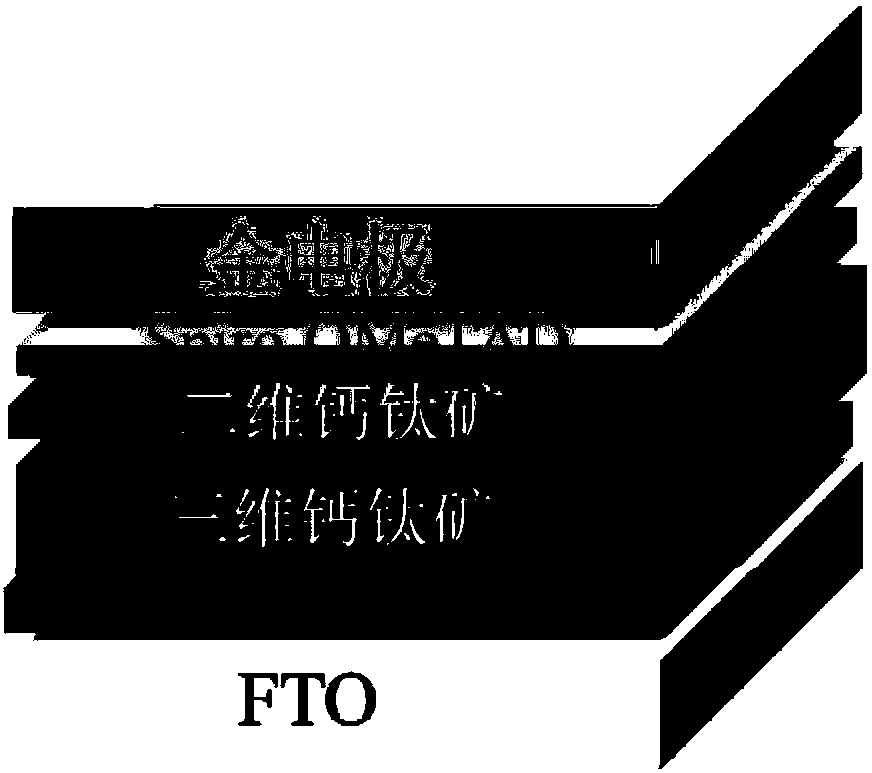

Perovskite plane heterojunction solar cell and preparation method therefor

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of perovskite film-forming quality, complex preparation methods, solvent toxicity, etc., to reduce material consumption costs and uniform reaction , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

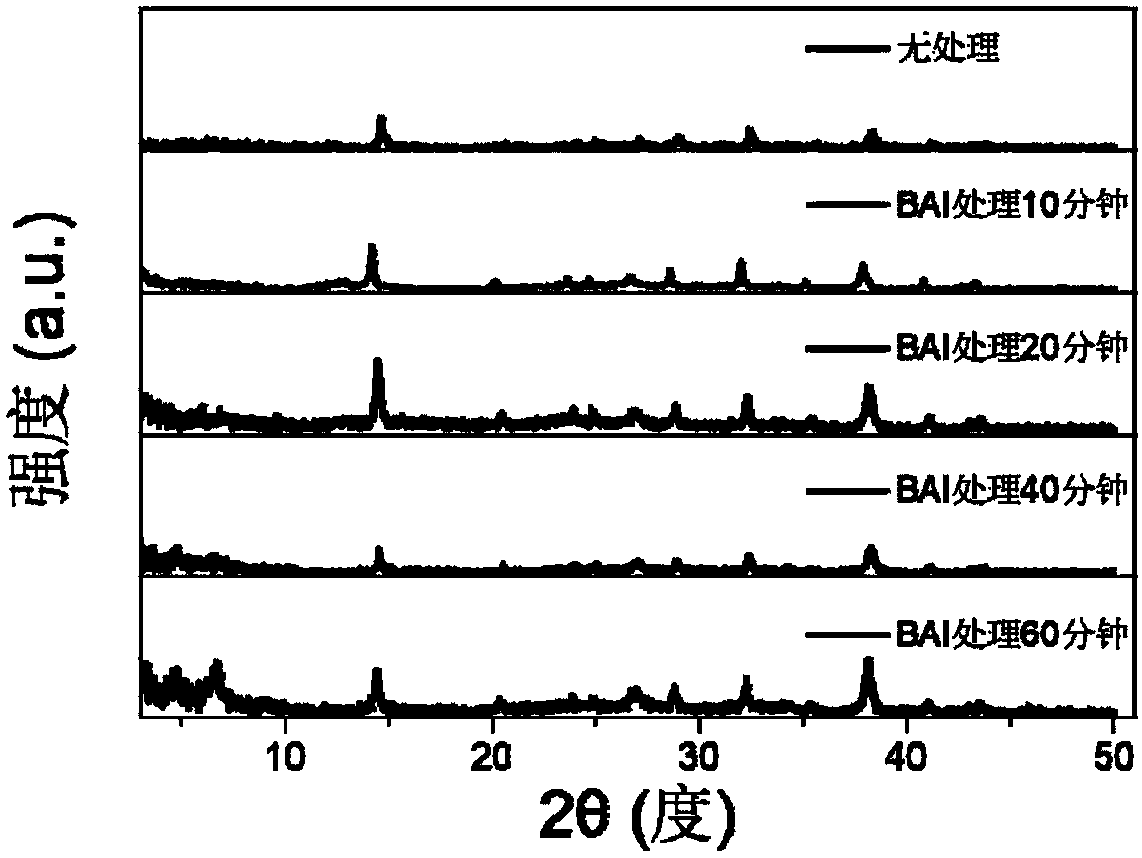

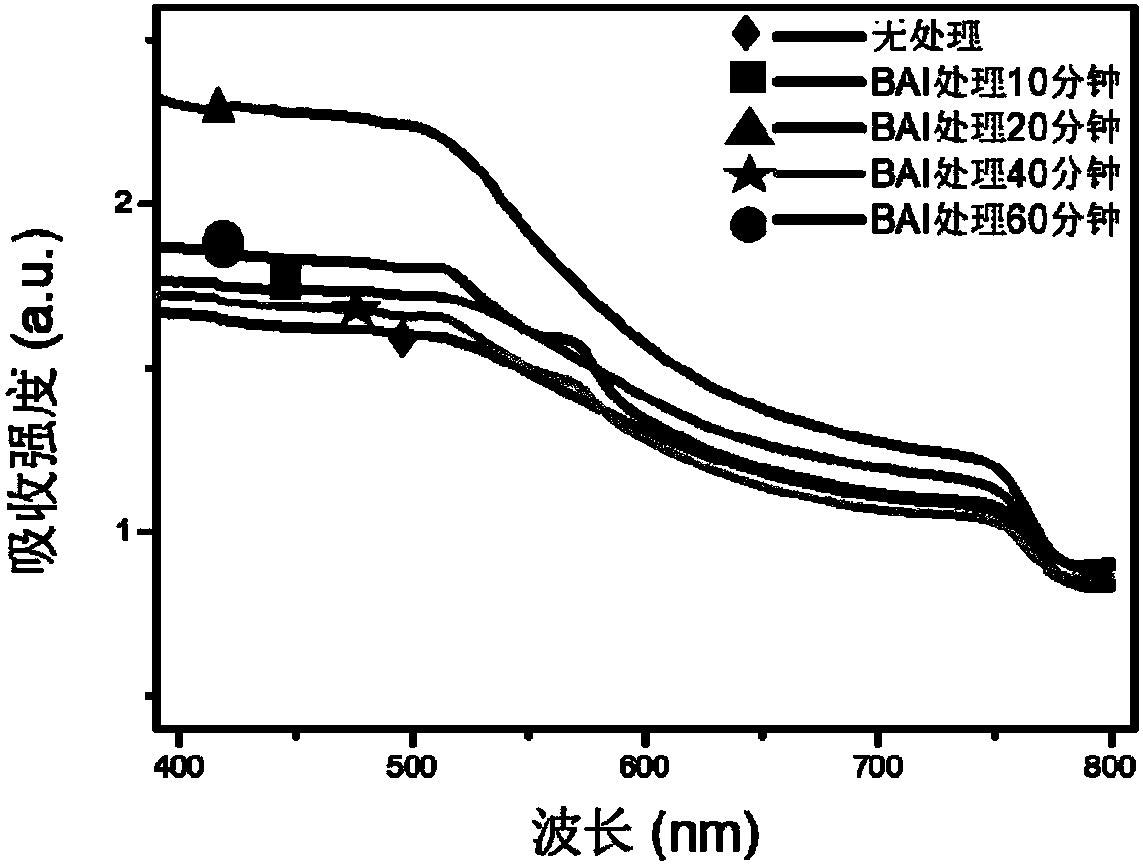

[0038] Treatment of MAPbI with BAI steam at different times based on gas phase method 3 Thin film fabrication of highly stable perovskite planar heterojunction solar cells.

[0039] The FTO substrate with a square resistance of 15Ω / □ and an area of 15mm×15mm was etched with zinc powder and dilute hydrochloric acid to form a rectangle with an area of 5mm×15mm as the test terminal of the battery anode. The etched FTO substrate was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol in sequence, and the ultrasonic cleaning time was 15 minutes each. The cleaned FTO substrate is blown dry with N2 gas, and the area of 3mm×15mm is covered with high temperature resistant tape to form a mask. electrode.

[0040] Then put the base on O 2 O 2 plasma treatment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com