Manufacturing method of high-strength type reflection film

A manufacturing method and technology of reflective film, applied in the direction of chemical instruments and methods, optics, optical components, etc., can solve the problems of uneven pressure-sensitive adhesive layer, affecting product bonding performance, wasting pressure-sensitive adhesive, etc., and achieve glue saving material, low cost, smooth coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiment steps of the manufacturing method of the high-strength grade reflective film of the present invention are described below in conjunction with the accompanying drawings:

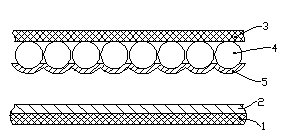

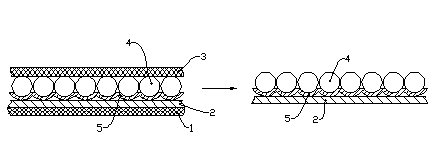

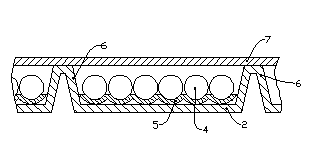

[0025] a. Take the sheet-shaped first substrate 1, and coat the adhesive layer 2 on the surface of the first substrate. The first substrate is made of BOPP film, and the adhesive layer is made of polyester hot melt adhesive so that the two can be evenly attached and convenient peel off;

[0026] b. Get the second substrate 3 with pressure-sensitive adhesive on one side, cloth glass beads 4 on the surface of the pressure-sensitive adhesive of the second substrate to form a bead-planting layer, and coat the outer surface of the glass beads of the bead-planting layer with a reflective layer 5. The second base material is BOPET film, its surface is coated with acrylate pressure-sensitive adhesive, and the reflective layer is aluminum-plated material;

[0027] The product form after steps a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com