Automatic assembling equipment for check ring of three-convex balance wheel base

An automatic assembly and wheel seat technology, which is applied in metal processing equipment, assembly machines, metal processing, etc., can solve the problems of low production efficiency and high work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

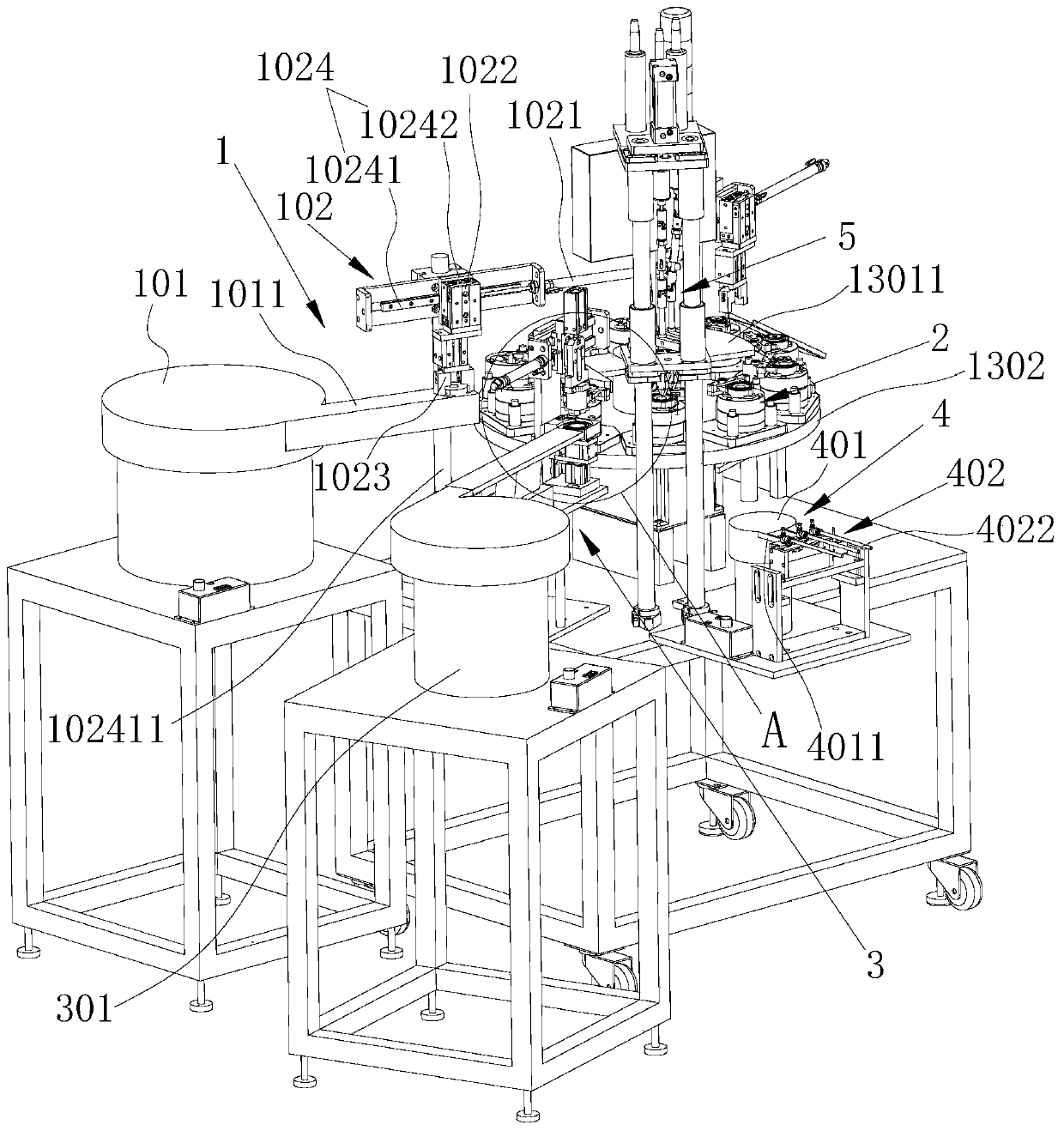

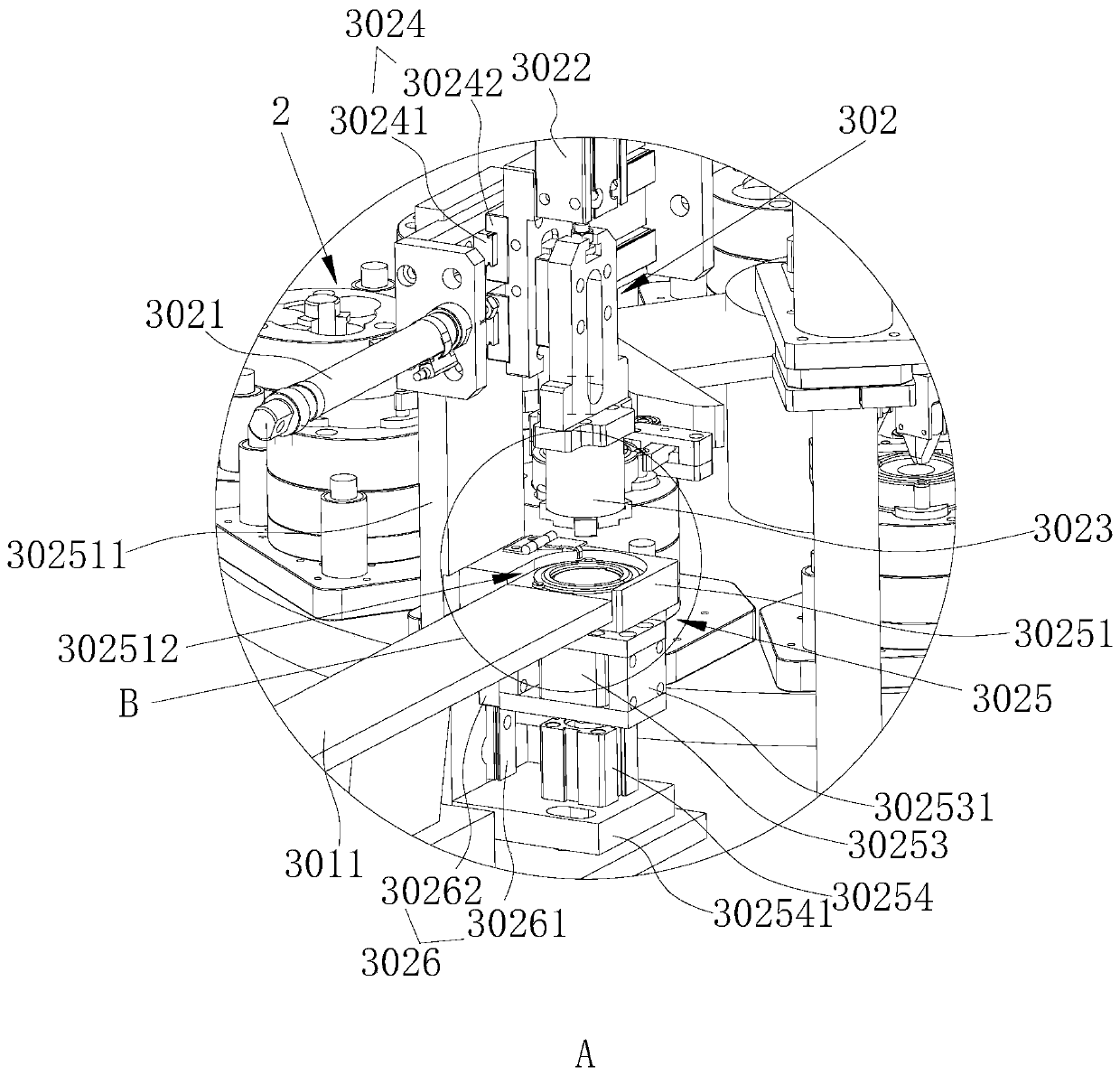

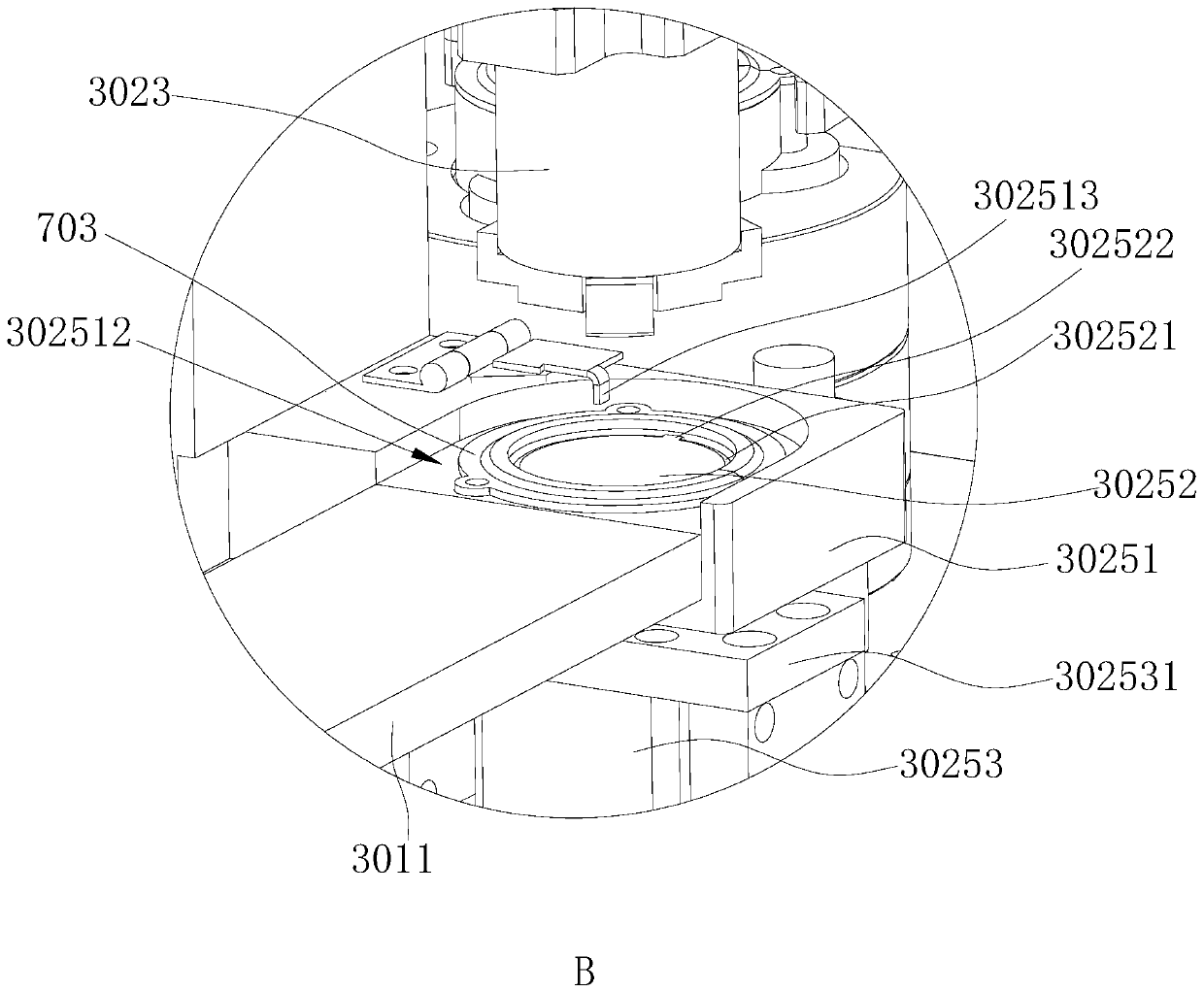

[0062] refer to figure 1 , figure 2 , Figure 5 as well as Image 6 , the present embodiment discloses automatic assembly equipment for retaining rings of a three-convex balance wheel seat, including a balance wheel seat feeding device 1, a balance wheel seat positioning and clamping device 2, a retaining ring feeding device 3, a screw feeding device 4, a screw The screw device 5 and the unloading device 6, the balance wheel seat loading device 1 loads the balance wheel seat 701 onto the balance wheel seat positioning and clamping device 2, and the balance wheel seat positioning and clamping device 2 is used for adjusting the balance wheel seat 701 Positioning and clamping, the retaining ring feeding device 3 and the screw feeding device 4 respectively feed the retaining ring 703 and the fastening screw 704 to the positioned and clamped balance wheel seat 701 on the balance wheel seat positioning and clamping device 2, The screwing device 5 is used to fasten the fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com