Method for preparing cassava starch octenyl succinate by sub-gelatinization technology

A technology of octenyl succinic acid and octenyl succinic anhydride, which is applied in the field of preparation of octenyl succinic acid tapioca starch ester, can solve the problems of severe reaction, limited application of tapioca starch raw material, uneven reaction, etc., to achieve uniform reaction, Convenience for continuous production and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

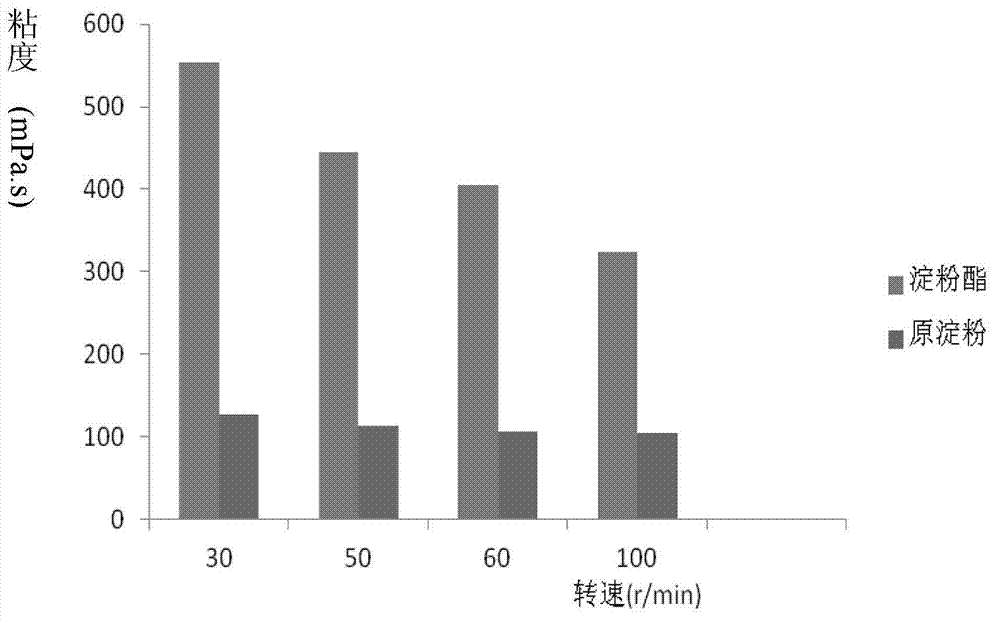

[0049] The influence of embodiment 1-5 starch emulsion concentration (weight ratio of starch and ethanol solution) on degree of substitution and reaction efficiency of octenyl succinic acid tapioca starch ester

[0050] Weigh a certain amount of cassava starch respectively, put it into a beaker containing 100g of ethanol solution with a volume fraction of 50%, keep stirring and gelatinizing for 2h in a constant temperature magnetic stirrer at 68.7°C, and cool the solution to 35 DEG C, keep this temperature in the constant temperature magnetic stirrer, be that the NaOH solution of 3% with mass fraction adjusts the reaction system to pH8.2, the octenyl succinic anhydride (octenyl succinic anhydride) Accounting for the mass fraction of starch dry base is 3%, the volume ratio of absolute ethanol and acid anhydride is 5: 1) is added in batches, is constantly adjusted with NaOH in the whole reaction process, makes it maintain under alkaline conditions, and reacts for a period of 2.5 ...

Embodiment 6-9

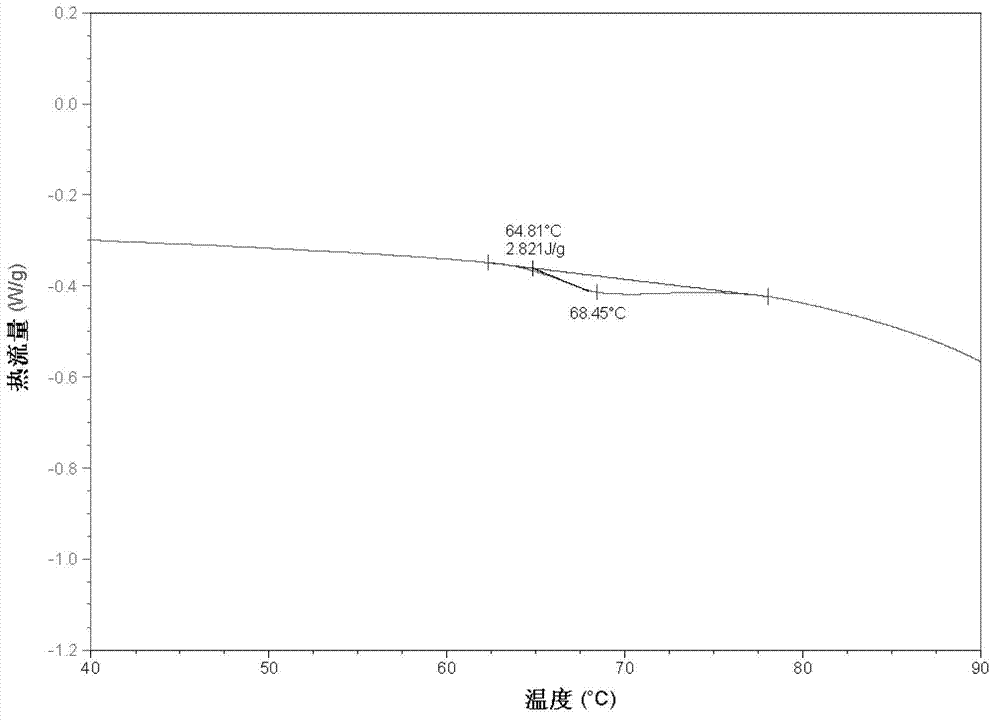

[0054] The influence of embodiment 6-9 gelatinization temperature on octenyl succinic acid tapioca starch ester degree of substitution and reaction efficiency

[0055] Weigh 25g of tapioca starch respectively, put it into a beaker containing 100g of ethanol solution with a volume fraction of 50%, keep stirring and gelatinizing for 2h in a constant temperature magnetic stirrer at different temperatures, and cool the solution to 35 ℃, keep this temperature in the constant temperature magnetic stirrer, with the NaOH solution that mass fraction is 3%, the reaction system is adjusted to pH8. The mass fraction of starch dry base is 3%, and the volume ratio of absolute ethanol to acid anhydride is 5:1) added in batches, constantly adjusted with NaOH during the whole reaction process, so as to maintain it under alkaline conditions, and react for a period of 2.5h Finally, use 0.1mol / L HCl to drop to pH 6.5 to terminate the reaction. The reaction product is filtered through a Buchner fu...

Embodiment 10-14

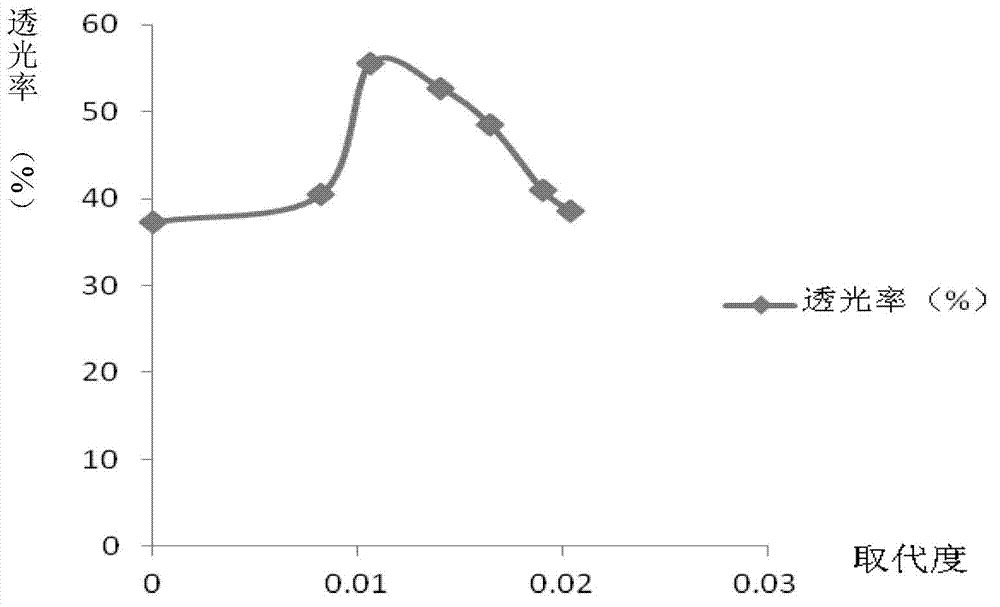

[0059] The volume fraction of embodiment 10-14 ethanol solution is on the influence of degree of substitution and reaction efficiency of octenyl succinic acid tapioca ester

[0060] Weigh 25g of tapioca starch respectively, put them into beakers containing 100g of ethanol solutions with different volume fractions, keep stirring and gelatinizing for 2h in a constant temperature magnetic stirrer at 68.7°C, and cool the solution to 35°C after the reaction is completed. Keep this temperature in a constant temperature magnetic stirrer, use a mass fraction of 3% NaOH solution to adjust the reaction system to pH8.2, and octenyl succinic anhydride (octenyl succinic anhydride) The mass fraction of base is 3%, the volume ratio of absolute ethanol and acid anhydride is 5: 1) add in batches, constantly adjust with NaOH in the whole reaction process, make it maintain under alkaline condition, after reacting for a period of 2.5h, use 0.1mol / L HCl was dropped to pH6.5 to terminate the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com