Adhesive tape lapping process

A tape and process technology, applied in the field of tape overlap technology, can solve the problems of rising mold cost, rising product cost, high cost, etc., and achieve the effect of improving cost advantage, improving efficiency and output, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

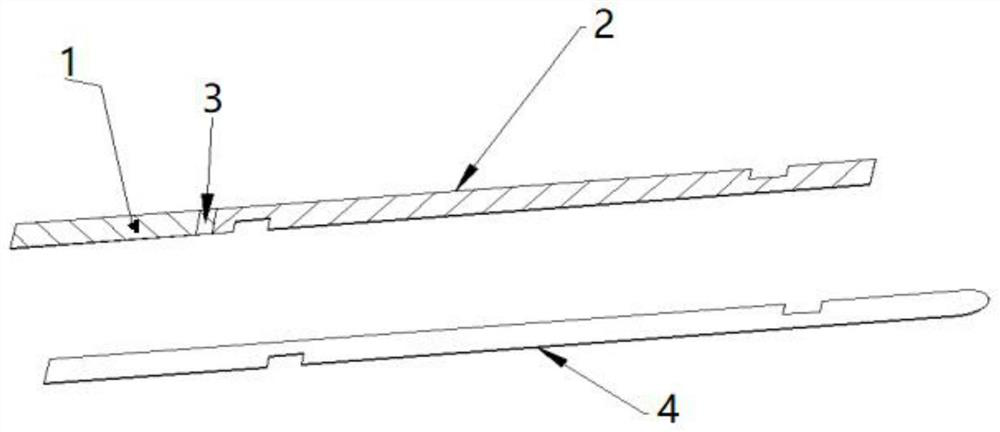

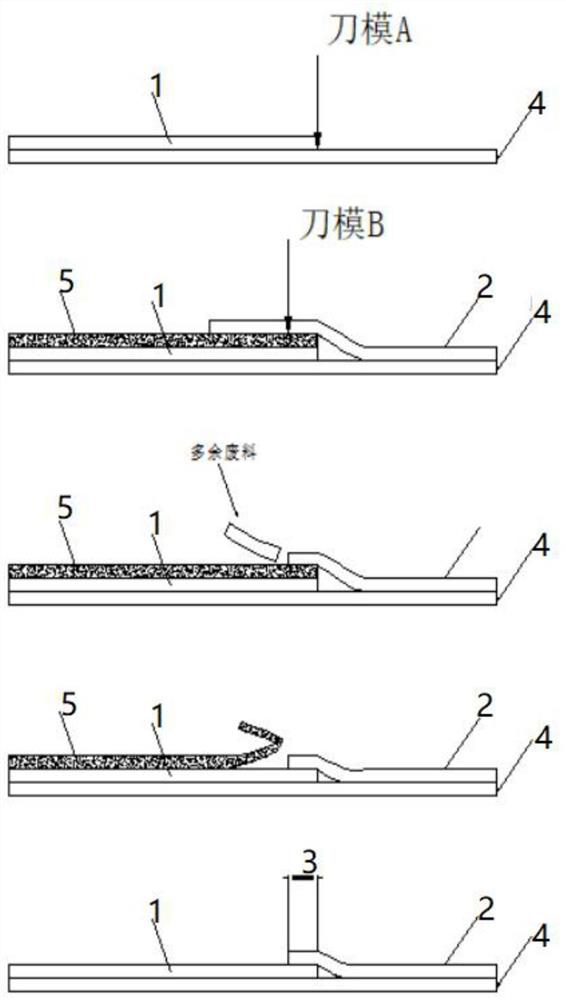

[0047] 1 Cut out the interface on the 0.03mm conductive adhesive copper foil (that is, the first tape) through the die-cutting knife die A;

[0048] 2. Compound a layer of 0.07mm double-sided silicone oil paper on the surface of 0.03mm conductive adhesive copper foil and the interface of 0.03mm conductive adhesive copper foil can exceed 2mm;

[0049] 3. Use an automatic laminating machine to paste 0.03mm PET double-sided tape (ie, the second tape) on the other side of the silicone oil paper;

[0050] 4. Cut off the 0.03mm PET double-sided adhesive tape through the die-cutting knife die B, cut the incision on the 0.03 mm PET double-sided adhesive tape and cut off the PET double-sided adhesive tape, and the lower layer of silicone oil paper is continuous;

[0051] 5 After eliminating the waste of 0.03mm PET double-sided tape, pull out the silicone oil paper, and naturally contact the overlapping joint of 0.03mm conductive adhesive copper foil and 0.03mm PET double-sided adhesive...

Embodiment 2

[0053] 1 Cut out the interface on the 0.03mm conductive adhesive copper foil (that is, the first tape) through the die-cutting knife die A;

[0054] 2 Compound a layer of 0.06mm double-sided silicone oil paper on the surface of 0.03mm conductive adhesive copper foil and the interface between 0.03mm conductive adhesive copper foil can exceed 3mm;

[0055] 3. Use an automatic laminating machine to paste 0.04mm conductive adhesive copper foil (that is, the second adhesive tape) on the other side of the silicone oil paper;

[0056] 4 Cut off the 0.04mm conductive adhesive copper foil through the die-cutting knife die B, cut out the incision on the 0.04mm conductive adhesive copper foil and cut off the PET double-sided adhesive tape, and the lower layer of silicone oil paper is continuous;

[0057] 5 After excluding the waste of 0.04mm conductive adhesive copper foil, pull out the silicone oil paper, and naturally contact the overlapping joints of 0.03mm conductive adhesive copper ...

Embodiment 3

[0059] 1 Cut out the interface on the 0.03mm PET double-sided adhesive tape (that is, the first tape) through the die-cutting knife die A;

[0060] 2. Compound a layer of 0.05mm double-sided silicone oil paper and 0.03mm conductive adhesive copper foil on the surface of 0.03mm PET double-sided adhesive tape to exceed 4mm;

[0061] 3. Use an automatic laminating machine to paste 0.03mm PET double-sided tape (ie, the second tape) on the other side of the silicone oil paper;

[0062] 4 Cut off the 0.03mm PET double-sided adhesive of the second adhesive tape through the die-cutting knife die B, cut out the 0.03mm PET double-sided adhesive and cut off the PET double-sided adhesive of the second adhesive tape, and the lower layer of silicone oil paper is continuous;

[0063] 5 After excluding the waste of the PET double-sided adhesive of the 0.03mm second tape, pull out the silicone oil paper, and the overlapping of the PET double-sided adhesive of the 0.03mm first tape and the PET ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com