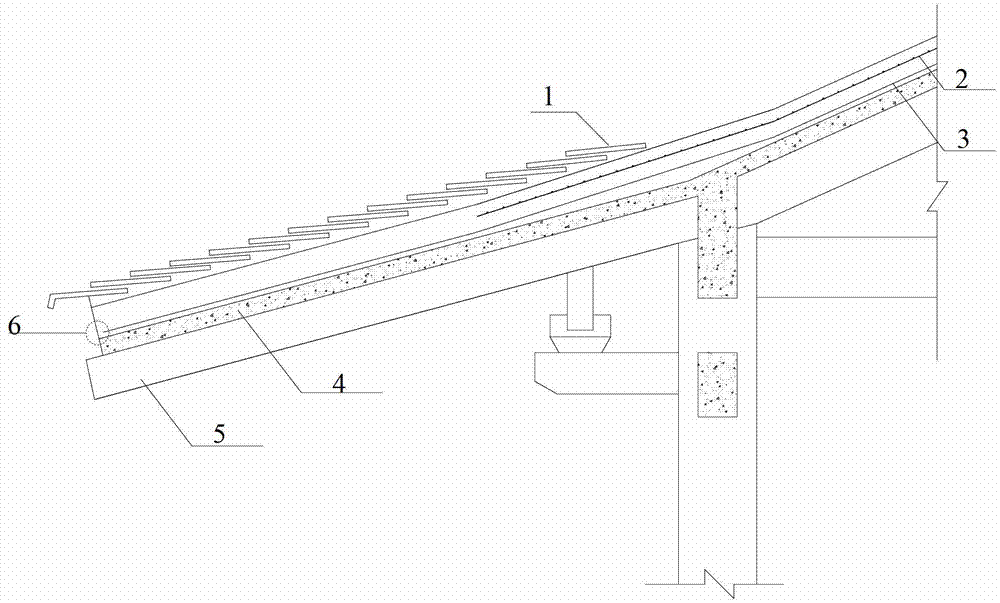

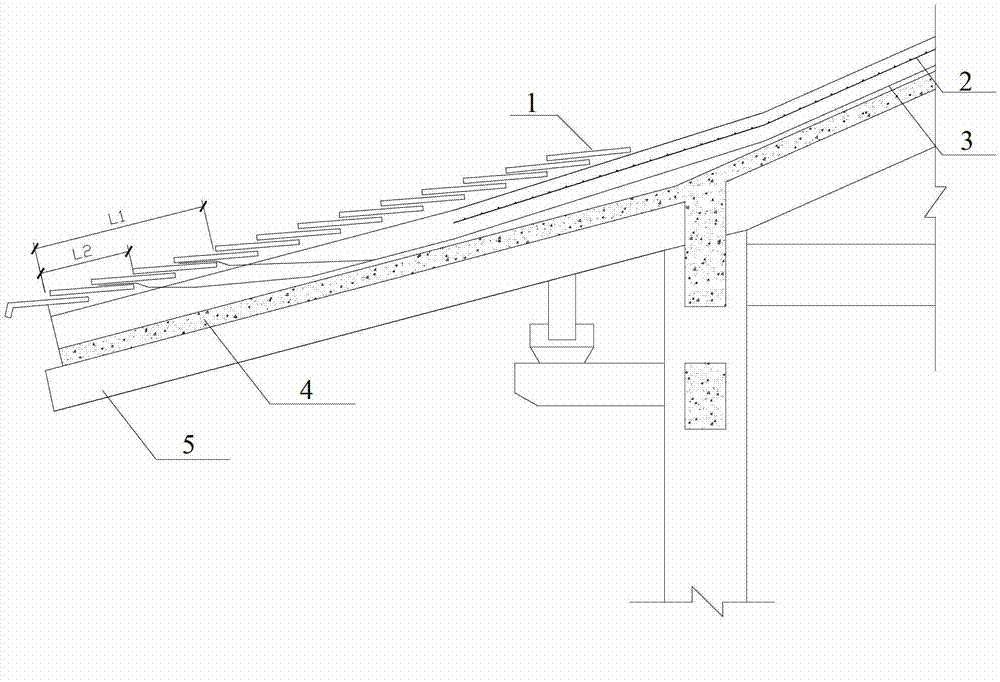

Method of crack resistance and seepage prevention for concrete roof eave edging in archaized architectures

ActiveCN103046698AMeet the fortification requirementsEnsure normal dischargeBuild-up roofsRoof drainageCrack resistanceRoof tile

The invention discloses a method of crack resistance and seepage prevention for concrete roof eave edging in archaized architectures. The method includes: turning up the lower end of a roof waterproof layer of an archaized architecture at positions L1 and L2 of the eave edging, and press-fitting the lower end to a roof tile lap joint so as to enable water on the surface of the waterproof layer to flow to the upper surfaces of roof tiles and flow to the end of an eave to drop along the tile surfaces; and directly adhering the roof tiles at the outer end of the eave to a concrete structural slab or reinforced mortar covering straw layer. Water seeping to the waterproof layer is drained in advance by changing the detail of waterproof structure of the roof eave without changing the appearance and the waterproof function of the archaized architecture roof, and the eave edging is protected from water erosion.

Owner:SHAANXI CONSTR ENG GRP NO 7 BUILDING ENG

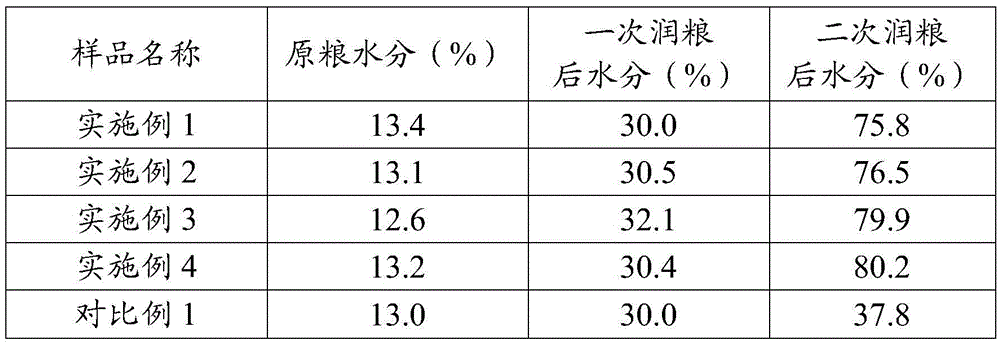

Grain wetting method in sauce fragrance baijiu brewing technology

InactiveCN105602782ASimple processImprove water absorptionAlcoholic beverage preparationAbsorption ratioDistillation

The invention provides a grain wetting method in sauce fragrance baijiu brewing technology. According to the grain wetting method, hot water with a temperature of 95 DEG C or higher is used for two times of grain wetting, and in each time of grain wetting, layer-by-layer stacking standing is adopted, so that water can be absorbed by grain as much as possible, grain water absorption ratio is as high as 65 to 70%, water content of dried grain is about 10%, water content of grain after grain wetting is increased to 75 to 80%, and grain gelatinization is promoted effectively in distillation.

Owner:四川郎酒股份有限公司

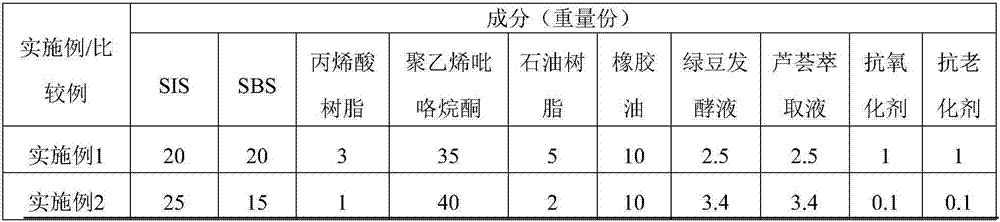

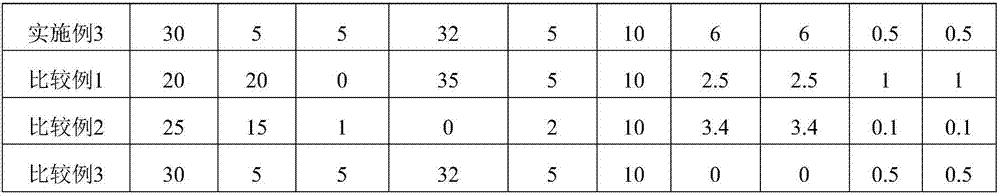

Special drug-loading hot-melt pressure-sensitive adhesive

InactiveCN106880623ALong-lasting stickinessGood antibacterial effectAntibacterial agentsNon-macromolecular adhesive additivesChemistryBacteriostatic agent

The invention discloses a special drug-loading hot-melt pressure-sensitive adhesive, which is prepared from the following components in parts by weight: 20-45 parts of a styrene-isoprene-styrene block copolymer thermoplastic elastomer, 1-5 parts of acrylic resin, 5-20 parts of styrene-butadiene-styrene block copolymer thermoplastic elastomer, 20-35 parts of a tackifier, 10-15 parts of a plasticizer, 5-12 parts of a bacteriostatic agent, 0.01-1 part of an age resister and the balance of anti-oxidant, wherein the tackifier is a mixture formed by mixing polyvinylpyrrolidone and one of petroleum resin, rosin resin, terpene resin, terpene-styrene resin and coumarone-terpene resin, wherein polyvinylpyrrolidone accounts for over 50% of the weight of the tackifier. The special drug-loading hot-melt pressure-sensitive adhesive is lasting in adhesivity, good in weather resistance and heat resistance, good in antibacterial effect, good in drug-loading effect and low in cost.

Owner:嘉好(太仓)新材料股份有限公司

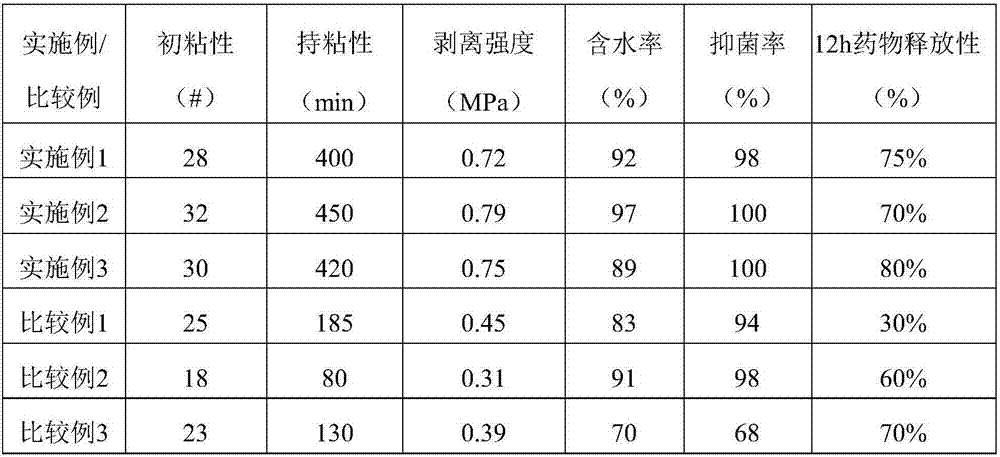

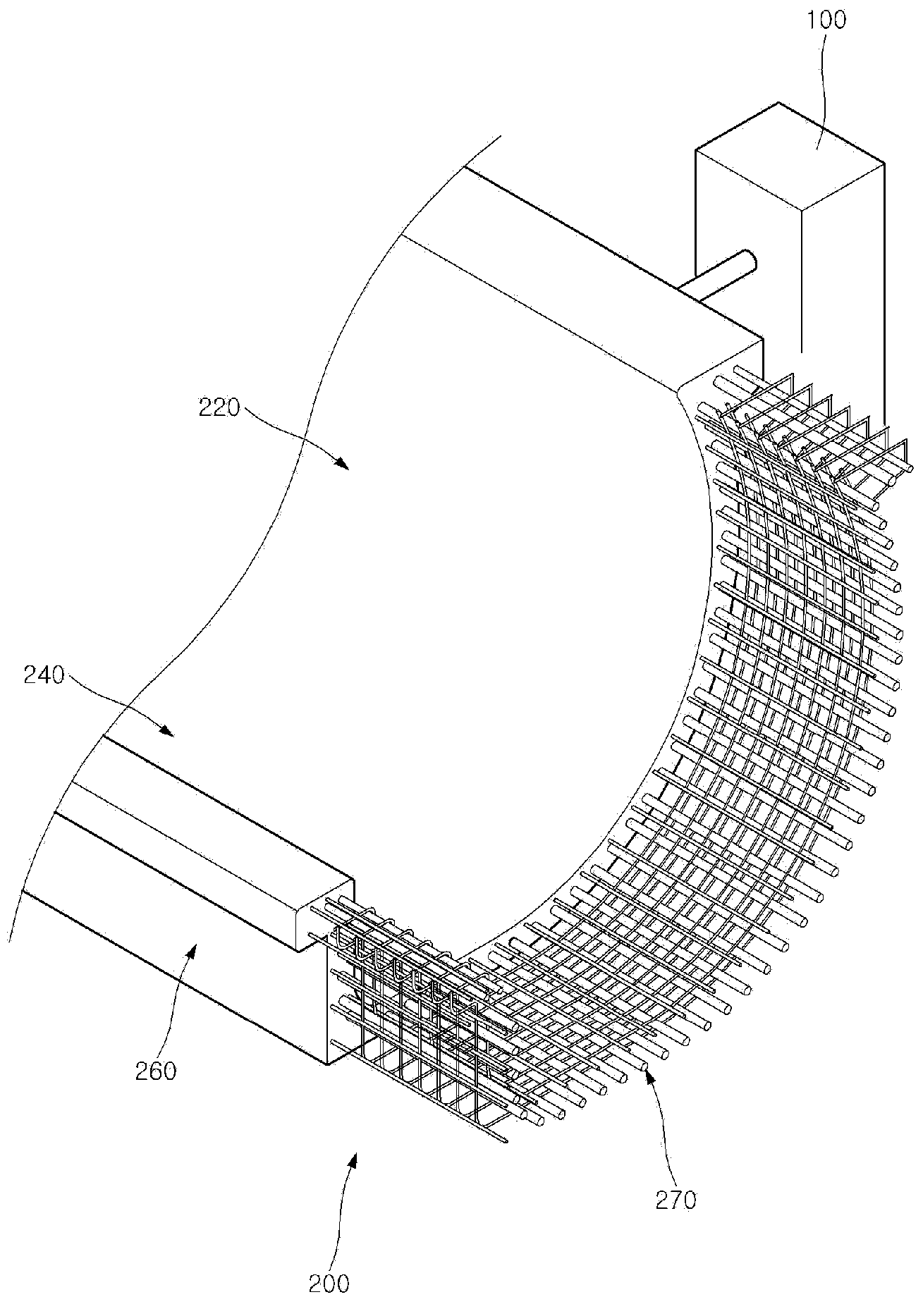

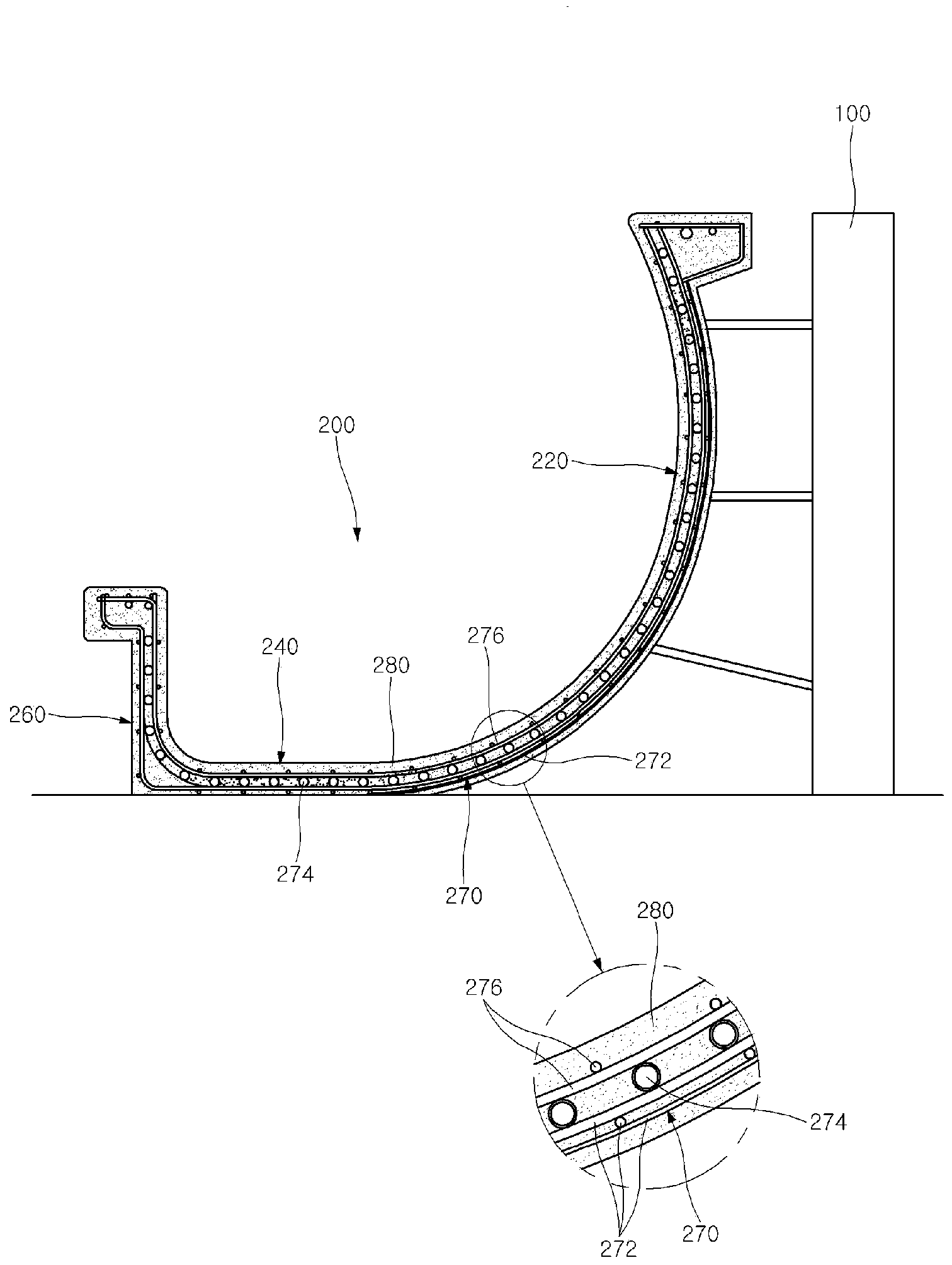

Method for constructing a bobsleigh course using a high-performance wet-type shotcrete composition

InactiveCN103906552AGood construction performanceHigh compressive strengthSki bindingsTunnel liningRough surfaceShotcrete

The present invention relates to a method for constructing a bobsleigh course using a high-performance wet-type shotcrete composition, and more particularly, to a method of constructing a bobsleigh course that uses a high-performance wet-type shotcrete composition which includes silica fumes and AE material, and which has increased pumpability prior to being deposited due to the presence of a superabundant amount of air, and increased shootability after being deposited since the amount of air present is decreased, thus imparting high constructability, high strength, and high durability to the composition. To this end, the method comprises: a framework-forming step of fixing a wire-mesh formwork, positioning a cooling pipe, strengthening adherence and holding strength, and installing a curvature-maintaining pipe; a shotcrete-laying step of laying the shotcrete composition; a first surface-finishing step of setting a curved surface and performing finishing using plastering; a second surface-finishing step of performing a rough surface finishing; and a wet curing step of performing wet curing.

Owner:KNU IND COOPERATION FOUND +1

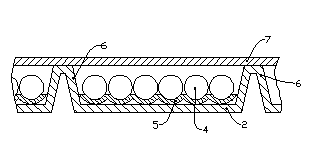

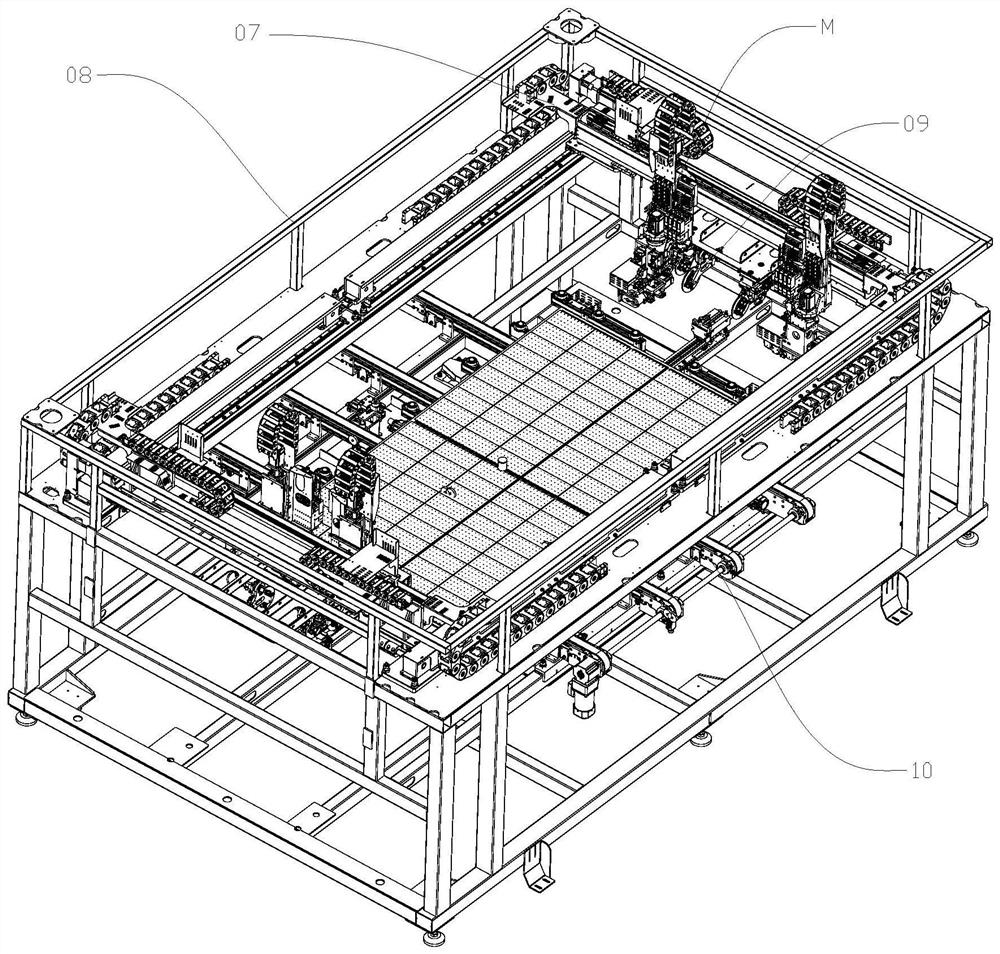

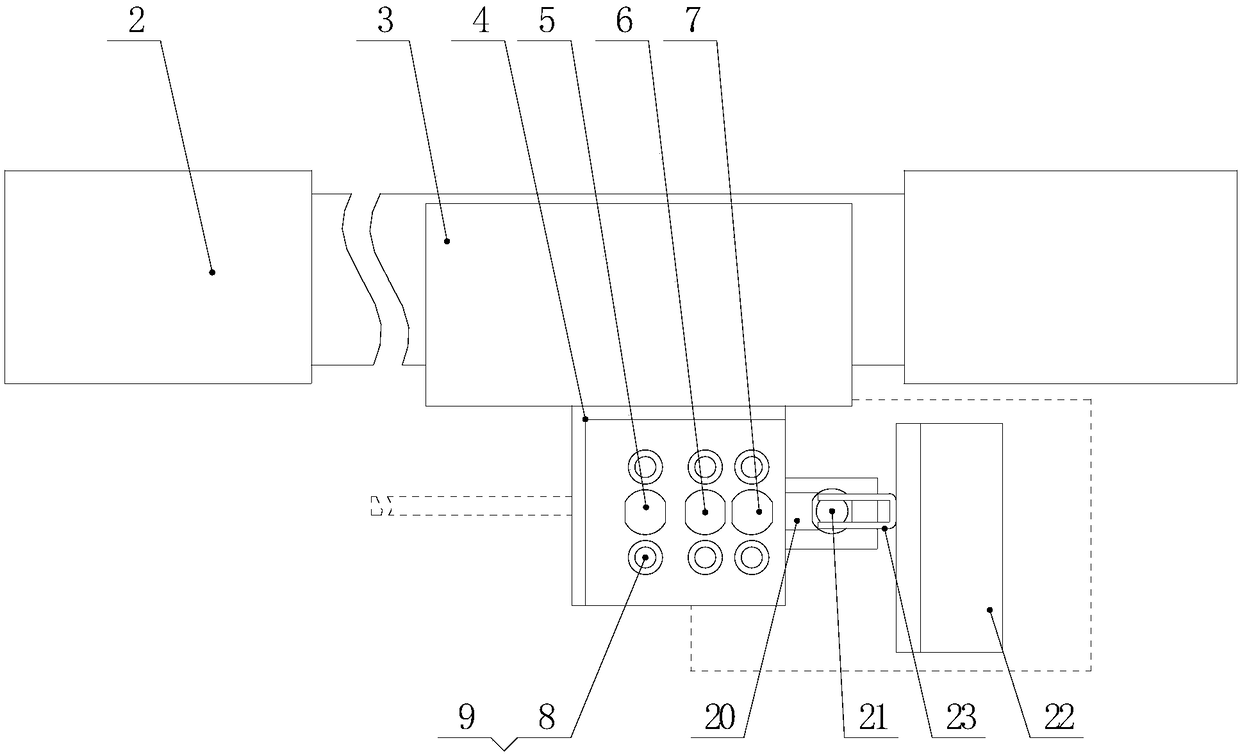

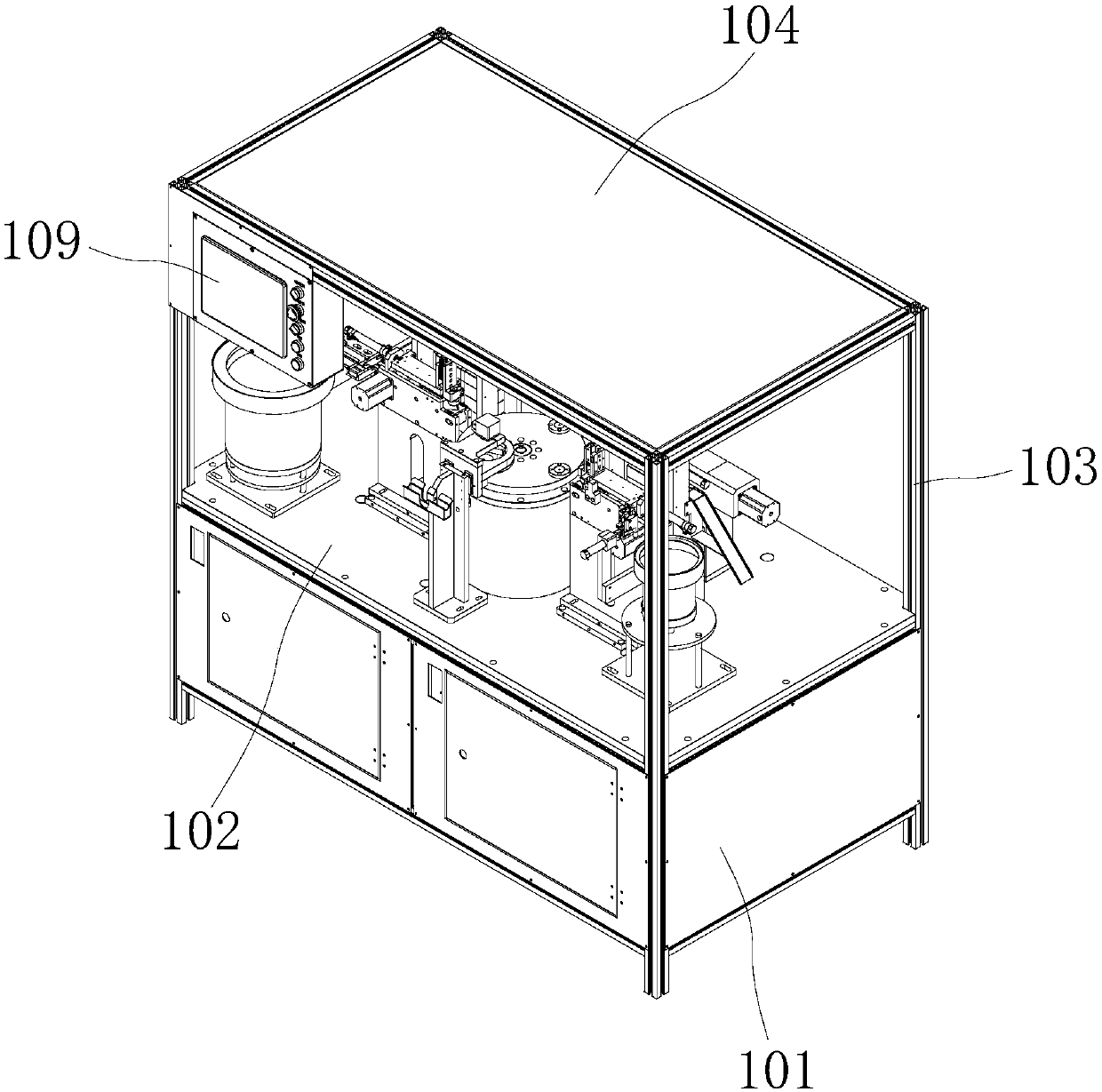

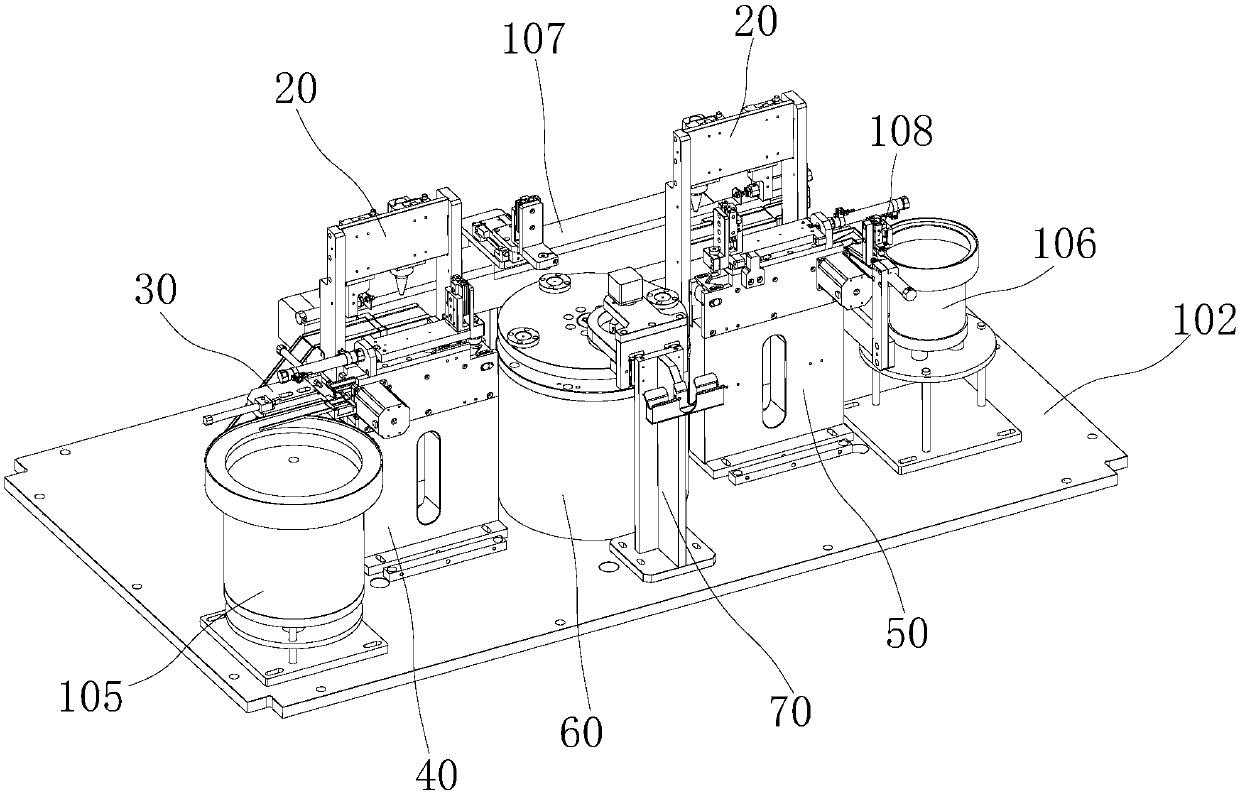

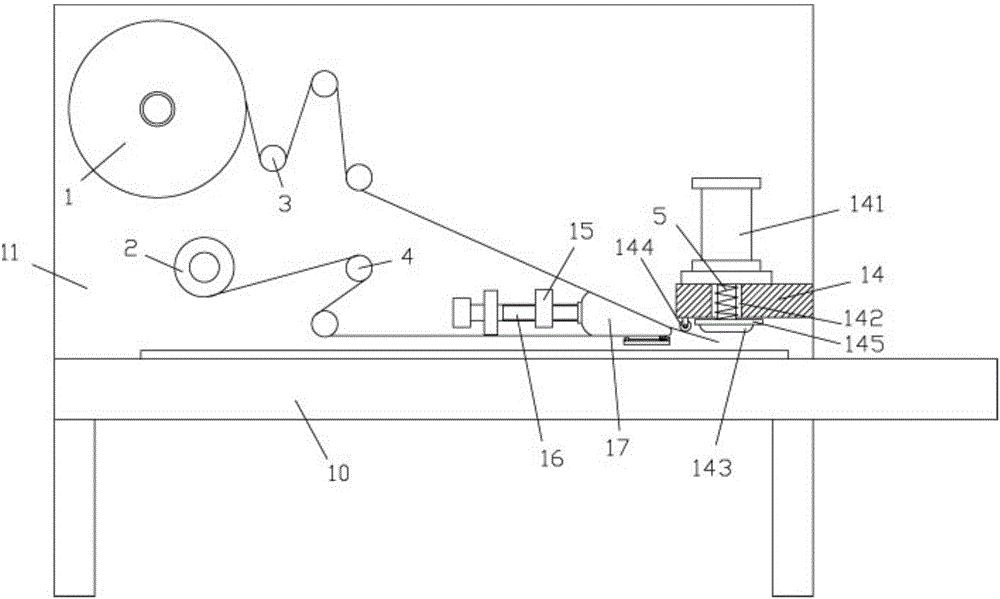

Battery string assembly adhesive tape automatic cutting and pasting all-in-one machine

ActiveCN112960456ARealize automatic replacementRealize huggingFinal product manufactureArticle deliveryAdhesive beltEngineering

The invention discloses a battery string assembly adhesive tape automatic cutting and pasting all-in-one machine. The battery string assembly adhesive tape automatic cutting and pasting all-in-one machine comprises a rack, a carrying device is fixedly arranged on the rack, a battery string assembly adhesive tape pasting device is arranged on the carrying device, and the carrying device can drive the battery string assembly adhesive tape pasting device to move in the long edge direction and the short edge direction of the rack. Full-coverage adhesive tape pasting on a battery string assembly is realized, the battery string assembly adhesive tape pasting device can rotate in the circumferential direction and can adapt to adhesive tape pasting of the battery string assembly in the transverse position and the longitudinal position, a battery string assembly conveying device is fixedly arranged below the rack, and an adhesive tape preparing device is fixedly arranged on the rack. The adhesive tape preparing device is adjacent to the battery string assembly adhesive tape pasting device, and the adhesive tape preparing device can automatically replace an adhesive tape for the battery string assembly adhesive tape pasting device. When the battery string assembly adhesive tape automatic cutting and pasting all-in-one machine is used, the adhesive tape can be automatically replaced, the pasting speed is high, the adhesive tape is firmly pasted, and the pasting efficiency is greatly improved.

Owner:NINGXIA XN AUTOMATION EQUIP CO LTD

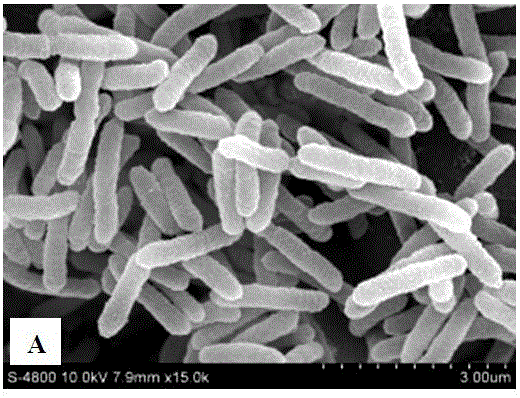

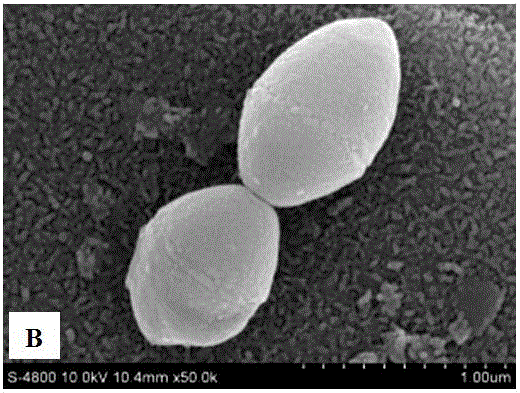

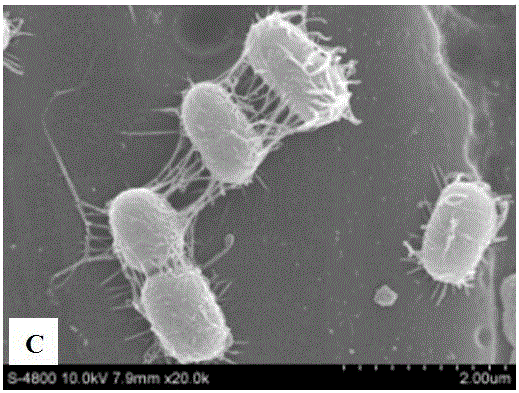

Sticking agent for making bacterial scanning electron microscope observation slice and preparation method thereof

InactiveCN106596608AEnriching Microscopic Observation and Production TechniquesRich technical approachesMaterial analysis by measuring secondary emissionEmulsionDistilled water

A sticking agent for making a bacterial scanning electron microscope observation slice and a preparation method thereof are disclosed; every 100 ml of the sticking agent comprises 3-5mL of egg white, 5-7mL of glutinous rice powder emulsion, and balance of distilled water; the preparation method is as follows: respectively taking 3-5mL of the egg white and 5-7mL of the glutinous rice powder emulsion to put into a beaker, using sterile water to fix the volume to 100mL, evenly mixing, using a disposable needle filter with the specification of 0.22 mu m for filtering to obtain filtrate as the sticking agent; a method for making the scanning electron microscope bacterial ultramicroscopic morphology observation slice from the sticking agent comprises the steps of collection of bacteria, fixation, sticking, dehydration, replacement, critical point drying, sticking on a sample platform and ion sputtering; the effective sticking agent aiming at bacterial scanning electron microscope observation experiments and the preparation method thereof and a slice preparation method are provided, and the effective sticking agent solves slice shedding and mixing phenomena in the bacterial scanning electron microscope observation experiments.

Owner:HENAN UNIV OF SCI & TECH

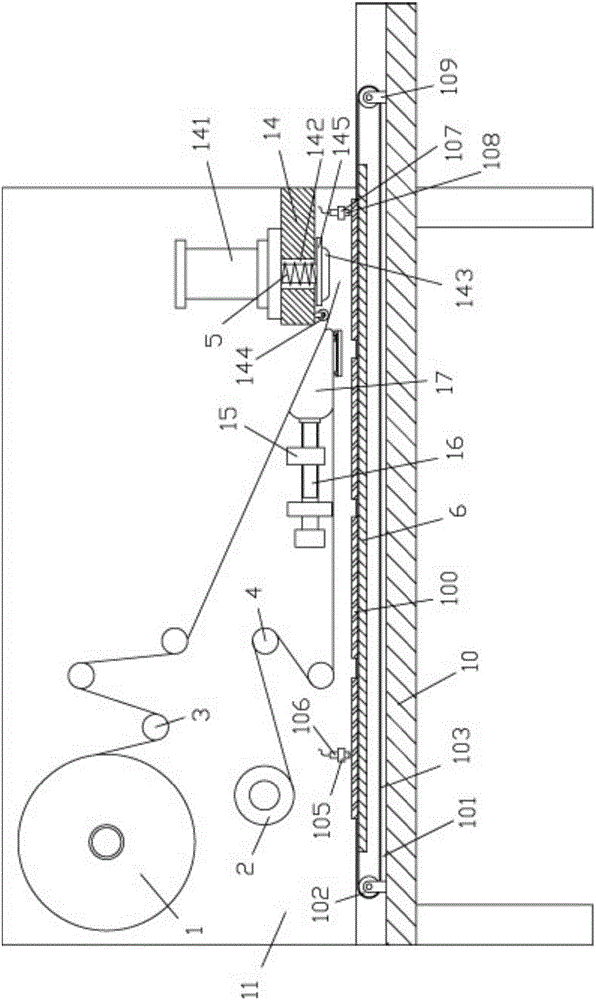

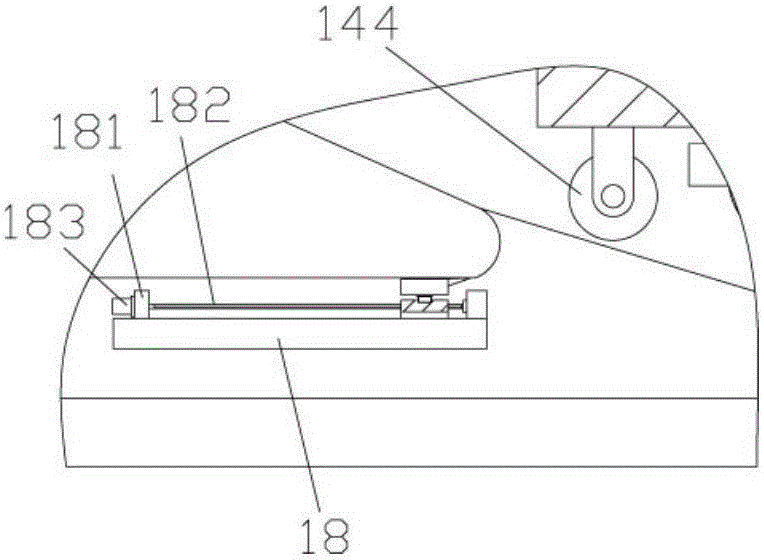

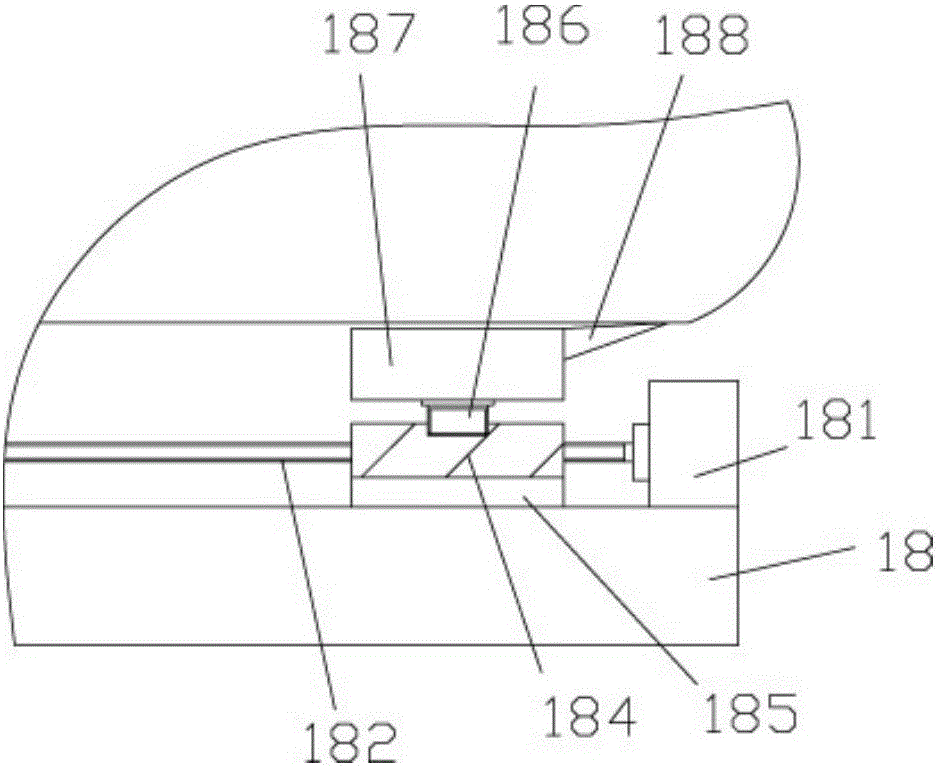

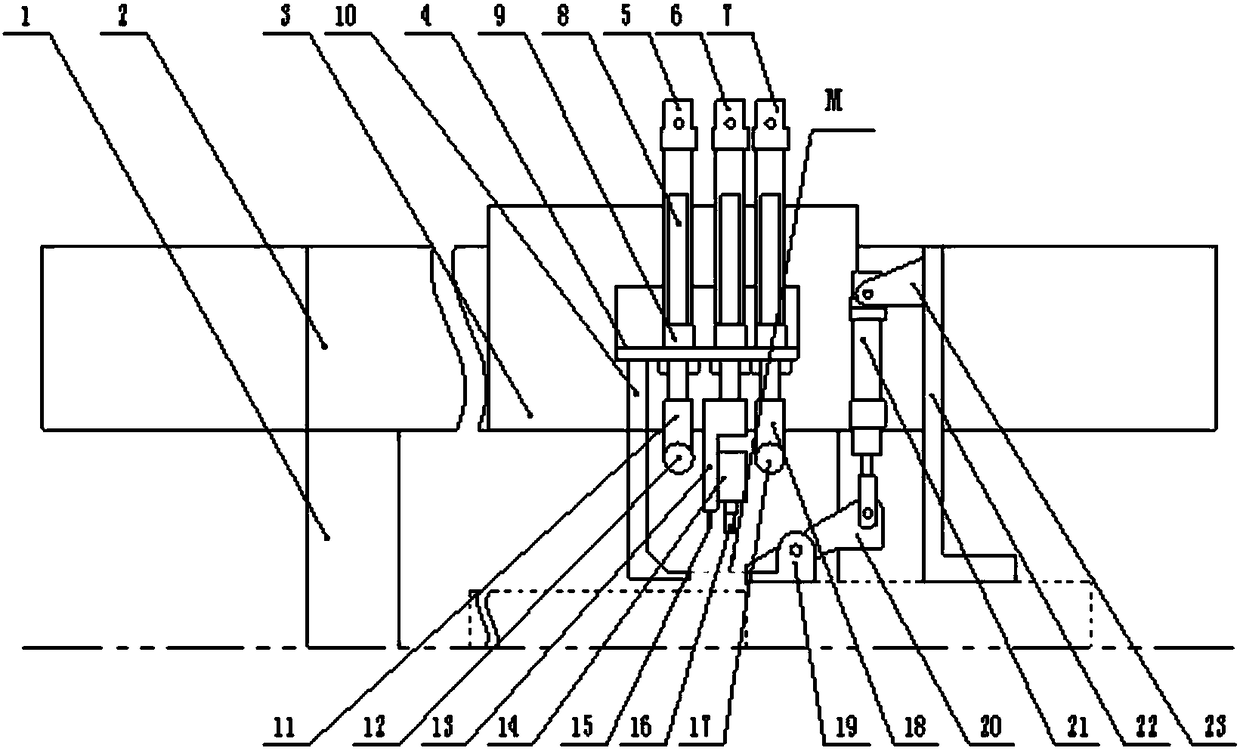

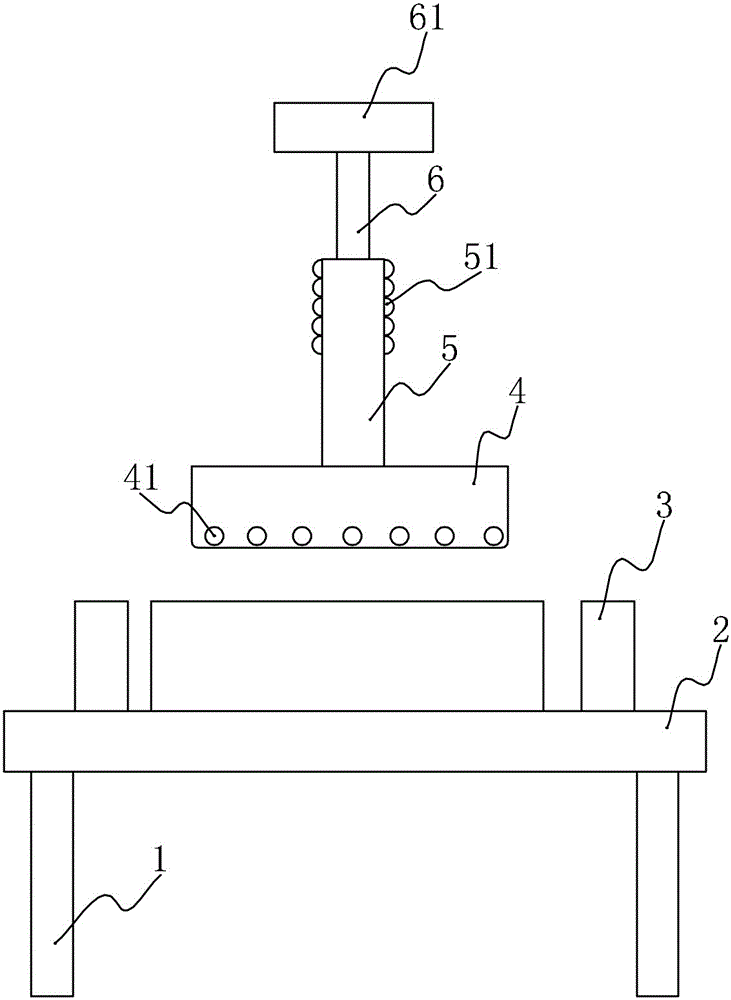

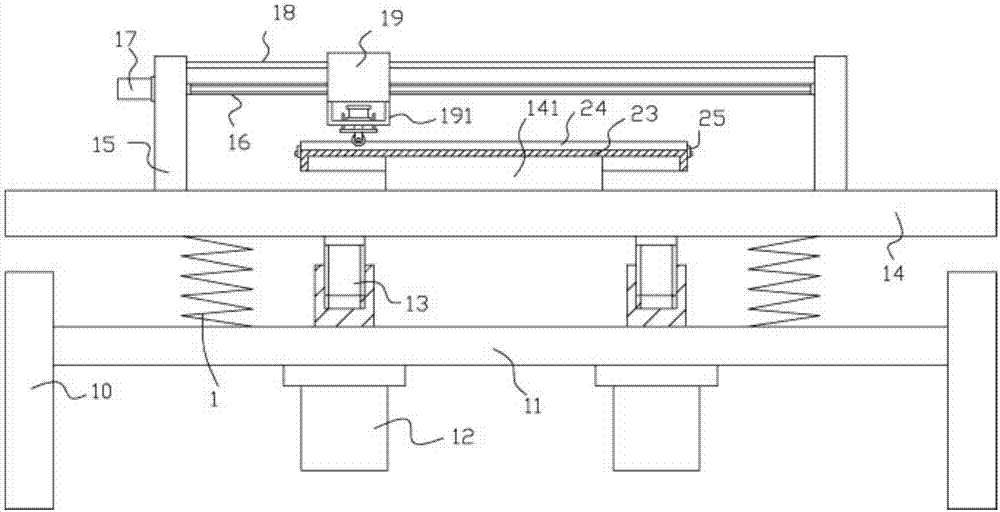

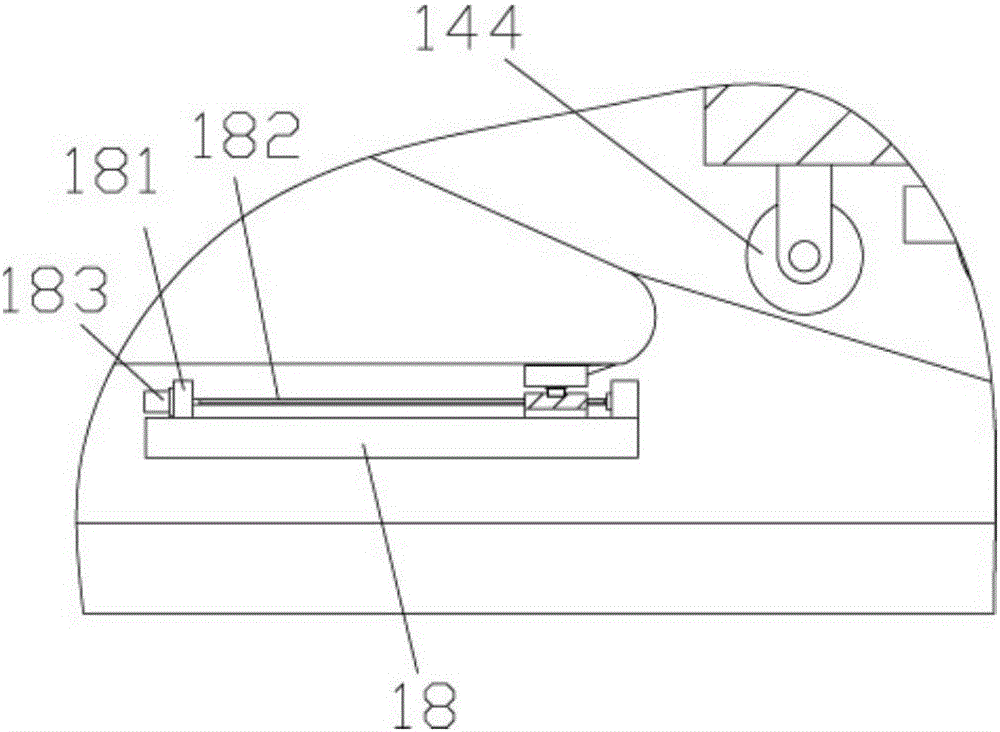

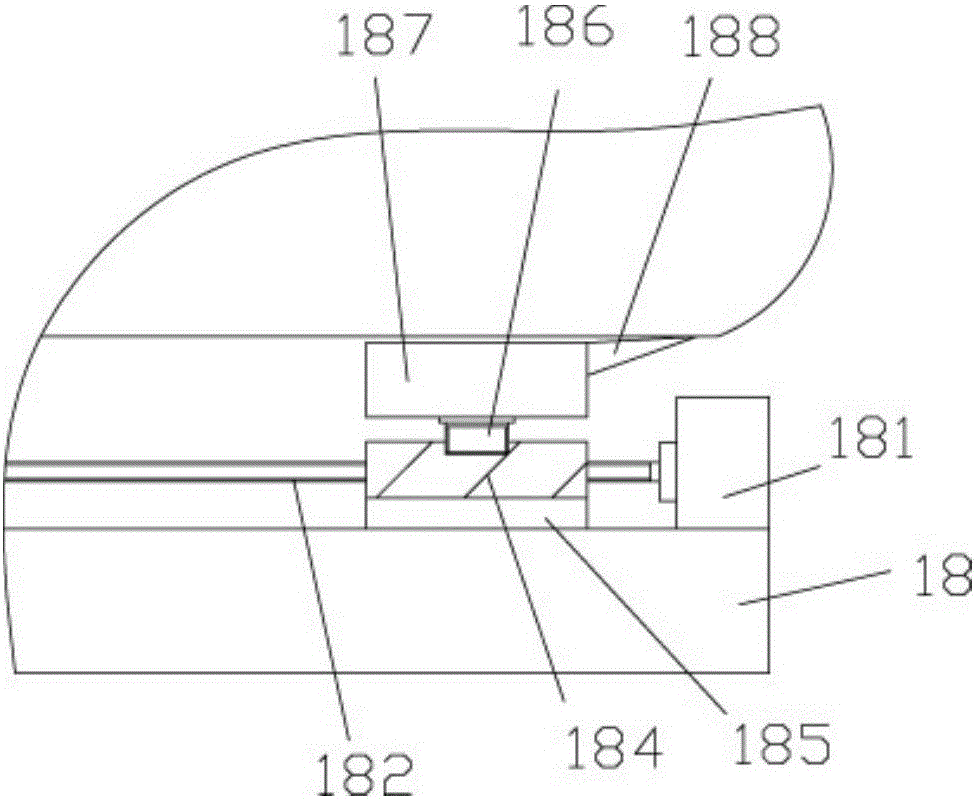

Prefabricated fragment strip adhesive tape adhering device

ActiveCN108106504AReduce deformationRealize automatic pasteAmmunitionEngineeringMechanical engineering

The invention discloses a prefabricated fragment strip adhesive tape adhering device. The prefabricated fragment strip adhesive tape adhering device comprises a rack, a downward pressing adhesive tapeholding device, a downward pressing cutter device, a downward pressing adhesive pressing device and an adhesive tape end portion clamping device, and the downward pressing adhesive tape holding device, the downward pressing cutter device, the downward pressing adhesive pressing device and the adhesive tape end portion clamping device are located on the A side of the rack and are sequentially arranged in the advancing direction of adhesive tape; the downward pressing adhesive tape holding device, the downward pressing cutter device and the downward pressing adhesive pressing device are all located over the advancing path of the adhesive tape; and the adhesive tape end portion clamping device is provided with a clamping port located in the advancing path of the adhesive tape. The prefabricated fragment strip adhesive tape adhering device is simple in structure, convenient to use and capable of achieving the effects that automatic adhering of the prefabricated fragment strip adhesive tape is achieved, the production efficiency is improved, meanwhile, the adhering precision and the adhering effect can be improved, and it is guaranteed that deformation of the adhesive tape is minimum,

Owner:中国兵器装备集团自动化研究所有限公司

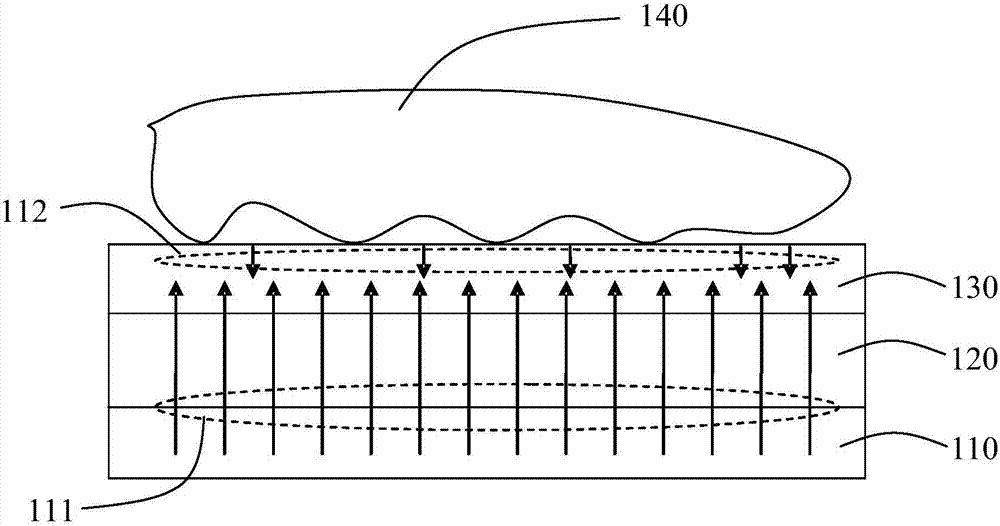

Optical fingerprint sensor module and manufacturing method thereof

InactiveCN107358139AImprove image qualityAvoid problemsCharacter and pattern recognitionComputer sciencePara position

The present invention provides an optical fingerprint sensor module and a manufacturing method thereof. The optical fingerprint sensor module comprises a first sub substrate having a first surface and a second surface; a second sub substrate having a third surface and a fourth surface; a circuit board located at the second surface, wherein the circuit has a photosensitive pixel area which comprises a transparent area; a color block or a color sublayer located at the third surface, wherein the first sub substrate and the second sub substrate are pasted together in para position, when the third surface has the color block, the photosensitive pixel area and the color block are opposite, when the third surface has the color sublayer, the photosensitive pixel area and the color sublayer are opposite; and a transmission medium located between the photosensitive pixel area and the color block or located between the photosensitive pixel area and the color sublayer. The optical fingerprint sensor module is optimized in structure and improved in performance.

Owner:SHANGHAI OXI TECH

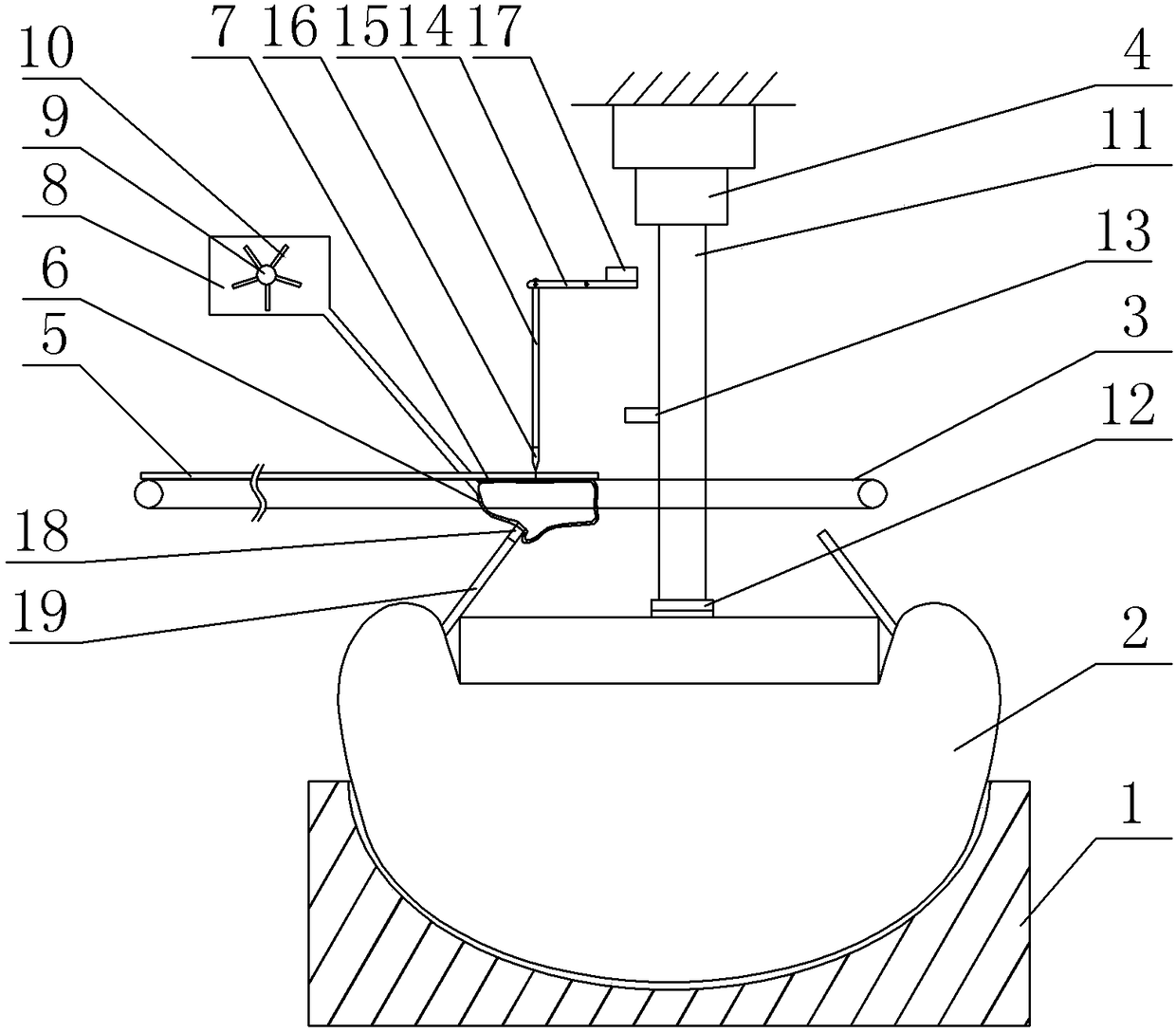

Auxiliary painting equipment for putty on back face of building decoration ceramic tile

InactiveCN108756152APrevent precipitationImprove pasting effectBuilding constructionsEngineeringContinuous rotation

The invention relates to auxiliary painting equipment for putty on the back face of a ceramic tile, in particular to auxiliary painting equipment for the putty on the back face of a building decoration ceramic tile. According to the auxiliary painting equipment for the putty on the back face of the building decoration ceramic tile, the putty can be directly attached to the back face of the ceramictile, and the putty in a putty barrel can be automatically stirred. According to the technical scheme, the auxiliary painting equipment for the putty on the back face of the building decoration ceramic tile comprises a base, a supporting seat, the putty barrel, a funnel, a valve, an arc-shaped plate, a slideway, a sliding shaft, a swinging rod and the like. The supporting seat is arranged on theleft side of the top of the base, and the putty barrel is arranged at the top of the supporting seat. According to the auxiliary painting equipment for the putty on the back face of the building decoration ceramic tile, the putty barrel, the funnel, the valve and a suction disc are arranged, so that a decorator can place a supporting plate on the suction disc and then open the valve, the putty canautomatically flow to the supporting plate, and then the putty on the supporting plate is scraped and leveled, so that the putty is not required to be poured on the back face of the ceramic tile oneby one, and the putty on the back of the ceramic tile is not required to be scraped and leveled one by one. The putty in the putty barrel can be automatically stirred by the continuous rotation of a rotating motor.

Owner:詹凤程

Powder coating used on automotive aluminium wheels and suitable for balance weights to bond and preparation method thereof

ActiveCN105038519AHigh heat distortion temperatureImprove thermal stabilityPowdery paintsEpoxy resin coatingsPolyester resinBond properties

The invention discloses a powder coating used on automotive aluminium wheels and a preparation method thereof. The powder coating comprises the following components in parts by weight: 30-45 parts of carboxyl saturated polyester resin, 40-70 parts of bisphenol A epoxy resin, 0.5-2 parts of surfactant, 0-8 parts of single salt flatting curing agent, 5-10 parts of additives, 15-40 parts of fillers and 0-3 parts of pigments. The prepared powder coating used on automotive aluminium wheels has good breathability and excellent levelling property and balance weight bonding property.

Owner:GUANGZHOU KINTE IND

Automatic glue applying device for rubber soles

InactiveCN105057181AApply evenlyImprove pasting effectLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an automatic glue applying device for rubber soles. The automatic glue applying device comprises a bracket, wherein shoe molds for clamping the rubber soles are arranged on the bracket in a sliding manner; the automatic glue applying device further comprises a handheld mold, wherein the handheld mold comprises a clamping block of which the bottom is hollow, and holes communicated with the inner cavity of the clamping block are formed in the surface of the clamping block and uniformly distributed around the clamping block; a hollow connecting rod is fixed on the clamping block and communicated with the empty cavity of the clamping block; a piston rod is arranged in the connecting rod, and a thrust head is fixed on the end head extending out of the connecting rod of the piston rod. Through the hollow clamping block and the connecting rod, glue can be stored at the inner part of the clamping block, and through operating the piston rod, the glue at the inner part of the clamping block is pushed out of the holes; because the soles to be stuck sleeve the clamping block, the glue pressed out of the holes can uniformly adhere on the inner walls of the side edges of the soles. The automatic glue applying device disclosed by the invention has the advantages that the automatic glue applying device is convenient to operate, and the glue can be rapidly and uniformly applied.

Owner:CHONGQING HUIMEI IND CO LTD

Method for moistening corn

InactiveCN102533511AAvoid lostImprove grain gelatinization effectAlcoholic beverage preparationWater contentChemistry

The invention relates to a method for moistening corn, which belongs to the technical field of brewing. The invention aims to solve the technical problem of improving the method for moistening the corn, so that not only can the effect for moistening the corn be improved, but also resource waste can be avoided. The method for moistening the corn comprises the following steps of: adding water in the corn, and soaking for 1-2 hours, wherein the weight of the water added in the corn is Skg, the moisture content of the corn after soaking with the water is Y, the moisture content of the corn before soaking with the water is X, the weight of the corn before soaking with the water is Mkg, Y is equal to 40-60 weight percent, and S is equal to (Y-X)*M.

Owner:LUZHOU PINCHUANG TECH

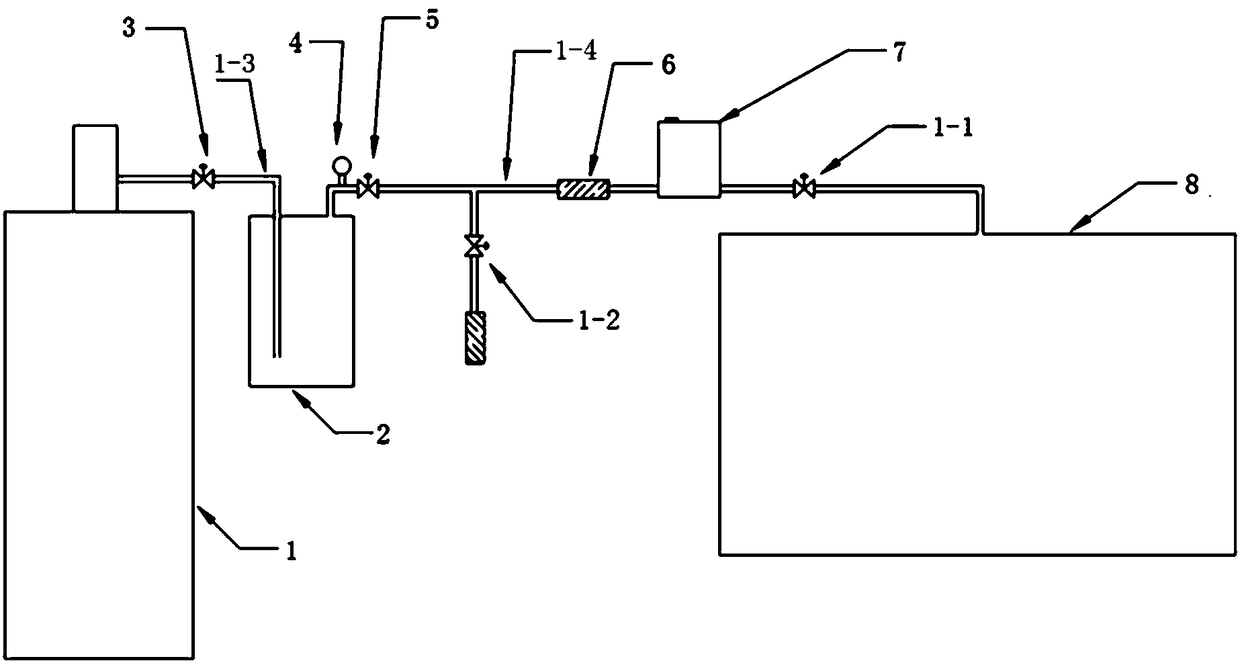

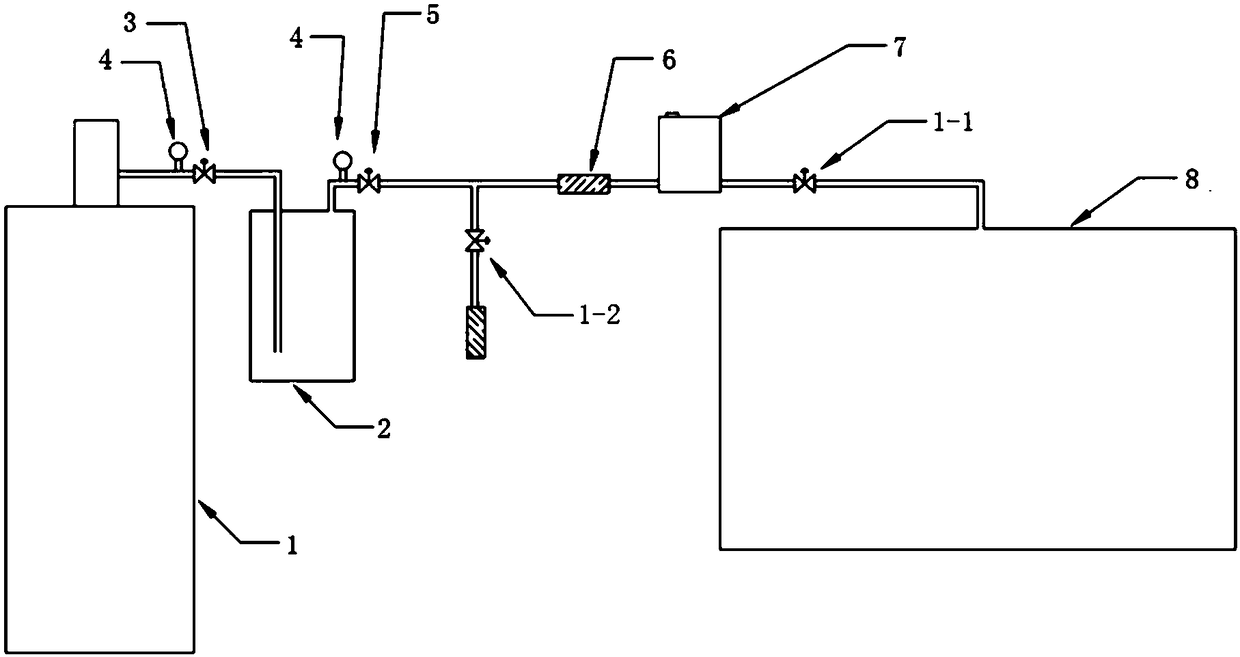

Gas supply system and gas supply method

PendingCN108506730AEasy to installGood sealingAmino compound purification/separationOrganic compound preparationPlasma surfaceControl valves

The invention discloses a gas supply system and a gas supply method. The gas supply system comprises a gas supply device and a buffer tank. The gas supply device communicates with an inlet of the buffer tank through a pipe E. A pipe F is connected with an outlet of the buffer tank. A pressure control valve is arranged on the pipe E. A digital display pressure gauge and a buffer gas outlet valve are installed on the pipe F on the outlet of the buffer tank respectively. The pipe F is provided with a gas filter and a gas quality and flow controller in sequence. When the gas supply system is usedfor supplying gas to a plasma surface treatment shoe machine, the gas in the gas supply device firstly flows into the buffer tank, so that the pressure of the buffer tank is kept at a stable and low value all the time, it is avoided that gas inlet stability is influenced by gas liquefaction, solid impurities are filtered out by the gas filter, flow of the gas is accurately controlled automaticallyby the gas quality and flow controller, the gas flows into a vacuum chamber of the shoe machine finally, and the whole gas supply system is easy to operate and convenient to install.

Owner:SUZHOU WEIPENG ELECTRICAL TECH CO LTD

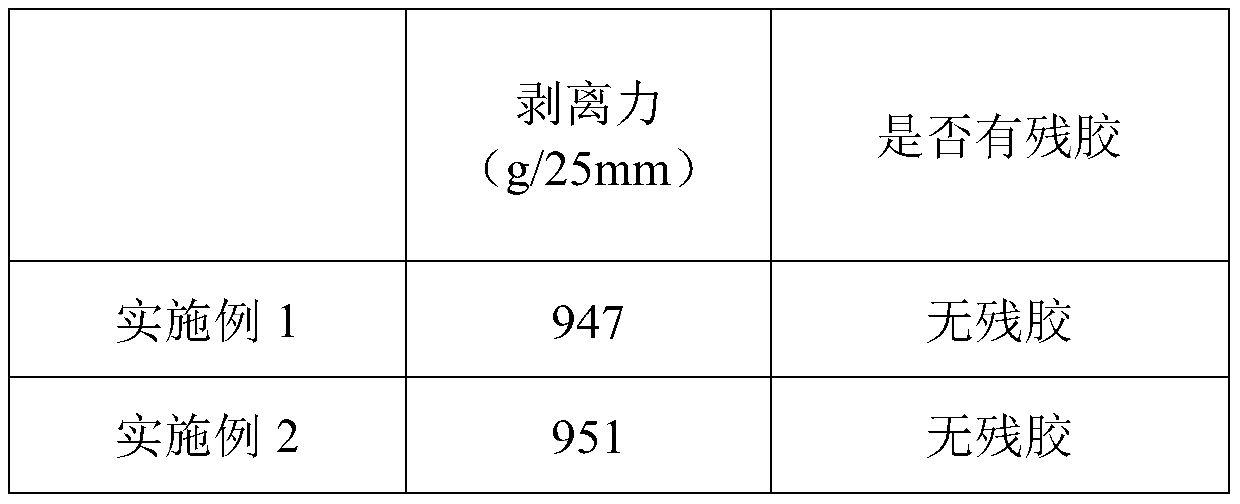

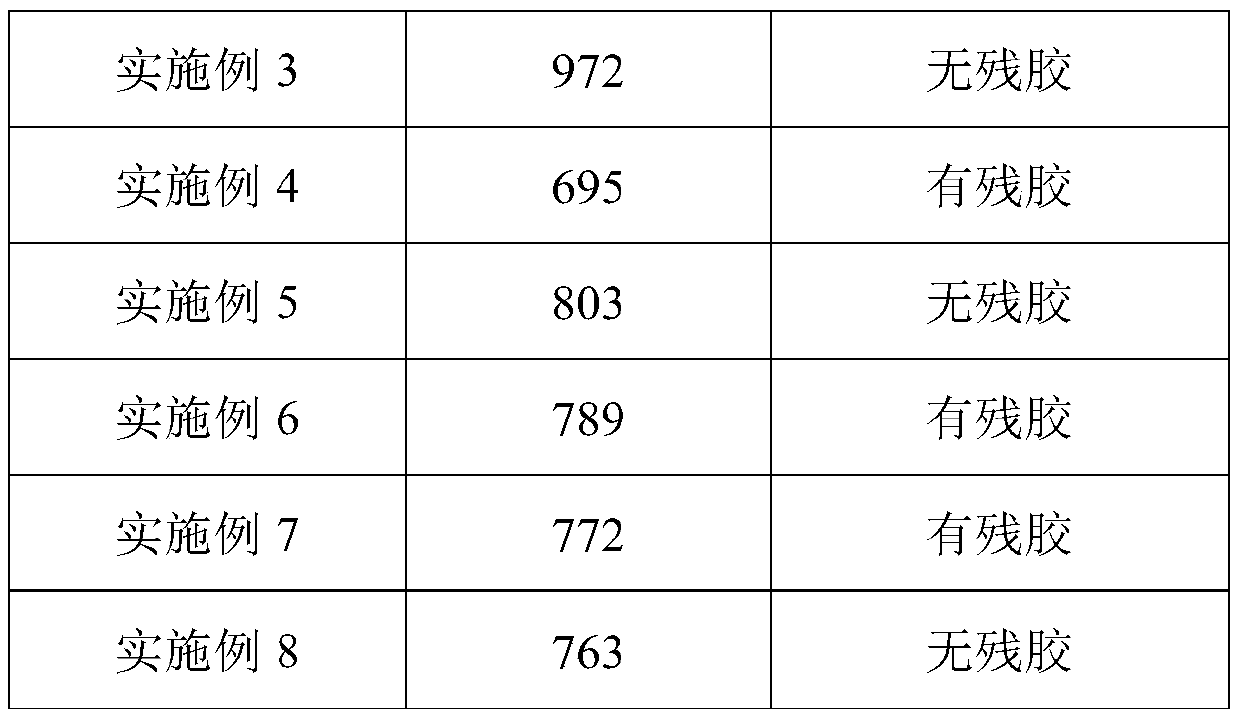

Thermal visbreaking protective film and preparation method thereof

InactiveCN111218229AAchieve strippingHigh peel strengthPolyureas/polyurethane adhesivesHeat-activated film/foil adhesivesThermal dilatationPolymer science

The invention relates to the related field of semiconductors, and more specifically provides a thermal visbreaking protective film and a preparation method thereof. The invention provides a thermal visbreaking composition, which comprises the following raw materials: an acrylate substance, a solvent, a curing agent and an expansion material, wherein the acrylate substance comprises a polyacrylatesubstance and an acrylate monomer, and the viscosity of the polyacrylate substance is less than 250mPa.s at 23DEG C. The thermal visbreaking protective film is prepared from the specific thermal visbreaking composition, the protective film obtained through the specific acrylate substance and the thermal expansion material can achieve high peel strength before heat treatment, high adhesiveness is achieved, meanwhile, residual-glue-free peeling can be achieved at a low temperature, the peel strength is low, and the protective film is very convenient to use in the actual use process.

Owner:广东硕成科技股份有限公司

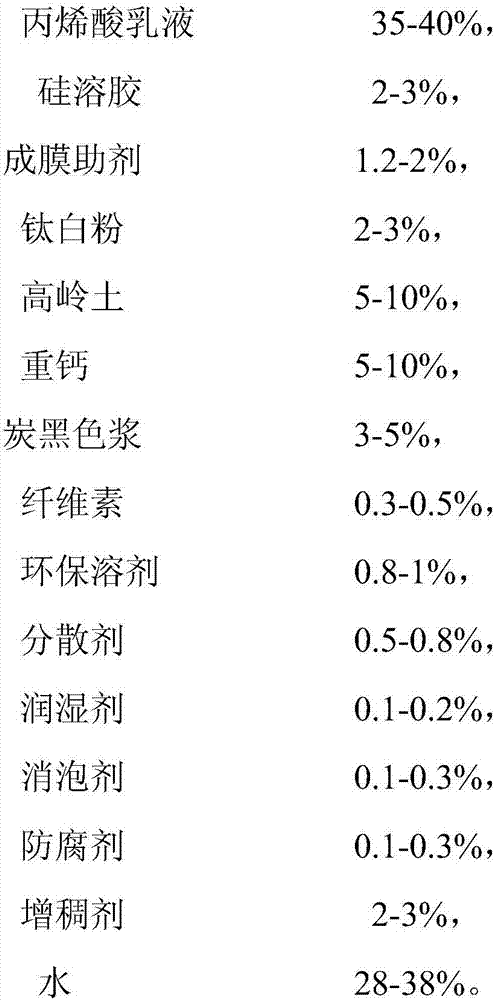

Special joint pointing black paint for outer wall imitation brick process and preparation method of black paint

InactiveCN107312400AStrong anti-masking paper effectImprove aging performanceAnti-corrosive paintsCelluloseBrick

The invention discloses special joint pointing black paint for an outer wall imitation brick process and a preparation method of the black paint. The special joint pointing black paint comprises, in weight percentage, 35-40% of acrylic emulsion, 2-3% of silica solution, 2-3% of titanium dioxide, 5-10% of kaolin, 5-10% of calcium carbonate, 0.8-1% of environment-friendly solvents, 0.2-3% of film coalescing aid, 0.1-0.2% of moistening agents, 0.5-0.8% of dispersing agents, 0.3-0.5% of cellulose, 0.1-0.3% of defoaming agents, 0.1-0.3% of preservative, 0.2-3% of thickening agents, 3-5% of carbon black color paste and 28-35% of water. The special joint pointing black paint is green and environmentally friendly, alkali resistance of the black paint is normal within 144h, ageing resistance of the black paint is normal within 600h, and the black paint has grade-1 adhesive force and is high in textured-paper-resistant efficiency.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

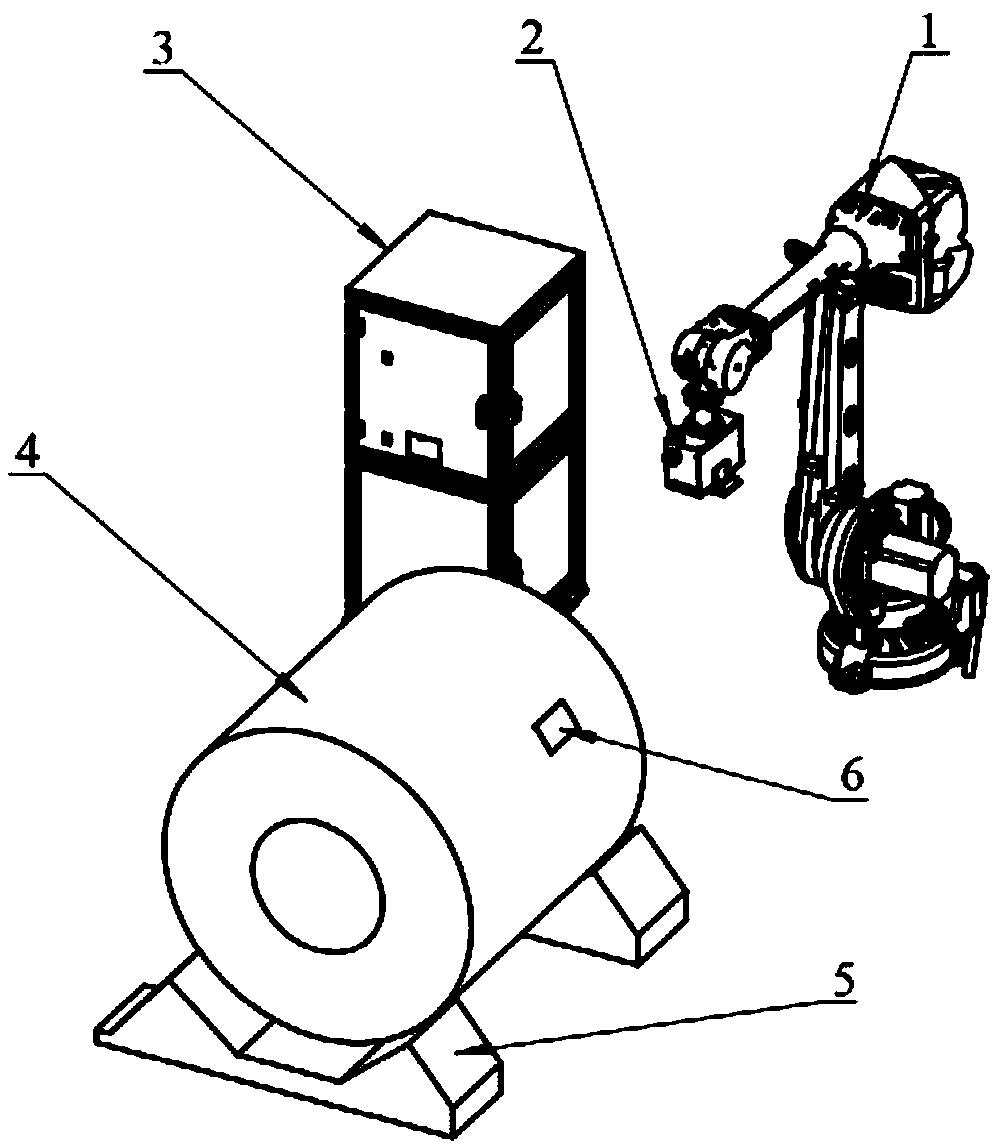

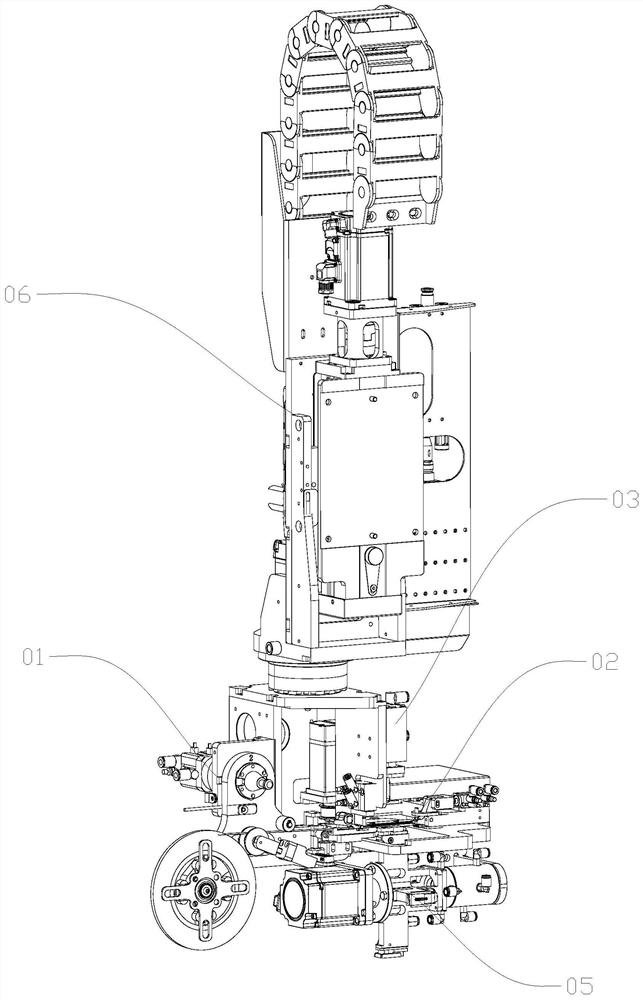

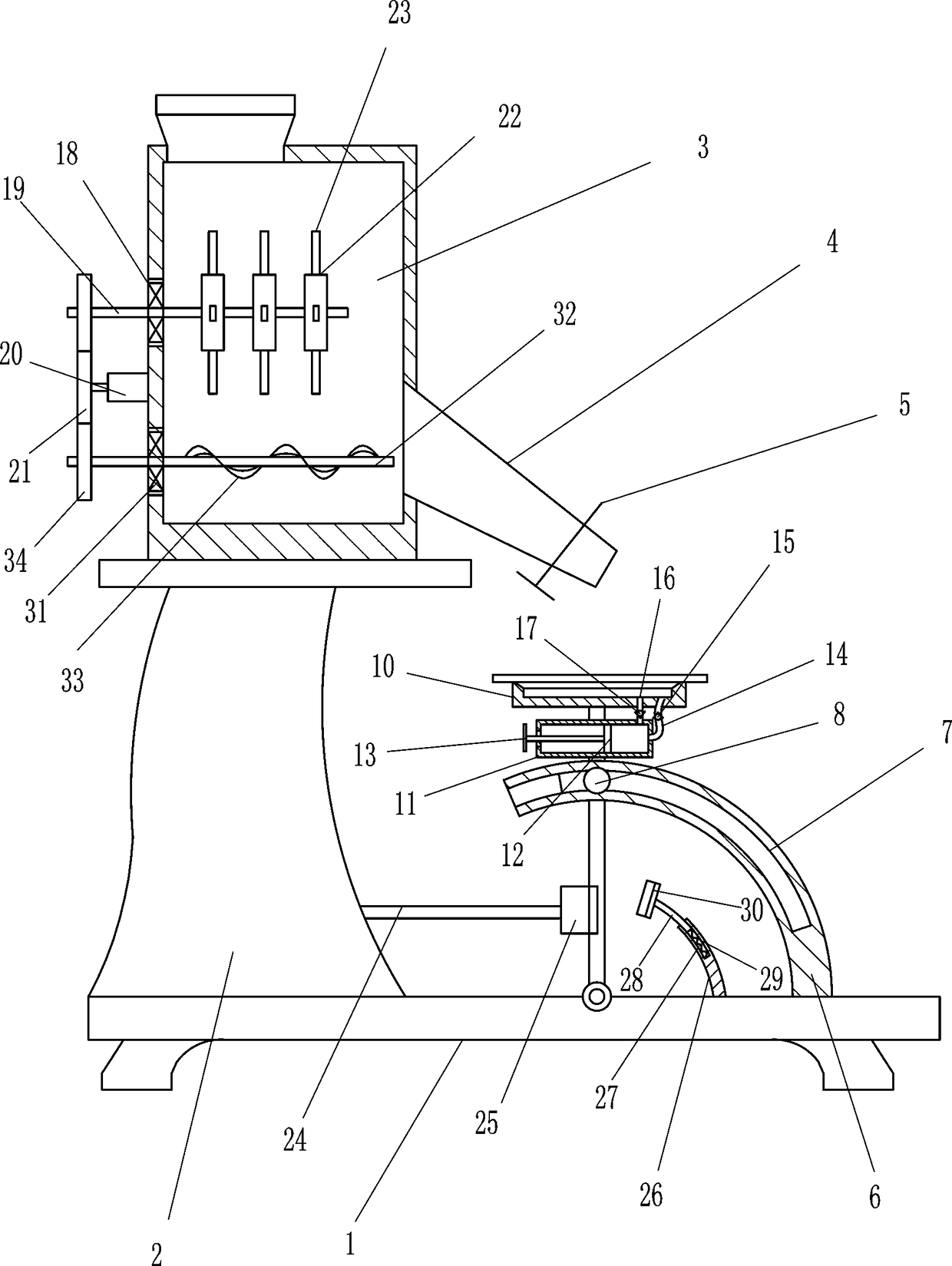

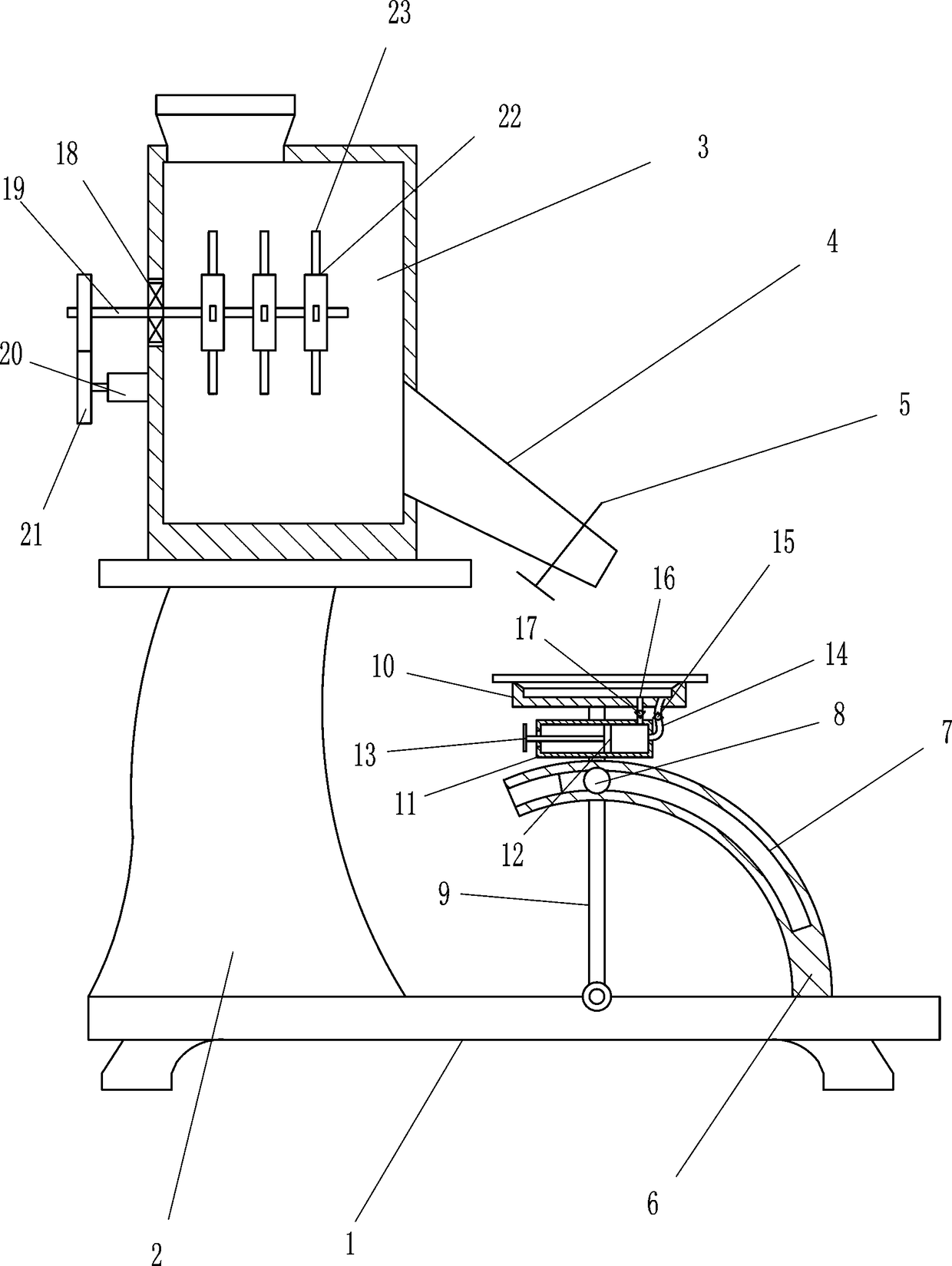

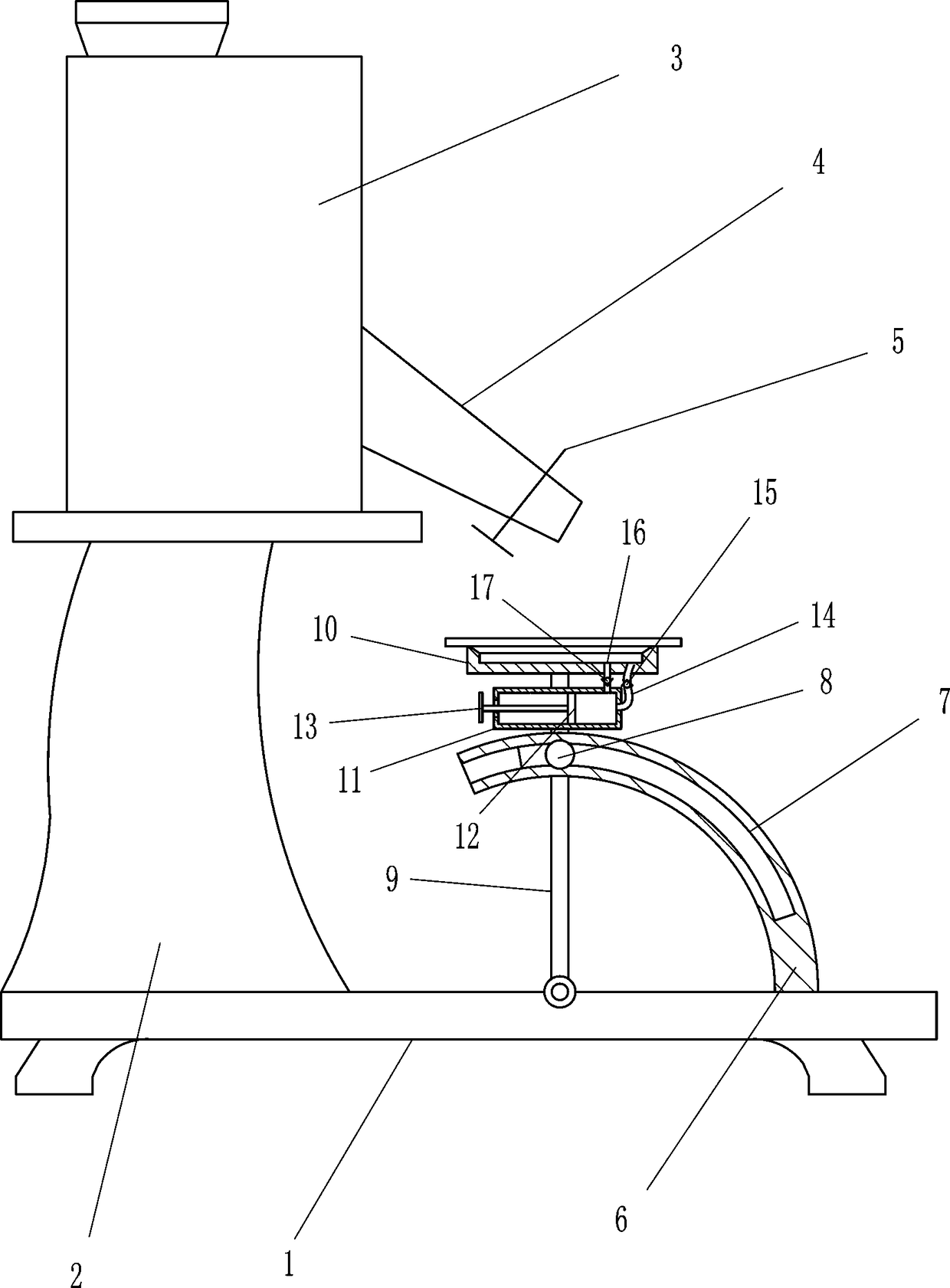

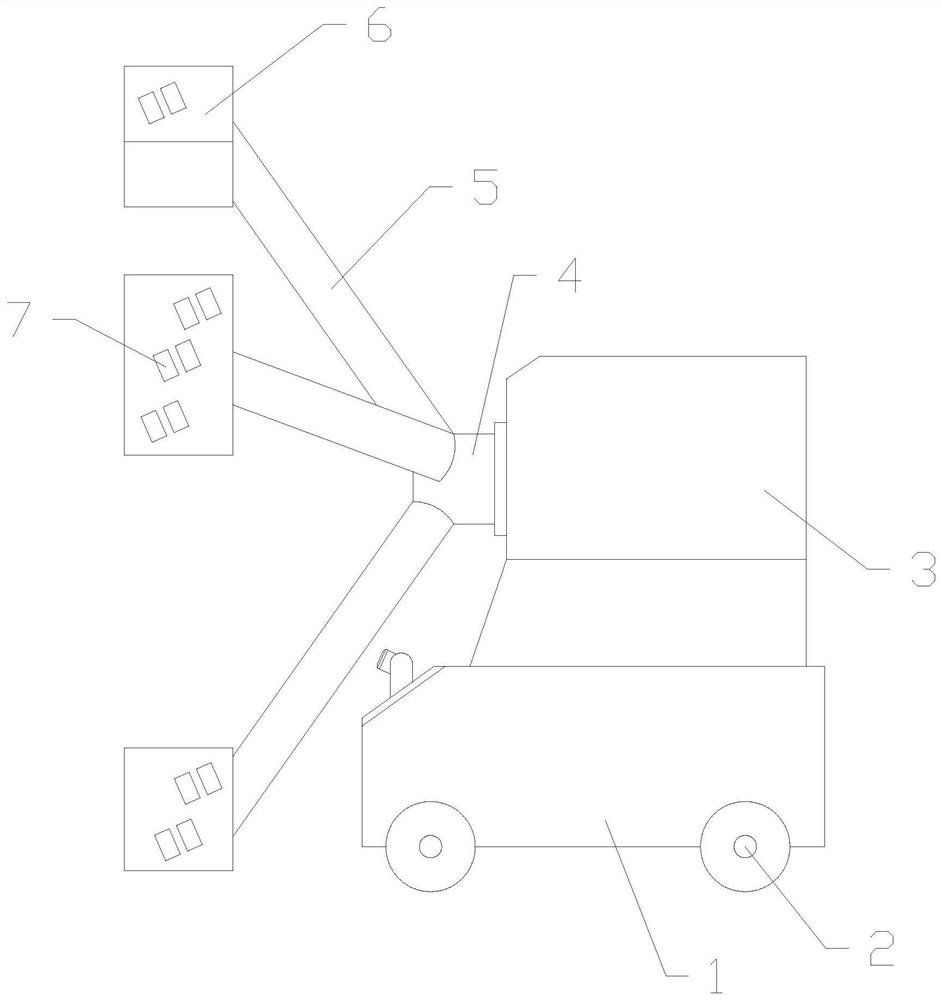

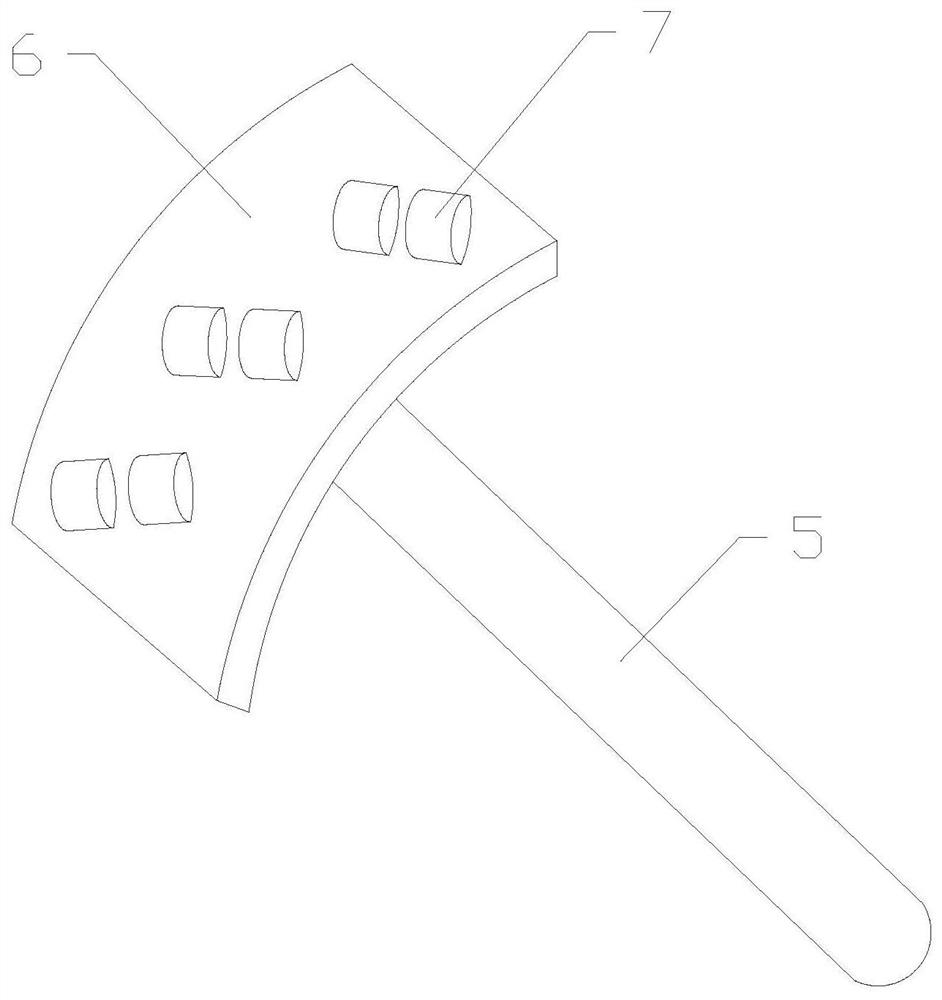

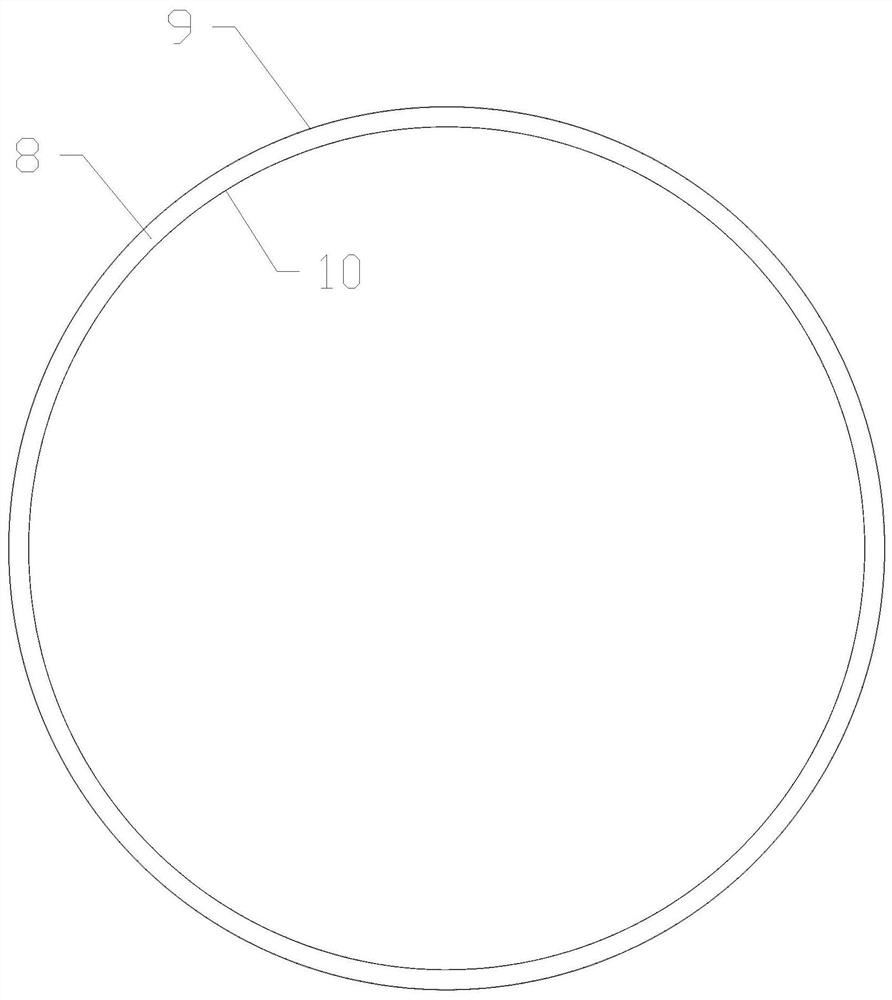

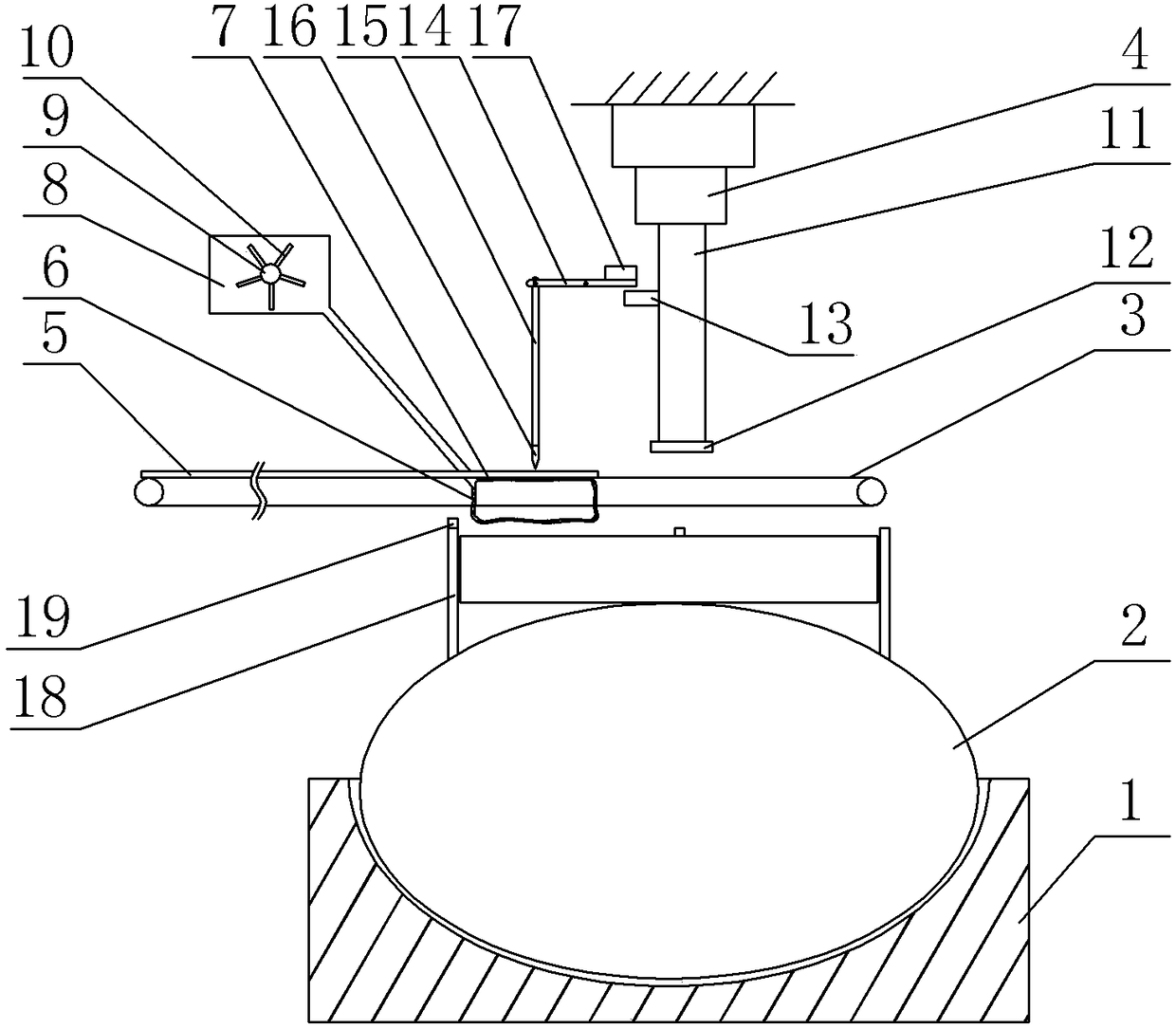

Robot-based underground pipe network repairing method

ActiveCN112628522AMake sure it is fully attachedImprove pasting effectPigs/molesSimulationStructural engineering

The invention discloses a robot-based underground pipe network repairing method. In the repairing method, a curing robot is used for performing auxiliary repairing on the inner wall of a pipeline. The curing robot comprises a main body, wheels, a camera, a servo motor, a rotating joint, steering rods, annular arc-shaped sheets and pressure applying rollers, wherein the pressure applying rollers, the steering rods and the annular arc-shaped sheets form an annular assembly, the curing robot conducts auxiliary repairing on the urban pipeline through the annular assembly, a cured lining pipe is tightly attached to the inner wall of the repaired pipeline through applied pressure by the pressure applying rollers, pressure is continuously applied to the lining pipe, and attaching between the lining pipe and the original pipeline is tighter. By means of the method, it can be guaranteed that the lining pipe is completely attached to the inner wall of the urban pipeline, the whole repaired pipeline is completely covered, missing attaching positions are avoided, the attaching performance of the lining pipe and the original pipeline is enhanced, and the attaching effect is effectively improved.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

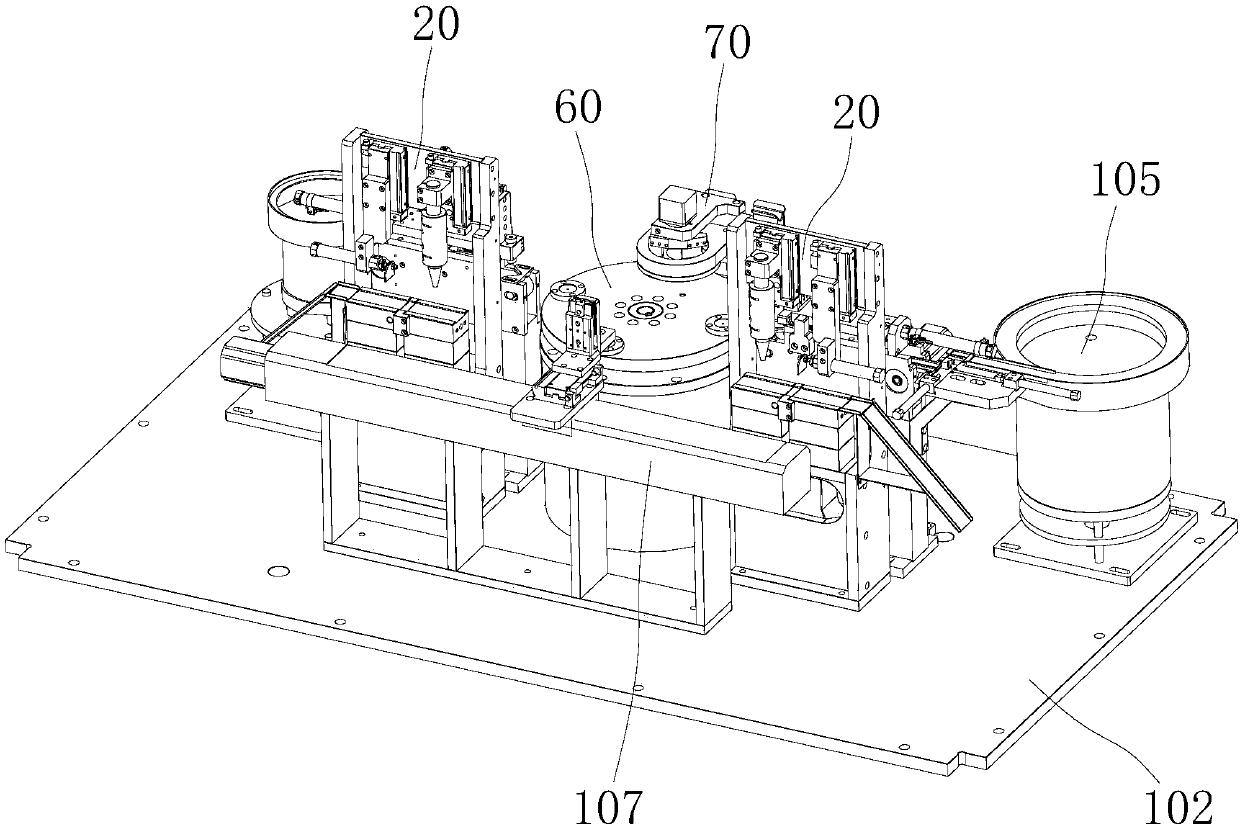

Soldering tin machine

ActiveCN107717162ARealize automatic pastingInhibit sheddingMetal working apparatusSoldering auxillary devicesEngineeringMechanical engineering

The invention discloses a soldering tin machine and relates to the technical field of battery production equipment. The soldering tin machine comprises a base plate, a vibrating plate arranged on thebase plate, aluminum feeding assemblies, a first delivering assembly, a vibrating disc, a nickel sheet feeding assembly, a second delivering assembly, a rotating disc assembly, a tin cream assembly, amechanical arm assembly and discharging assemblies, wherein an aluminum sheet is placed in the vibrating plate and delivered by the aluminum feeding assembly to the first delivering assembly; the first delivering assembly moves the aluminum sheet to the rotating disc assembly; a nickel sheet is placed in the vibrating disc and delivered to the second delivering assembly by the nickel sheet feeding assembly; and the nickel sheet is moved to the upper surface of the aluminum sheet on the rotating disc assembly by the second delivering assembly, so the nickel sheet can be applied to the aluminumsheet. The beneficial effects are that full-automatic adhesion of the nickel and aluminum sheets can be realized; manual adhesion work can be unnecessary; and lithium battery production efficiency can be improved and labor cost can be lowered.

Owner:惠州市铝镁特自动化设备有限公司

Aluminum pipe fixing mechanism for LED fluorescent lamp aluminum pipe adhesive tape sticking machine

InactiveCN107327728AReduce generationEasy to paste manuallySemiconductor devices for light sourcesArchitectural engineeringFluorescent lamp

The invention discloses an aluminum tube fixing mechanism for an aluminum tube tape sticking machine for LED fluorescent lamps, which includes a frame. Lifting motors are fixed on both sides of the bottom of the middle connecting plate of the frame, and the output shaft of the lifting motor passes through the middle connecting plate. , the top of the output shaft of the lifting motor has a connecting screw hole, the lifting screw is screwed into the connecting screw hole, the lifting screw is fixed on the bottom surface of the upper horizontal plate, the upper horizontal plate is above the middle connecting plate, and the top surface of the upper horizontal plate Vertical support plates are fixed on both sides, the main connecting block is fixed on the middle top surface of the upper horizontal plate, the aluminum tube fixing block is fixed on the top surface of the main connecting block, the top surface of the aluminum tube fixing block has installation grooves The bottom surface of the aluminum tube is an arc-shaped surface that matches the aluminum tube, and the left and right ends of the aluminum tube fixing block are fixed with limit blocks; it can fix the aluminum tube and move it laterally, which is convenient for manual pasting and automatically pressed by the pressure roller to improve the pasting effect. , to reduce the generation of air bubbles.

Owner:FOSHAN KERUIFEI NEW ENERGY TECH CO LTD

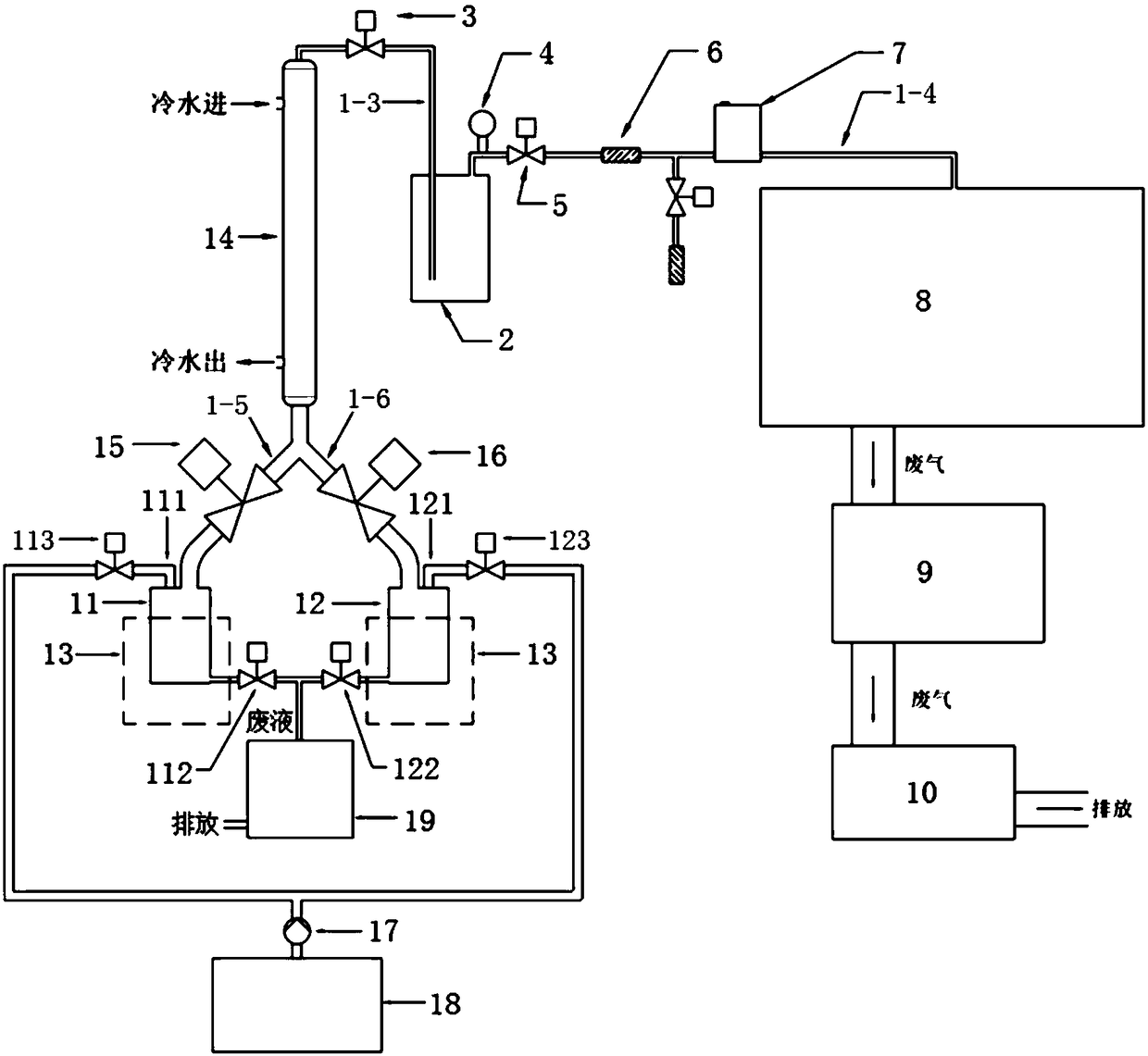

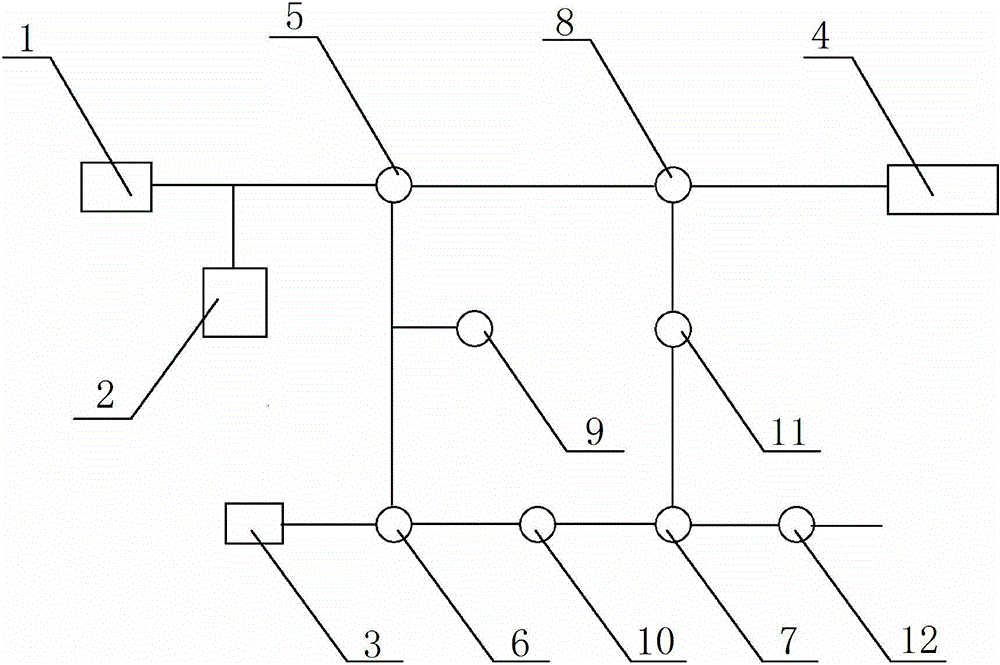

Air distribution system for manufacturing engine heat insulation layer and control method of air distribution system

ActiveCN104875470AEliminate the effects ofEliminate quality issuesControlling laminationLaminationAxial compressorInsulation layer

The invention discloses an air distribution system for manufacturing an engine heat insulation layer and a control method of the air distribution system, and belongs to the technical field of the manufacturing of solid rocket engine heat insulation layers. The air distribution system comprises a first switching valve, a second switching valve, a third switching valve and a fourth switching valve which are sequentially connected by a pipeline, wherein the fourth switching valve is connected with the first switching valve to form a circulation channel; the first switching valve is also connected with a vacuum pump and a vacuum cabin; the second switching valve is connected with a rubber air bag; the third switching valve is also provided with an evacuation pipeline; the fourth switching valve is also connected with an air compressor. The system provided by the invention can eliminate influences of gas generated by pre-stage operation, residual solvents and the like via vacuumization; under the vacuum state, the air bag is pressed to patch so as to prevent gases generated by operation from being brought in; the normal pressure is combined with the air compressor, so that the patching pressure of the rubber air bag is enhanced further, and the pasting effect can be enhanced; the bonding quality and the appearance quality of a mold surface are enhanced obviously.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

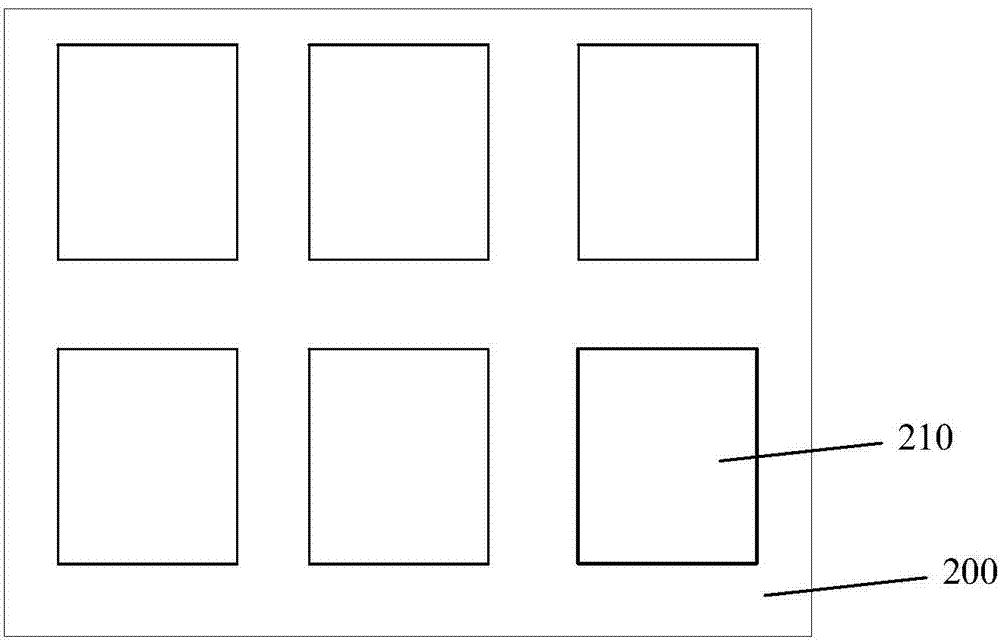

Battery labeling equipment

PendingCN108502289AGuaranteed neatnessImprove stabilityLabelling flat rigid surfacesLabelling machinesEngineeringConveyor belt

The invention relates to the field of labeling, in particular to battery labeling equipment. The battery labeling equipment comprises a support table, an air bag, two conveyor belts, a cylinder and acutting mechanism, wherein a glue holding bag is arranged on a rack, and a plurality of pores communicated with the inside of the glue holding bag are formed in the upper surface of the glue holding bag; a labeling rod is fixed on an output shaft of the cylinder; the cutting mechanism comprises a trigger block, a first connecting rod, a second connecting rod and a cutting knife, the middle of thefirst connecting rod is hinged to the rack, one end of the first connecting rod is hinged to one end of the second connecting rod, the second connecting rod is glidingly connected with the rack, and the other end of the second connecting rod is fixedly connected with the cutting knife; the trigger block is fixedly arranged on the output shaft of the cylinder, can be contacted with the other end ofthe first connecting rod and pushes the first connecting rod to rotate; the air bag is arranged on the support table, a plurality of positioning rods are fixed on the surface of the air bag, and partof the positioning rods can be contacted with and squeeze the glue holding bag. With adoption of the technical scheme, stability and regularity of battery labeling can be improved, and a battery cannot be deformed in the labeling process.

Owner:贵州鸿兴时代动力新能源科技有限公司

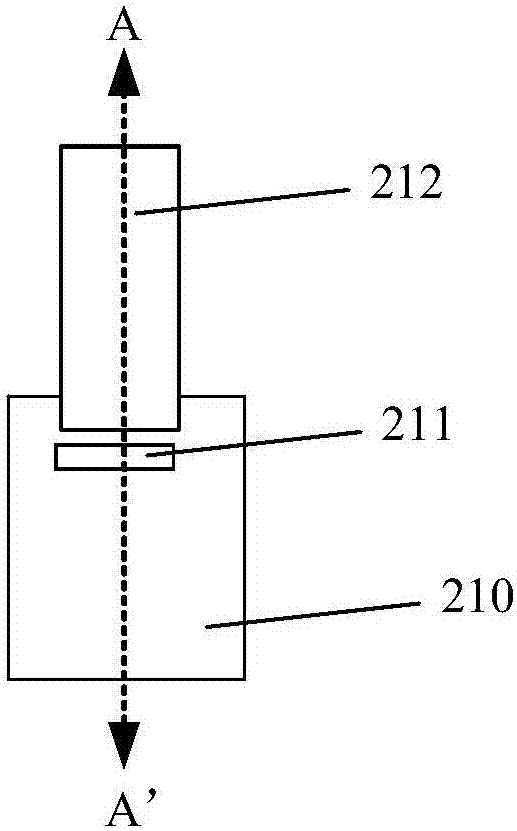

A tape vacuum pasting mechanism

The invention relates to a tape vacuum sticking mechanism, which comprises a lifting arm driven by a lifting cylinder, positioning pins are arranged at both ends of the lifting arm, a positioning pin hole adapted to the positioning pin is arranged at the lower end of the transfer tray, and a film bearing is arranged on the upper part of the transfer tray. On the surface, there is also a vacuum nozzle on the lifting arm. The lower end of the transfer tray is provided with an air pipe joint suitable for the vacuum nozzle. The air pipe joint is connected to the inner cavity of the transfer tray. through pinholes. The sticking mechanism vacuumizes the inside of the transfer tray with pinholes distributed on the surface by adding a vacuum nozzle and a suction pipe, so that the film placed on the upper part of the tray can be tightly combined with the tape due to the vacuum suction. It is beneficial to improve the paste effect.

Owner:SUZHOU NEW DISTRICT KEXING WILL ELECTRONICS

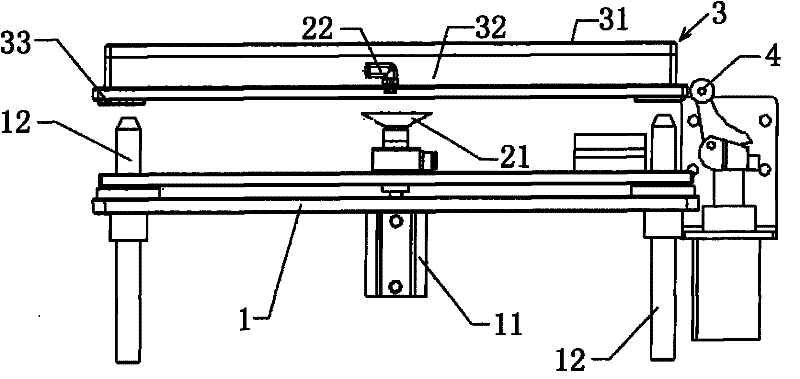

Semi-automatic plane labeler

ActiveCN106672368AAdjustable tensionGuaranteed separation effectLabelling machinesSemi automaticDrive motor

The invention discloses a semi-automatic plane labeler. The semi-automatic plane labeler comprises a rack. A main support plate is fixed to the position behind a top plate of the rack. A main driving motor is fixed to the back face of the upper portion of the left side of the main support plate. An output shaft of the main driving motor extends forwards to get out of the main support plate and is provided with a label roll. A subsidiary driving motor is fixed to the back face of the lower portion of the left side of the main support plate. An output shaft of the subsidiary driving motor extends forwards to get out of the main support plate and is provided with a rolling drum. Multiple support rollers are fixed to the upper portion of the main support plate, and multiple subsidiary support rollers are fixed to the lower portion of the main support plate. A support block is fixed to the lower portion of the right side of the main support plate. Two guiding blocks are fixed to the positions, located at the left side of the support block, of the main support plate. The left end of an adjusting screw rod is inserted into the corresponding guiding block in a sleeved manner, and the right end of the adjusting screw rod is connected into the guiding block at the right side in a threaded manner. By means of the semi-automatic plane labeler, the conveying tension degree of a paper tape can be adjusted; meanwhile, it can be guaranteed that the paper tape of the label roll is separated from labels; and the label pasting effect is improved.

Owner:桐城市建设投资发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com