A resistor sheet riveting press

A technology of resistance sheet and riveting press, applied in the direction of adding lead-out resistors, feeding devices, positioning devices, etc., can solve the problems of unguaranteed quality, low production efficiency, and high production costs, and achieve the improvement of product quality, High production efficiency and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

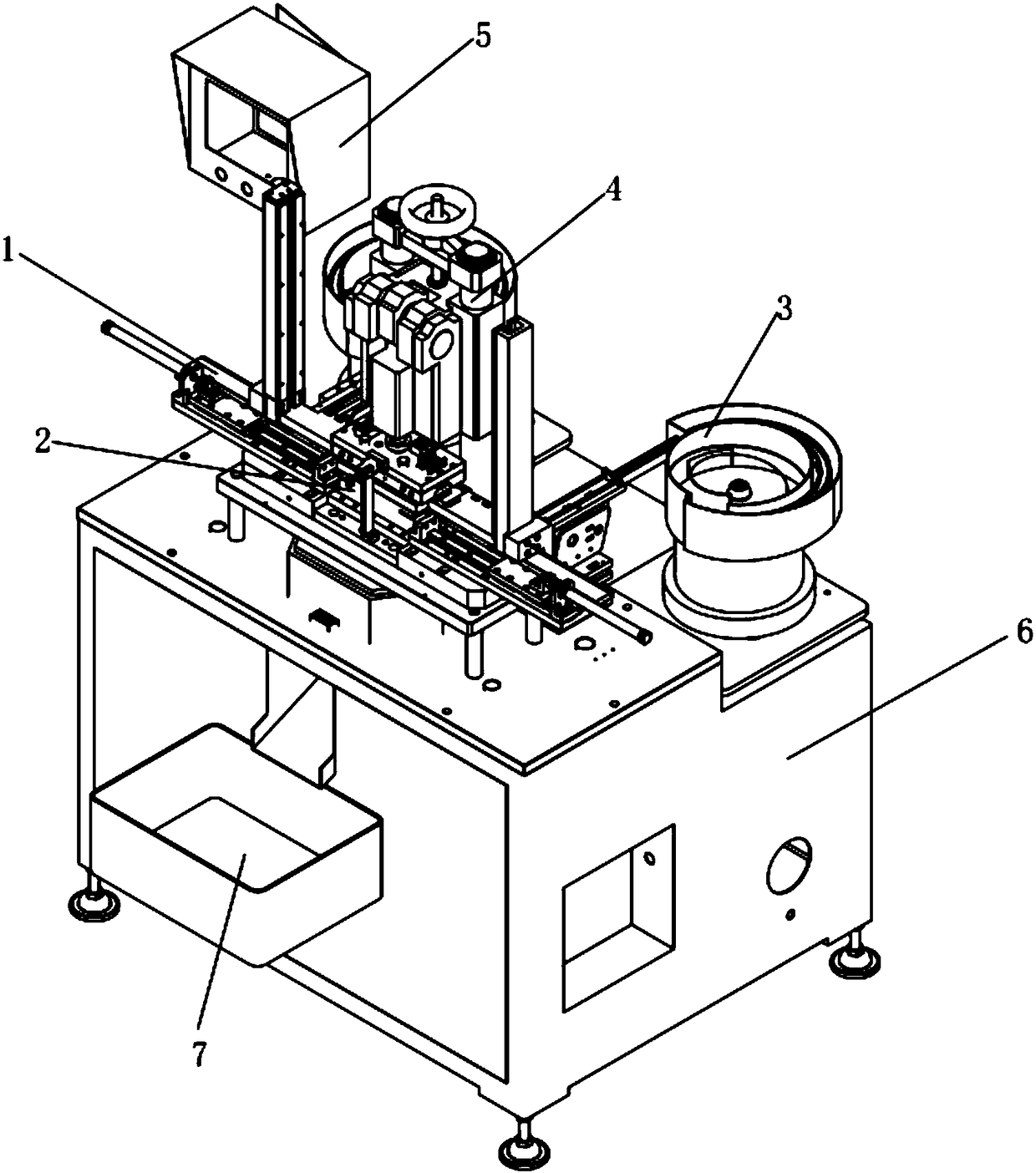

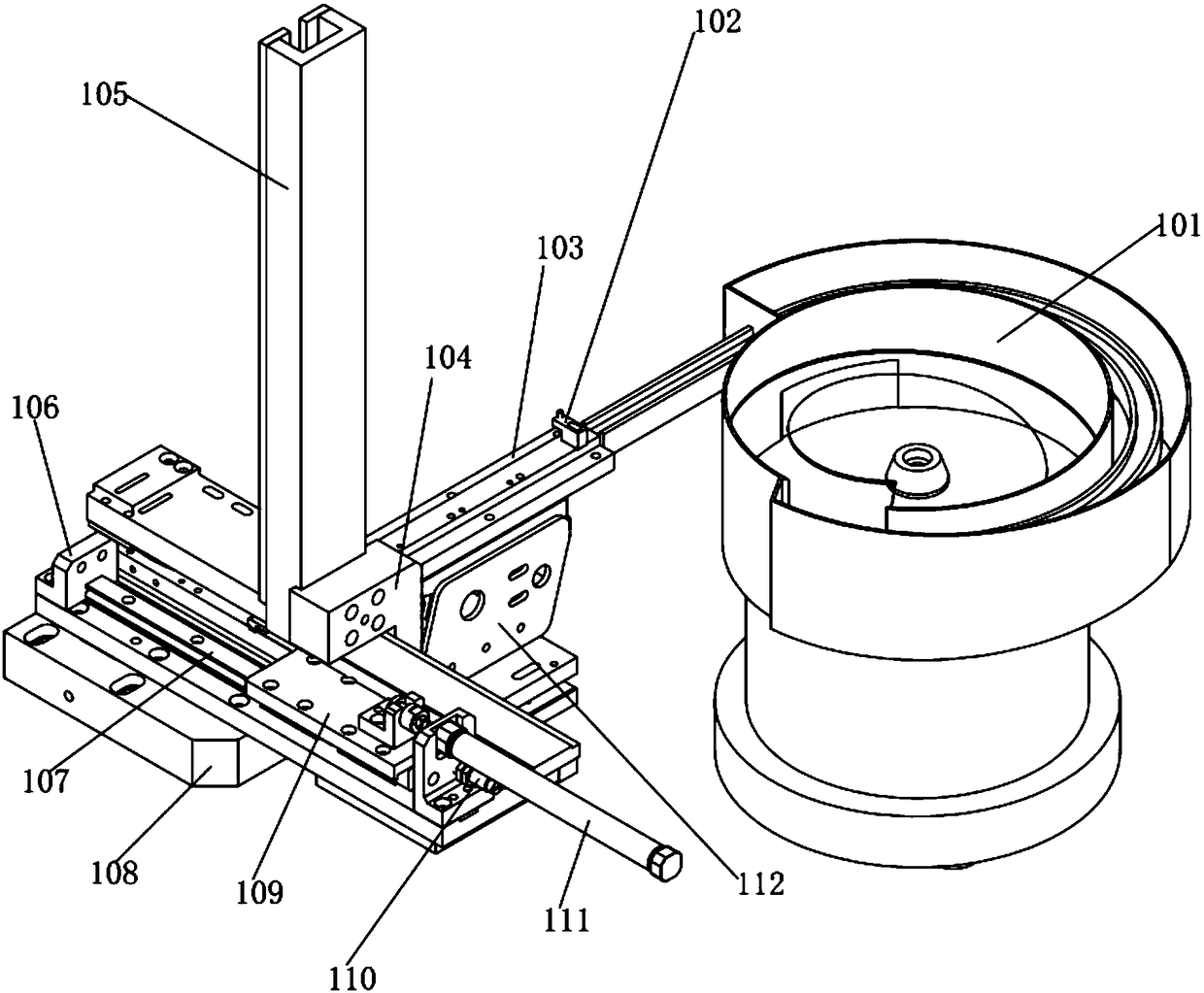

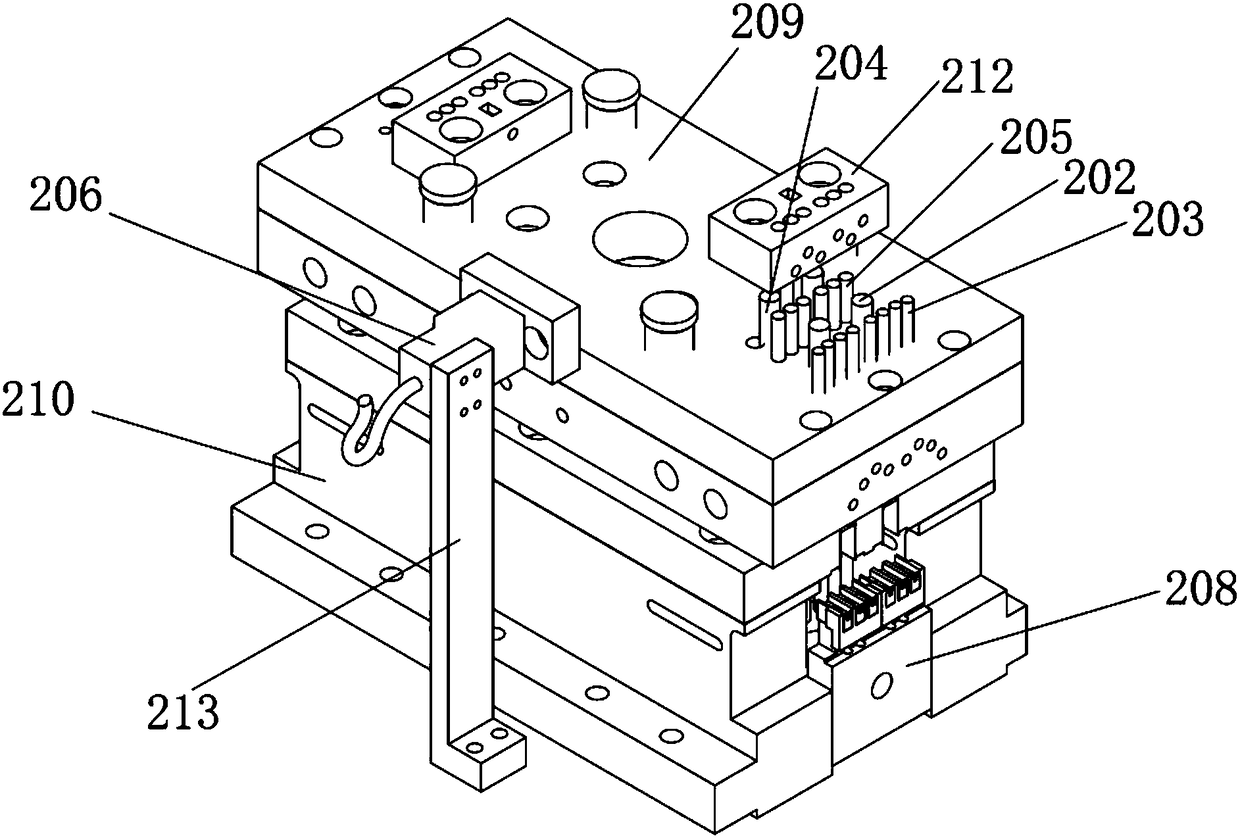

[0022] see Figure 1-4 , a resistance sheet riveting machine, comprising a first material taking mechanism 1 fixed on the main frame 6, a mold 2, a second material taking mechanism 3, a punch press 4 and a touch screen 5, the first material taking mechanism 1 and the second retrieving mechanism 3 are relatively placed, and the two ends of the mold 2 are respectively connected to the output ends of the first retrieving mechanism 1 and the second retrieving mechanism 3, and the upper part of the mold 2 is connected to the output end of the punch press 4, and the first taking The material mechanism 1 and the second material retrieving mechanism 3 input the resistors and terminals into the mold 2 according to the set position, and are driven by the punch 4 for riveting and punching. The opening in the mold 2 passes through the inclined downward materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com