Aluminum pipe fixing mechanism for LED fluorescent lamp aluminum pipe adhesive tape sticking machine

A technology of LED fluorescent lamps and fixing mechanisms, which is applied in the direction of light sources, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of affecting the paste effect, easy to generate air bubbles, and low manual paste efficiency, so as to improve the paste effect and reduce air bubbles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

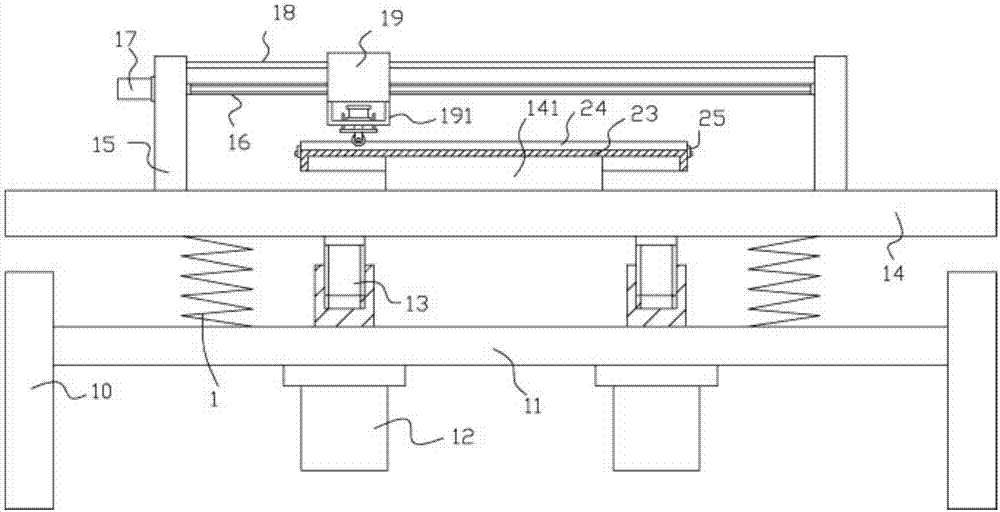

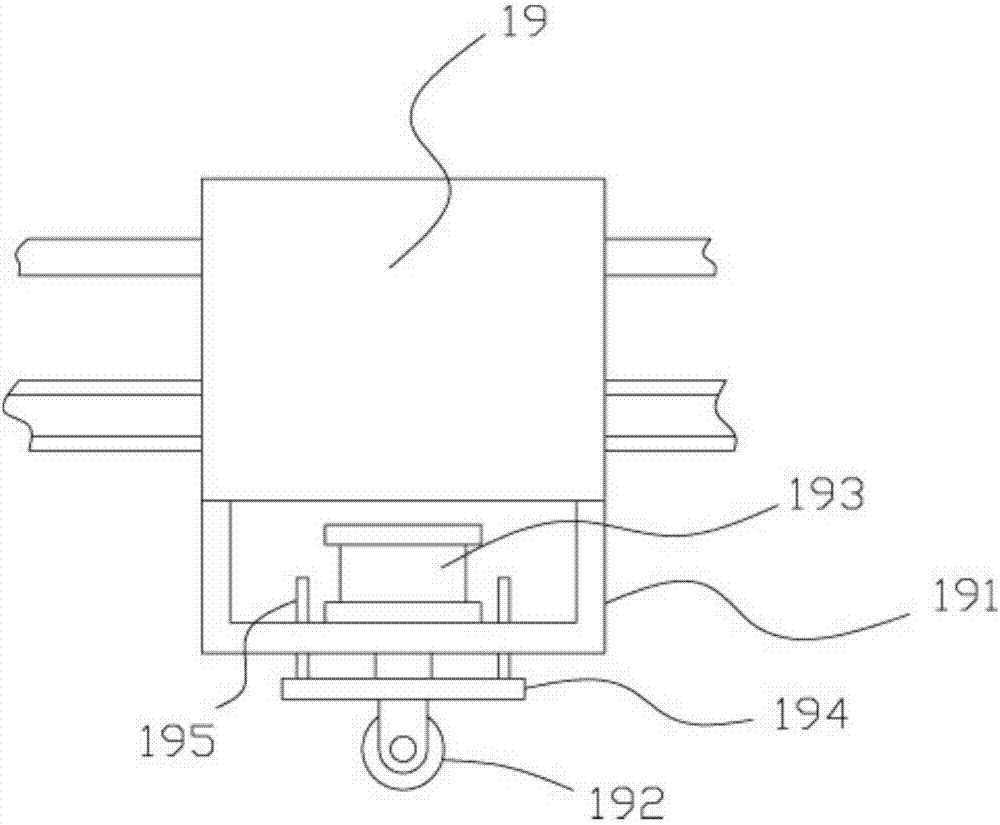

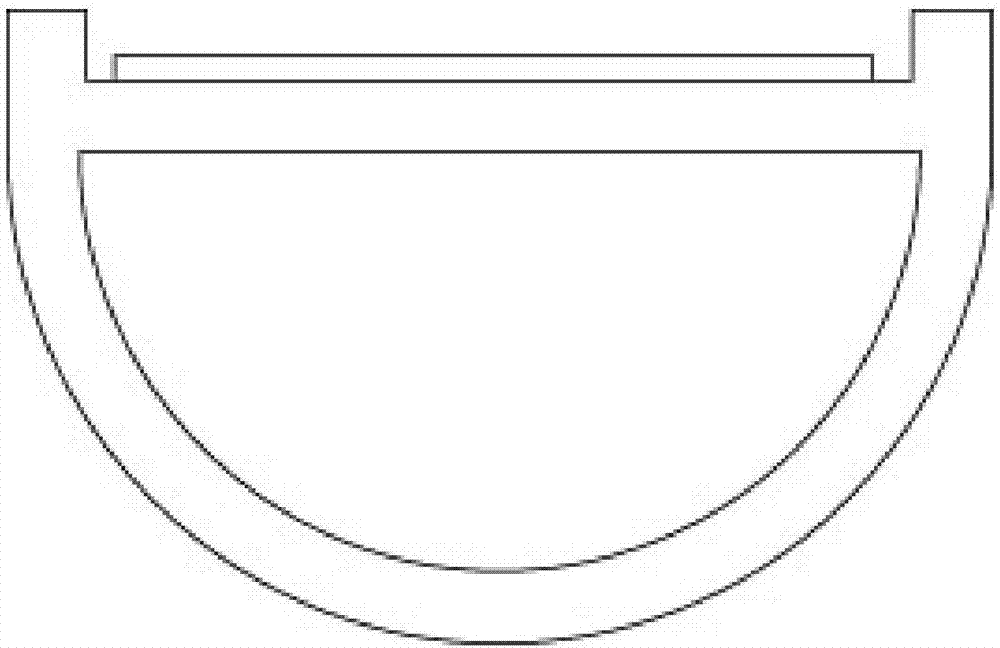

[0015] Example: see Figure 1 to Figure 3 As shown, an aluminum tube fixing mechanism for an aluminum tube adhesive tape machine for LED fluorescent lamps includes a frame 10, and a lifting motor 12 is fixed on both sides of the bottom surface of the middle connecting plate 11 of the frame 10, and the output shaft of the lifting motor 12 passes through the Through the intermediate connecting plate 11, the top of the output shaft of the lifting motor 12 has a connecting screw hole, the lifting screw 13 is screwed in the connecting screw hole, the lifting screw 13 is fixed on the bottom surface of the upper horizontal plate 14, and the upper horizontal plate 14 is in the middle connection. Above the plate 11, vertical support plates 15 are fixed on both sides of the top surface of the upper horizontal plate 14, and a main connecting block 141 is fixed on the middle top surface of the upper horizontal plate 14, and an aluminum tube fixing block is fixed on the top surface of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com