Automatic glue applying device for rubber soles

A gluing device and automatic technology, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as the inability to effectively guarantee the uniformity of application, low efficiency, and limited skill level of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

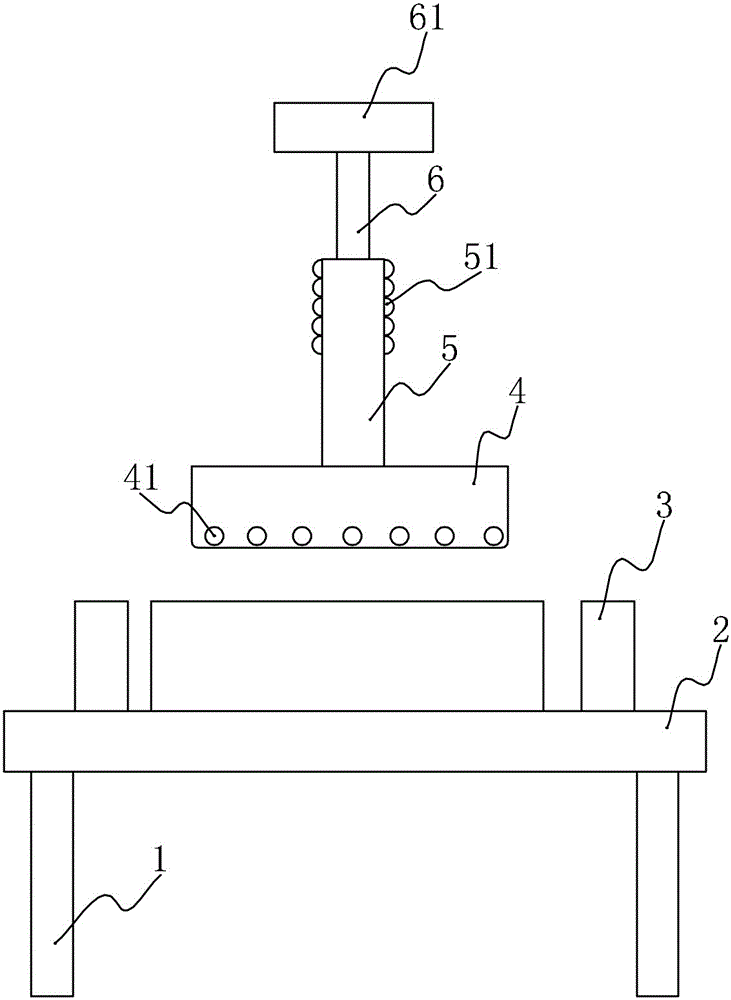

[0014] Such as figure 1 As shown, the rubber sole automatic gluing device of the present invention includes two parts, a fixed mold and a hand-held mold. Wherein, the fixed mold is provided with a support 1 placed on the ground, a base plate 2 is fixed on the support 1, four shoe molds 3 are distributed on the base plate 2, and the four shoe molds 3 can slide in the chutes on the base plate 2. When the four shoe molds 3 gather towards the middle, they can squeeze the sole and upper placed in the middle, and play the role of shaping and pressing during the bonding process of the sole and the upper. When the four shoe molds 3 are dispersed to the periphery, the soles can be loosened, which is convenient for taking off after pasting is completed. What cooperates with the fixed mold is a hand-held mold. The hand-held mold is an independent part and includes a hollow bottom block 4. The surface of the block 4 is provided with an opening 41 communicating with the inner cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com