Patents

Literature

47results about How to "Realize automatic paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

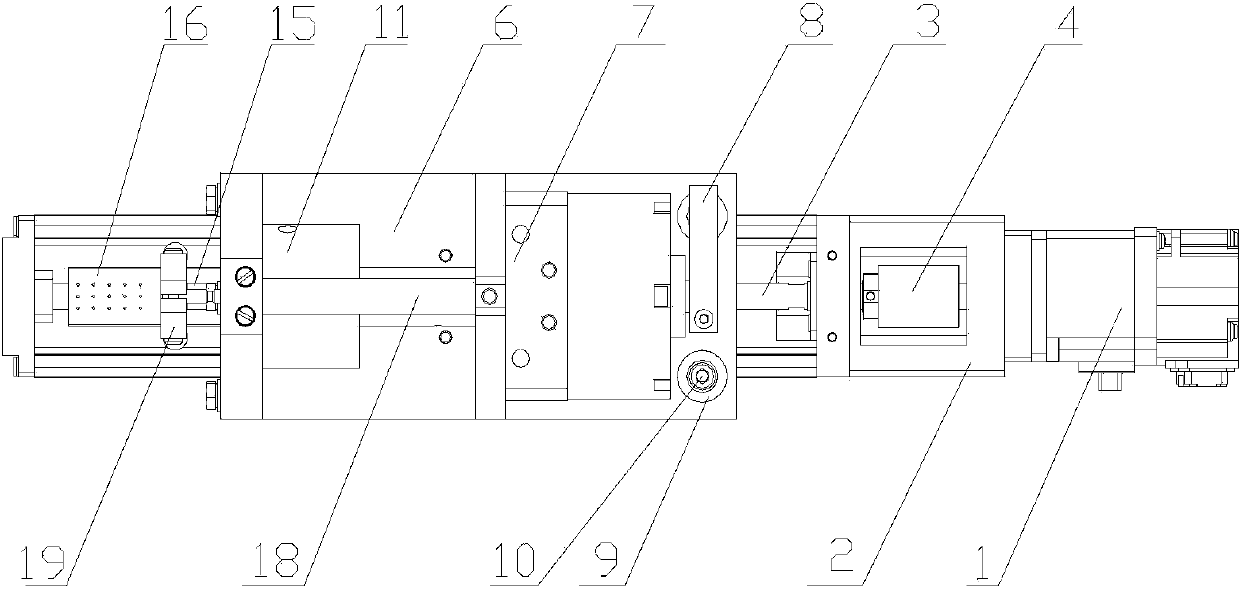

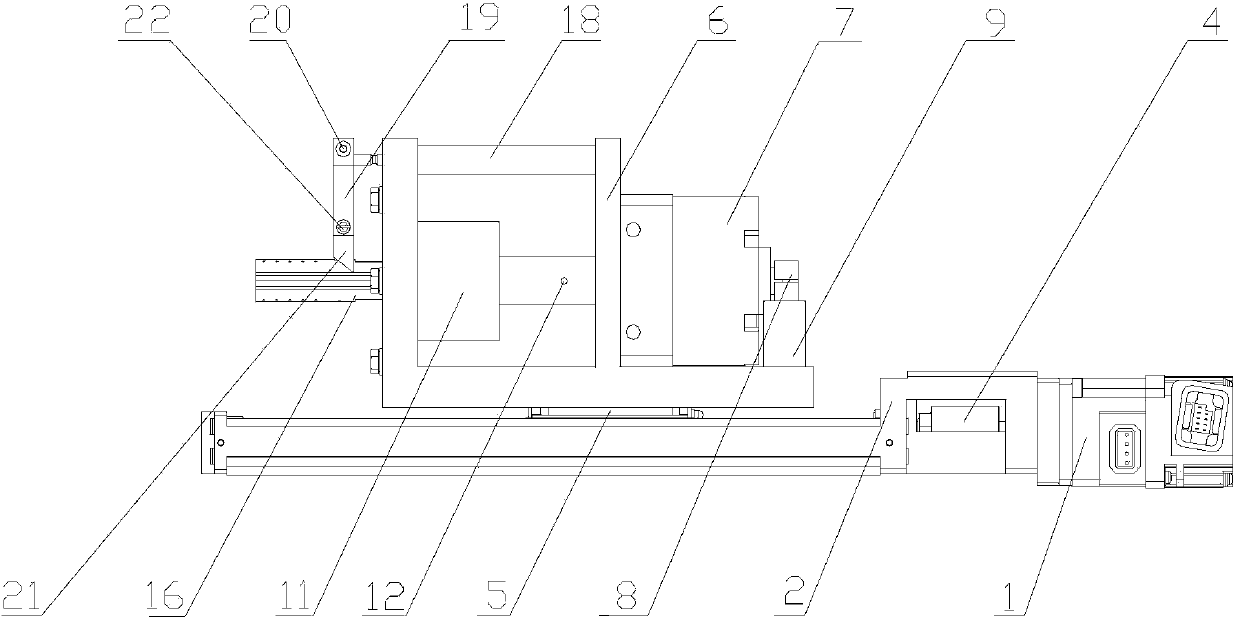

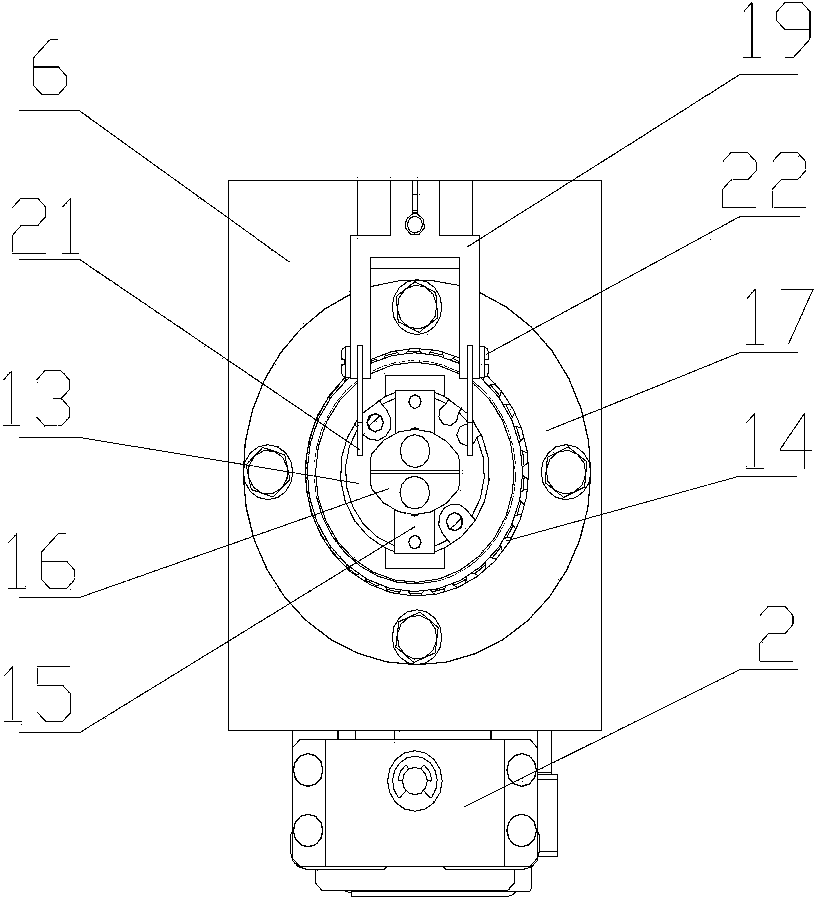

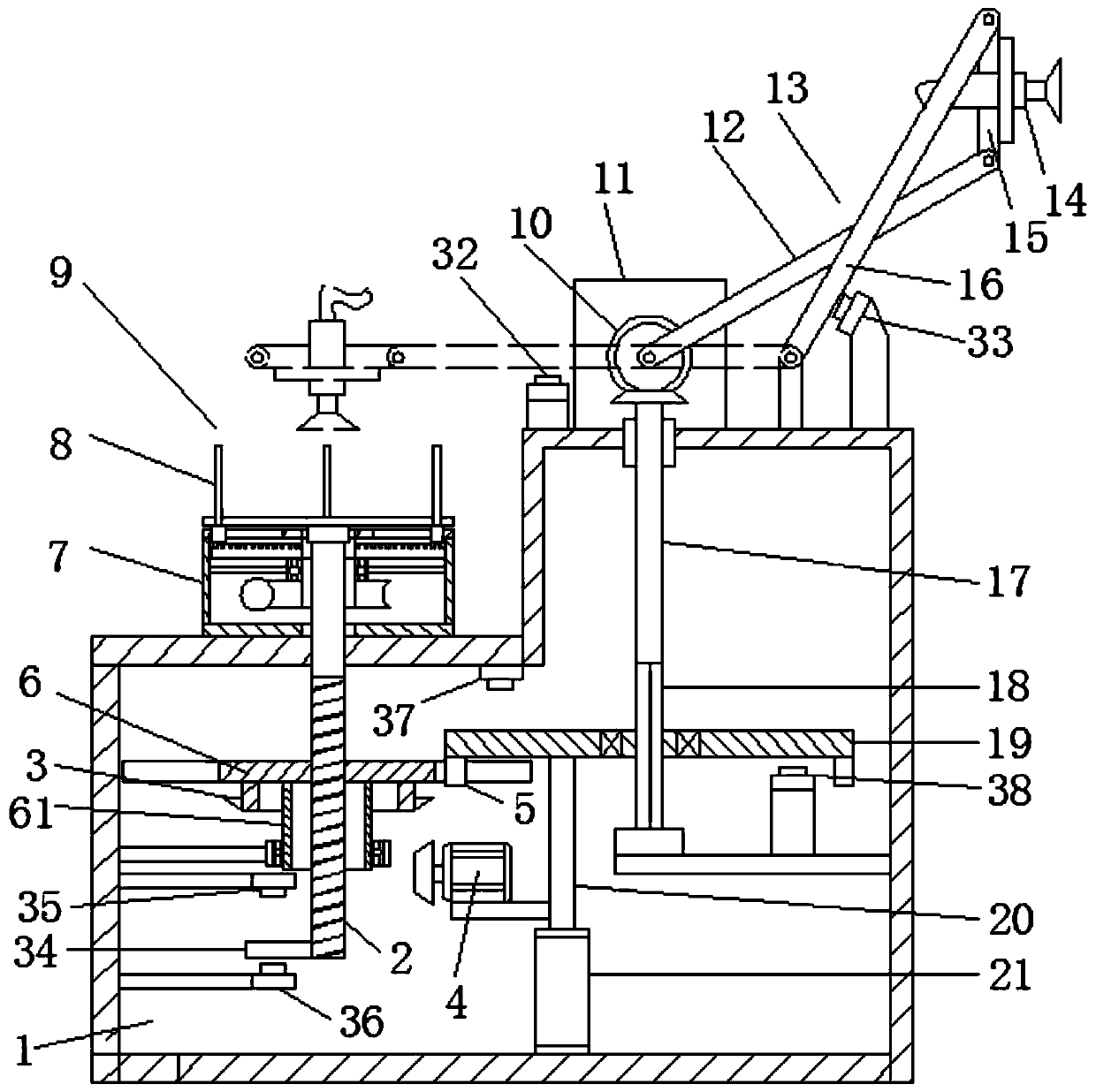

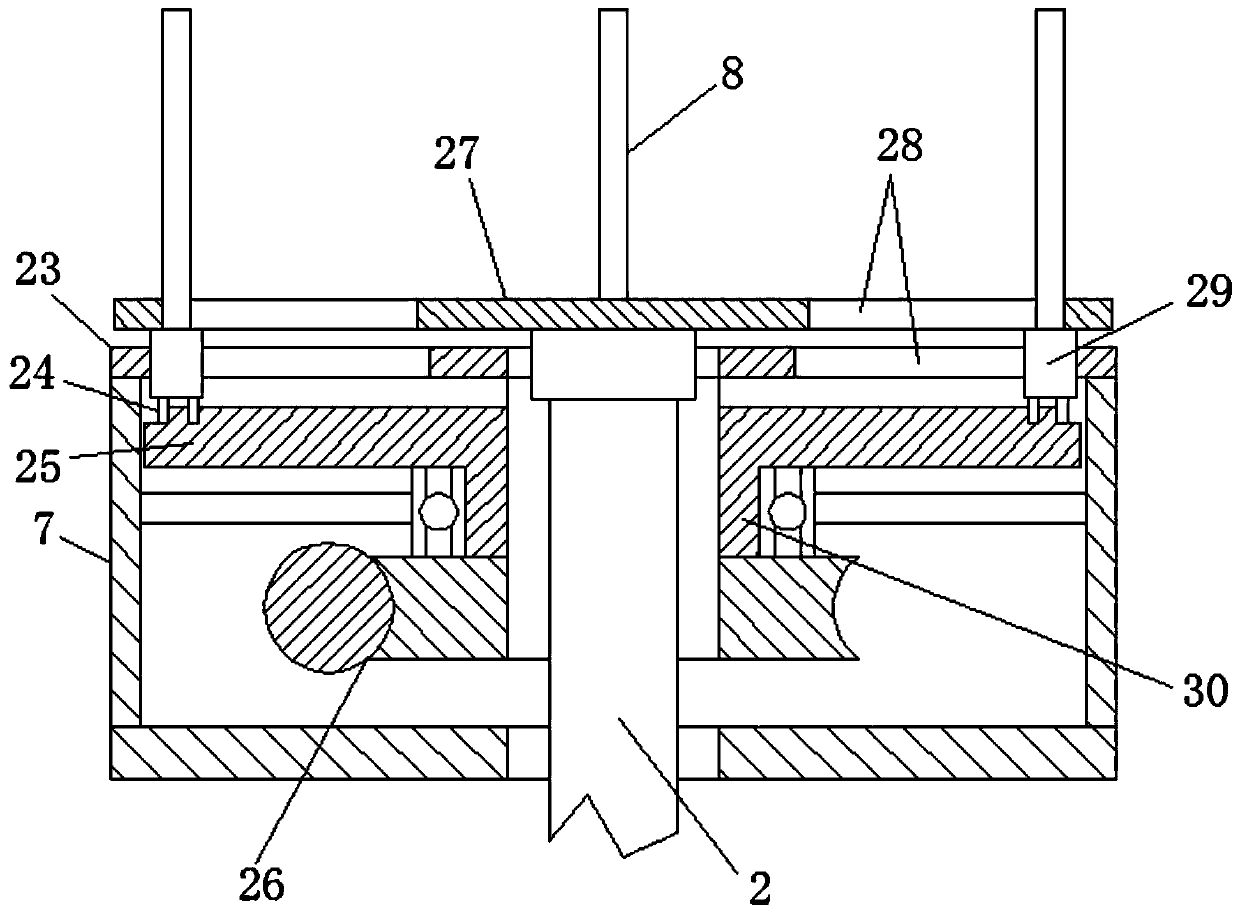

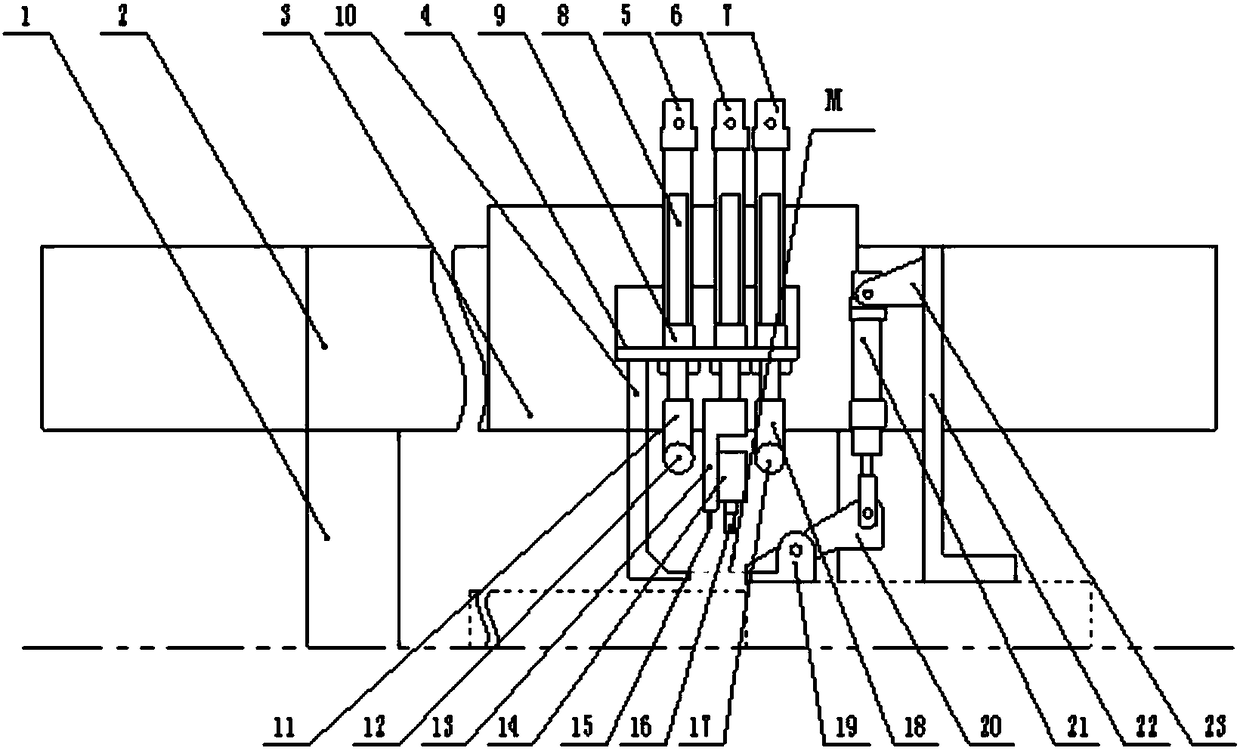

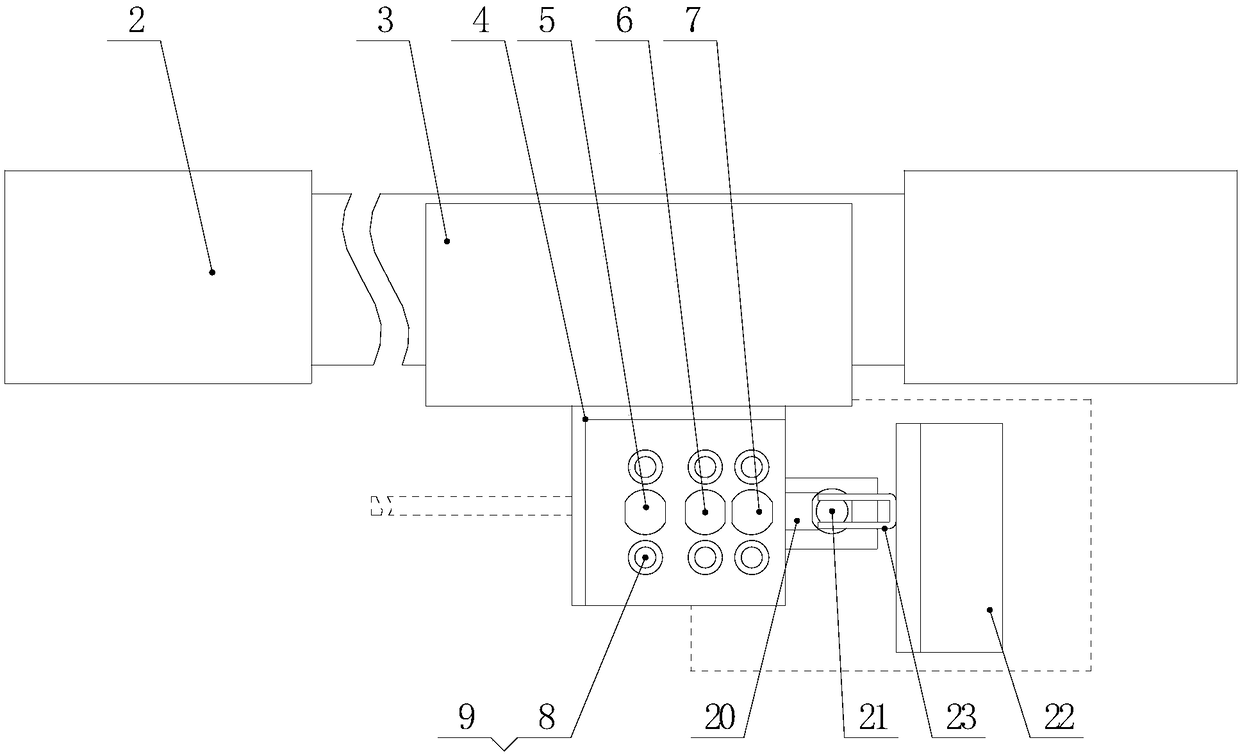

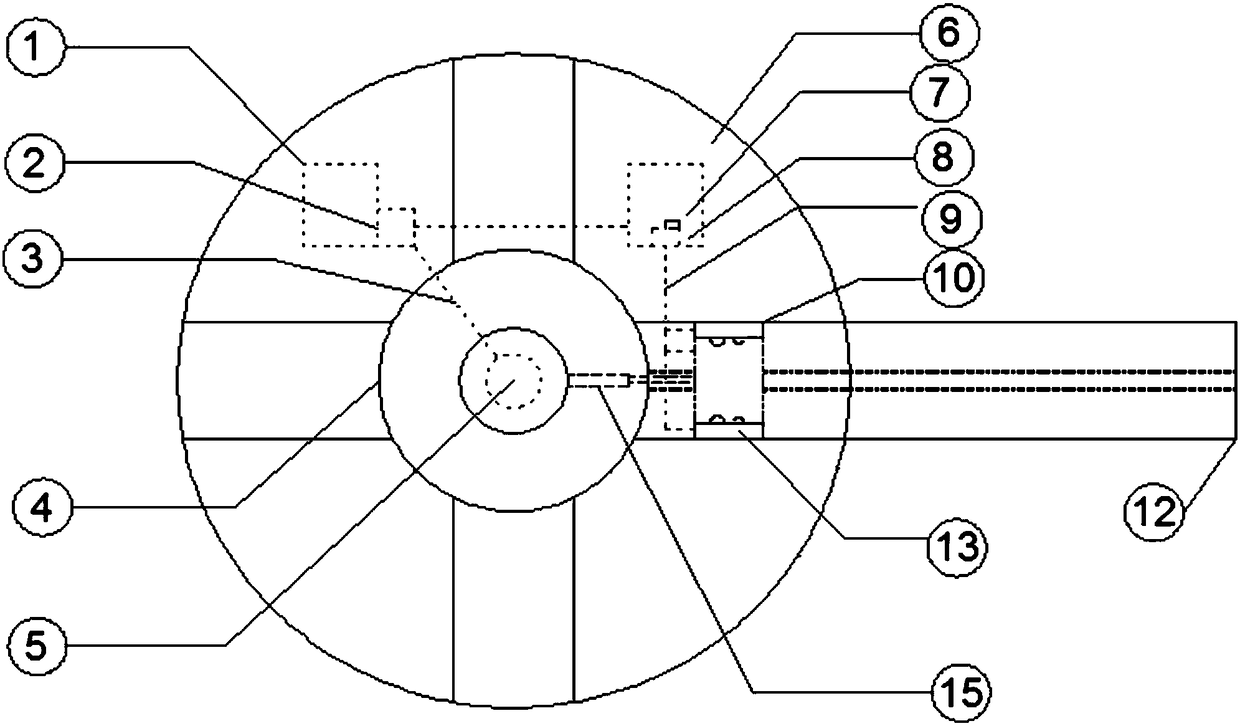

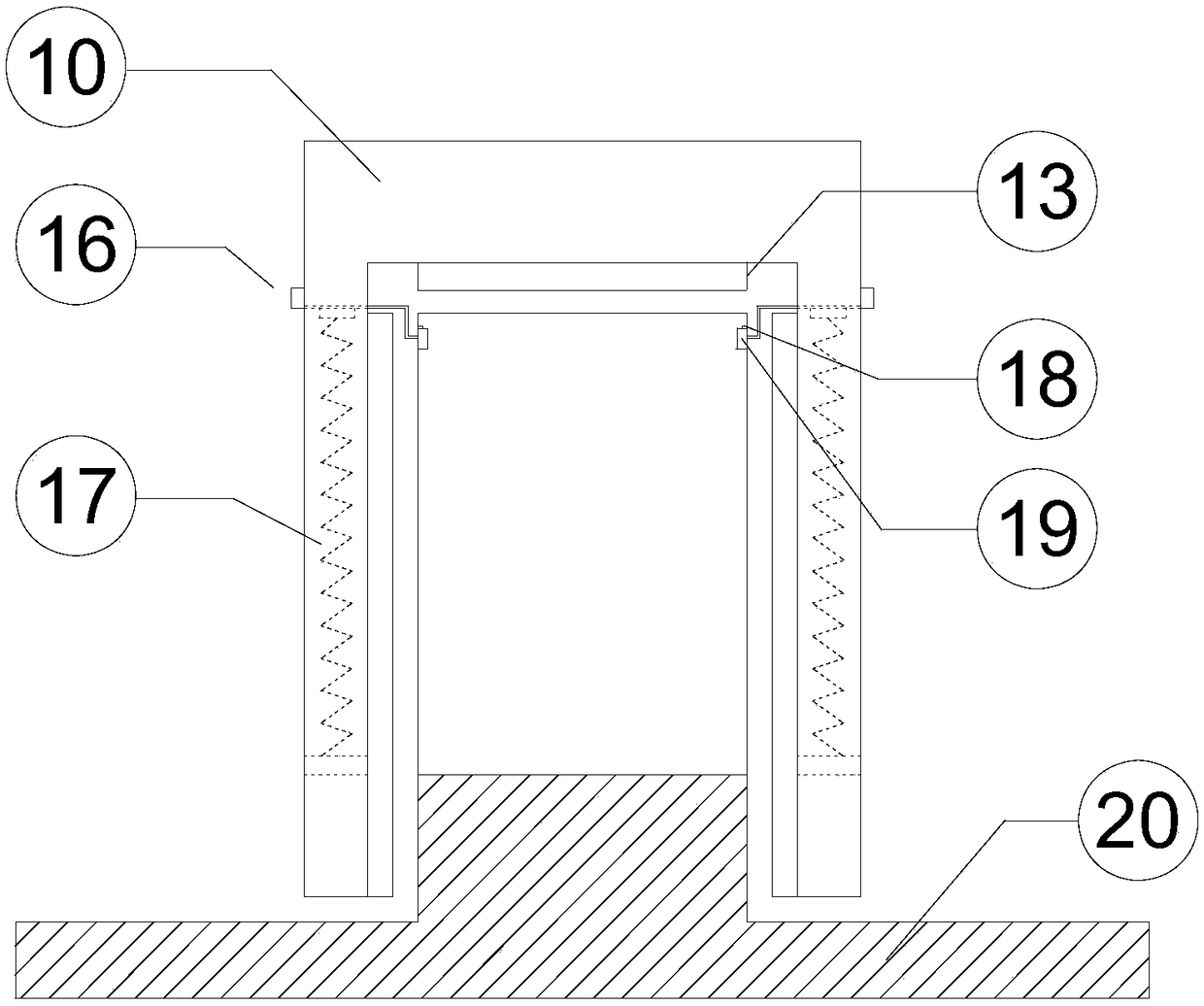

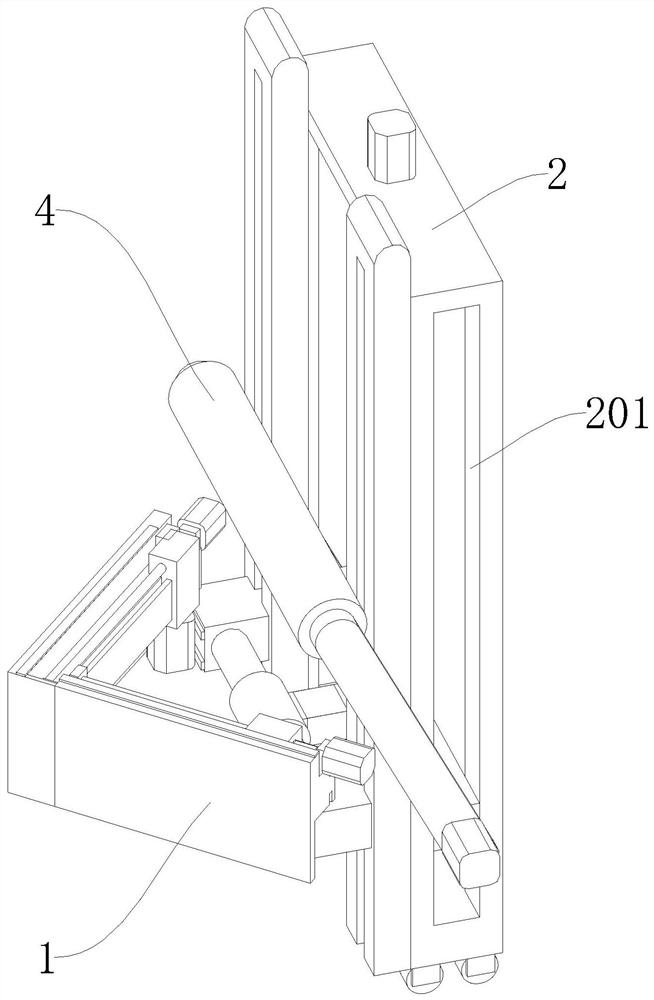

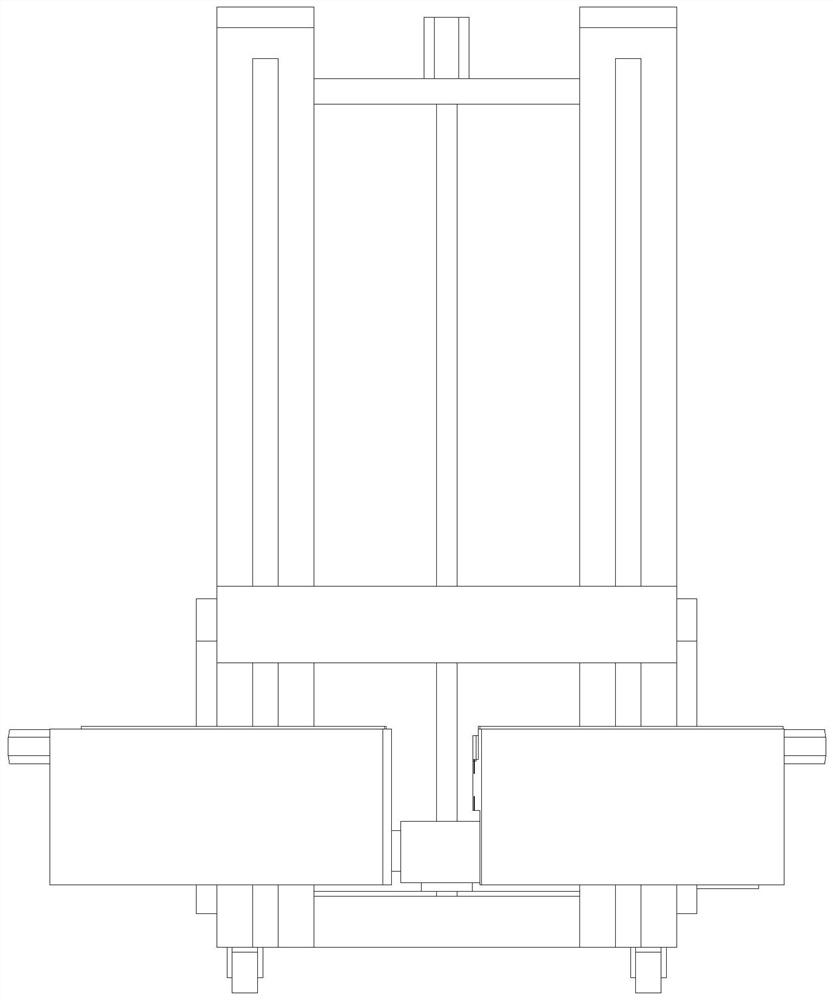

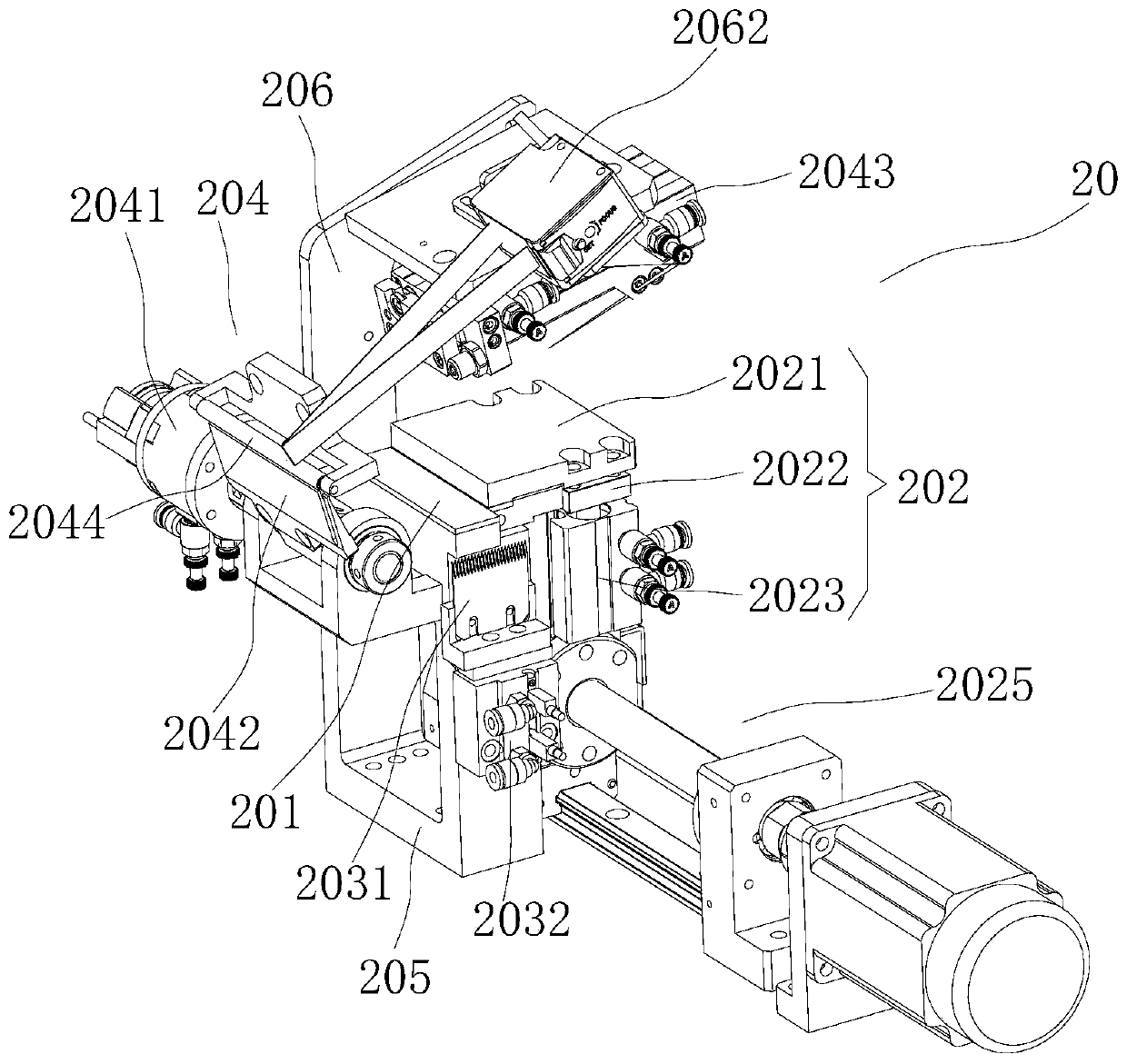

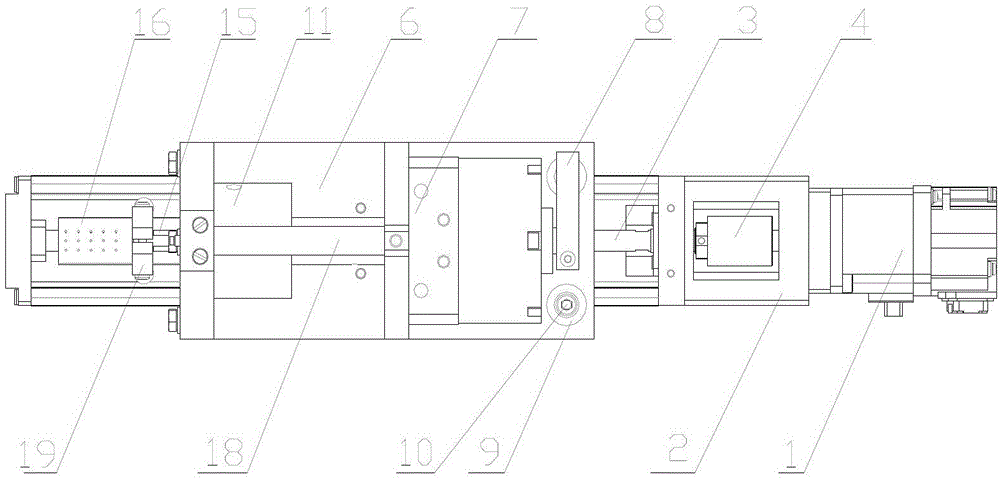

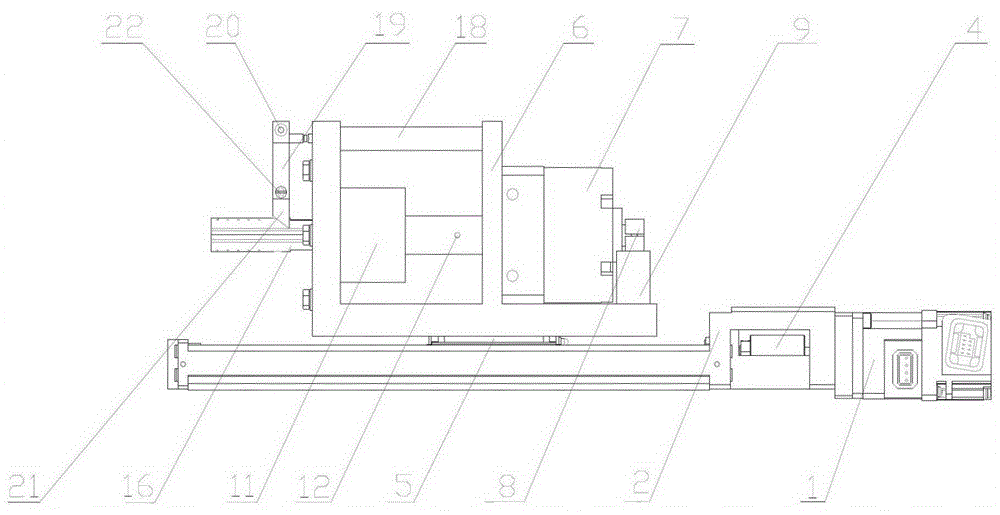

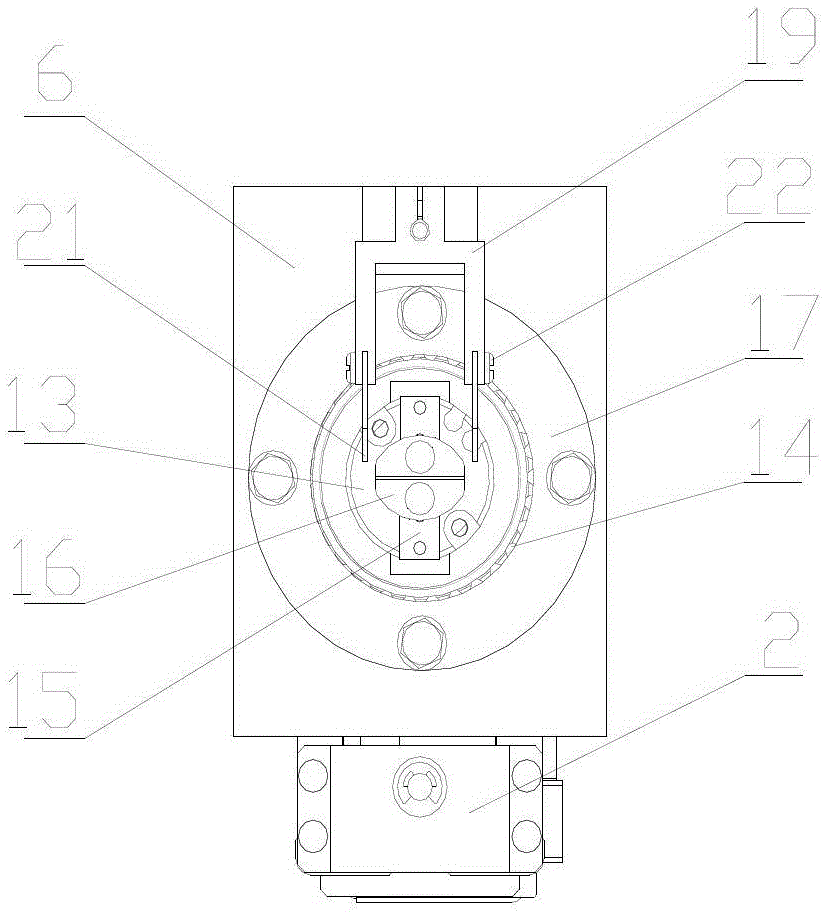

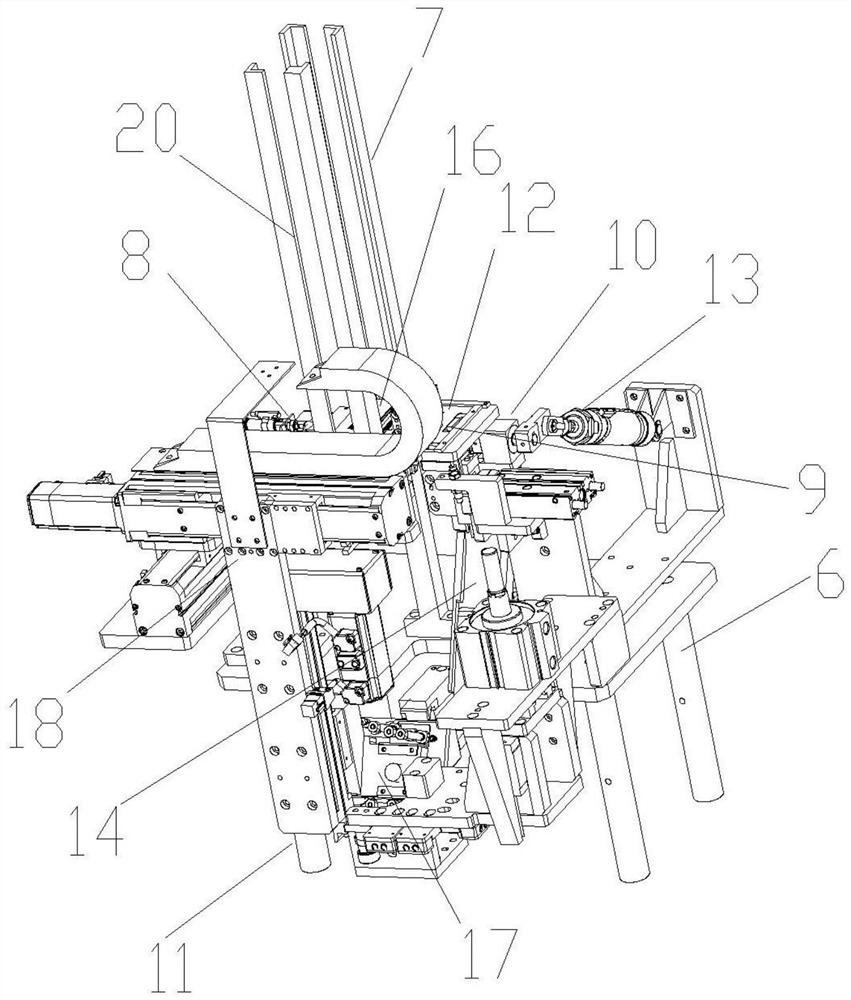

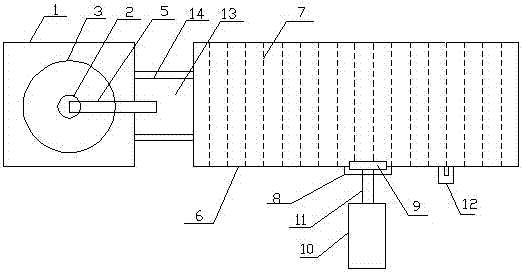

Strain gauge pasting mechanism

ActiveCN103438066ARealize automatic pastePaste depth precise controlFastening meansLinear motionElastomer

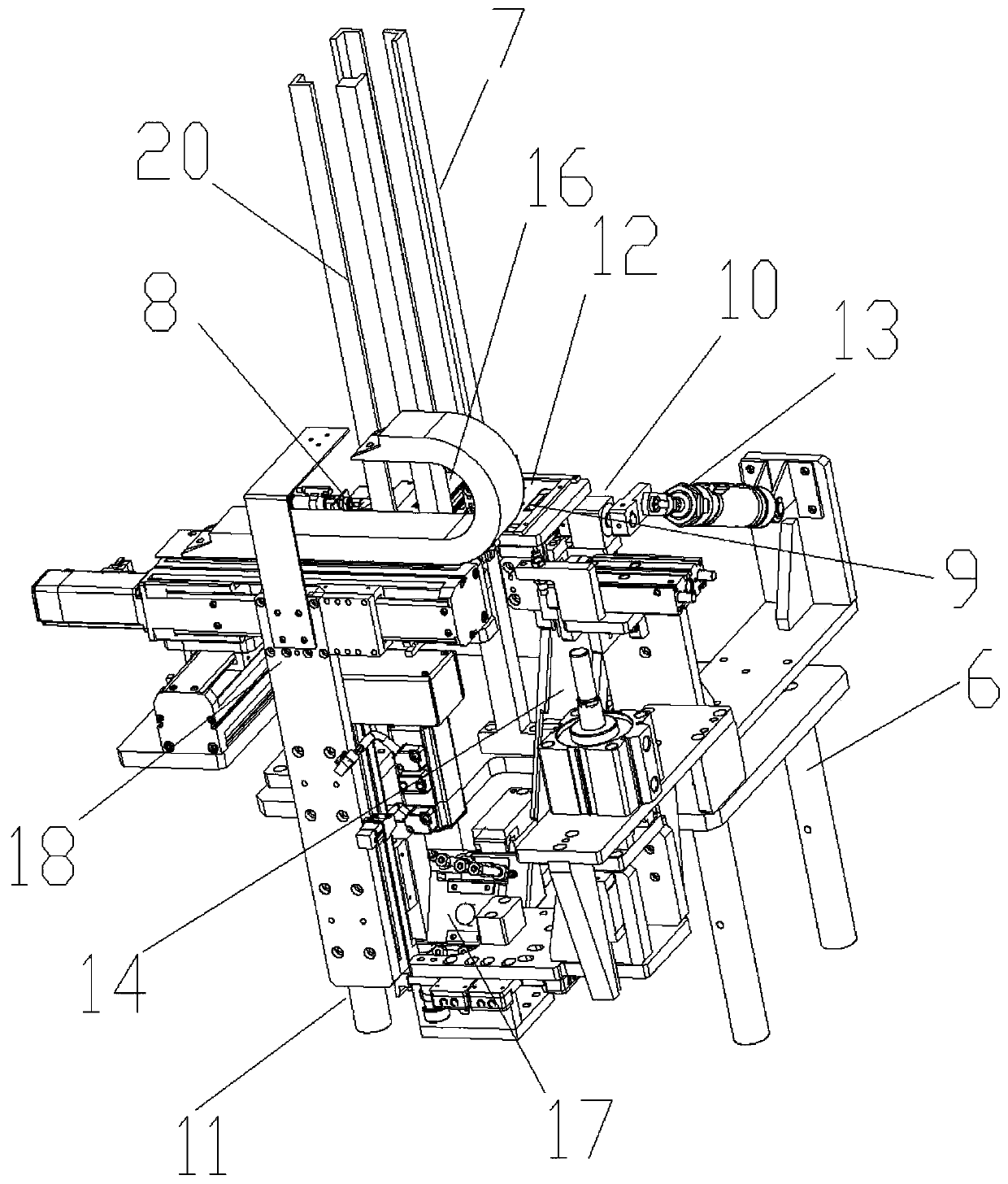

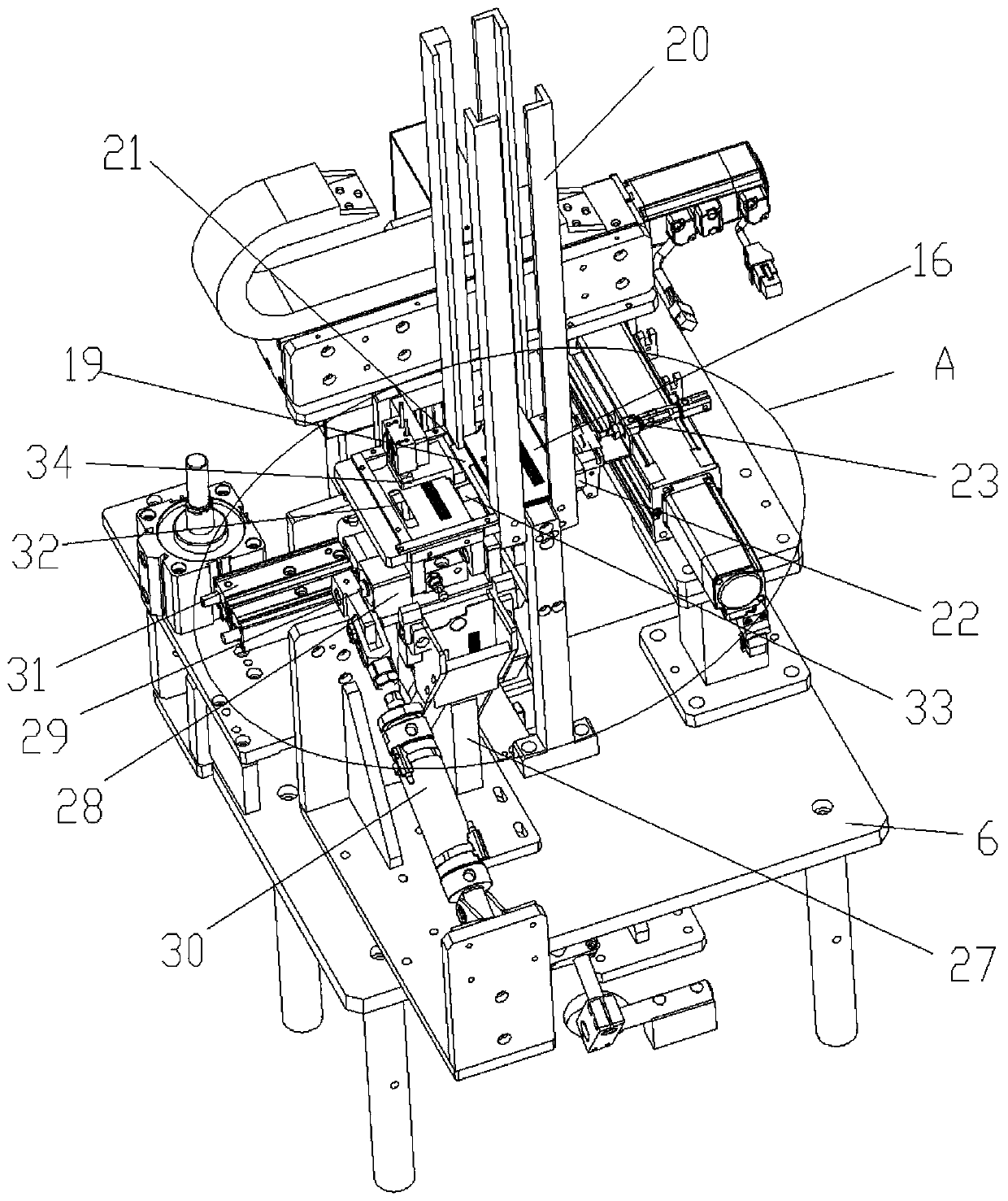

The invention relates to a strain gauge pasting mechanism, in particular to a strain gauge pasting mechanism which can achieve automatic pasting of hole internal strain gauges. The strain gauge pasting mechanism solves the problems that due to the fact that common elastomer hole internal strain gauge pasting is completed mainly through manual work, accuracy and quality are low. According to the technical scheme, the strain gauge pasting mechanism is novel and mainly comprises a servo motor, a linear guide rail, a lead screw, a slider, an F-shaped motion base, an overturn air cylinder, pneumatic claws, pasting heads, a telescopic air cylinder, a tool rest and a blade. The linear motion combination of the servo motor, the lead screw and the linear guide rail is adopted, and therefore accuracy control over strain gauge hole internal pasting depth is achieved. Vertical opening-and-closing motion is achieved through the two arc-shaped pasting heads, and therefore strain gauges can be firmly pasted in elastomer holes. Two strain gauges can be pasted in the holes at a time through 180-degree rotation of the overturn air cylinder. The strain gauge pasting mechanism achieves automatic pasting of the hole internal strain gauges, greatly improves accuracy, and improves quality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

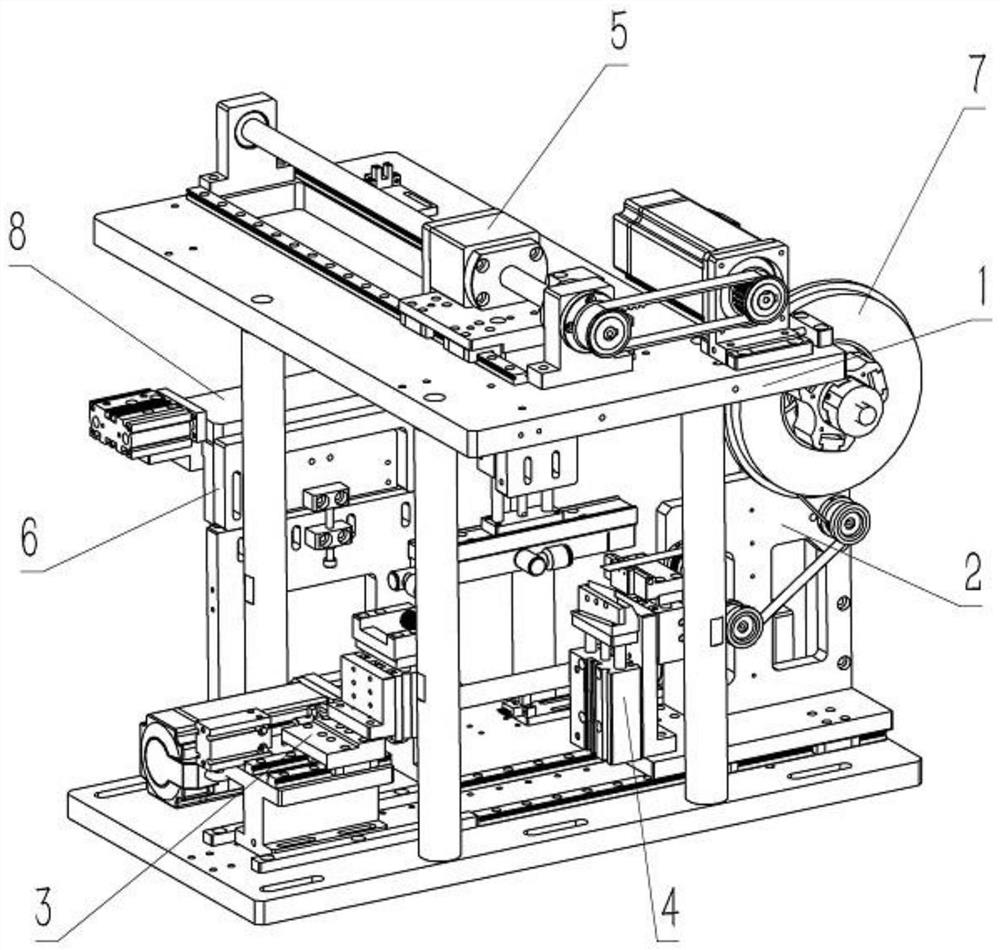

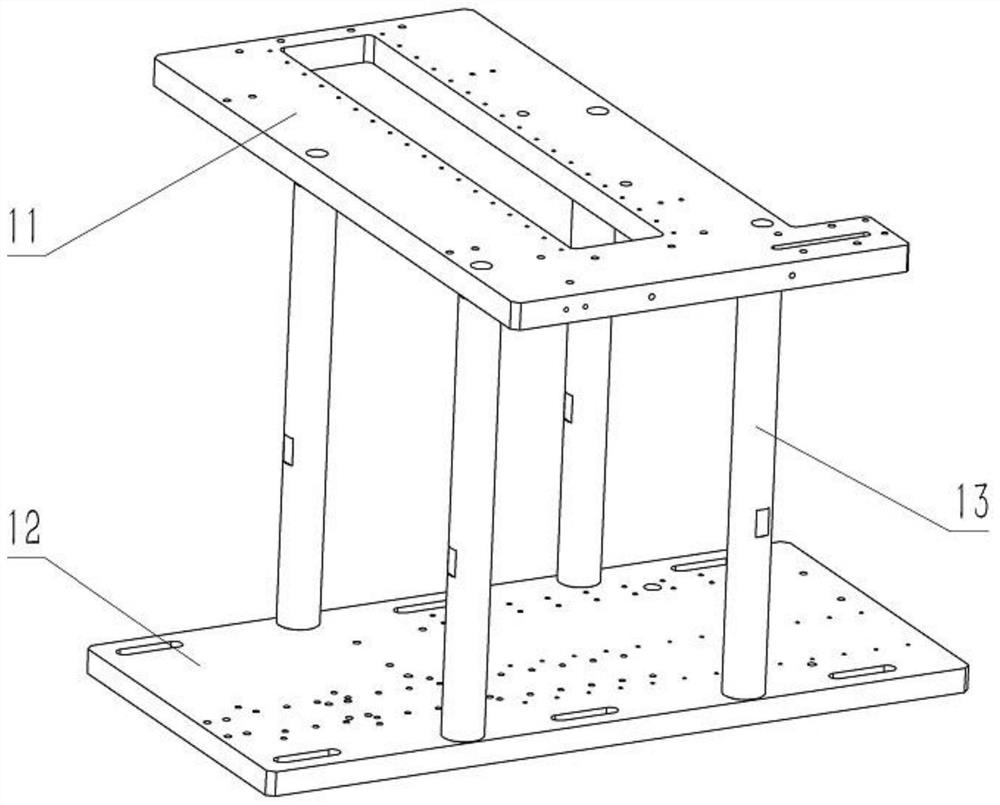

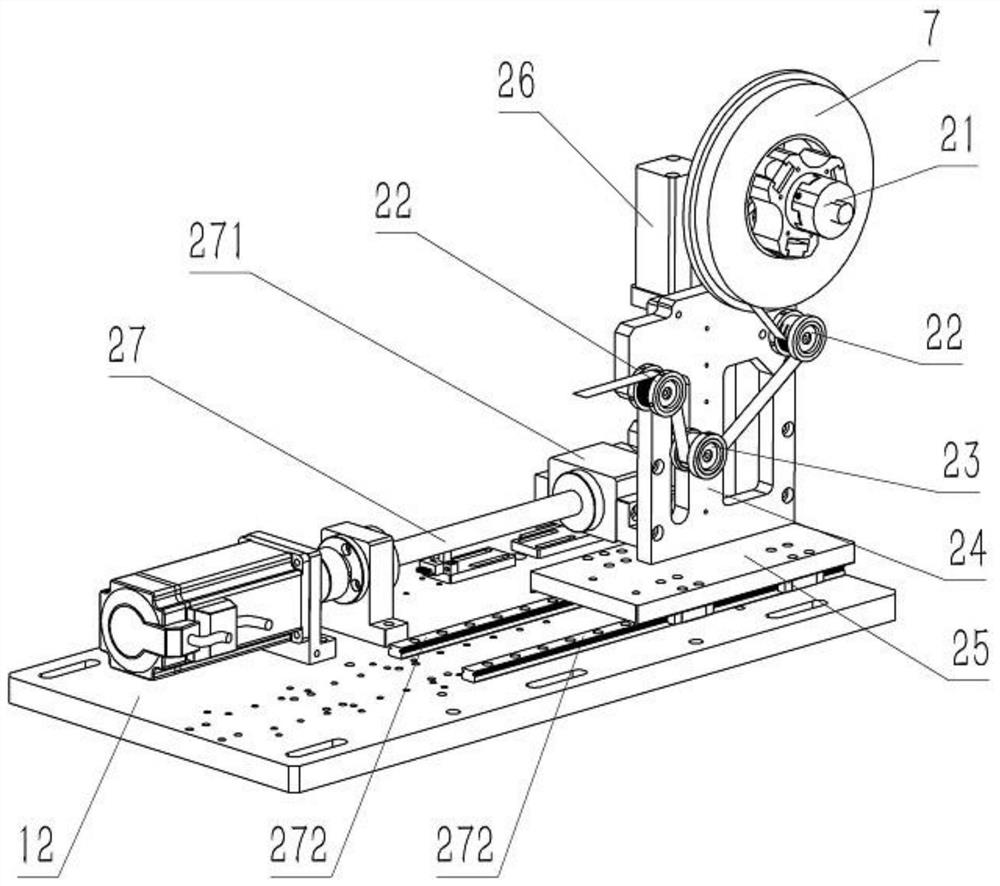

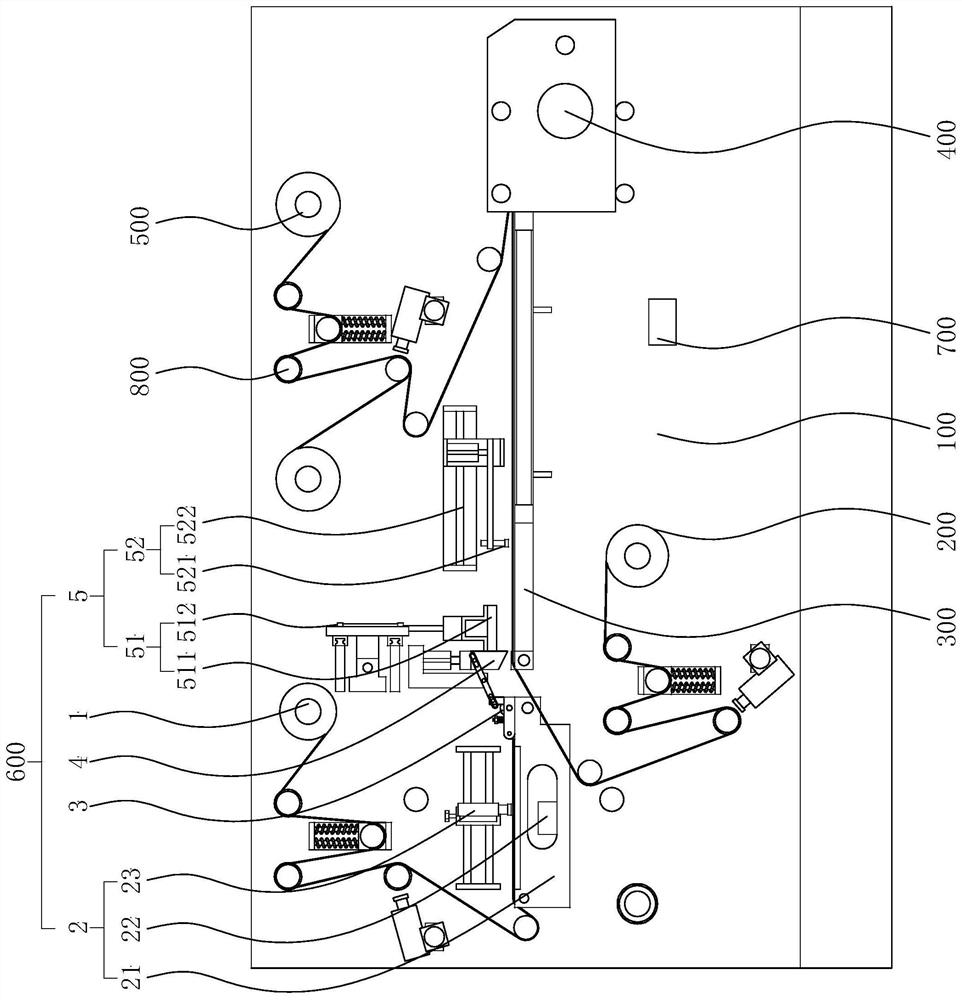

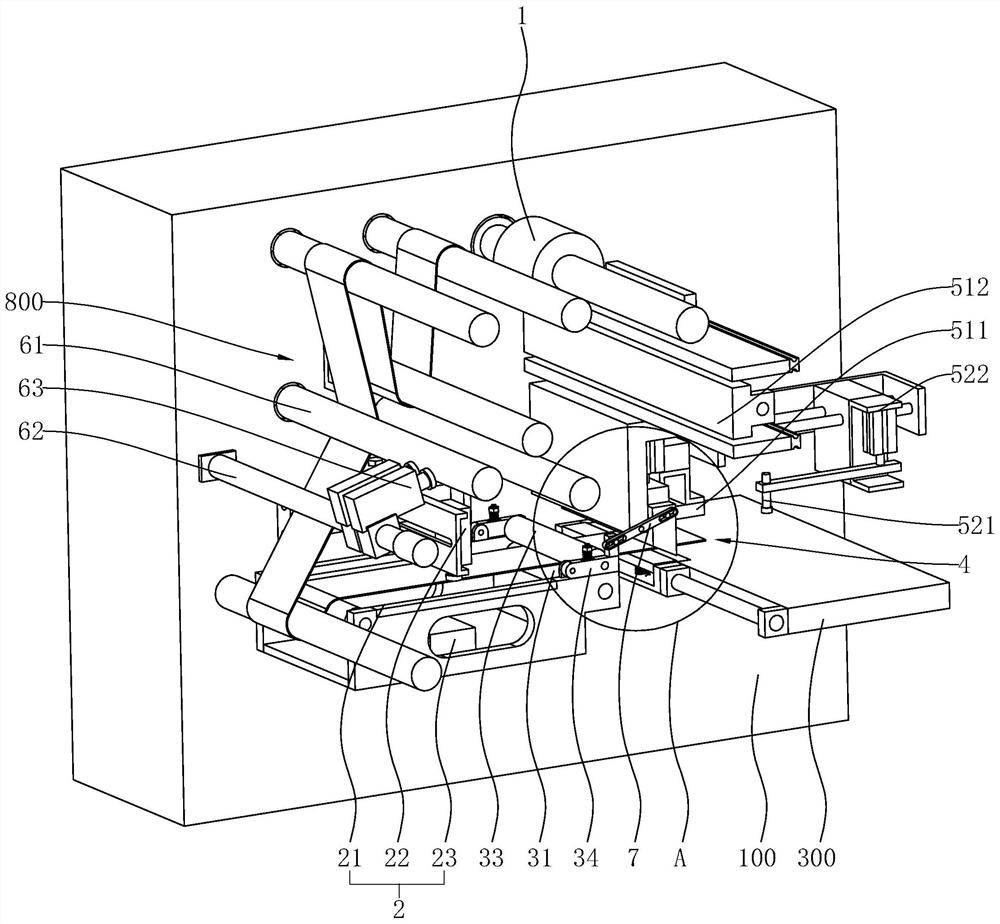

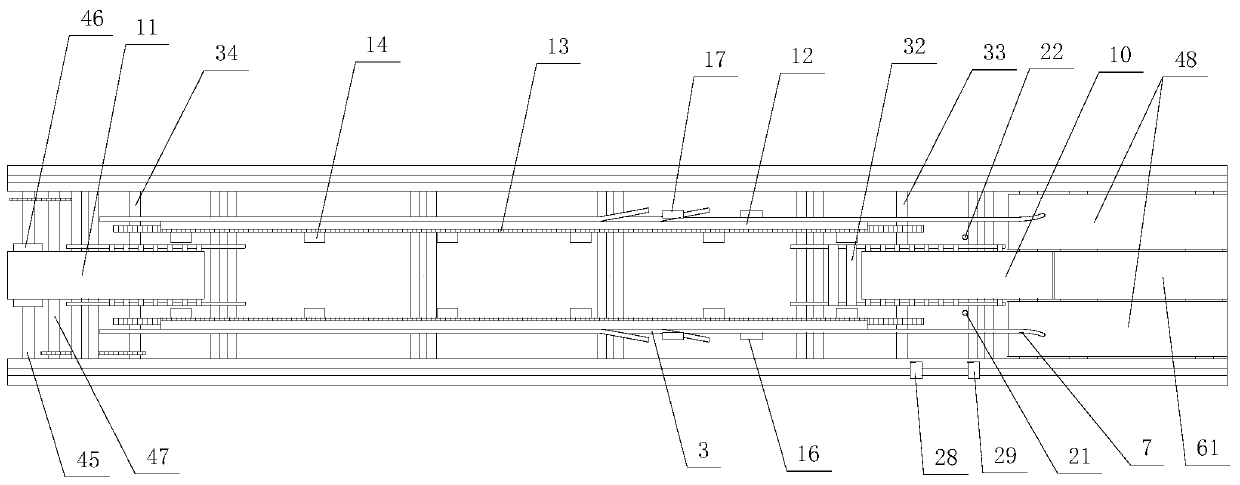

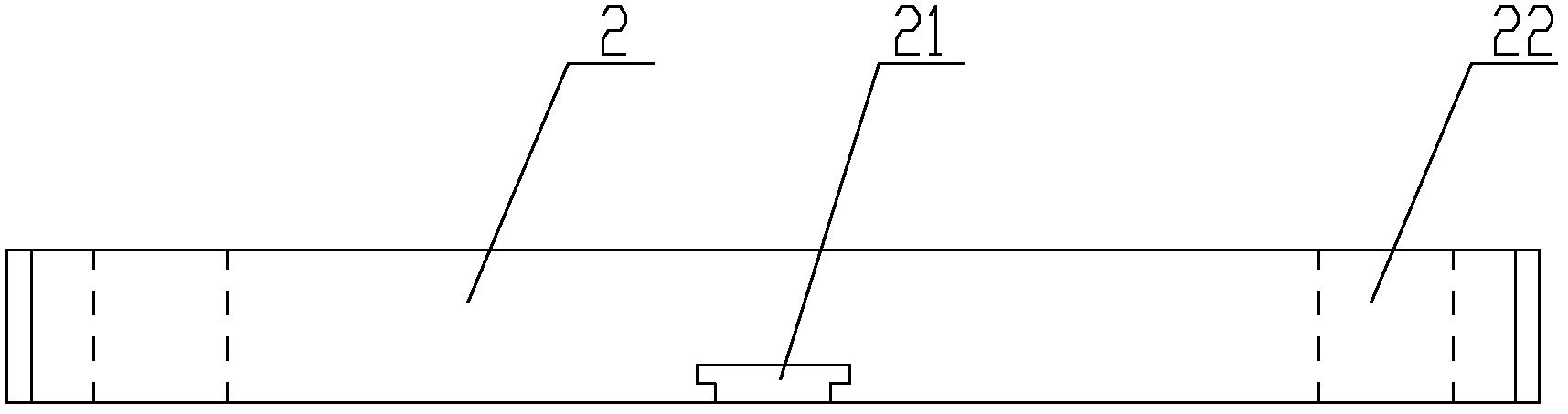

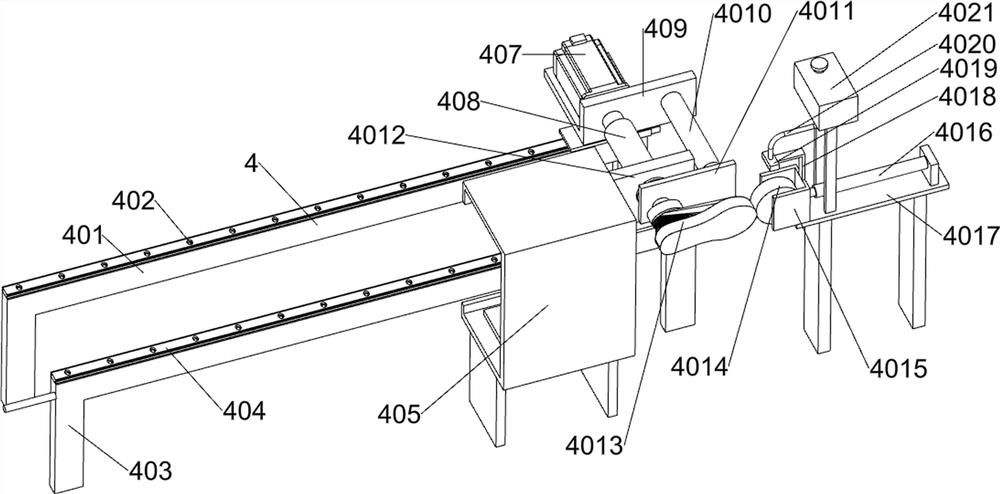

Adhesive tape sticking device

The invention discloses an adhesive tape sticking device which is used for pressing adhesive tape on the surface of an adhesive object. A layered support comprises an upper layer and a lower layer, the lower layer is used for installing a movable feeding mechanism, an adhesive tape head positioning mechanism and an adhesive tape positioning and cutting mechanism, and the upper layer is used for installing an adhesive tape pressing mechanism; the adhesive tape head positioning mechanism fixes one end of the adhesive tape, and is matched with movement of the movable feeding mechanism to pull outthe adhesive tape from an adhesive tape tray; the adhesive tape positioning and cutting mechanism is installed on the movable feeding mechanism, synchronously moves along with the movable feeding mechanism and is used for fixing the rear end of the stretched-out adhesive tape and cutting off the adhesive tape according to the required length; and an adhesive object positioning mechanism is positioned on one side of the lower layer and used for providing a supporting platform for pressing the adhesive tape to the adhesive object and fixing the adhesive object at a corresponding position. Automatic adhesive tape feeding, adhesive tape cutting and adhesive tape pressing can be realized, and the working efficiency is greatly improved.

Owner:HUBEI TKD ELECTRONICS TECH

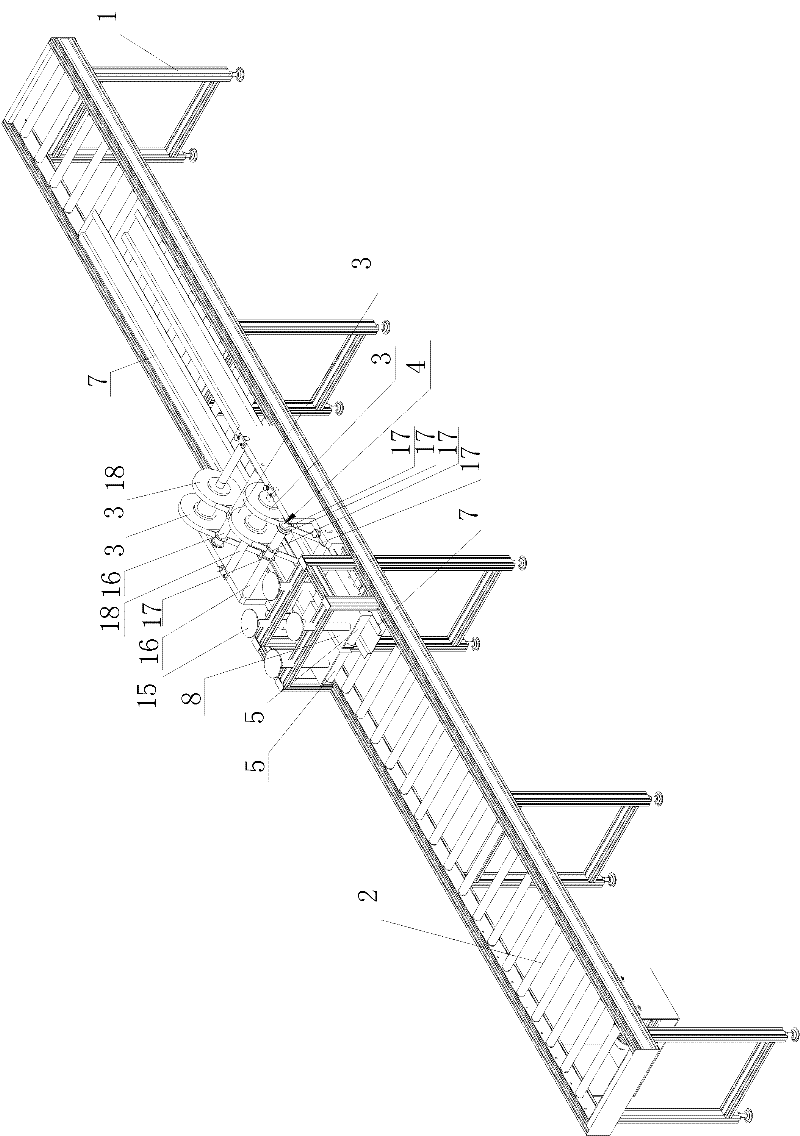

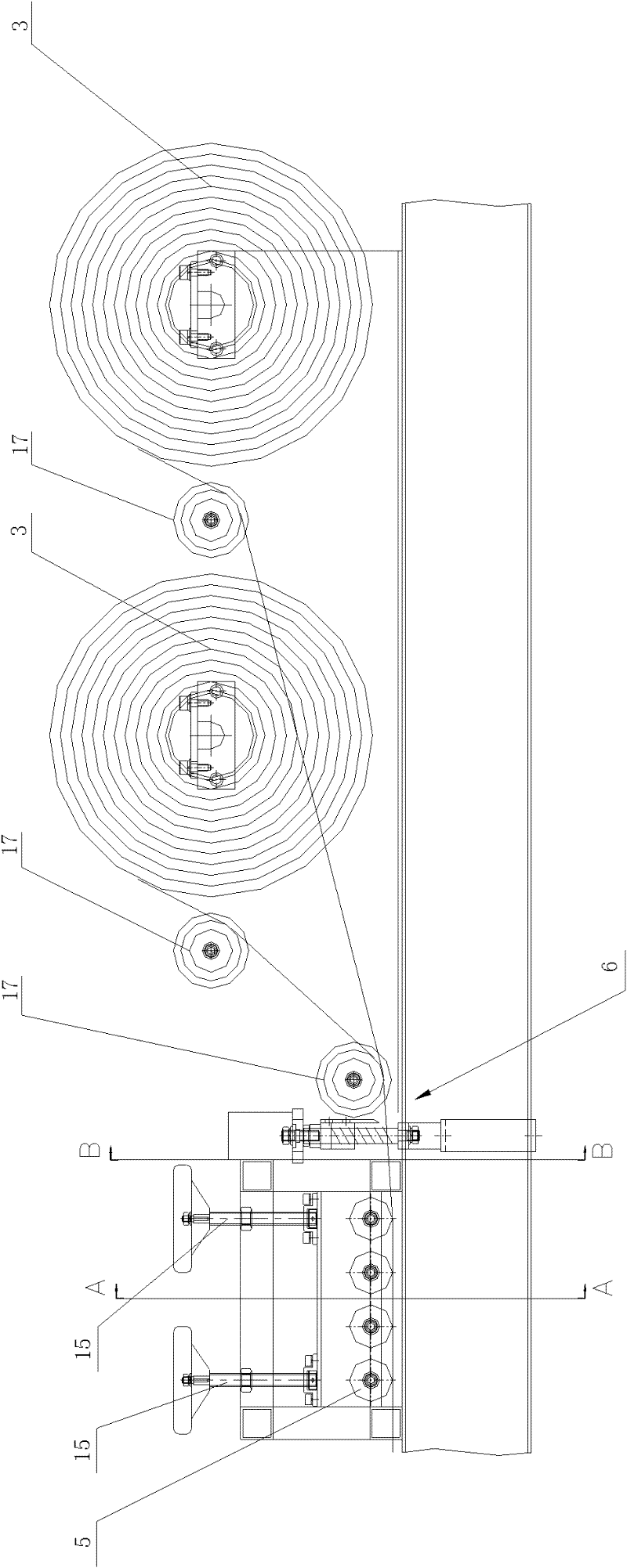

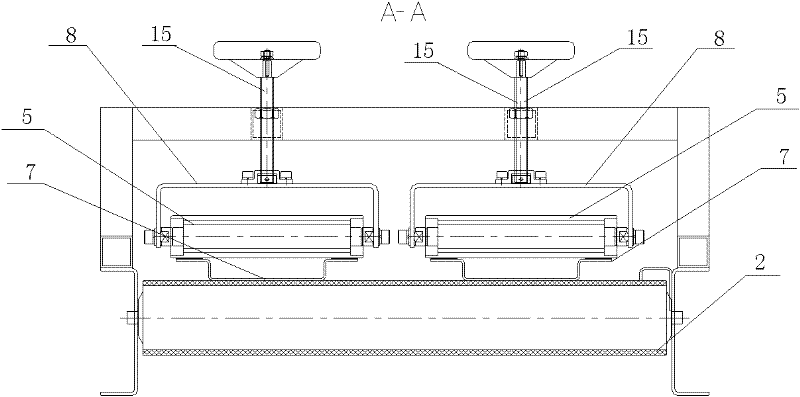

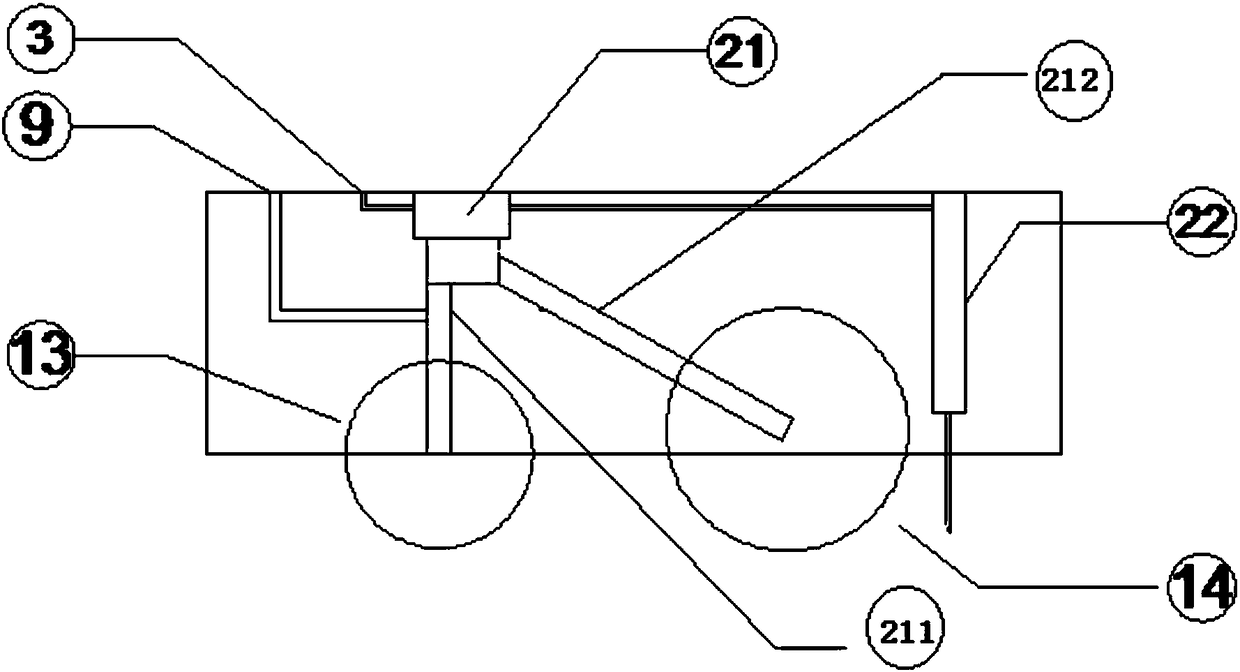

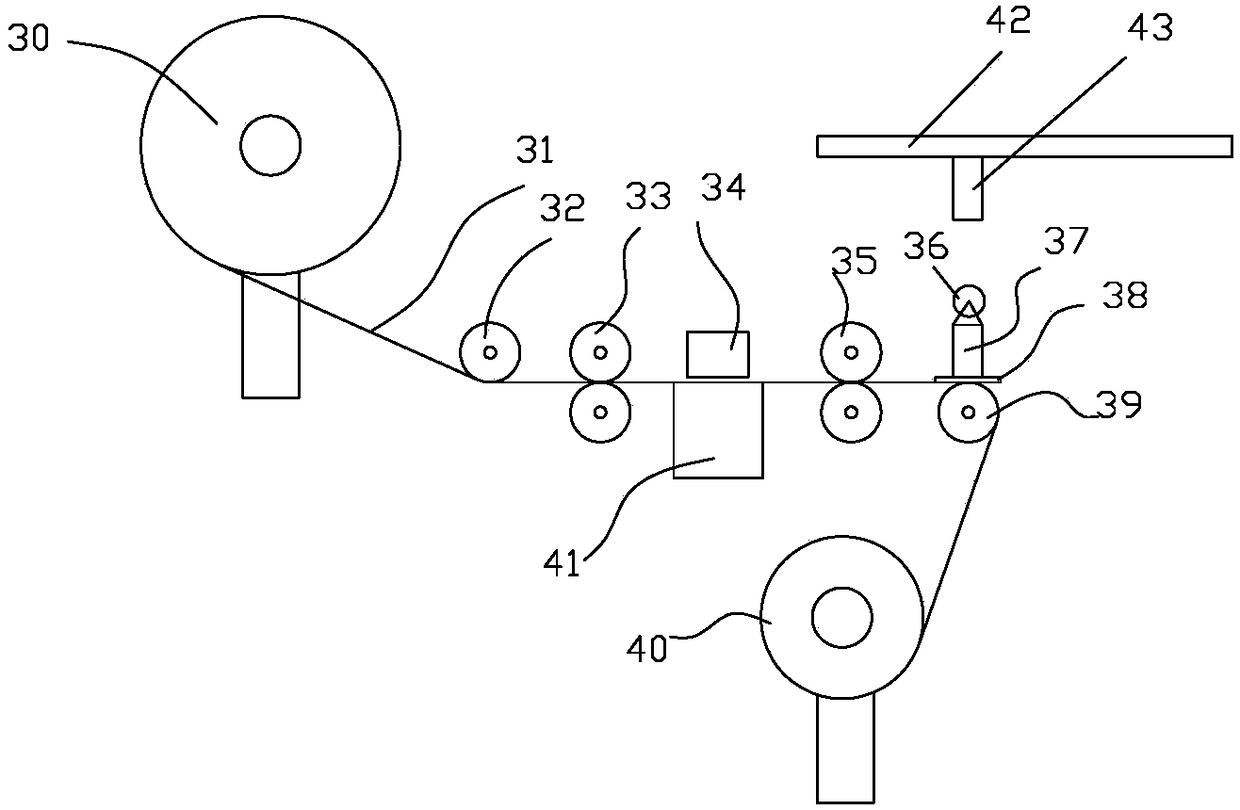

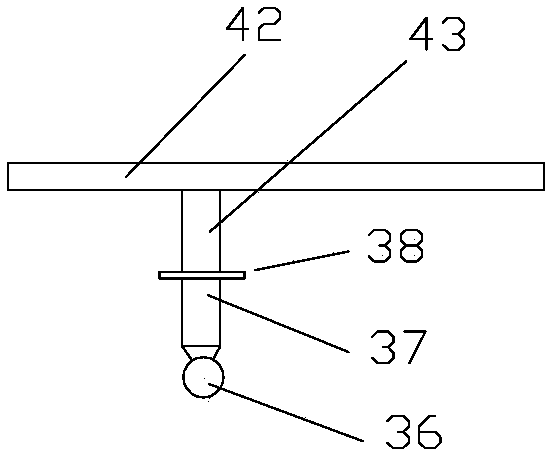

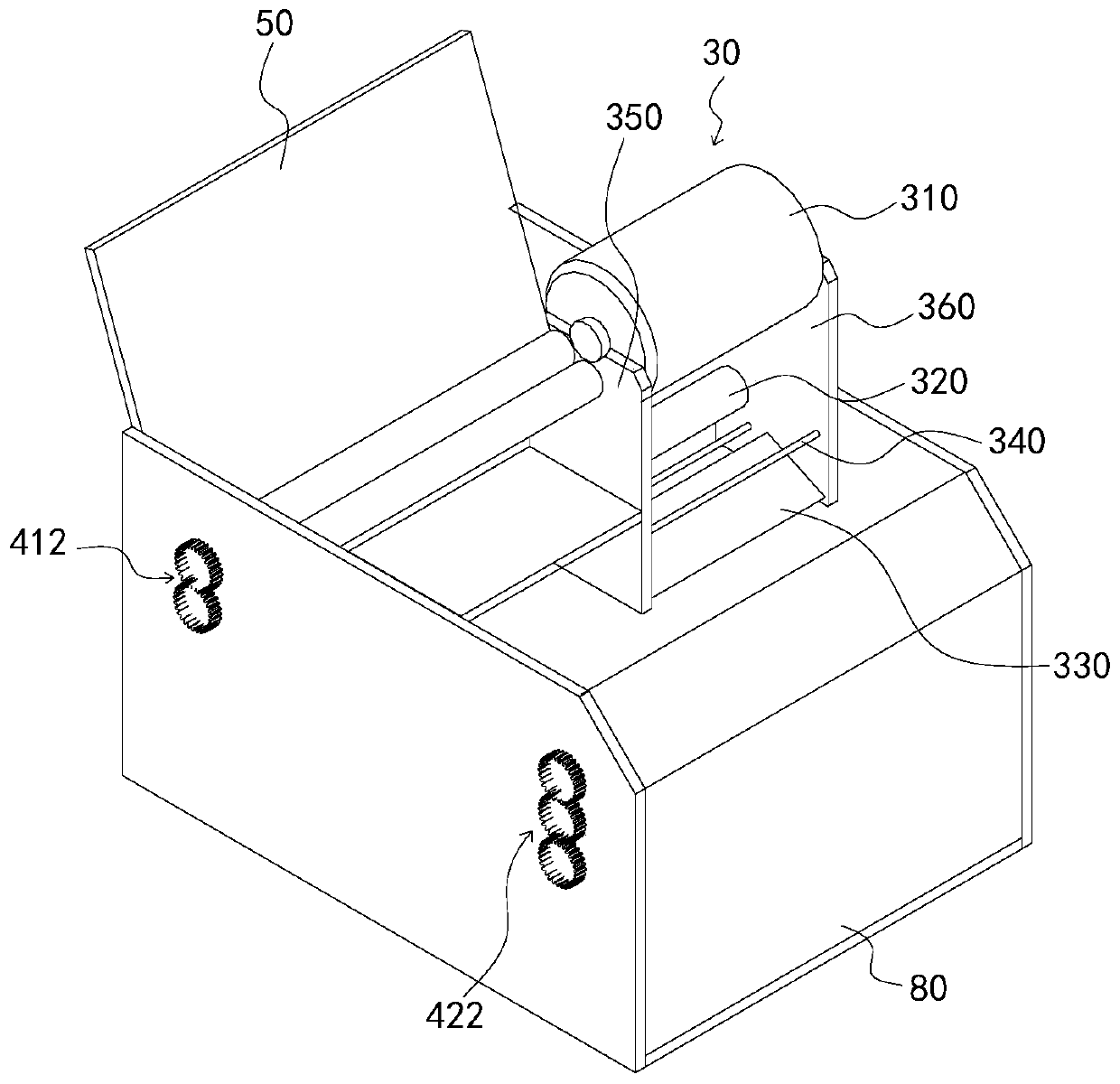

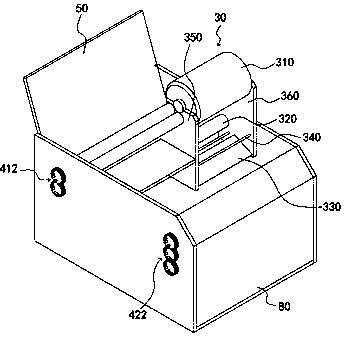

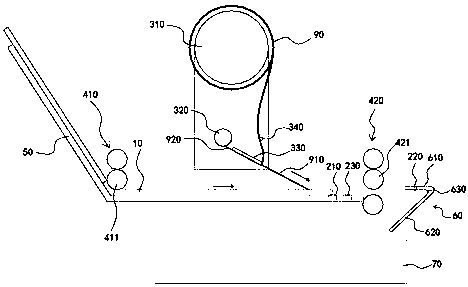

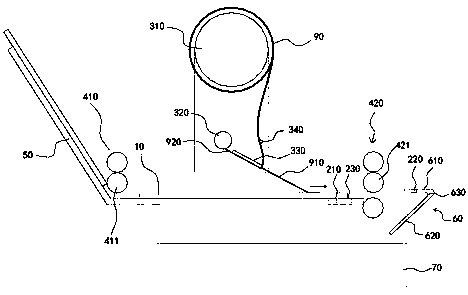

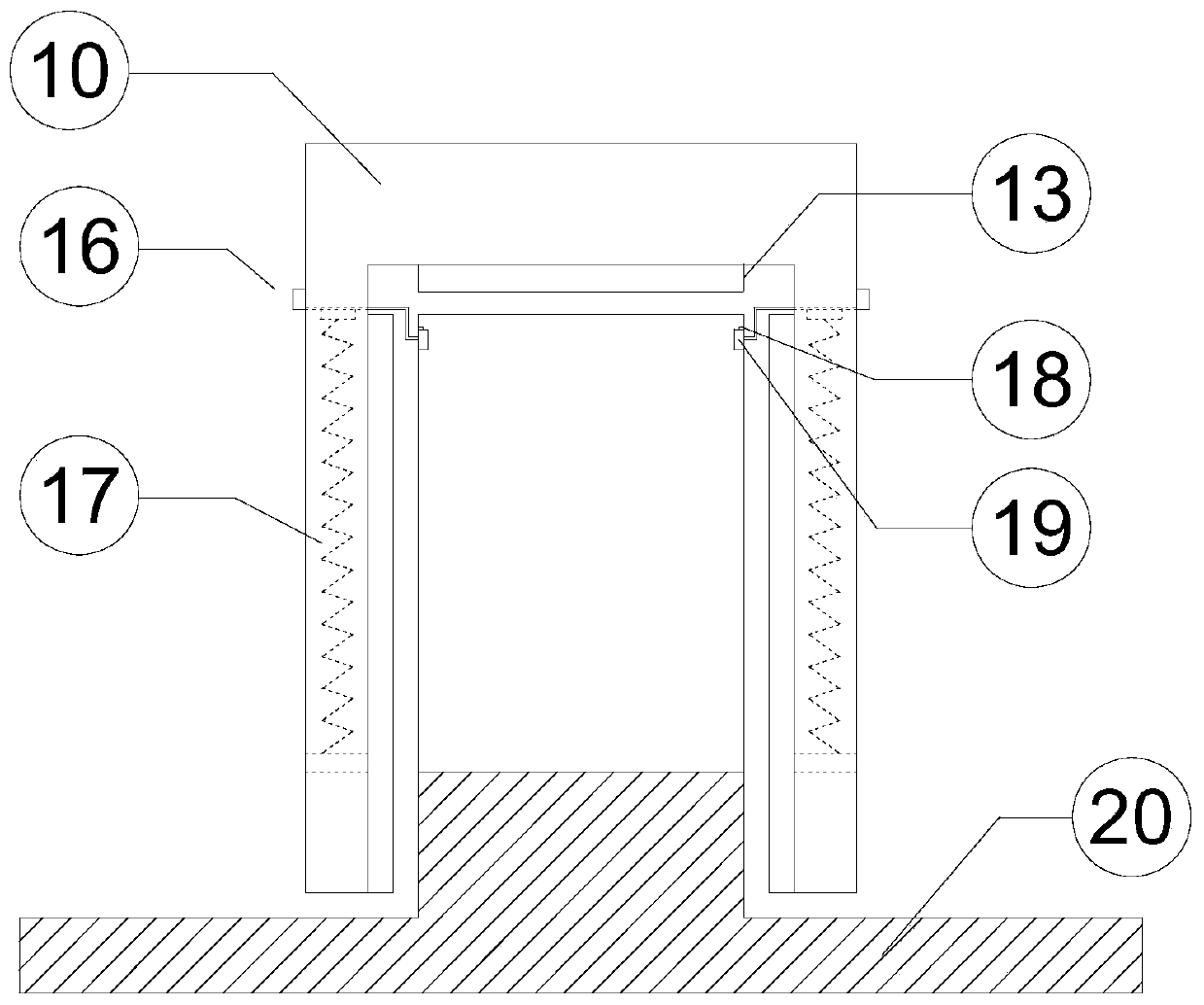

Sticking device for car wall reinforcement in elevator car

InactiveCN102297184AReduce risk of sheddingRealize automatic pasteBuilding liftsFastening meansSilicone tapeCarriage

The invention discloses an adhesion device of a car wall reinforcing rib of an elevator car, comprising a carriage, a plurality of driving transmission rollers which can be rotationally arranged on the carriage and are used for horizontally conveying the reinforcing rib, a disc-shaped double-sided tape which can be arranged above the driving transmission rollers on the carriage and rotate around the self axis, a guiding device which is arranged on the carriage and can guide the disc-shaped double-sided tape to move so that the tape is in alignment with or moves to a position at which the reinforcing rib is to be adhered, a driven pressure roller which is arranged above the driving transmission rollers and can compact the tape on the reinforcing rib above the driving transmission rollers, and a cutting device capable of cutting the tape on the tail end of the reinforcing rib. The adhesion device of the car wall reinforcing rib of the elevator car realizes the automatic adhesion of the tape, so that the production efficiency is improved and the labor intensity is reduced; and simultaneously, due to the device, the double-sided tape can be stably and reliably adhered on the reinforcing rib, so that the product quality is improved, the possible risk that the reinforcing rib falls off is greatly reduced, and the personal safety of a passenger is ensured.

Owner:SJEC CORP

Labeling device for outer packaging of tape products and using method thereof

ActiveCN109850301ARealize automatic pasteReduce human involvementLabelling machinesEngineeringMechanical engineering

Owner:蔡以恒

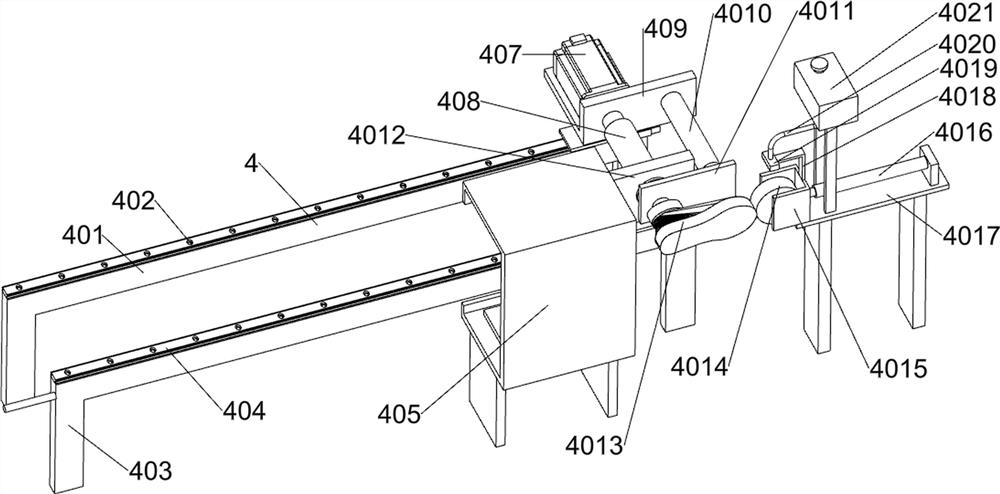

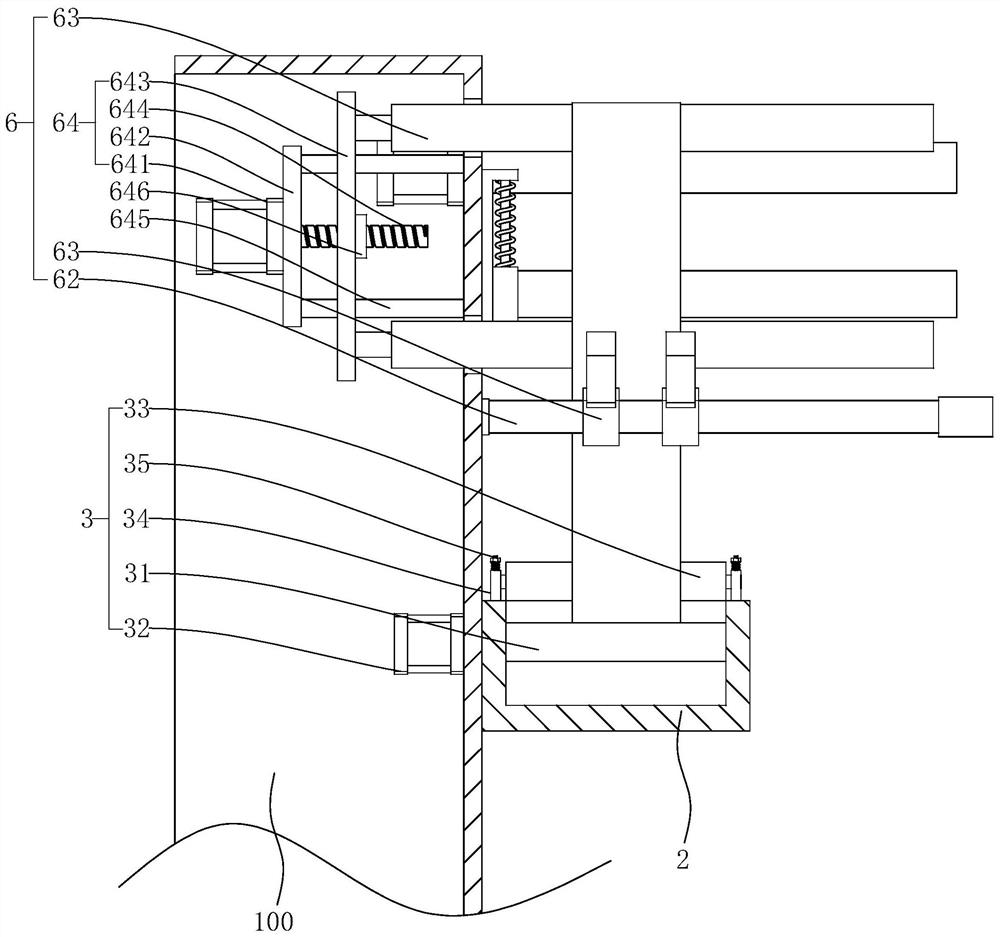

Prefabricated fragment strip adhesive tape adhering device

ActiveCN108106504AReduce deformationRealize automatic pasteAmmunitionEngineeringMechanical engineering

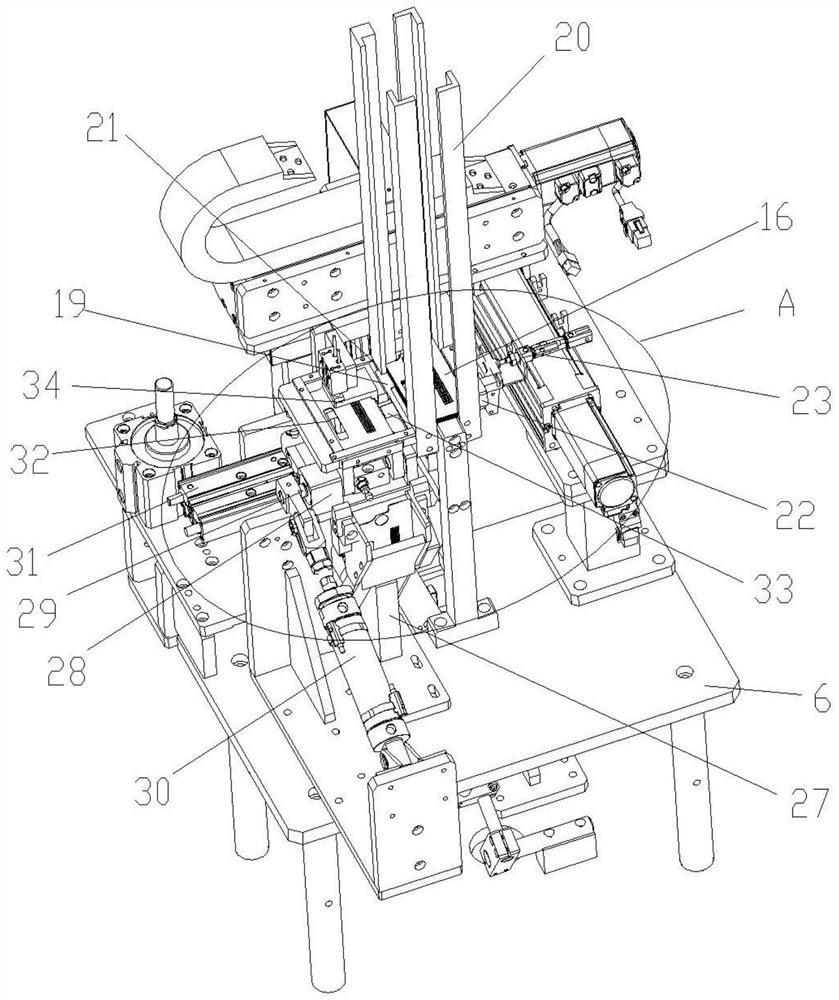

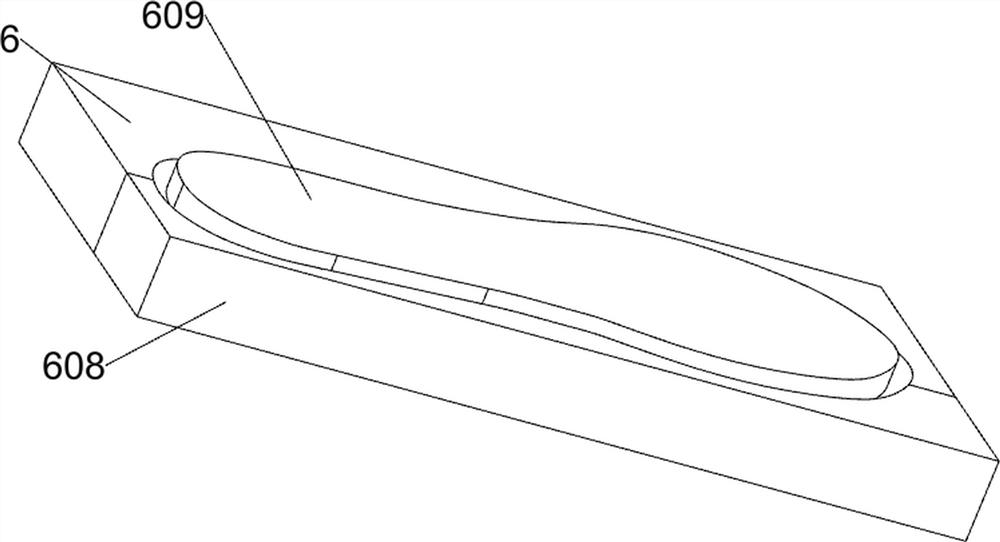

The invention discloses a prefabricated fragment strip adhesive tape adhering device. The prefabricated fragment strip adhesive tape adhering device comprises a rack, a downward pressing adhesive tapeholding device, a downward pressing cutter device, a downward pressing adhesive pressing device and an adhesive tape end portion clamping device, and the downward pressing adhesive tape holding device, the downward pressing cutter device, the downward pressing adhesive pressing device and the adhesive tape end portion clamping device are located on the A side of the rack and are sequentially arranged in the advancing direction of adhesive tape; the downward pressing adhesive tape holding device, the downward pressing cutter device and the downward pressing adhesive pressing device are all located over the advancing path of the adhesive tape; and the adhesive tape end portion clamping device is provided with a clamping port located in the advancing path of the adhesive tape. The prefabricated fragment strip adhesive tape adhering device is simple in structure, convenient to use and capable of achieving the effects that automatic adhering of the prefabricated fragment strip adhesive tape is achieved, the production efficiency is improved, meanwhile, the adhering precision and the adhering effect can be improved, and it is guaranteed that deformation of the adhesive tape is minimum,

Owner:中国兵器装备集团自动化研究所有限公司

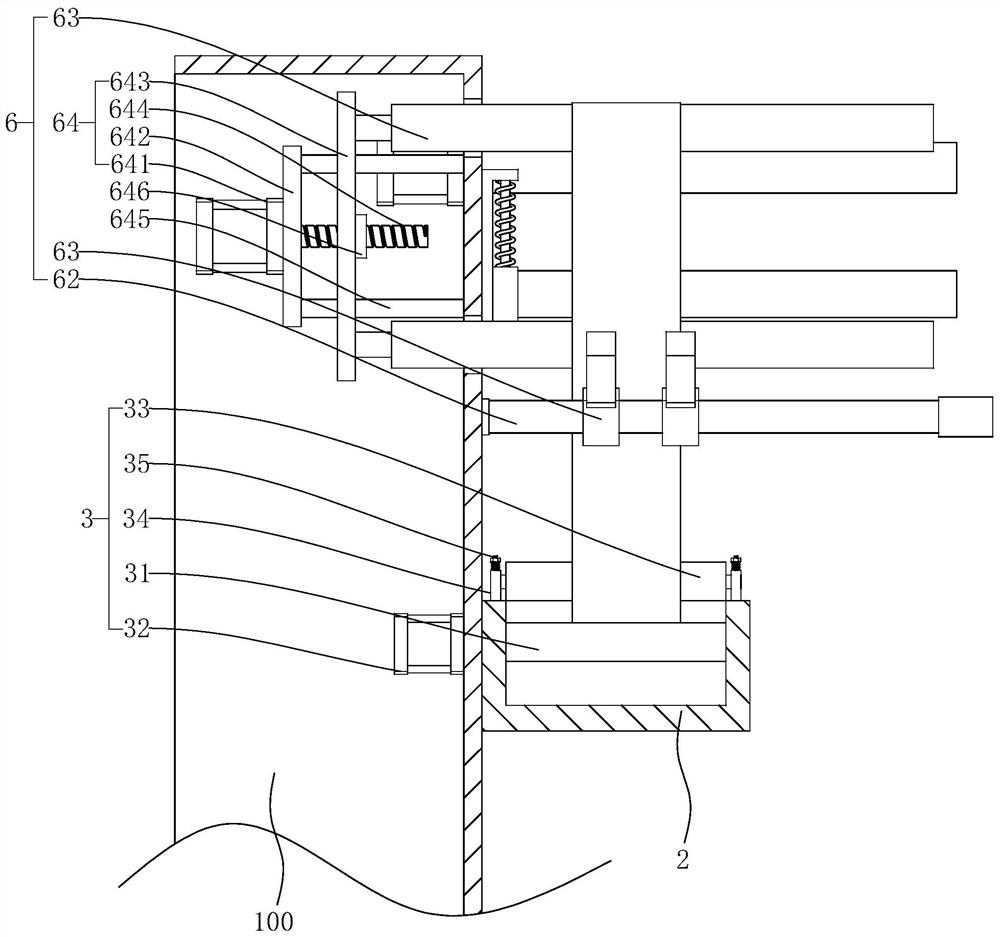

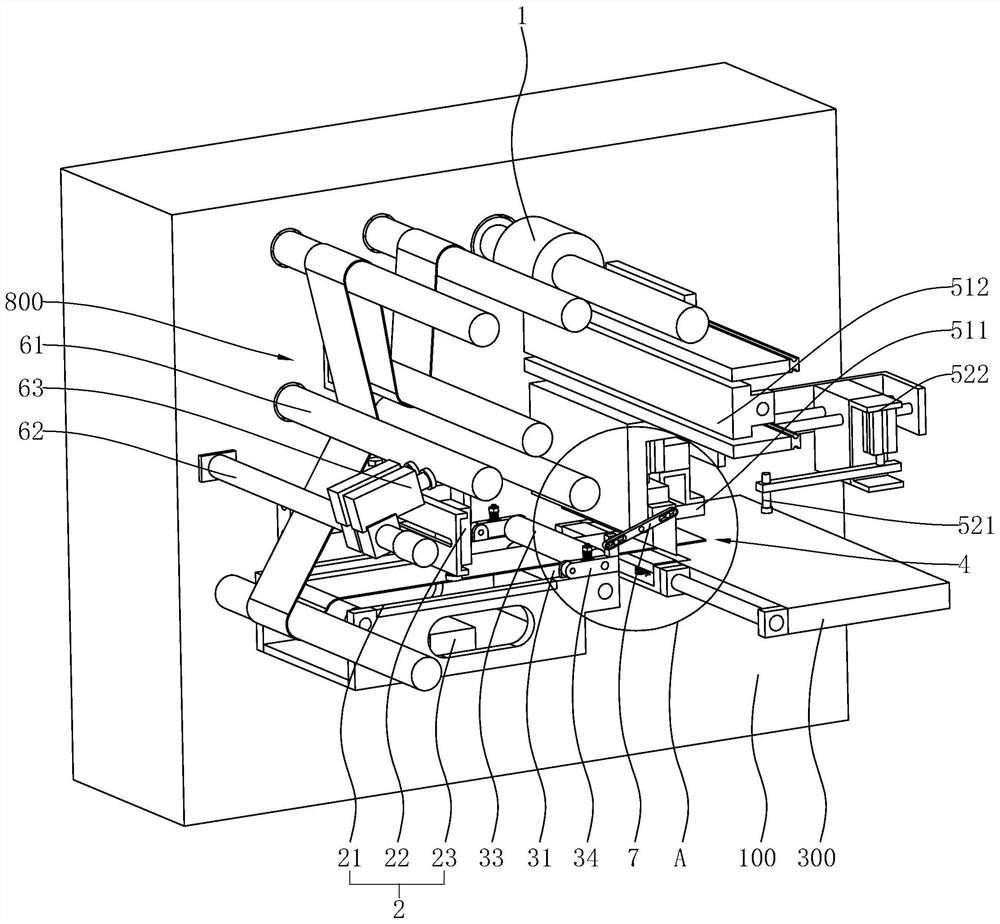

Automatic carbon fiber sheet reinforcement construction device suitable for variable cross-section ribbed structure

The invention discloses an automatic carbon fiber sheet reinforcement construction device suitable for a variable cross-section ribbed structure. The automatic carbon fiber sheet reinforcement construction device comprises a gluing pasting module installed slidably, and the gluing pasting module can be used for brushing an adhesive and pasting a carbon fiber sheet on the surface of a component. Inorder to adapt to the variable cross-section structure, the side face of gluing pasting module comprises a cutting device which can walk along the cross section. The cutting device comprises a spring, a roller is installed on the spring, the roller is located between a gluing roller and a carbon fiber sheet roll, and a cutting blade is installed on the roller and is not rotated with the roller and used for cutting the sheet roll. The automatic carbon fiber sheet reinforcement construction device suitable for the variable cross-section ribbed structure can solve the complex problem of carbon fiber sheet pasting in construction, comprehensively strengthens the carbon fiber sheet of the complex cross-section (mainly ramped variable cross-section ribbed structure) structure, the degree of automation is high, construction quality is stable, the device is portable, the operation of worker is facilitated.

Owner:HOHAI UNIV

Canvas shoe sole inner layer adhesive tape pasting treatment method

The invention relates to the field of canvas shoes, in particular to a canvas shoe sole inner layer adhesive tape pasting treatment method. The technical problem to be solved by the invention is to provide the canvas shoe sole inner layer adhesive tape pasting treatment method. According to the canvas shoe sole inner layer adhesive tape pasting treatment method, the following processing equipment is adopted, and the processing equipment comprises a working machine tool plate, an adhesive attaching system, an adhesive tape pasting system, a remaining edge separating system and the like; and the lower portion of the working machine tool plate is welded to a supporting foot stand. According to the method, the effects of automatically pasting the inner-layer adhesive tape of the semi-finished shoe, automatically and uniformly smearing the adhesive to the bottom of the outer surface of the semi-finished shoe, automatically conveying and heating to uniformly diffuse the adhesive, cutting and separating the part, higher than the sole surface of the semi-finished shoe, of the adhesive tape, and enabling the subsequent sole pasting to be firmer and tighter are achieved.

Owner:温岭市世界风鞋材有限公司

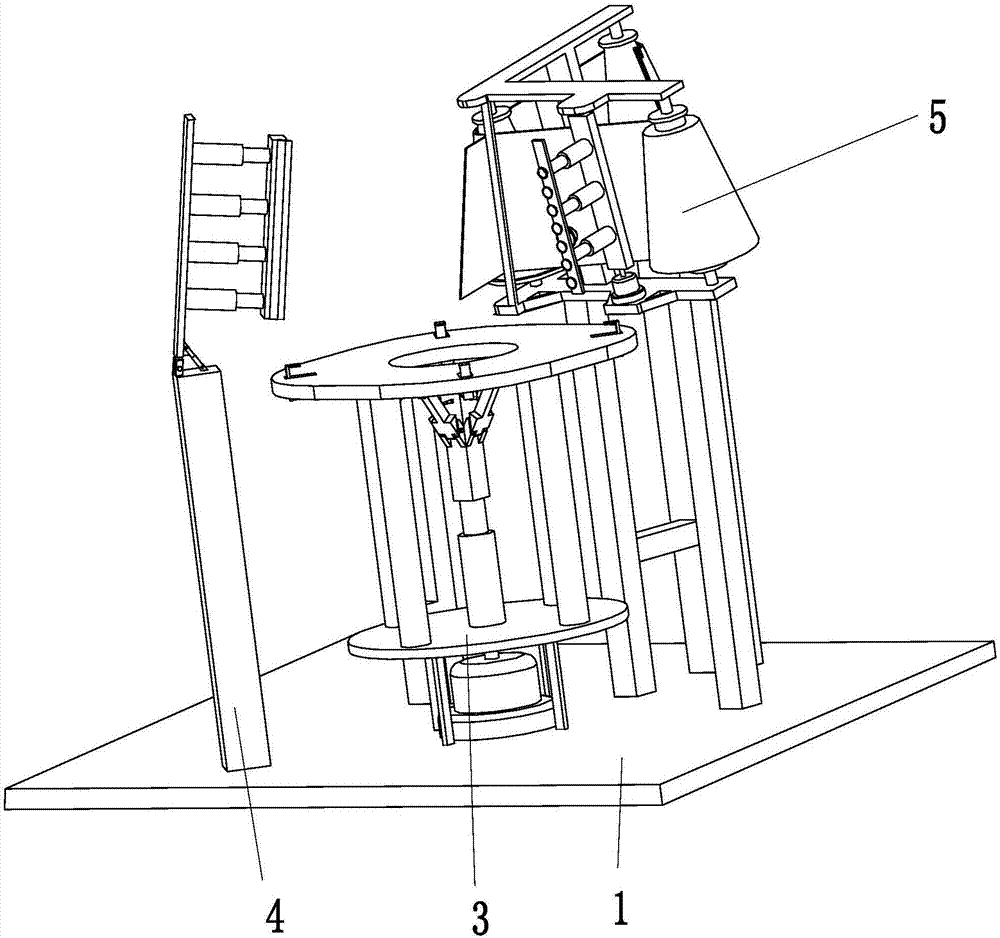

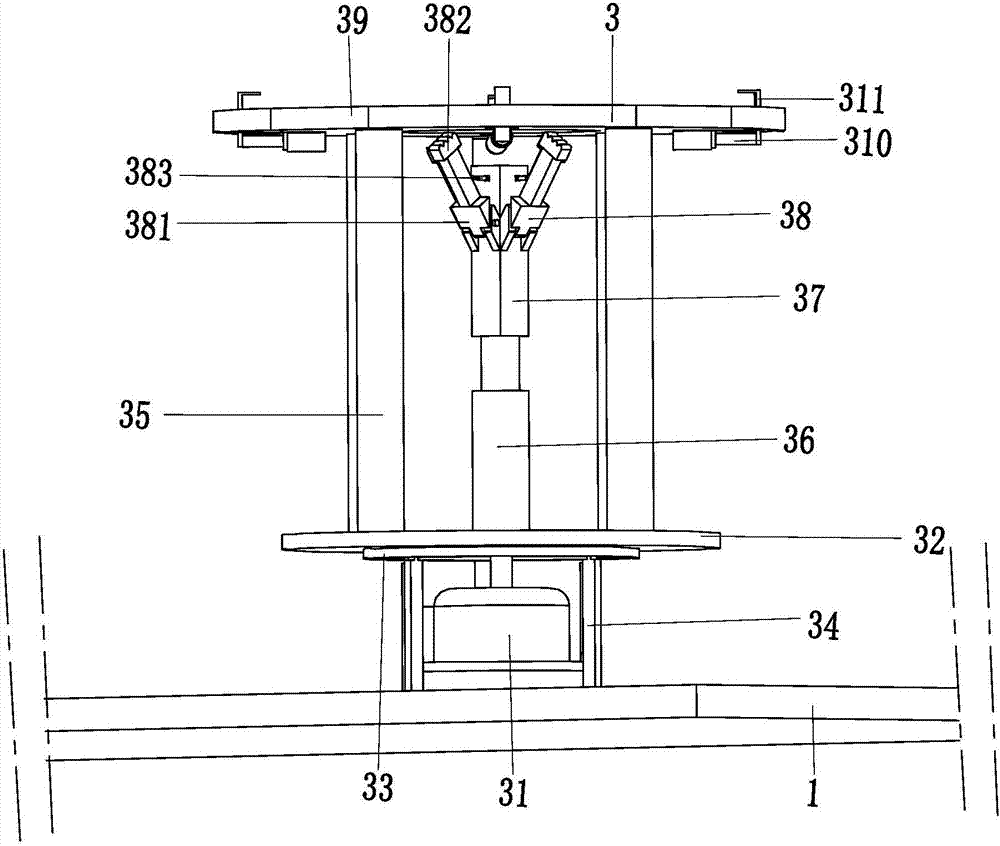

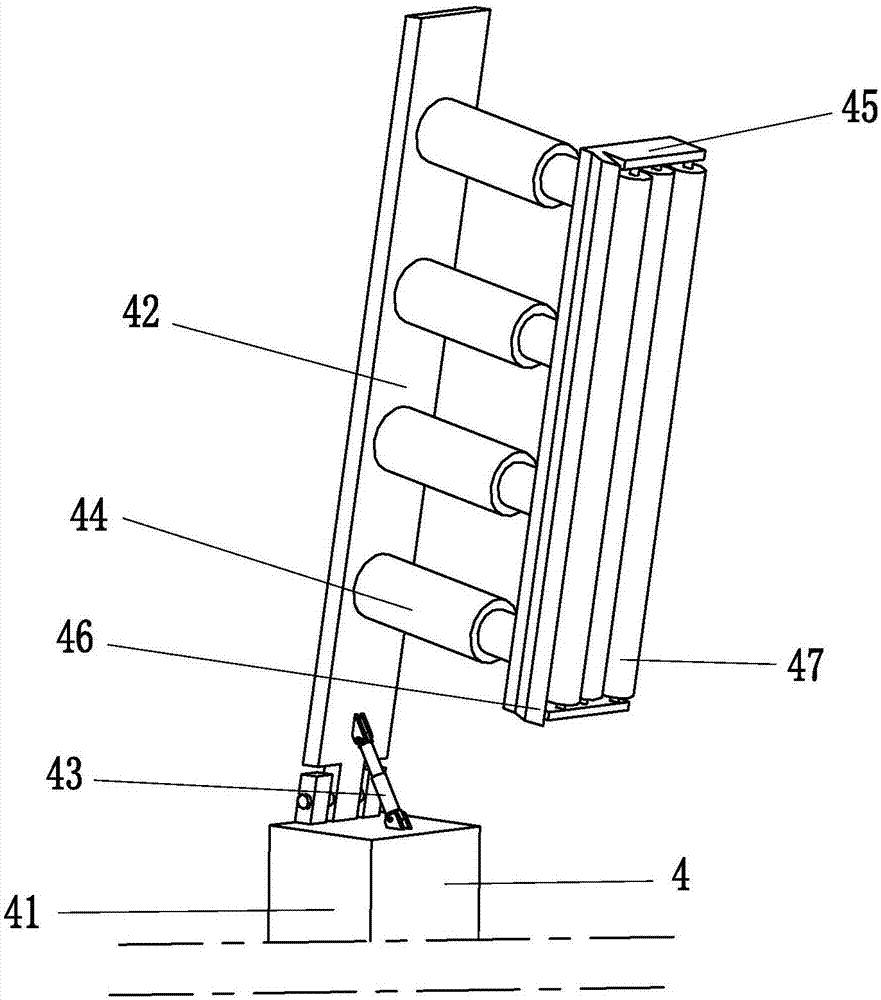

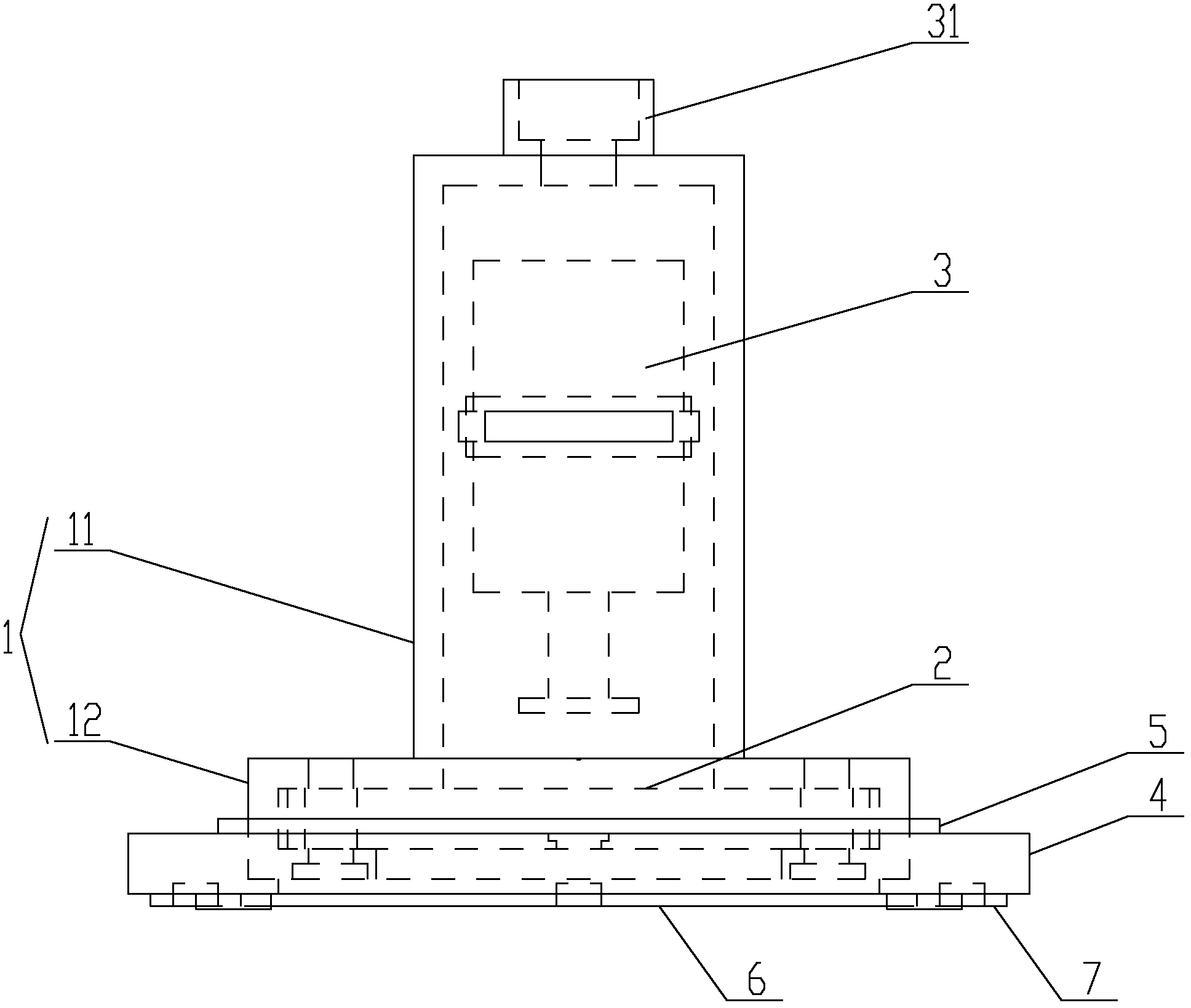

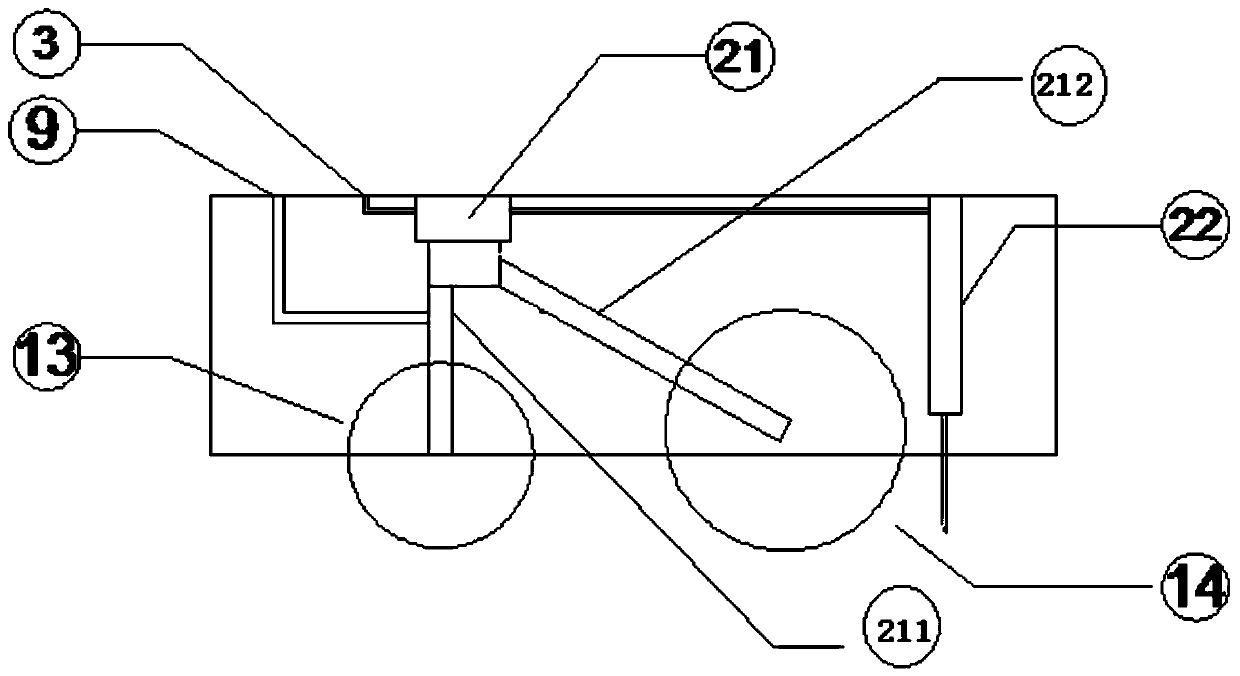

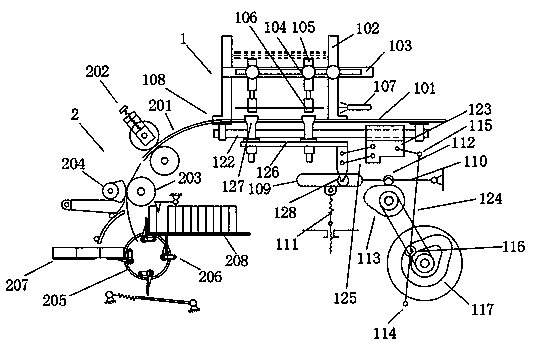

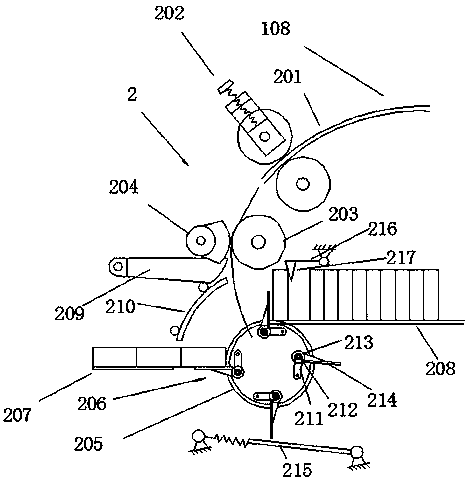

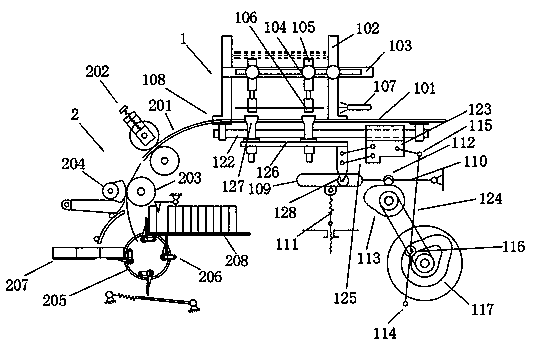

Automatic pasting machine of reflective stickers for special road cones of outdoor traffic or city road intersection lanes

InactiveCN107217616ARealize automatic pasteSolve efficiency problemsTraffic signalsRoad signsEngineeringAutomatic testing

The invention relates to an automatic pasting machine of reflective stickers for special road cones of outdoor traffic or urban road intersection lanes. The automatic pasting machine comprises a base, a positioning rotation device, a rolling device and a pasting device; the base is of a cuboid structure, the positioning rotation device is mounted on the central part of the base, the rolling device is located on the front side of the positioning rotation device, and the rolling device is mounted on the base, the pasting device is located on the back side of the positioning rotation device, and the pasting device is mounted on the base. The automatic pasting machine can solve the difficult problems of low work efficiency, overly cumbersome work, non-smooth reflective stickers when pasted on road cones and hard handling of reflective papers on the reflective stickers when service staff paste stickers on road cones currently; the functions of automatic pasting of reflective stickers on road cones and smooth rolling are achieved through high mechanization, and the automatic pasting machine has the advantages of high work efficiency, highly mechanized pasting of the reflective stickers, smoothness of reflective stickers when pasted on road cones, and automatic winding of reflective papers on reflective stickers.

Owner:合肥集知网信息技术有限公司

Device for mounting nameplates on electric meters

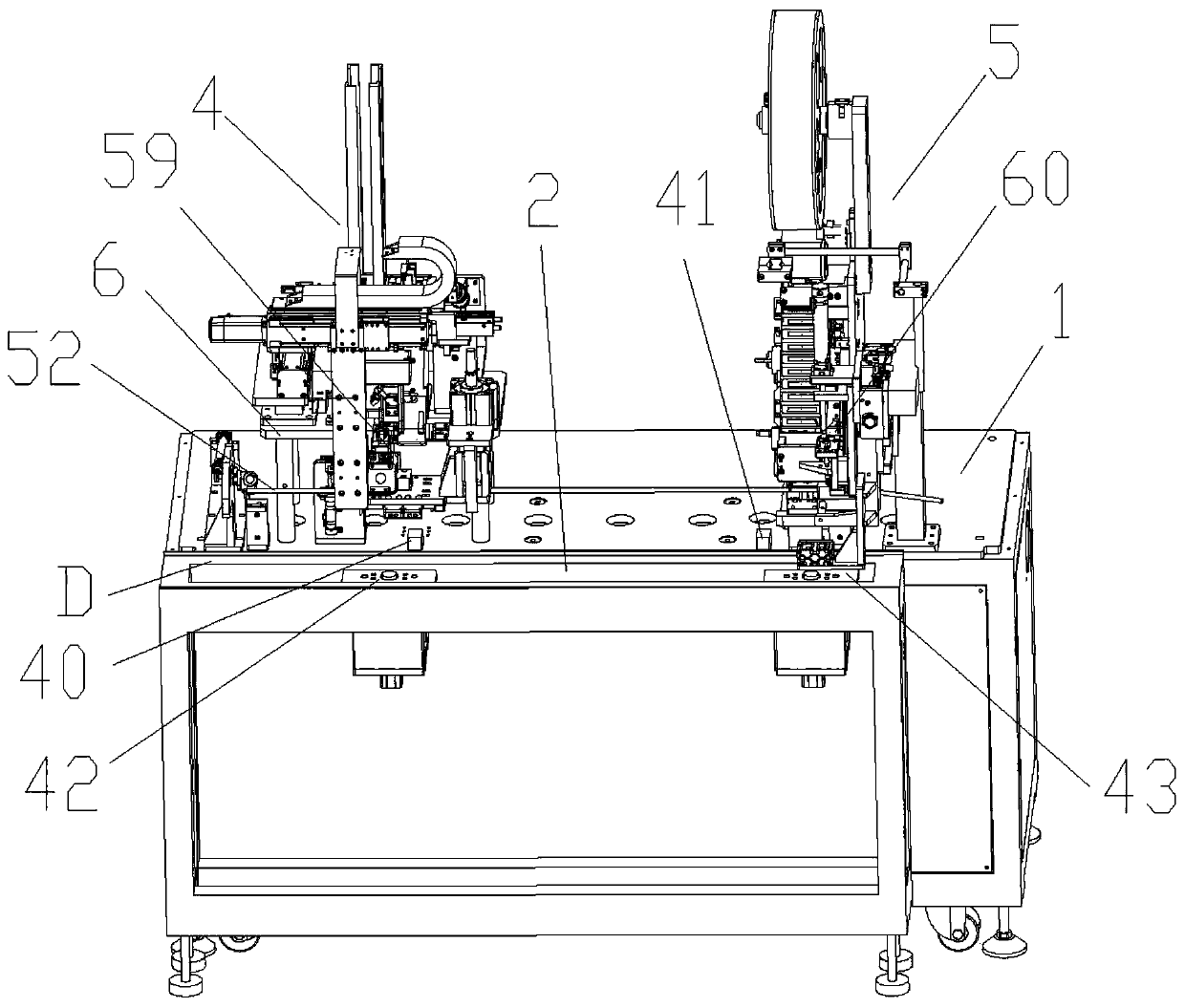

ActiveCN110127154ARealize automatic pasteThe pasting position is accurateMetal working apparatusLabelling machinesBarcodeAssembly line

The invention discloses a device for mounting nameplates on electric meters. The device is characterized by comprising a table body, an automatic assembly line and a nameplate back-side bar code pasting device, wherein the automatic assembly line is arranged on the table body and is used for conveying the electric meters, and the nameplate back-side bar code pasting device is arranged on the tablebody and is located on one side of the automatic assembly line; the device further comprises a limiting device, wherein the limiting device is arranged on the table body; the nameplate back-side barcode pasting device comprises a transmission roller assembly, a third vacuum adsorption device and a second XYZ three-axis driving device, the transmission roller assembly is arranged on the table body and is used for continuously conveying roll-type back-side bar codes, the third vacuum adsorption device is used for adsorbing the back-side bar codes, and the second XYZ three-axis driving device is used for driving the third vacuum adsorption device to move; a first bar code scanning gun used for scanning front-side bar codes of the nameplates and a second bar code scanning gun used for scanning the back-side bar codes on the transmission roll assembly are sequentially arranged on the table body along the advancing direction of the automatic assembly line. The device for mounting the nameplates on the electric meters is high in production efficiency and accuracy.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

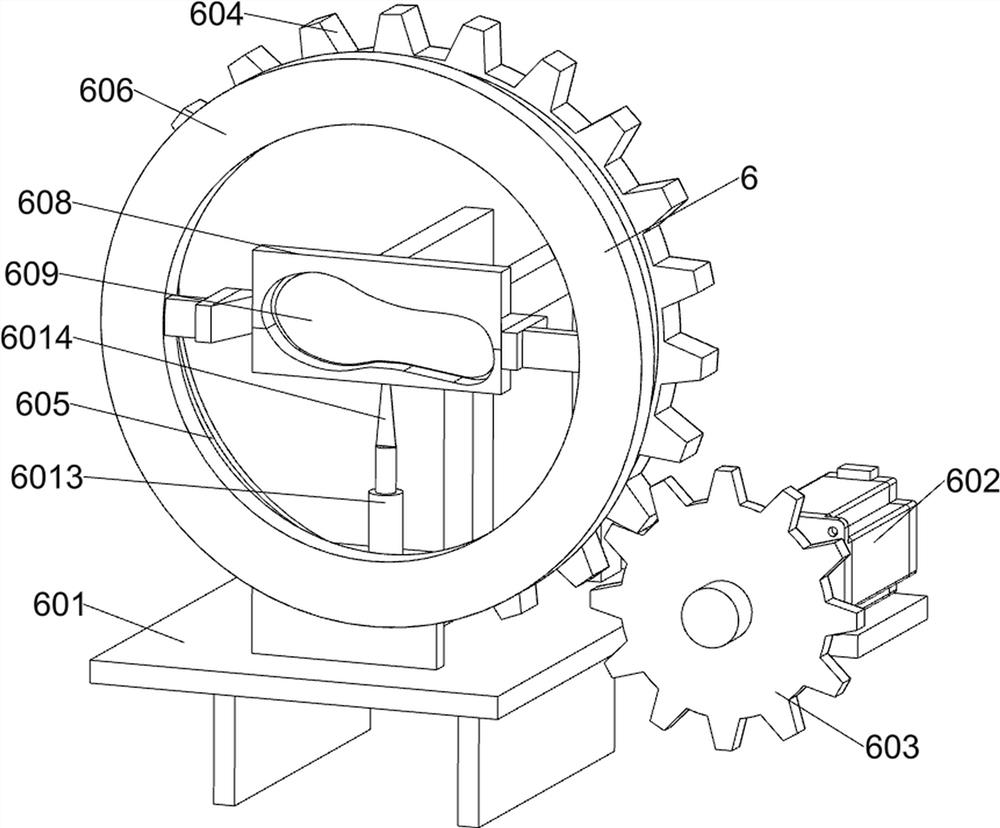

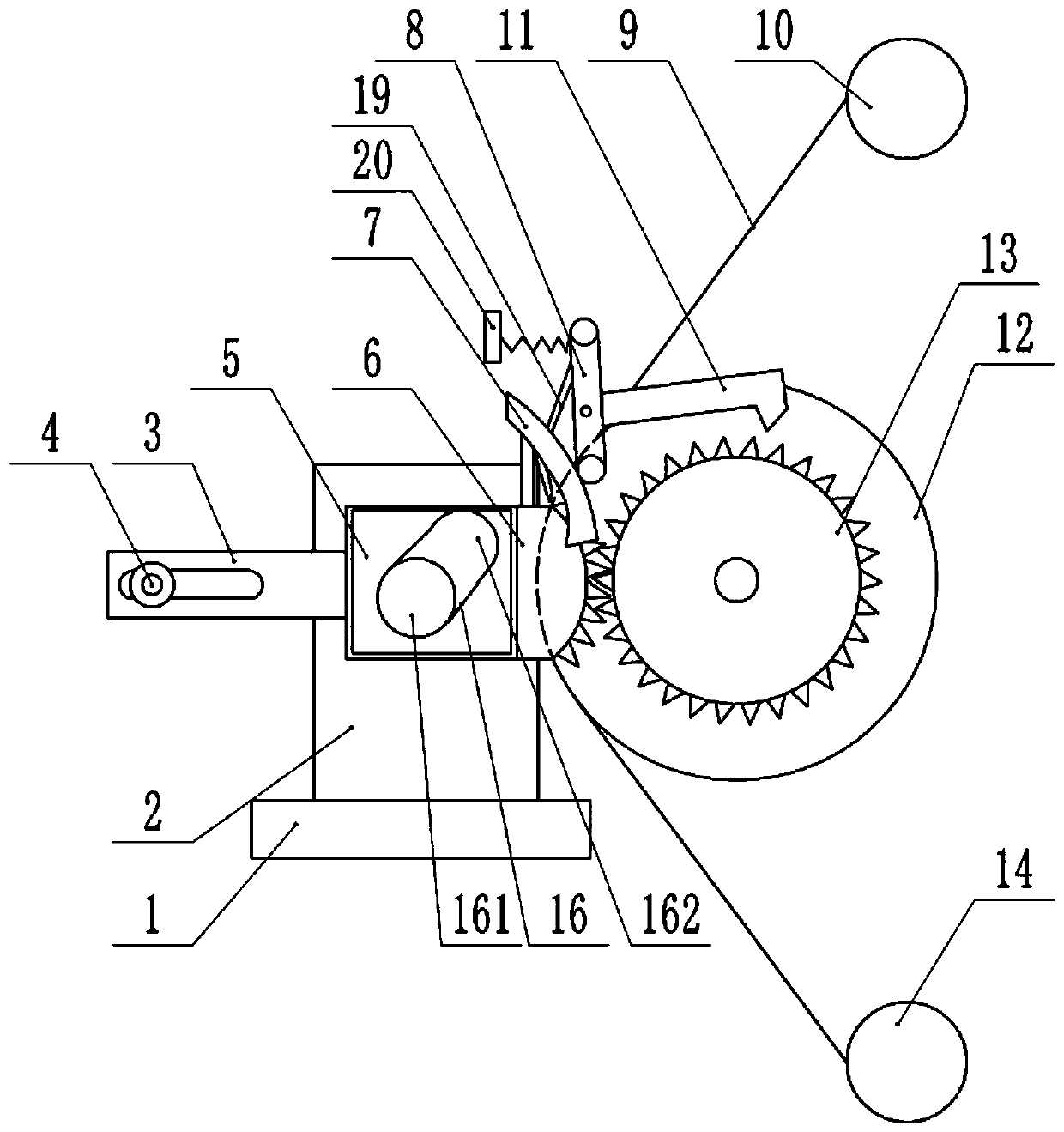

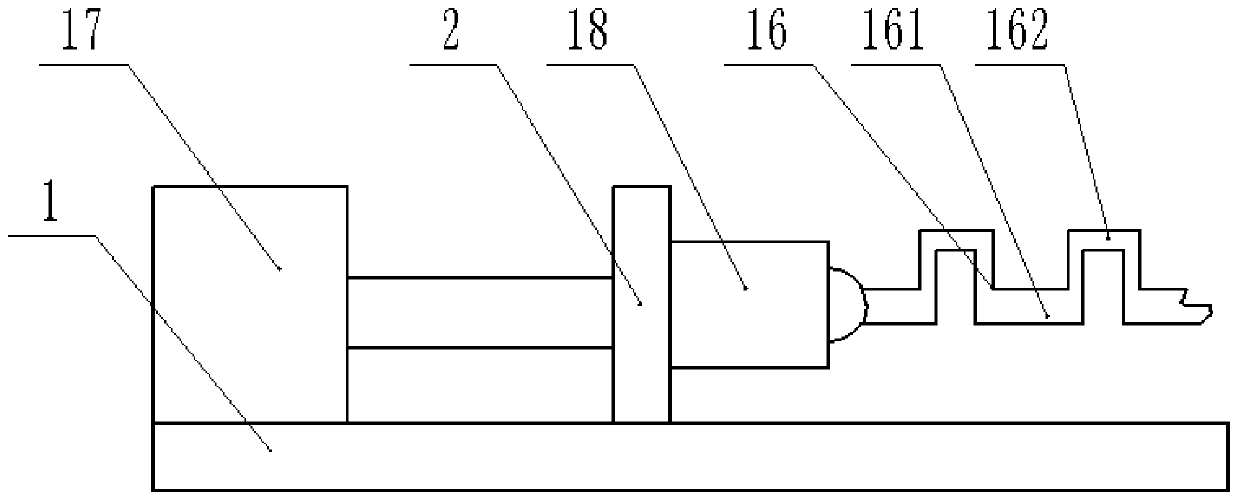

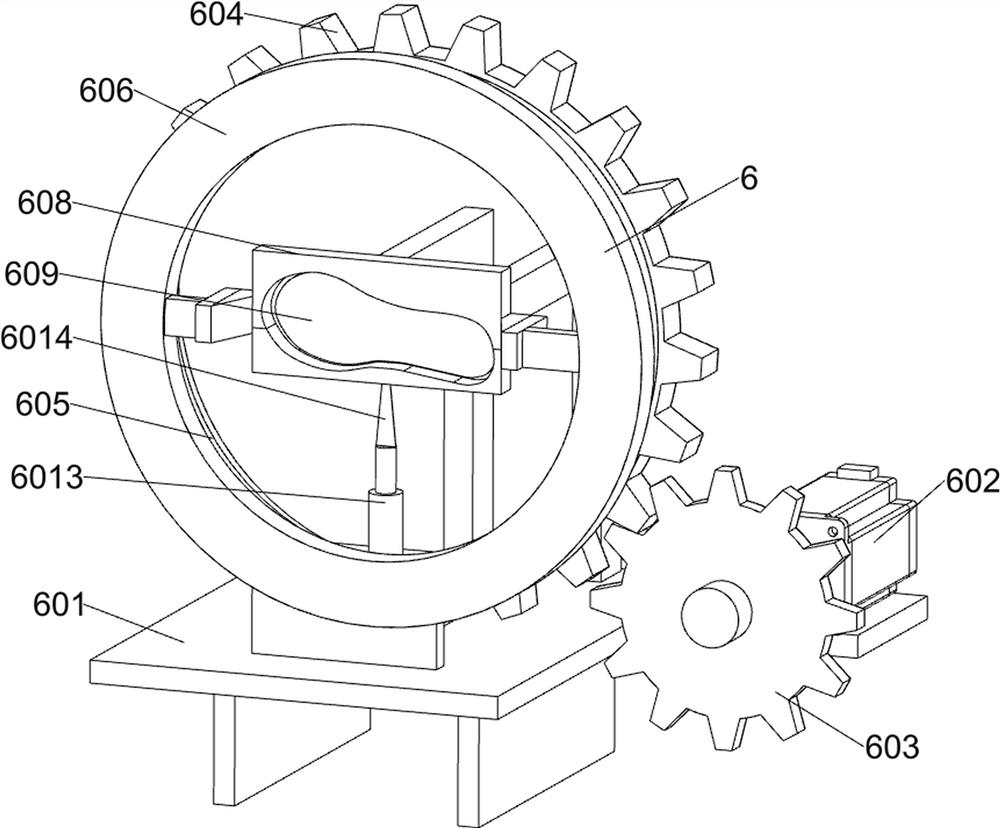

Crankshaft labelling device

ActiveCN108177836ARealize automatic pasteRealize automatic separationLabelling machinesLabelling elongated objectsCrankshaftMechanical engineering

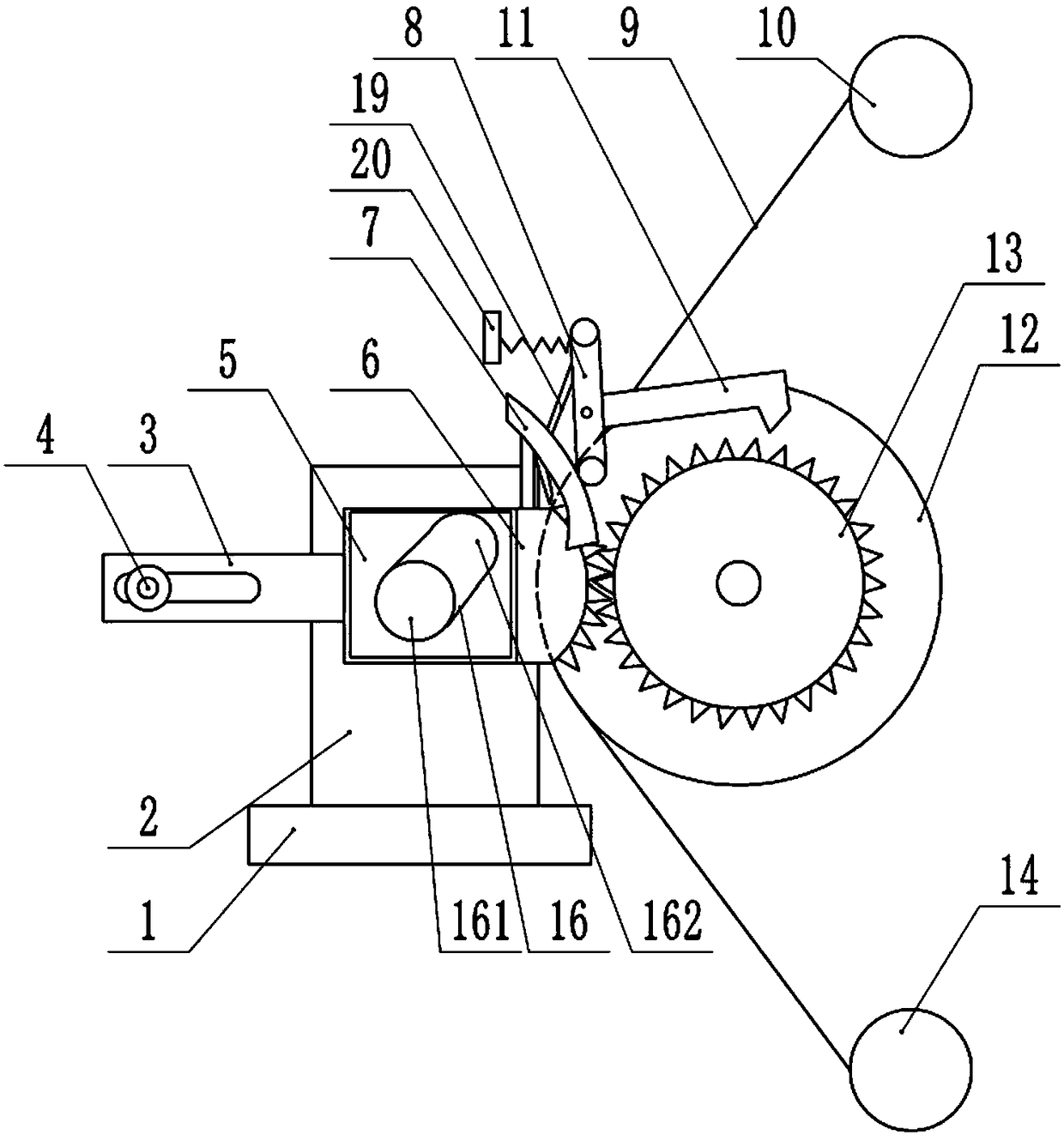

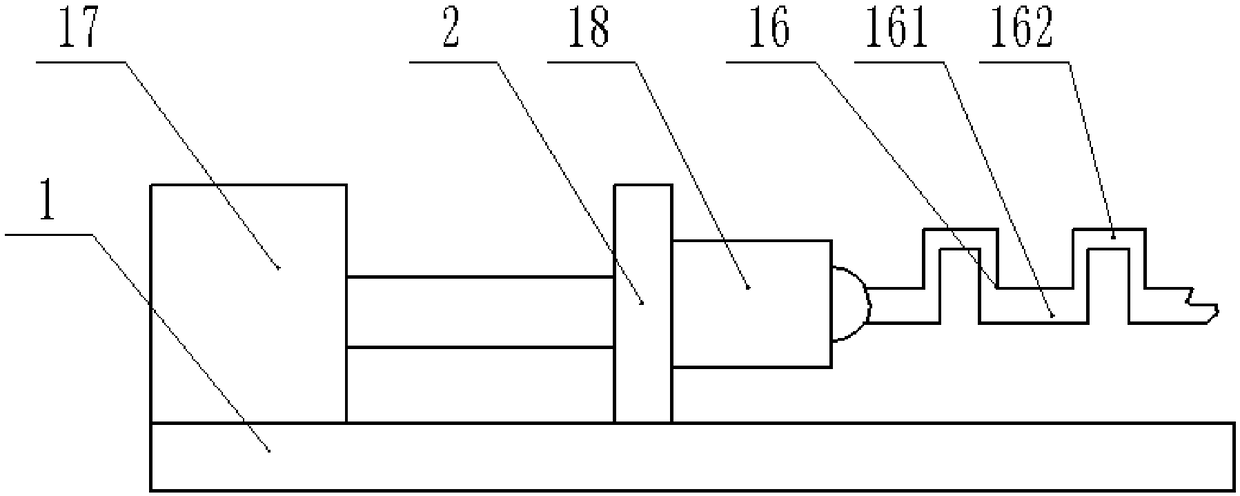

The invention relates to a crankshaft labelling device, which comprises a rack. A motor is arranged on the rack; a vertically placed oscillating plate is arranged on the rack; a through hole is formedin the middle of the oscillating plate; two opposite side parts of the oscillating plate are provided with pulling teeth and a connecting plate; the connecting plate is movably connected onto the rack; a gear meshed with the pulling teeth is rotatably connected onto the rack; a grinding plate is connected onto the gear; a clamping rod is arranged above the gear; a clamping block and a vertical rod clamped on the gear are arranged on the two ends of the clamping rod; the middle part of the vertical rod is rotatably connected onto the rack; an arc-shaped blade is arranged on the top part of thevertical rod; an elastic piece is arranged between the rack and the top end of the vertical rod; an arc-shaped rod pressing against the bottom end of the vertical rod is arranged on the oscillating plate; a discharging roller is arranged above the grinding plate; a winding roller is arranged below the grinding plate; a double-faced adhesive reel is arranged on the discharging roller; a double-faced adhesive tape winds on the double-faced adhesive reel; and one end, far away from the double-faced adhesive reel, of the double-faced adhesive tape extends onto the winding roller. According to thescheme, the double-faced adhesive tape is automatically adhered onto a crankshaft.

Owner:CHONGQING HONGLEI MACHINERY MFG

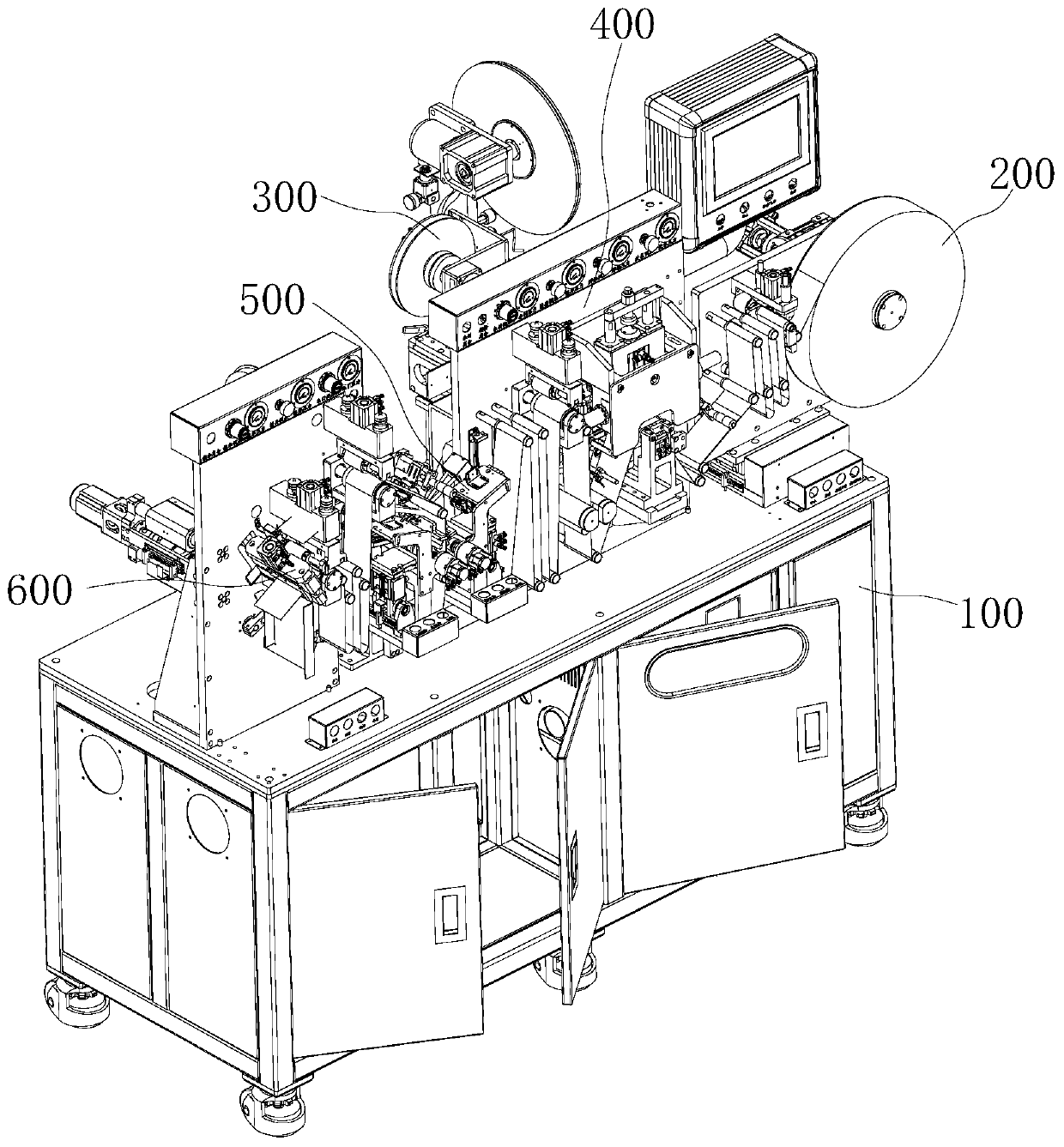

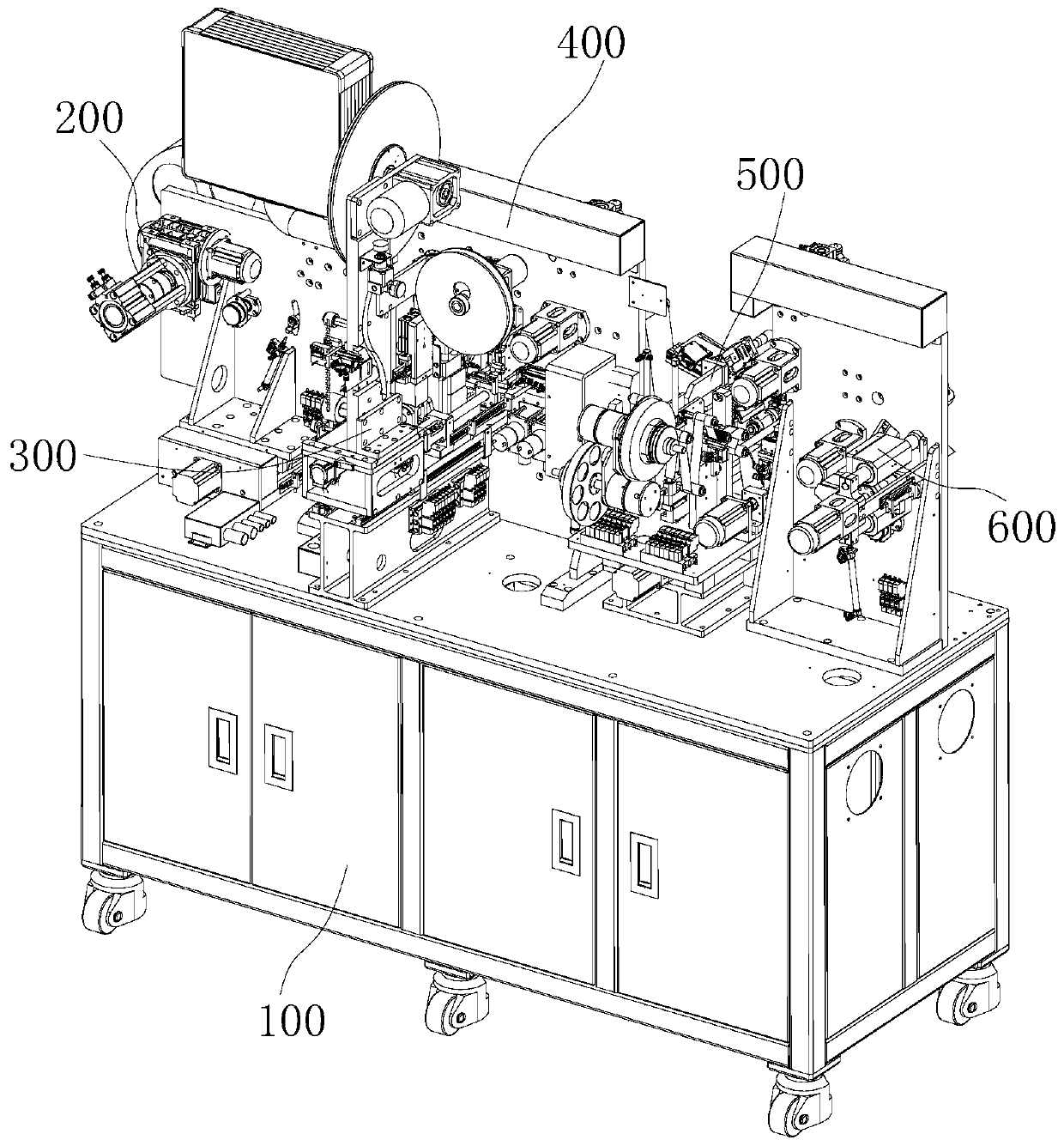

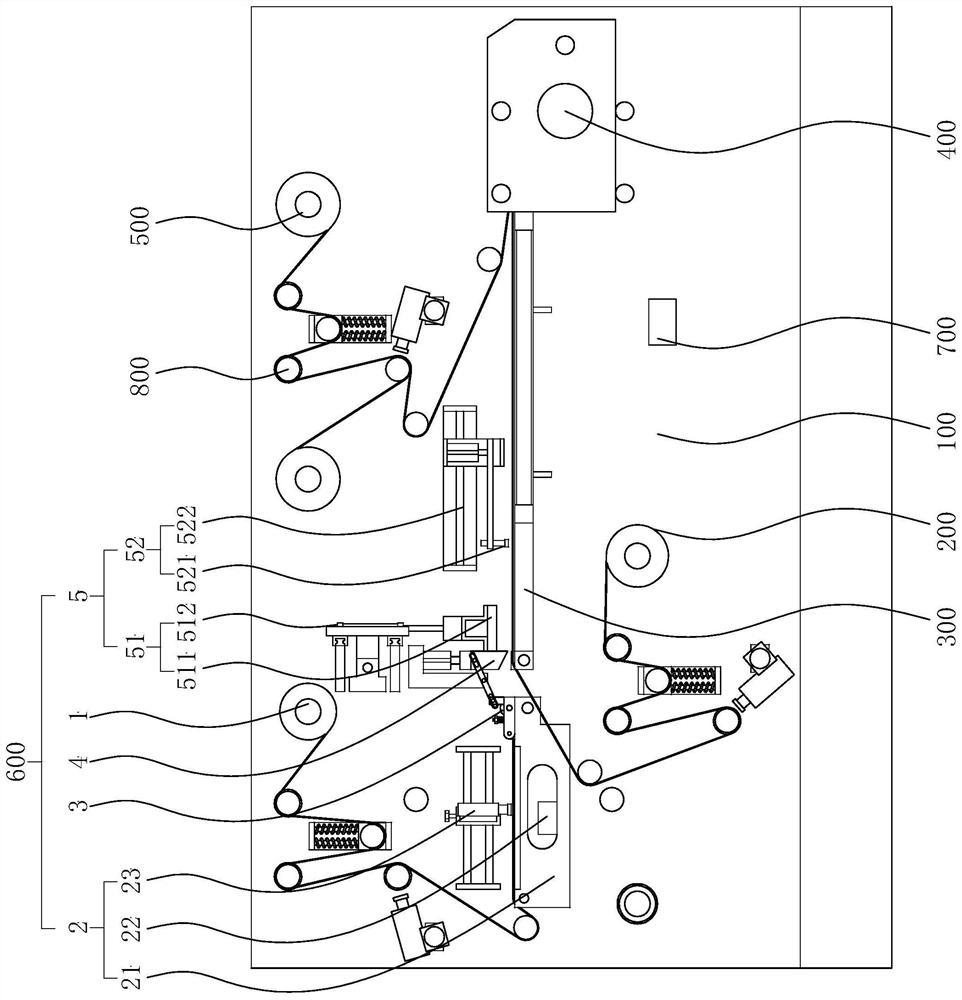

Labeling machine for producing RFID labels

ActiveCN112850260ARealize automatic pasteHigh degree of automationRecord carriers used with machinesArticle deliveryMechanical engineeringElectrical and Electronics engineering

The invention relates to the technical field of electronic label production equipment, in particular to a labeling machine for producing RFID labels. The labeling machine comprises a rack, an isolation paper unwinding device, a workbench, a composite winding device and a surface paper unwinding device, and further comprises a chip pasting device and a control module, the chip pasting device comprises a chip roll unwinding mechanism, a detection mechanism which is used for detecting the quality of a chip roll and is electrically connected with the control module, a traction mechanism which is used for pulling the chip roll to carry out transmission, a cutting mechanism which is used for cutting the chip roll step by step to form a plurality of independent chips, and a picking and placing mechanism which is located above the workbench, the control module is used for controlling the picking and placing mechanism to grab the independent chips and place the independent chips at a preset position based on the quality of the chip roll, and the surface paper unwinding device is used for covering isolation paper pasted with the independent chips with surface paper and guiding the surface paper into the composite winding device along with the isolation paper. The automation degree of the production process can be improved, and therefore the production efficiency is improved.

Owner:SHENZHEN LEADERCOLOR SMART CARD CO LTD

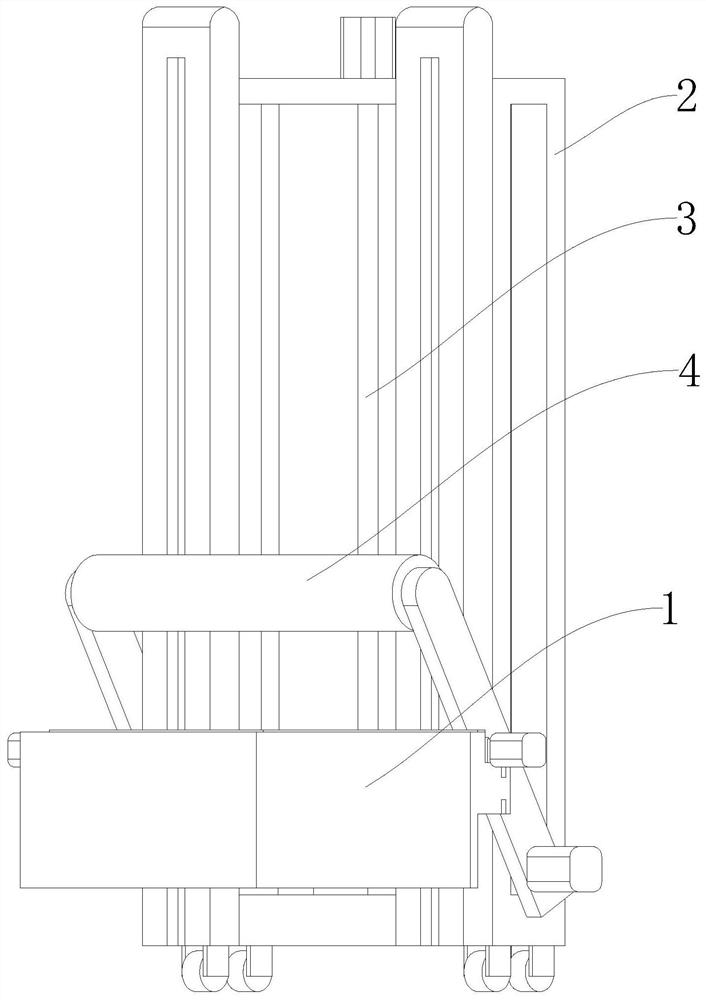

Wallpaper pasting method for building decoration

The invention relates to a wallpaper pasting method for building decoration. The wallpaper pasting method for building decoration uses a wallpaper pasting device to flatly paste wallpaper, and the wallpaper pasting method for building decoration comprises the following steps of S1, selecting the proper wallpaper; S2, shoveling the wall skin; S3, brushing a base film and scraping putty; S4, brushing glue; and S5, pasting the wallpaper. The wallpaper pasting method for building decoration has the advantages that by utilizing combination of a paper pressing plate and a rolling shaft and cooperation of a feeding mechanism, automatic wallpaper pasting is achieved, manual work can be replaced, the working efficiency is improved, and the risk of climbing operation of personnel is avoided; and moreover, a movable push plate mechanism and a plurality of limiting switches are used, wallpaper pasting can be carried out on a wall with a socket, and wallpaper cutting at the socket can be automatically completed.

Owner:宁波源码智能机械科技有限公司

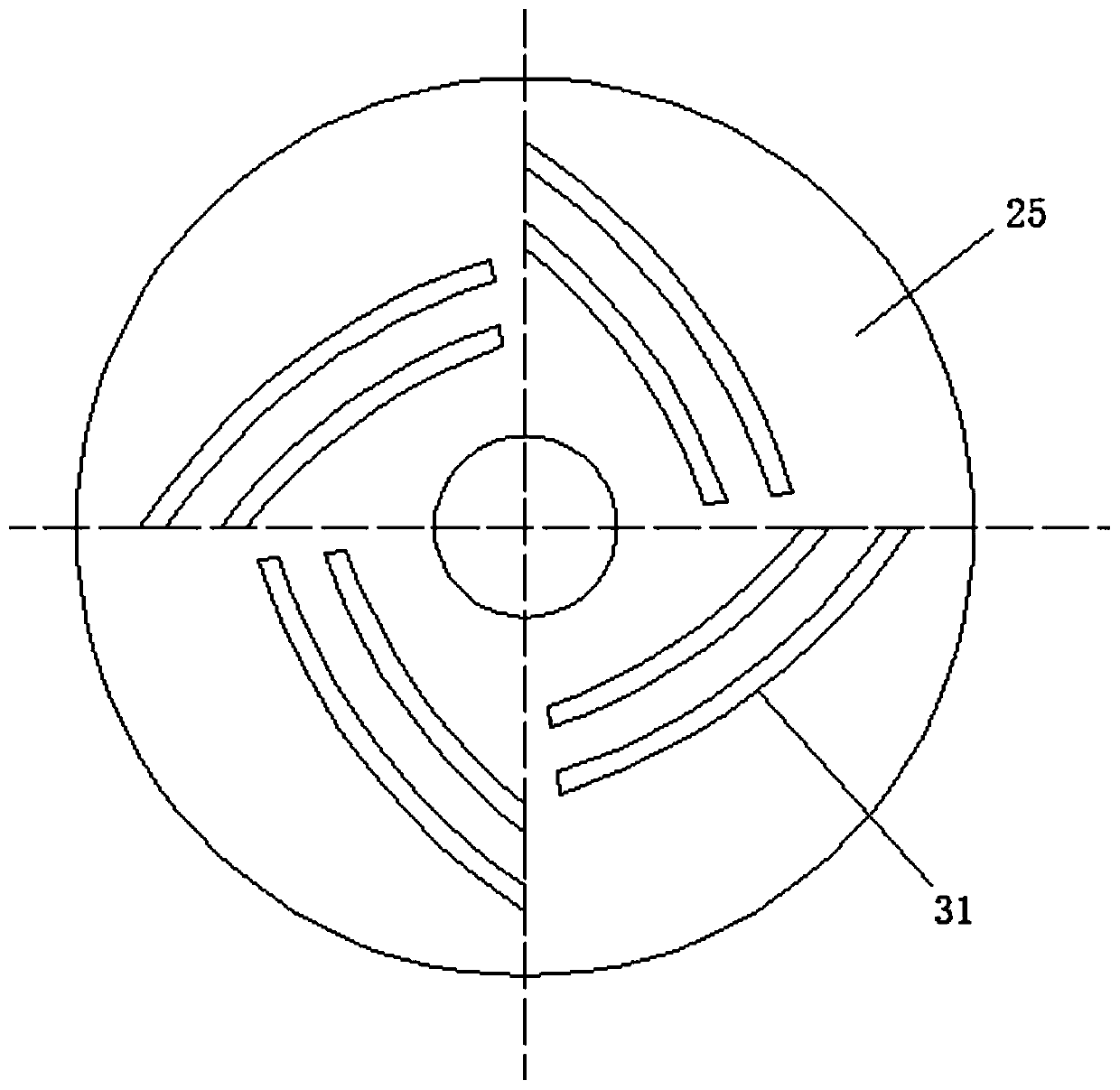

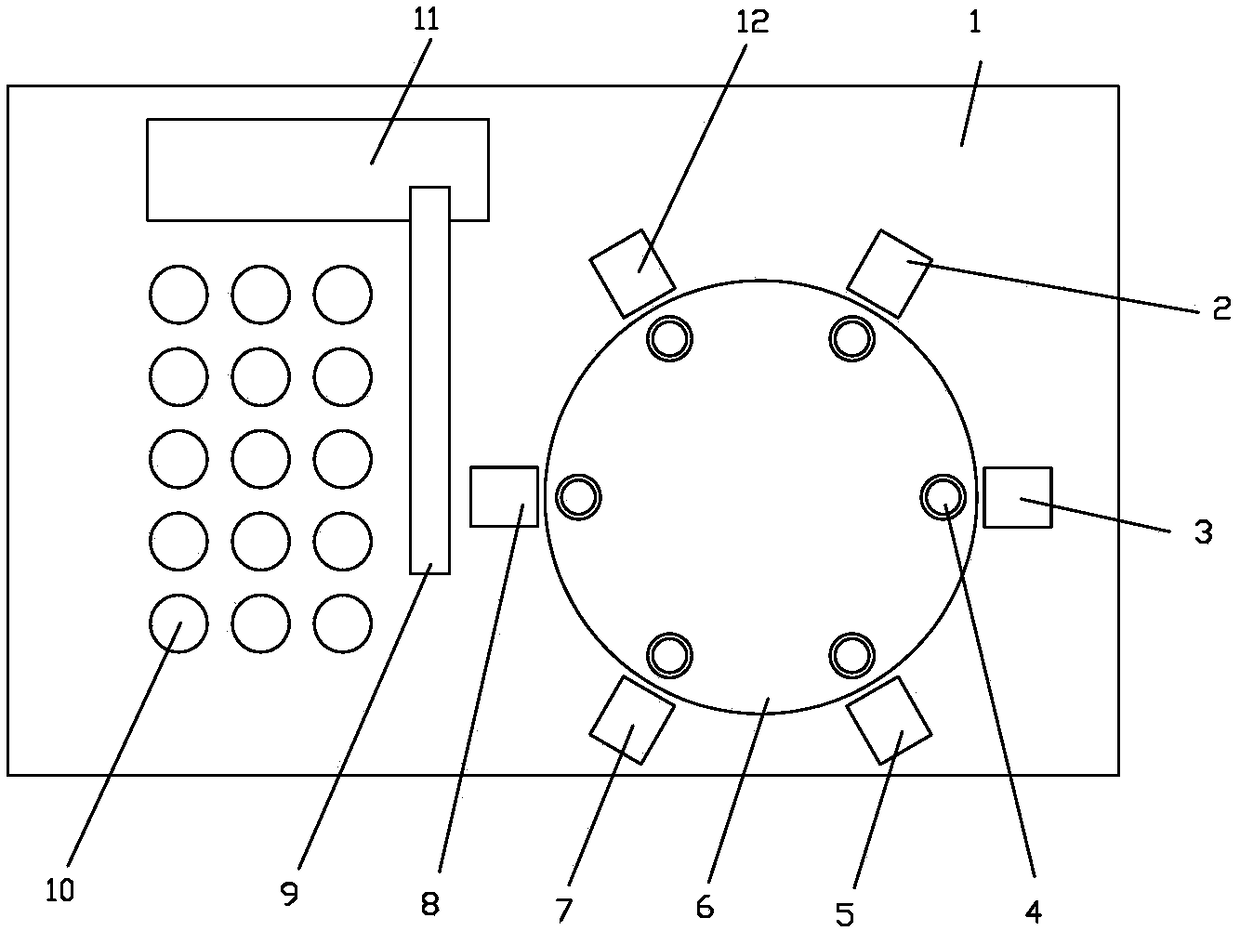

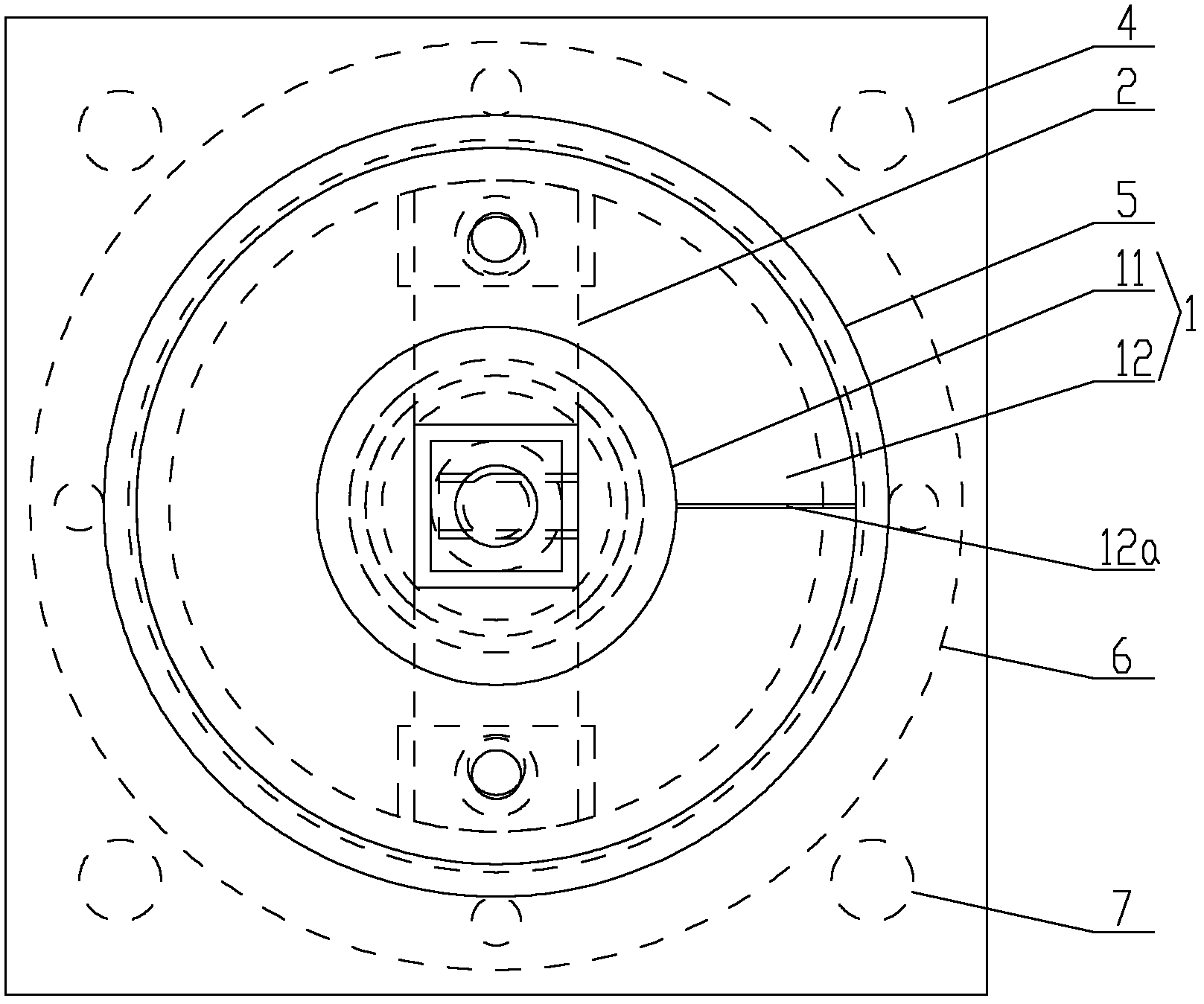

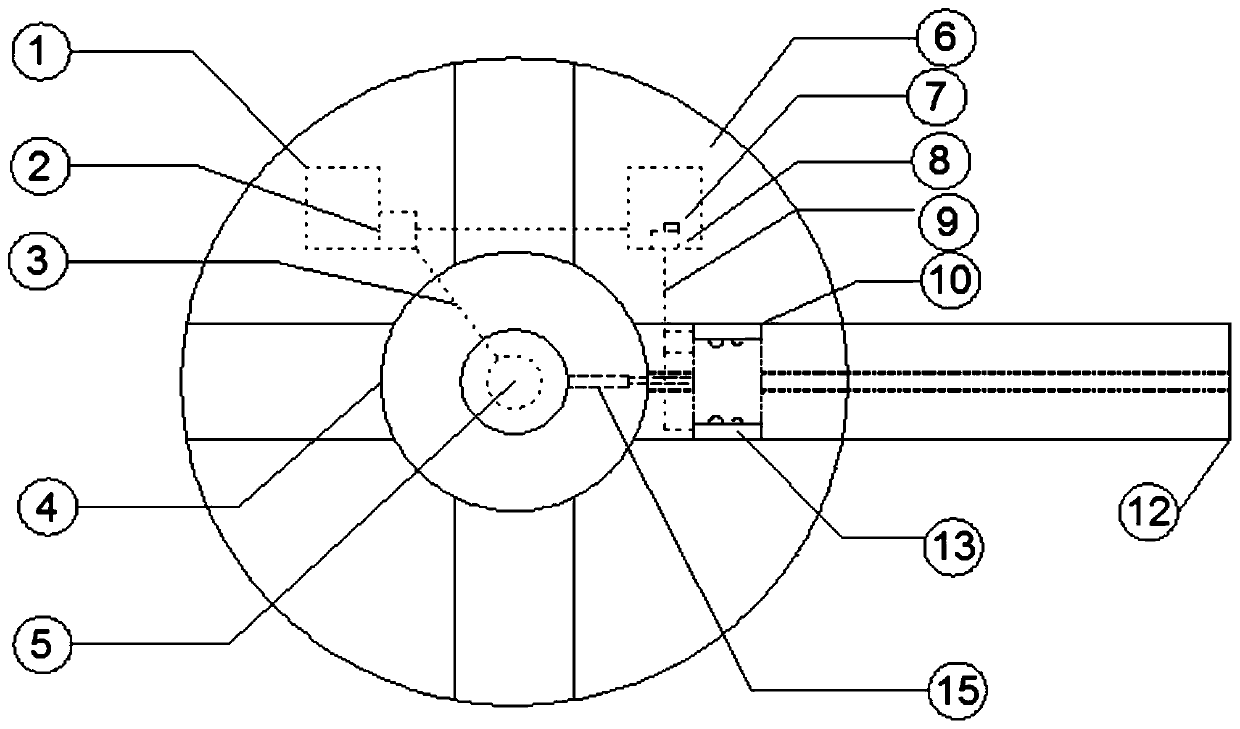

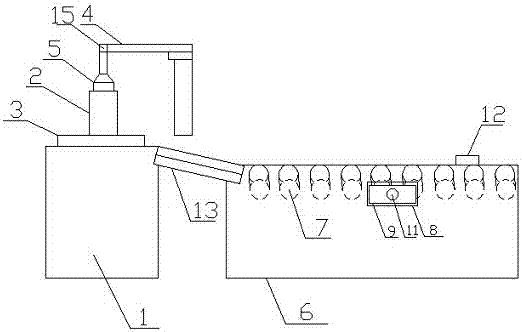

Blood collection tube labeling device

ActiveCN112249459AAchieve extrusionReduce misposting rateLabelling short rigid containersLabelling machinesBlood collectionControl cell

The invention relates to the field of medical instruments, and particularly relates to a blood collection tube labeling device. The blood collection tube labeling device comprises a plurality of labeling units, a control unit and an input unit, wherein the control unit controls the corresponding labeling units to work according to labeling content input by the input unit; each labeling unit comprises a containing chamber used for transversely containing blood collection tubes and a labeling machine used for making labels out, wherein the blood collection tubes placed in the single containing chamber are the same in color; each containing chamber communicates with a conveying channel used for conveying the corresponding blood collection tube to a label outlet of the corresponding labeling machine; the bottom of each containing chamber is rotationally connected with a transversely-arranged conveying disc; a first motor used for driving the corresponding conveying disc to rotate is arranged at the bottom of each containing chamber; a plurality of arc-shaped grooves are formed in the edge of each conveying disc and evenly distributed around the circumference of the center line of the corresponding conveying disc; and each labeling unit further comprises an extrusion mechanism used for pasting the labels coming out of the label outlet of the corresponding labeling machine to the corresponding blood collection tubes. According to the scheme, the situation that the labels are pasted to the blood collection tubes in other colors by mistake is avoided.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

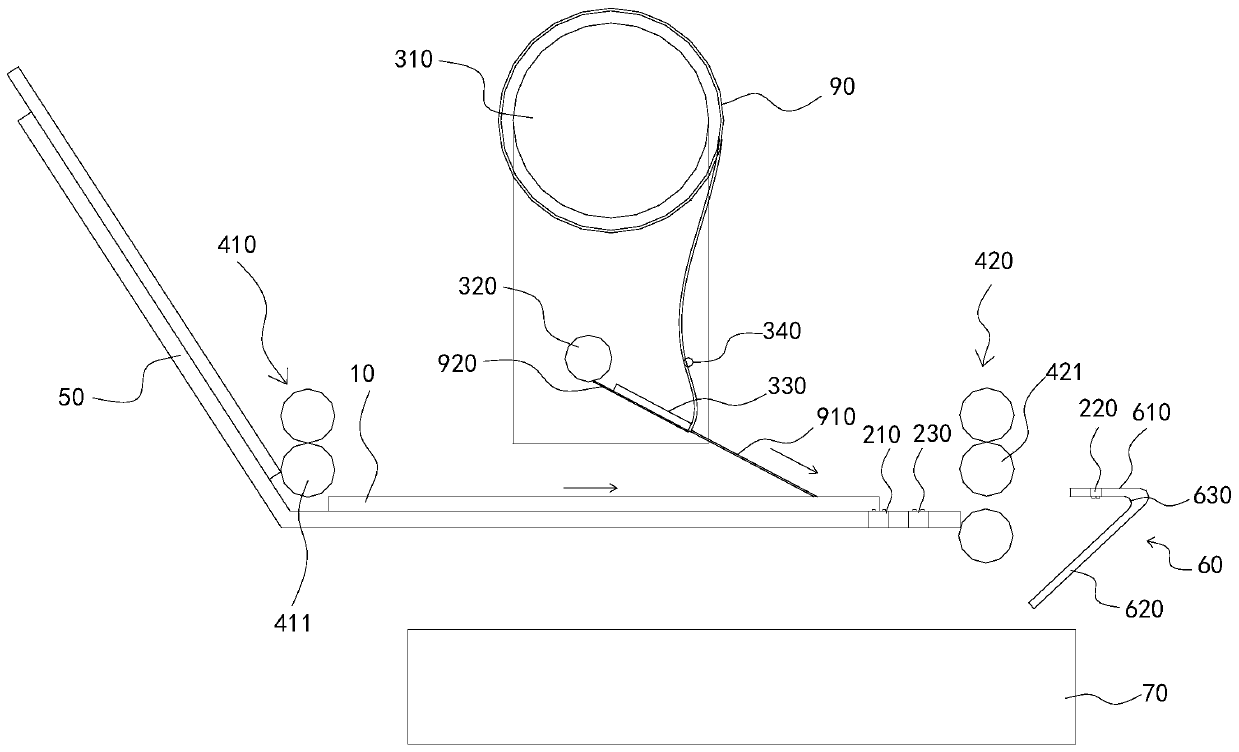

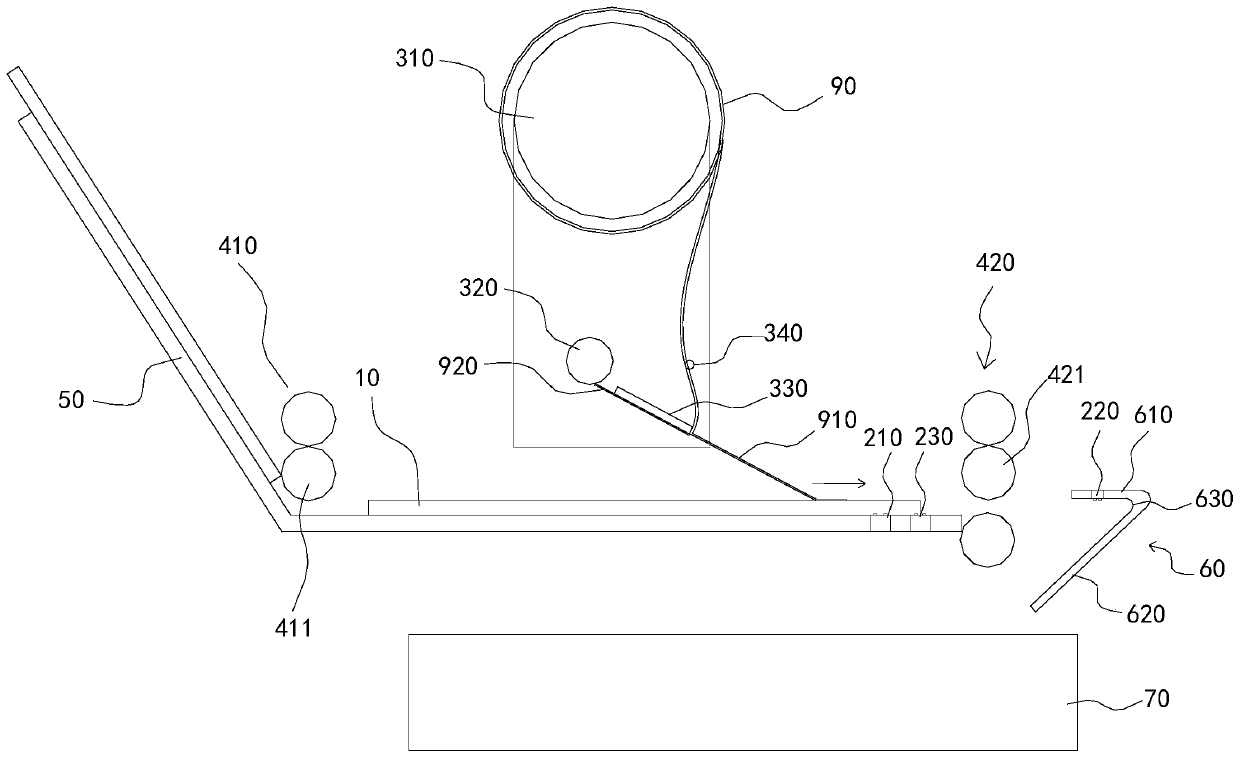

Inclined gummed paper pasting device and gummed paper pasting system

PendingCN110577100ARealize automatic pasteReduce manufacturing costArticle deliveryPulp and paper industry

The invention relates to the technical field of automatic equipment, in particular to an inclined gummed paper pasting device and a gummed paper pasting system. The inclined gummed paper pasting device comprises a supporting plate, a gummed paper assembly, a pressing wheel assembly and a cutting assembly, and the gummed paper assembly and the pressing wheel assembly both are installed on the supporting plate; the gummed paper assembly is used for providing gummed paper and pasting the gummed paper on the surface of a to-be-pasted product; the pressing wheel assembly is used for pressing the gummed paper pasted on the surface of the to-be-pasted product; and the cutting assembly is used for separating the gummed paper pasted on the surface of the to-be-pasted product from the gummed paper assembly. The gummed paper pasting system comprises the inclined gummed paper pasting device. According to the inclined gummed paper pasting device, the gummed paper can be automatically pasted, the gummed paper is automatically cut, and the production cost is advantageously lowered.

Owner:LANS INTELLIGENT ROBOT CHANGSHA CO LTD

Polymer cutoff pelleter

PendingCN110834356ARealize automatic feedingRealize automatic croppingElectrode manufacturing processesMetal working apparatusPole pieceMechanical engineering

The invention discloses a polymer cutoff pelleter and relates to the technical field of pelleters. The polymer cutoff pelleter comprises a pole piece unreeling mechanism, a tab dividing mechanism, a tab welding mechanism and a contraposition rubberizing mechanism, wherein the pole piece unreeling mechanism is positioned on one side of the tab welding mechanism and is used for providing pole piecesof to-be-welded tabs for the tab welding mechanism; the tab dividing mechanism is positioned below the tab welding mechanism and is used for providing to-be-welded tabs for the tab welding mechanism;and the contraposition rubberizing mechanism is positioned on the other side of the tab welding mechanism and is used for rubberizing the pole piece. The polymer cutoff pelleter has the benefits of realizing automatic tab supply and automatic rubberizing of gummed paper, increasing the degree of automation and improving the production efficiency.

Owner:深圳市兴盛林科技有限公司

Reaction tube label printing, conveying and pasting method

ActiveCN108248972ARealize automatic pasteNo human intervention requiredLabelling machinesWebs handlingPulp and paper industryReaction tube

The invention discloses a reaction tube label printing, conveying and pasting method. The method comprises the steps that a, printing is carried out, and particularly, label paper is printed on a label belt; b, the label paper is peeled off, and particularly, the label paper is peeled off from the label belt based on a first suction cup; c, the label paper is rotated, and particularly, the first suction cup is rotated based on a rotating mechanism; D, the label paper is transferred, and particularly, the label paper is transferred from the first suction cup to a second suction cup based on thesecond suction cup; E, the label paper is conveyed, and particularly, the label paper is conveyed by a label paper conveying device to two rollers by means of a terrestrial heat suction cup; and F, the label paper is pasted, particularly, a reaction tube is moved to the label paper, the two rollers are driven, and the label paper is pasted to the reaction tube. The reaction tube label printing, conveying and pasting method is easy to implement, high in automation degree and high in label paper pasting efficiency.

Owner:义乌市富顺箱包有限公司

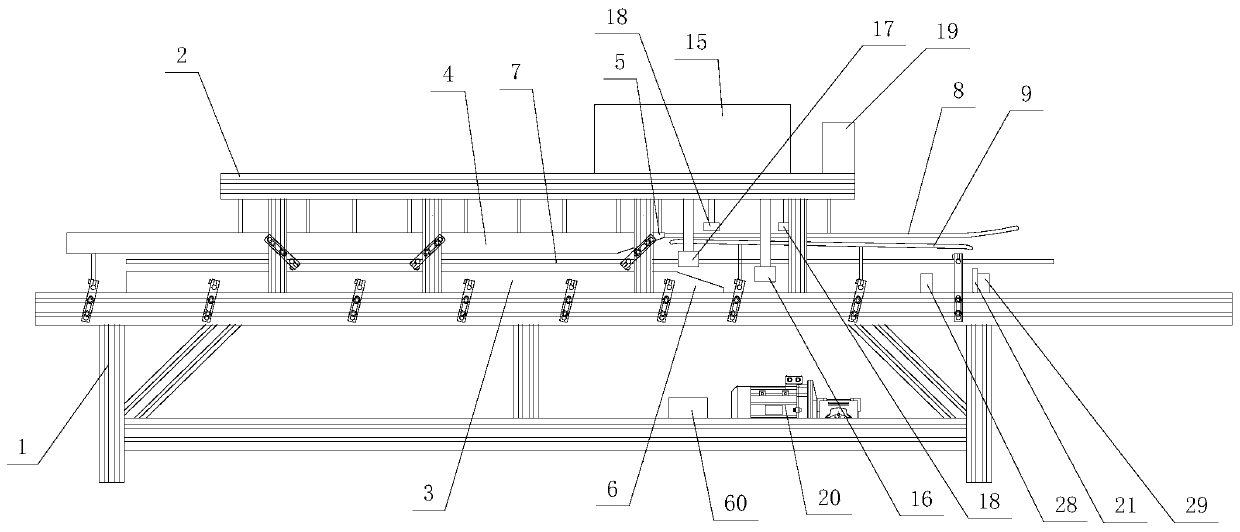

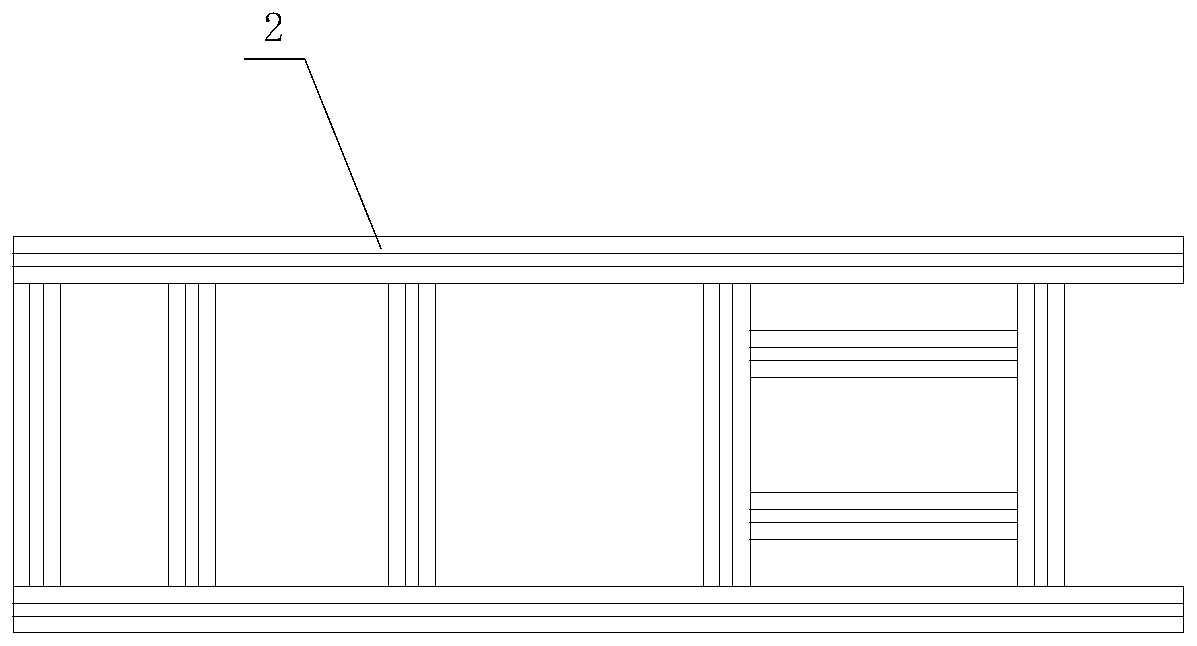

Assembly line for bonding of packaging boxes

PendingCN111231409ARealize automatic pasteSimple structureBox making operationsPaper-makingAssembly lineChain link

The invention discloses an assembly line for bonding of packaging boxes. The assembly line comprises a bottom frame and a top frame; the top frame is fixedly mounted on the top surface of the bottom frame; lower reshaping plates are symmetrically arranged on the left and right sides of the bottom frame; upper reshaping plates are arranged above the lower reshaping plates; guiding rods are arrangedbetween the upper reshaping plates and the lower reshaping plates; pressing rods are arranged on the inner sides of the tops of the upper reshaping plates; a feeding conveying belt is arranged at thefront end of the bottom frame, and a receiving conveying belt is arranged at the back end; guiding sliding strips are mounted between the feeding conveying belt and the receiving conveying belt; feeding chains are mounted on the inner sides of the guiding sliding strips; pushing blocks are mounted on the feeding chains at equal intervals; a main machine of a hot-melt glue spraying machine is mounted on the top frame; lower spraying guns of the hot-melt glue spraying machine are mounted in front of the lower reshaping plates; upper spraying guns of the hot-melt glue spraying machine are mounted in front of the upper reshaping plates; and glue spraying inductive probes corresponding to the lower spraying guns and the upper spraying guns are mounted. By the aid of the assembly line, automatic bonding of top cover turned edges and bottom cover turned edges of the packaging boxes is realized.

Owner:成都杰润智能包装有限公司

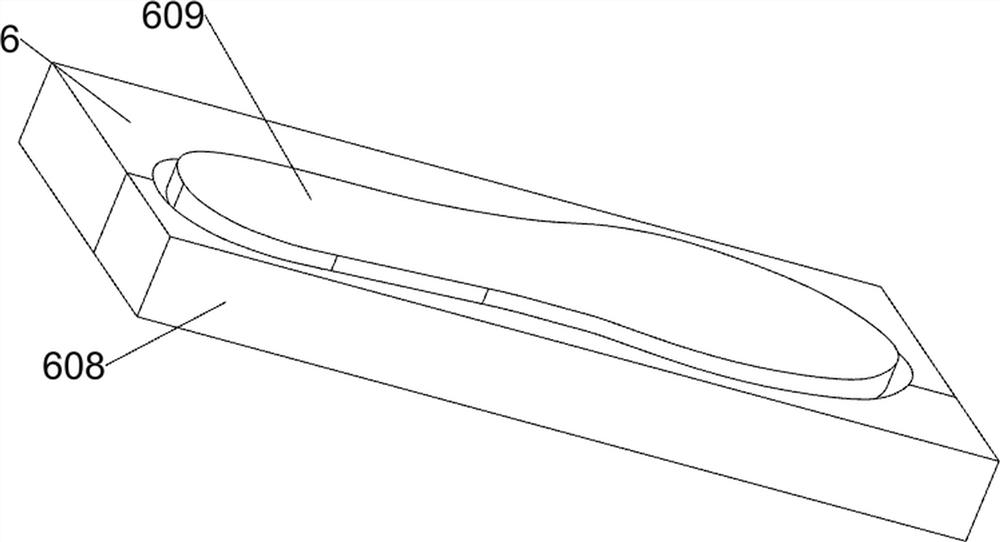

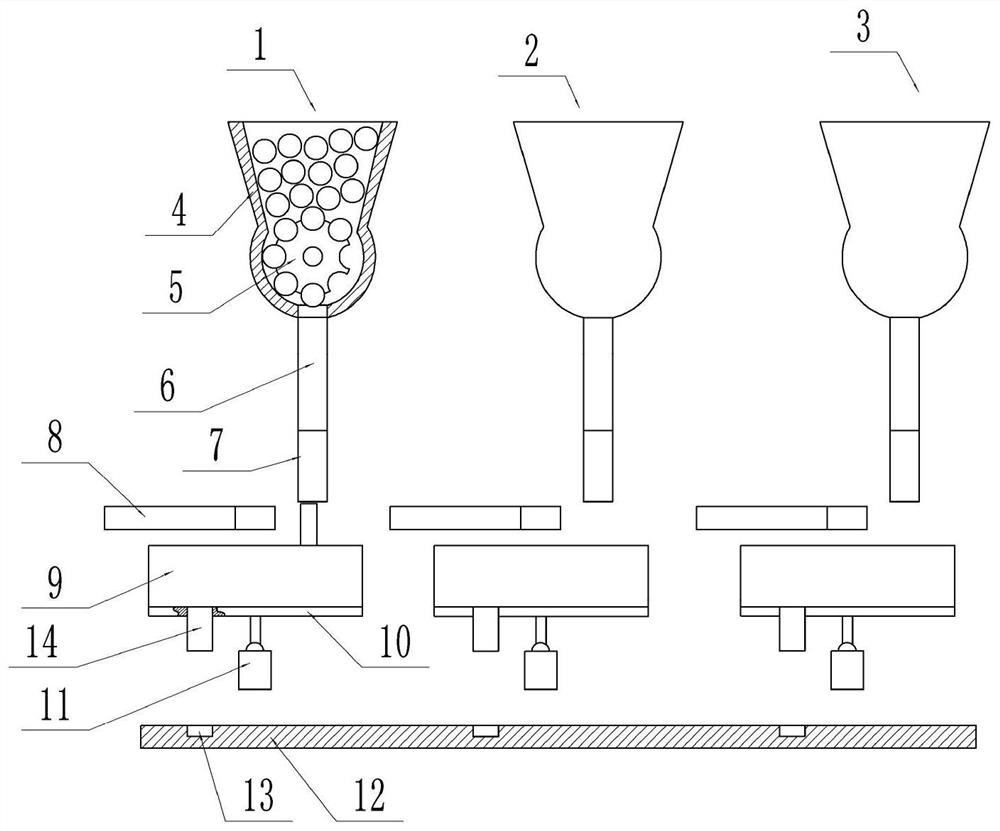

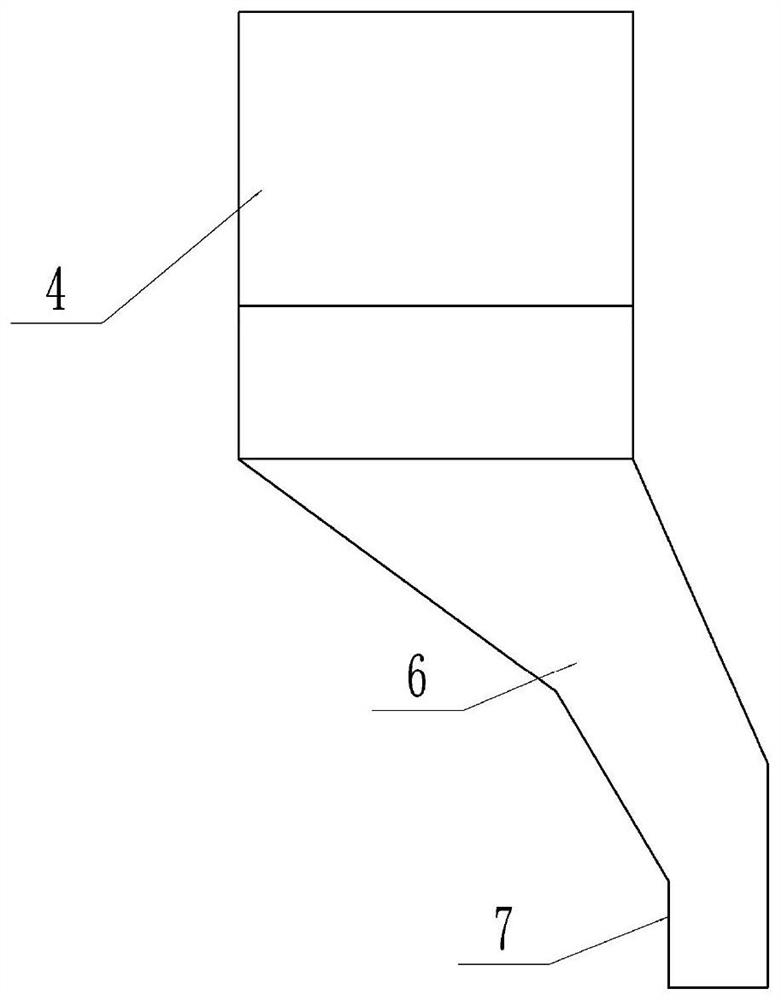

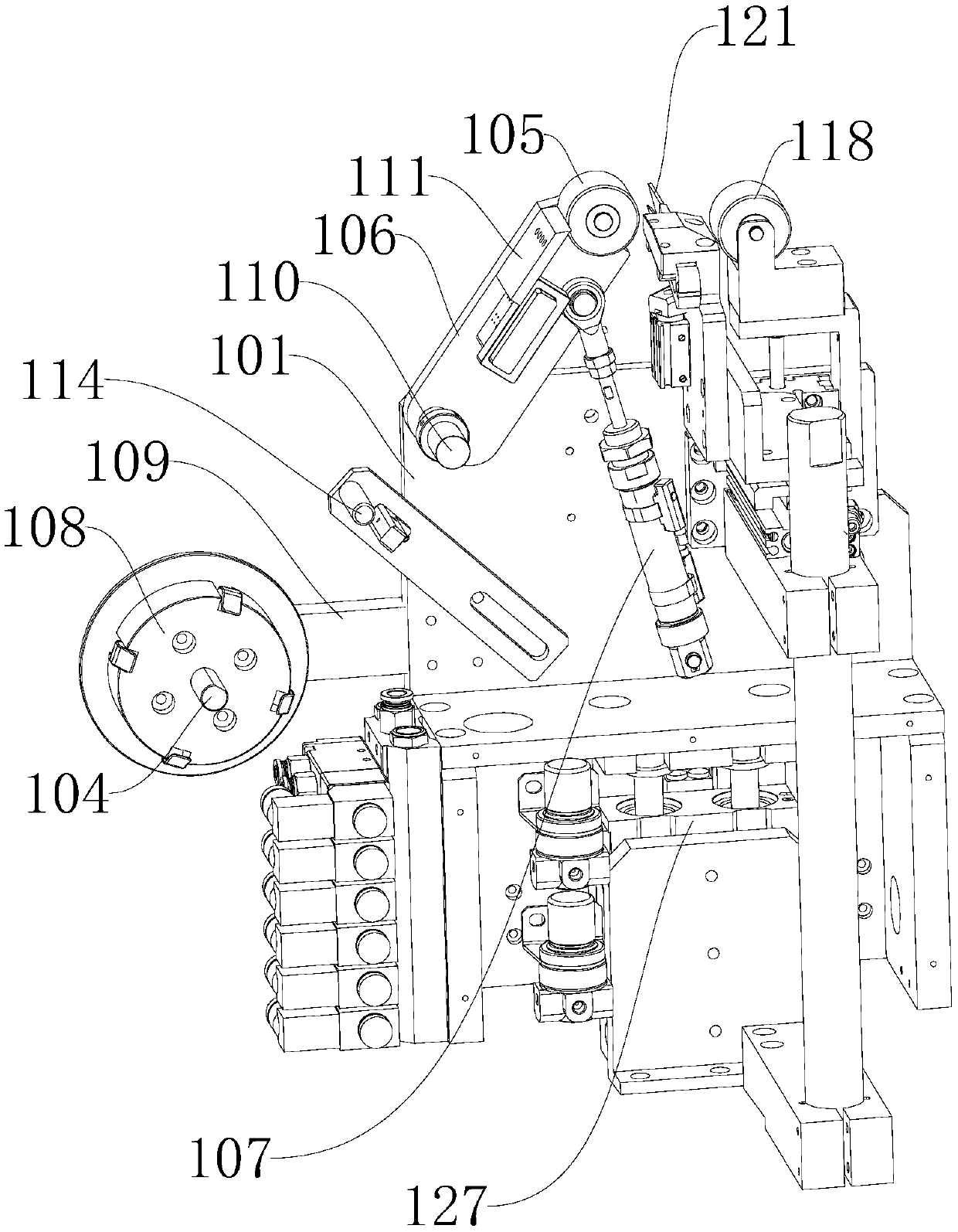

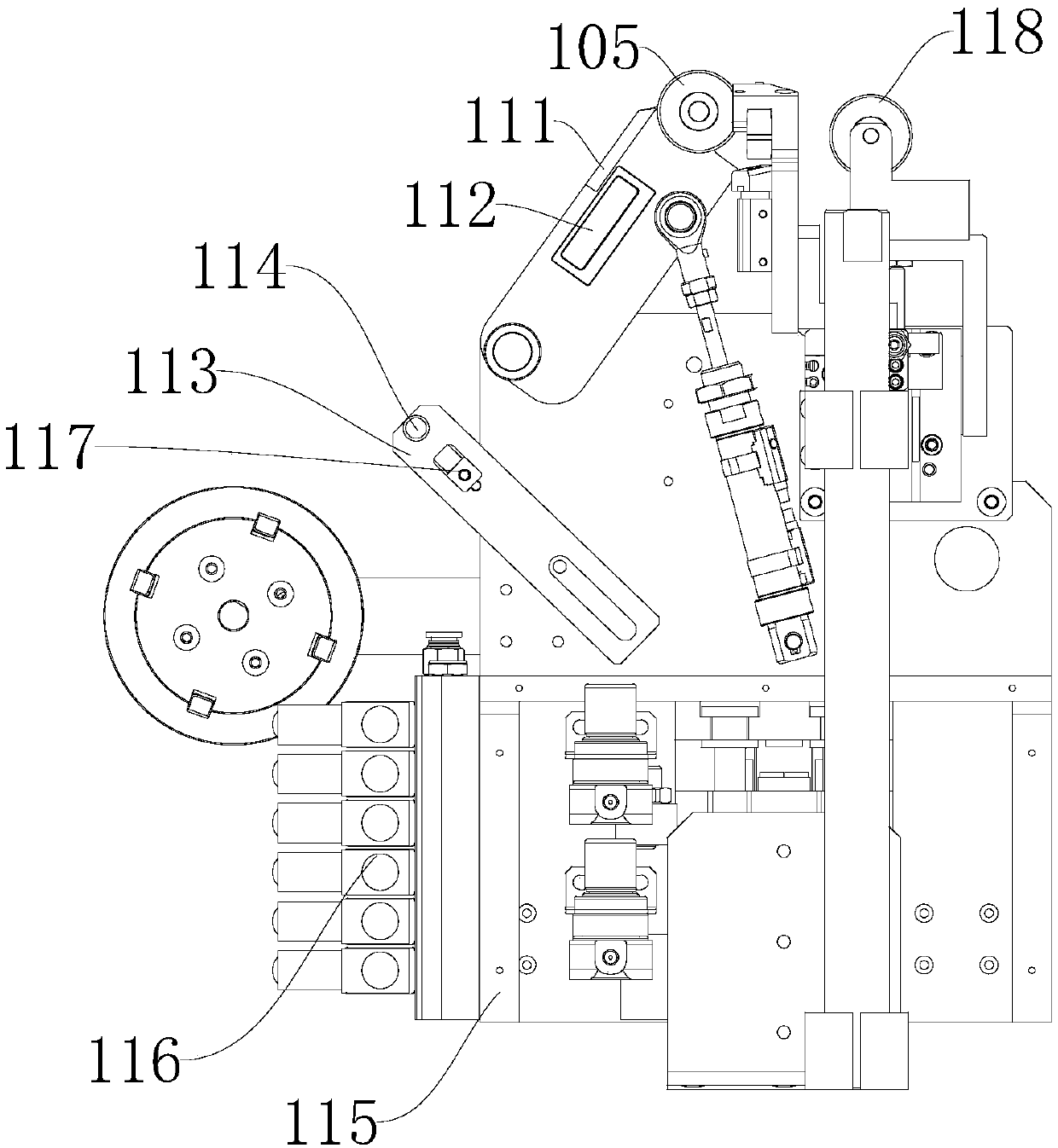

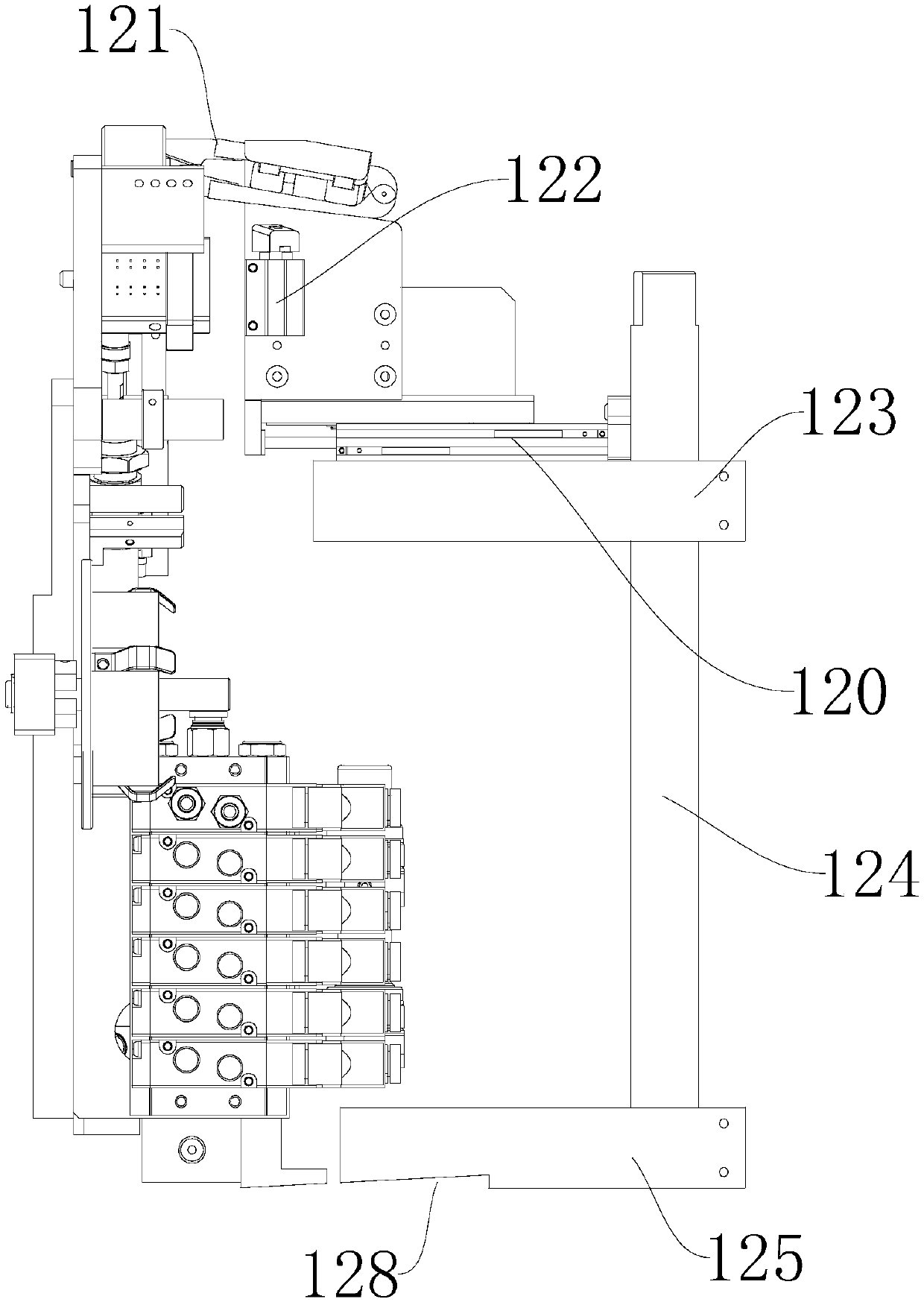

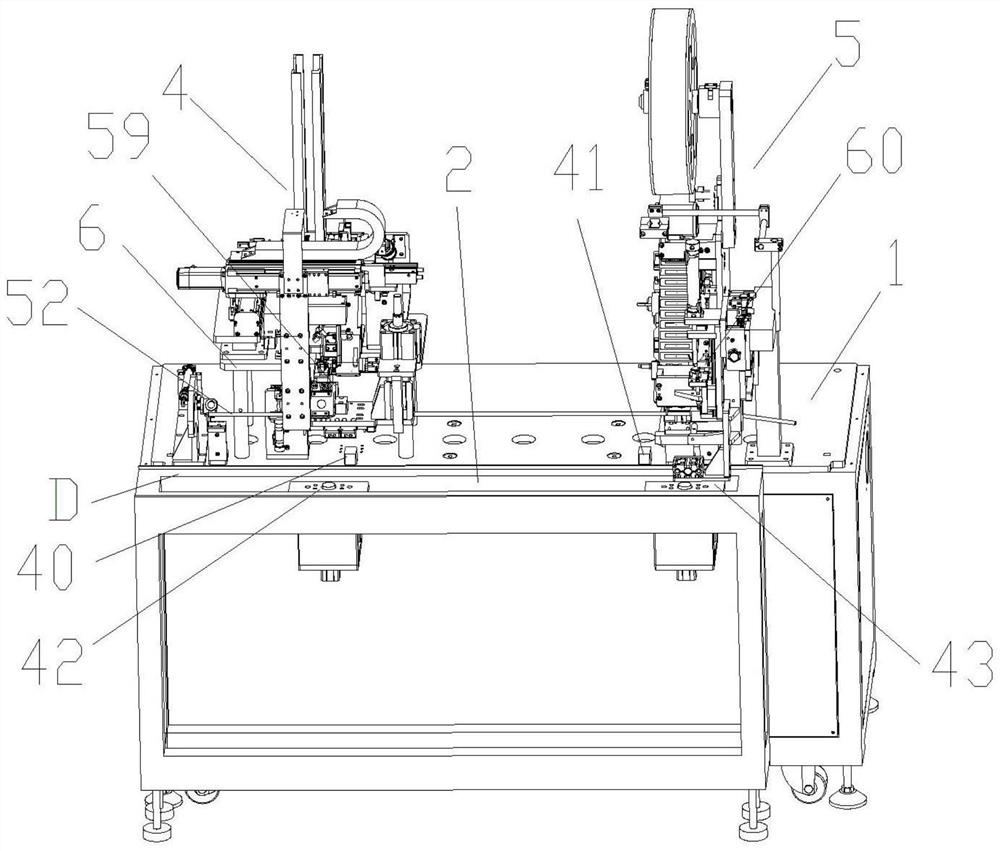

Pasting device for foil gauge

ActiveCN102393177BRealize automatic pasteImprove pasting efficiencyElectrical/magnetic solid deformation measurementReciprocating motionEngineering

Owner:SANY AUTOMOBILE MFG CO LTD

Identification card automatic paste device

ActiveCN106927103BRealize automatic pasteReduce labor costsLabelling machinesControl engineeringMechanical engineering

The invention relates to an automatic identification card pasting device. The automatic identification card pasting device comprises a conveying device used for driving an object where a card is to be pasted to move along a first moving path, a first sensor, a second sensor, a labeling mechanism for driving the identification card to move along a second moving path, and a controller electrically connected with the conveying device, the first sensor, the second sensor and the labeling mechanism, wherein the first sensor and the second sensor are sequentially arranged in the advancing direction of the first moving path; the second moving path and the first moving path are arranged obliquely; the advancing direction of the side, facing the first moving path, of the second moving path is the same as the advancing direction of the first moving path; and the tail end of the second moving path intersects with the first moving path and is located on the side, opposite to the second sensor, of the first sensor. By means of the device, the identification card is automatically pasted to the object where the card is to be pasted, and manual operation is avoided in the operating process, so that labor is released, the labor cost and the manufacturing cost are reduced, and pasting quality and working efficiency are improved.

Owner:GAC HONDA AUTOMOBILE CO LTD

A labeling machine for producing rfid labels

ActiveCN112850260BRealize automatic pasteHigh degree of automationRecord carriers used with machinesArticle deliveryQuality controlMechanical engineering

Owner:SHENZHEN LEADERCOLOR SMART CARD CO LTD

A strain gauge sticking mechanism

ActiveCN103438066BRealize automatic pastePaste depth precise controlFastening meansElastomerLinear motion

The invention relates to a strain gauge pasting mechanism, in particular to a strain gauge pasting mechanism which can achieve automatic pasting of hole internal strain gauges. The strain gauge pasting mechanism solves the problems that due to the fact that common elastomer hole internal strain gauge pasting is completed mainly through manual work, accuracy and quality are low. According to the technical scheme, the strain gauge pasting mechanism is novel and mainly comprises a servo motor, a linear guide rail, a lead screw, a slider, an F-shaped motion base, an overturn air cylinder, pneumatic claws, pasting heads, a telescopic air cylinder, a tool rest and a blade. The linear motion combination of the servo motor, the lead screw and the linear guide rail is adopted, and therefore accuracy control over strain gauge hole internal pasting depth is achieved. Vertical opening-and-closing motion is achieved through the two arc-shaped pasting heads, and therefore strain gauges can be firmly pasted in elastomer holes. Two strain gauges can be pasted in the holes at a time through 180-degree rotation of the overturn air cylinder. The strain gauge pasting mechanism achieves automatic pasting of the hole internal strain gauges, greatly improves accuracy, and improves quality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Attaching device for sheet-like self-adhesive material

InactiveCN109649772ARealize automatic pasteReduce labor costsLabelling machinesSelf adhesiveElectrical and Electronics engineering

The invention relates to an attaching device for a sheet-like self-adhesive material. The attaching device comprises a conveying device, a first sensor, a second sensor, a labeling mechanism and a controller, wherein the conveying device is used for driving an adherend to move along a first travelling path; the first sensor and the second sensor are arranged in sequence in the advancing directionof the first travelling path; the labeling mechanism is used for driving an identification card to move along a second travelling path; the controller is electrically connected to the conveying device, the first sensor, the second sensor and the labeling mechanism; the second travelling path and the first travelling path are slantwise arranged; the advancing direction of one side, facing toward the first travelling path, of the second travelling path is the same as the advancing direction of the first travelling path; and the tail end of the second travelling path is connected to the first travelling path and is located at one side, backing on to the second sensor, of the first sensor. The device automatically adheres the identification card to the adherend, and does not need to be manually operated in the operational process, thereby releasing manpower, reducing the cost of manpower and manufacturing, and improving the adhering quality and working efficiency.

Owner:COLAMARK GUANGZHOU LABELING EQUIP

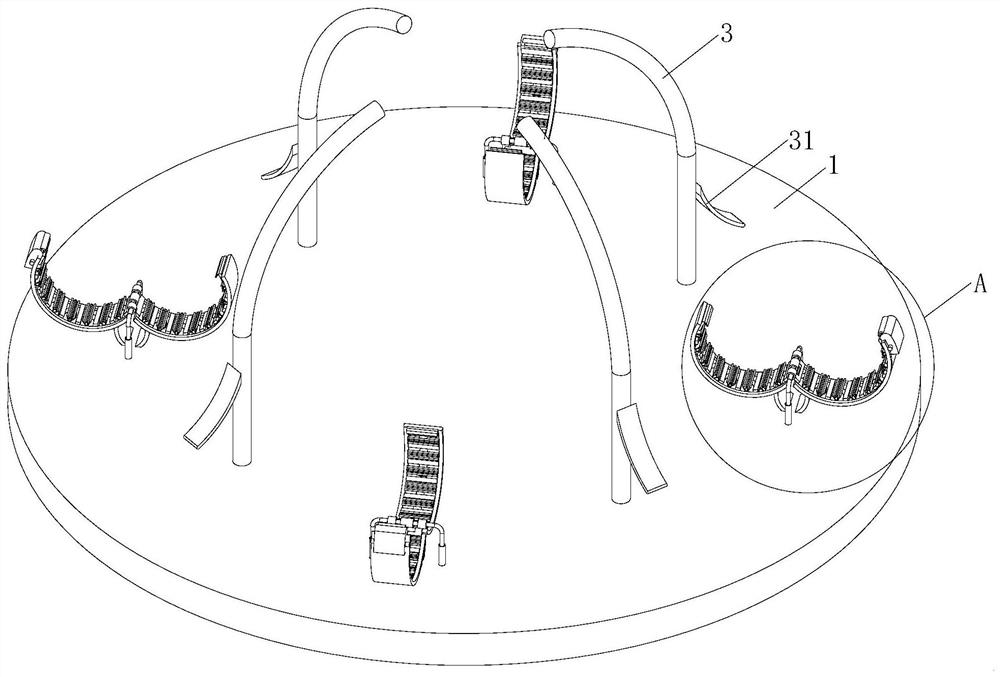

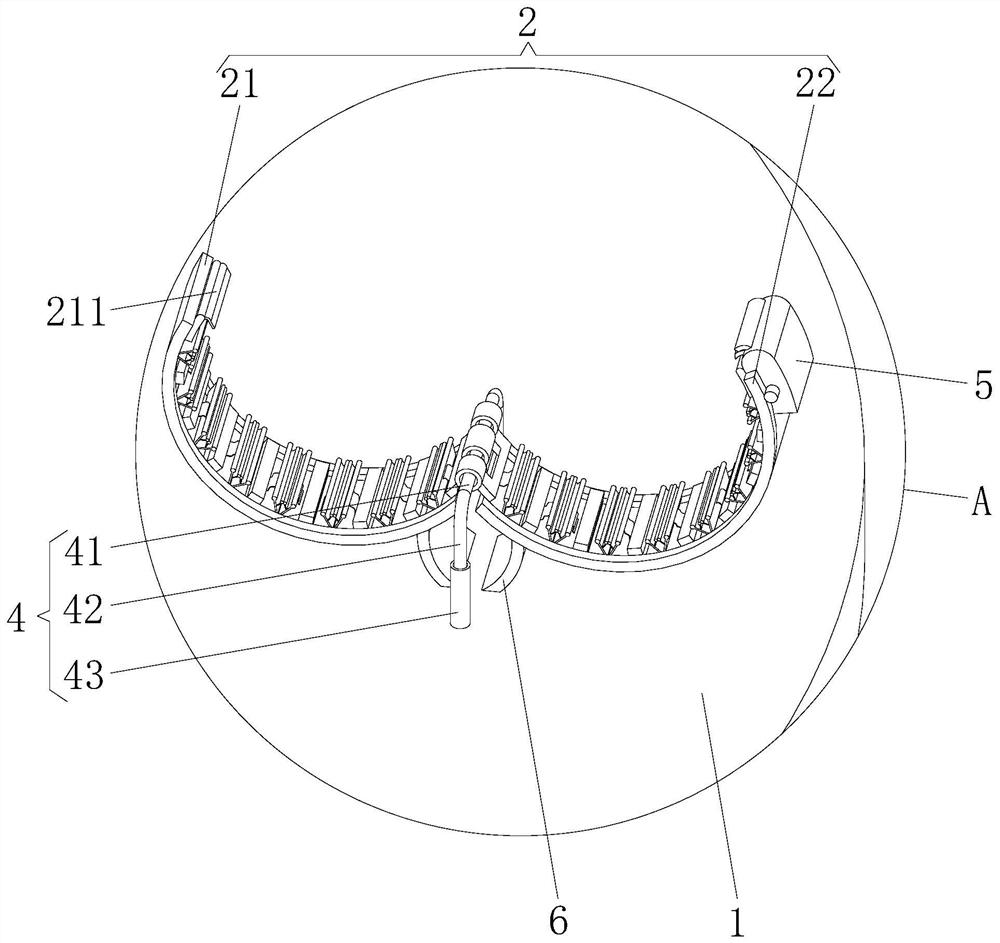

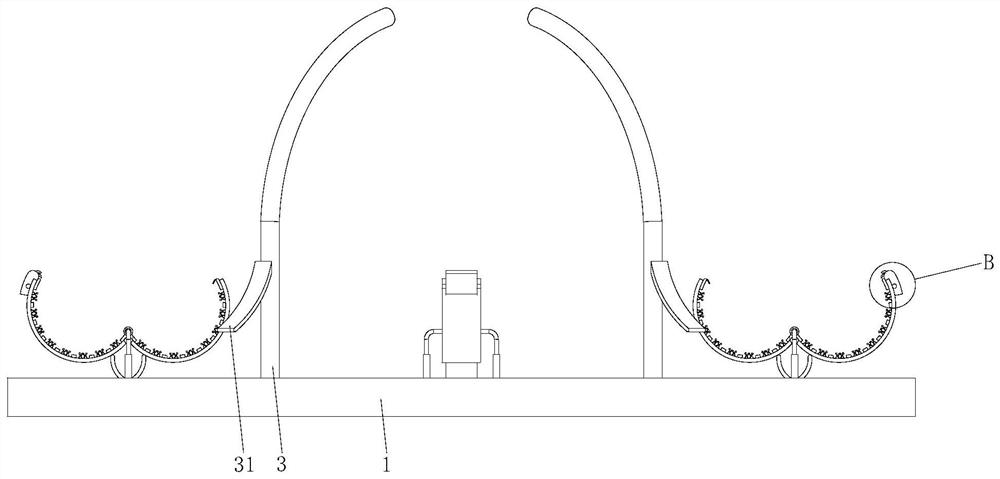

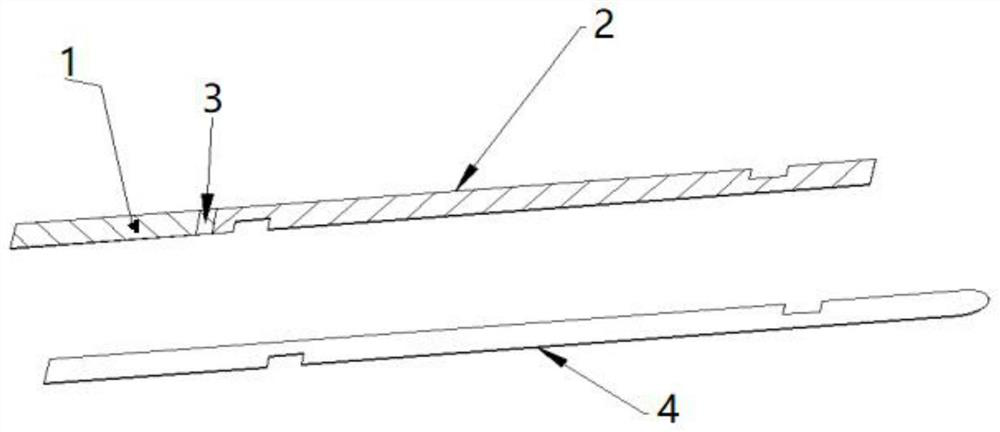

Reflective strip attaching device for life buoy production

InactiveCN113145384ARealize automatic pasteImprove bonding efficiencyLiquid surface applicatorsCoatingsEngineeringBuoy

The invention discloses a reflective strip attaching device for life buoy production, and relates to the technical field of life buoy manufacturing. The reflective strip attaching device for life buoy production comprises a bottom plate, four sets of attaching mechanisms and auxiliary fixing strips are fixed to the top of the bottom plate, and the attaching mechanisms and the auxiliary fixing strips are arranged alternately. Each attaching mechanism comprises a first attaching arc plate and a second attaching arc plate, wherein the first attaching arc plate and the second attaching arc plate are both in a semicircular ring shape. According to the reflective strip attaching device for life buoy production, the first attaching arc plates and the second attaching arc plates in the attaching mechanisms can descend under the gravity effect of a life buoy, arc-shaped supporting pieces can drive the first attaching arc plates and the second attaching arc plates to be combined so that reflective strips placed on the attaching mechanisms can be automatically attached to the life buoy, manual attaching of the reflective strips is not needed, in addition, the first laminating arc plates and the second laminating arc plates perform attaching of the reflective strips at the same time, the speed is high, and the attaching efficiency of the reflective strips is improved.

Owner:苏曼婷

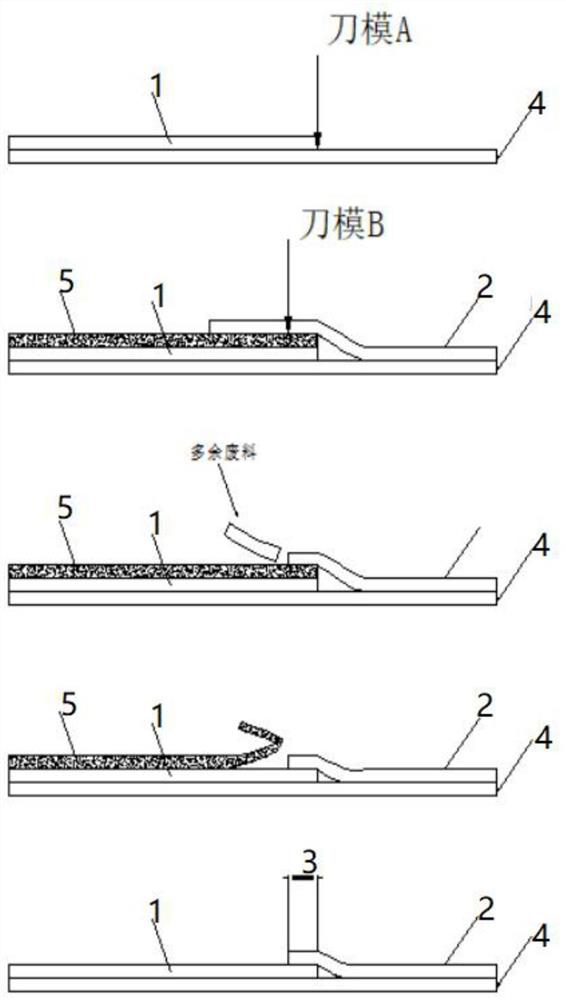

Adhesive tape lapping process

PendingCN113308199ARealize automatic pasteHigh cost advantageAdhesive processesSilicone tapeWaste material

The invention discloses an adhesive tape lapping process. The adhesive tape lapping process comprises the following steps: preparation of a first adhesive tape: preparing the first adhesive tape on backing paper, and at least partially attaching double-sided release paper to one side, far away from the backing paper, of the first adhesive tape to meet the requirement that the double-sided release paper at least covers a lapping work region on the first adhesive tape, wherein the lapping work region is set at least according to lapping parameters of the first adhesive tape and a second adhesive tape; attaching of the second adhesive tape: attaching the second adhesive tape to the side, away from the first adhesive tape, of the double-sided release paper, wherein the overlapping range of the first adhesive tape, the double-sided release paper and the second adhesive tape is located in the lapping work region; die cutting: cutting the second adhesive tape off in the lapping work region according to the lapping parameters, and moving cut-off waste materials out; and lapping: pulling the double-sided release paper away, and attaching the parts, in the lapping work region, of the first adhesive tape and the second adhesive tape. The above scheme is simple and efficient, and effectively overcomes the defects of low efficiency and high cost when small quantities of diversified adhesive tapes are attached in the prior art.

Owner:SUZHOU HI TECH ELECTRONICS CO LTD

A crankshaft labeling device

ActiveCN108177836BRealize automatic pasteRealize automatic separationLabelling machinesLabelling elongated objectsGear wheelClassical mechanics

The invention relates to a crankshaft labelling device, which comprises a rack. A motor is arranged on the rack; a vertically placed oscillating plate is arranged on the rack; a through hole is formedin the middle of the oscillating plate; two opposite side parts of the oscillating plate are provided with pulling teeth and a connecting plate; the connecting plate is movably connected onto the rack; a gear meshed with the pulling teeth is rotatably connected onto the rack; a grinding plate is connected onto the gear; a clamping rod is arranged above the gear; a clamping block and a vertical rod clamped on the gear are arranged on the two ends of the clamping rod; the middle part of the vertical rod is rotatably connected onto the rack; an arc-shaped blade is arranged on the top part of thevertical rod; an elastic piece is arranged between the rack and the top end of the vertical rod; an arc-shaped rod pressing against the bottom end of the vertical rod is arranged on the oscillating plate; a discharging roller is arranged above the grinding plate; a winding roller is arranged below the grinding plate; a double-faced adhesive reel is arranged on the discharging roller; a double-faced adhesive tape winds on the double-faced adhesive reel; and one end, far away from the double-faced adhesive reel, of the double-faced adhesive tape extends onto the winding roller. According to thescheme, the double-faced adhesive tape is automatically adhered onto a crankshaft.

Owner:CHONGQING HONGLEI MACHINERY MFG

Carbon fiber cloth reinforcement automatic construction device suitable for variable cross-section rib structure

The invention discloses an automatic carbon fiber sheet reinforcement construction device suitable for a variable cross-section ribbed structure. The automatic carbon fiber sheet reinforcement construction device comprises a gluing pasting module installed slidably, and the gluing pasting module can be used for brushing an adhesive and pasting a carbon fiber sheet on the surface of a component. Inorder to adapt to the variable cross-section structure, the side face of gluing pasting module comprises a cutting device which can walk along the cross section. The cutting device comprises a spring, a roller is installed on the spring, the roller is located between a gluing roller and a carbon fiber sheet roll, and a cutting blade is installed on the roller and is not rotated with the roller and used for cutting the sheet roll. The automatic carbon fiber sheet reinforcement construction device suitable for the variable cross-section ribbed structure can solve the complex problem of carbon fiber sheet pasting in construction, comprehensively strengthens the carbon fiber sheet of the complex cross-section (mainly ramped variable cross-section ribbed structure) structure, the degree of automation is high, construction quality is stable, the device is portable, the operation of worker is facilitated.

Owner:HOHAI UNIV

A meter-mounted nameplate device

ActiveCN110127154BRealize automatic pasteThe pasting position is accurateMetal working apparatusLabelling machinesBarcodeStructural engineering

The invention discloses a device for mounting nameplates on electric meters. The device is characterized by comprising a table body, an automatic assembly line and a nameplate back-side bar code pasting device, wherein the automatic assembly line is arranged on the table body and is used for conveying the electric meters, and the nameplate back-side bar code pasting device is arranged on the tablebody and is located on one side of the automatic assembly line; the device further comprises a limiting device, wherein the limiting device is arranged on the table body; the nameplate back-side barcode pasting device comprises a transmission roller assembly, a third vacuum adsorption device and a second XYZ three-axis driving device, the transmission roller assembly is arranged on the table body and is used for continuously conveying roll-type back-side bar codes, the third vacuum adsorption device is used for adsorbing the back-side bar codes, and the second XYZ three-axis driving device is used for driving the third vacuum adsorption device to move; a first bar code scanning gun used for scanning front-side bar codes of the nameplates and a second bar code scanning gun used for scanning the back-side bar codes on the transmission roll assembly are sequentially arranged on the table body along the advancing direction of the automatic assembly line. The device for mounting the nameplates on the electric meters is high in production efficiency and accuracy.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

A kind of processing method for sticking the inner layer rubber strip of canvas shoe sole

The invention relates to the field of canvas shoes, in particular to a processing method for sticking rubber strips on the inner layer of the sole of canvas shoes. The technical problem of the present invention is to provide a processing method for sticking the rubber strip of the inner layer of the sole of a canvas shoe. A method for sticking a rubber strip on the inner layer of a canvas shoe sole. The processing method for sticking a rubber strip on the inner layer of a canvas shoe sole adopts the following processing equipment. Edge separation system, etc.; the bottom of the machine tool board is welded with the support bracket. The invention realizes the automatic pasting of the inner layer rubber strip of the semi-finished shoe, automatically applies the adhesive evenly to the bottom of the outer surface of the semi-finished shoe, and automatically transmits and heats to make the adhesive spread evenly, and the rubber strip is raised above the sole of the semi-finished shoe. Part of the surface is cut and separated, so that the subsequent soles are more firmly and tightly attached.

Owner:温岭市世界风鞋材有限公司

A fully automatic suction and pasting system for the cover of a product box

InactiveCN108706169BRealize automatic reclaimingEasy to operateLabelling machinesPillow block bearingEngineering

The invention discloses a fully-automatic cover sucking and pasting system for a product box. The fully-automatic cover sucking and pasting system comprises a main beam (1), wherein the two sides of the main beam (1) are equipped with supporting plates (2); bearing bases (3) are arranged on the supporting plates (2); threaded shafts (4) are arranged on the bearing bases (3) in a penetrating mode;slide nuts (5) are in threaded fit to the threaded shafts (4); the two sides of the slide nuts (5) are equipped with nut side shafts (6); lifting rings (8) connected with lifting hooks (7) are rotatably connected on the nut side shafts (6); the end part of the main beam (1) is equipped with a lifting part (9); the lifting part (9) comprises end teeth (10) arranged on the end part of the main beam(1); the inner sides of the end teeth (10) are equipped with inner teeth (11); a clamping slot (12) is formed between the end teeth (10) and the inner teeth (11); one side of the clamping slot (12) ofthe inner teeth is provided with a vertical surface (13), and the lower part of the vertical surface (13) is equipped with an inclined surface (14), so that the clamping slot (12) is divided into anupper straight slot (15) and a lower inclined slot (16); and the lower parts of the inner teeth (11) are equipped with fastening bolts (17) which are inclined upwards.

Owner:WENZHOU UNIV OUJIANG COLLEGE

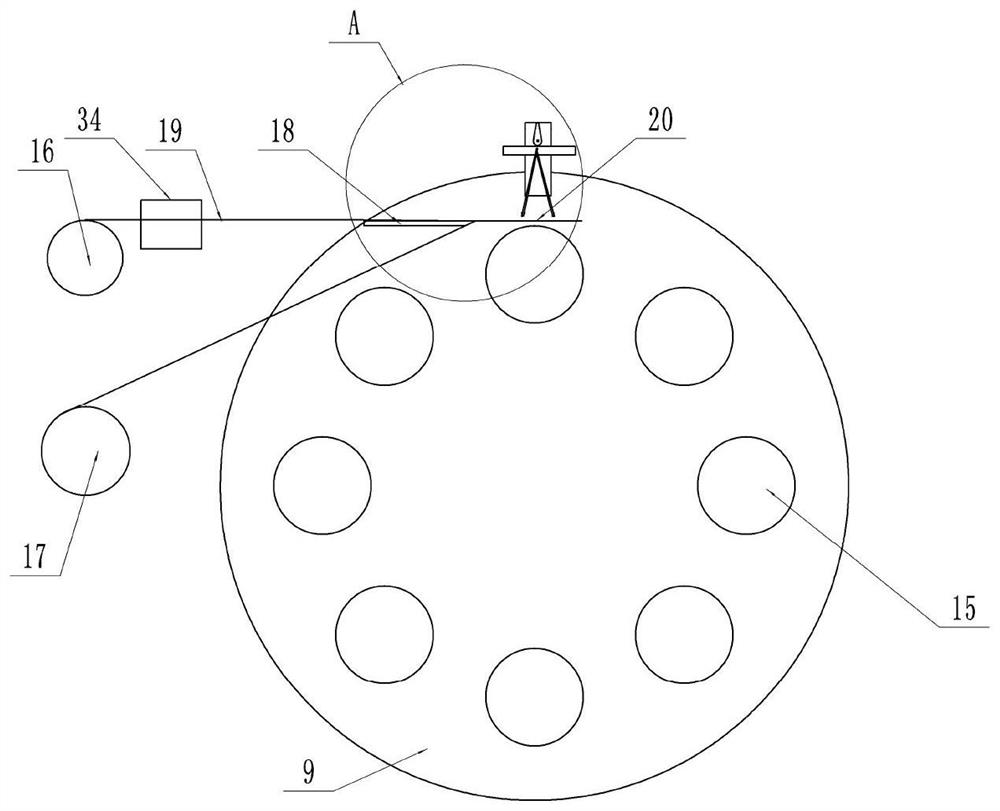

Packaging device for finished low-smoke and halogen-free cables

ActiveCN105197276BRealize automatic pasteEasy to operateWeb rotation wrappingCircular discEngineering

The invention discloses a device for packing finished products of low-smoke halogen-free cables. The device comprises a base, wherein a cylinder is arranged on the base; a disc is mounted on the cylinder; round cables are stacked on the disc; a support arm is arranged on the cylinder; the end of the support arm is parallel to the cylinder; a plastic film sleeve can be mounted on the support arm; a rotating clamp is arranged in the position where the support arm and the cylinder are connected and can drive the support arm to rotate around the cylinder; a transportation wire is arranged on one side of the base and driven by a transportation shaft; one end of the transportation shaft is higher than the other end; a slot hole is formed in the transportation wire on one downward side of the transportation shaft. The rotatable support arm is arranged and used for wrapping the cables, and the inclined transportation shaft is arranged, so that name plates can be automatically attached to the cables by means of the retracted name plate attaching plate; the device is simple in structure, the operation of a worker is simplified, and the production efficiency is improved.

Owner:WUHU SHUNCHENG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com