A fully automatic suction and pasting system for the cover of a product box

A fully automatic, cover technology, applied in labeling machines, transportation and packaging, packaging, etc., can solve the problems of high cost, affecting the normal circulation of beautiful products, and the inability to automate the whole process, so as to achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

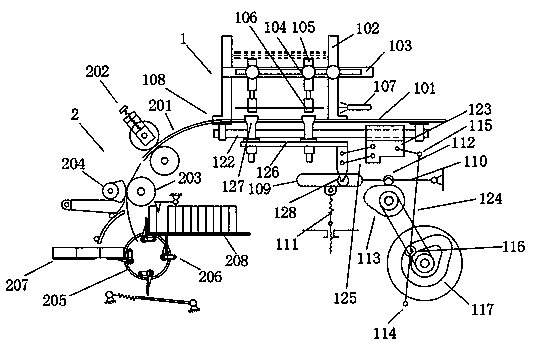

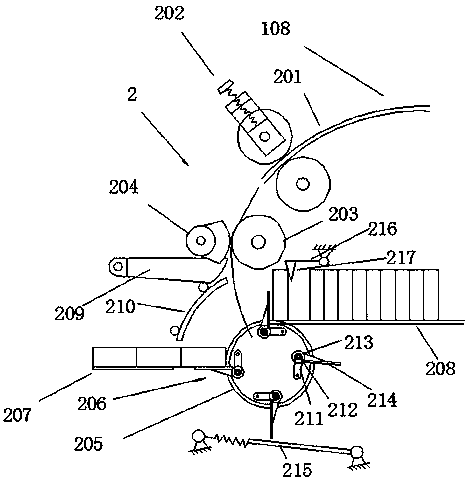

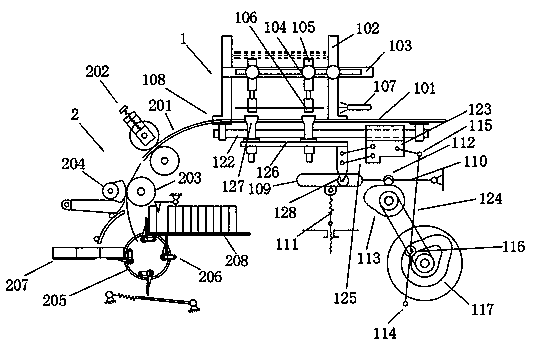

[0014] Embodiment: a kind of cover automatic absorption and pasting system of product box, as attached Figure 1-2 As shown, a suction mechanism 1 is included, and the discharge end of the suction mechanism 1 is connected with a paste mechanism 2; the suction mechanism 1 includes a frame 101, and a support 102 is provided above the frame 101, and the support is two vertical For the I-beam set, the support 102 is provided with a moving bracket 103, and the moving bracket is provided with a moving groove. An I-beam in the support is fixed in the moving groove by a screw, and the width is realized by moving the I-beam. adjust. The mobile bracket 103 is provided with a storage pole 104, the upper end of the storage pole 104 is provided with an upper storage rack 105, and the lower end of the storage pole 104 is provided with a lower storage rack 106, and the upper storage rack is used for fixing the laminated cover (shelving), when the bottom cover of the stacked cover of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com