Paper box lower portion folding and conveying mechanism of battery subsequent unmanned packing device

A folding mechanism and battery technology, applied in packaging and other directions, can solve the problems of high price, high cost, and lack of attention, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

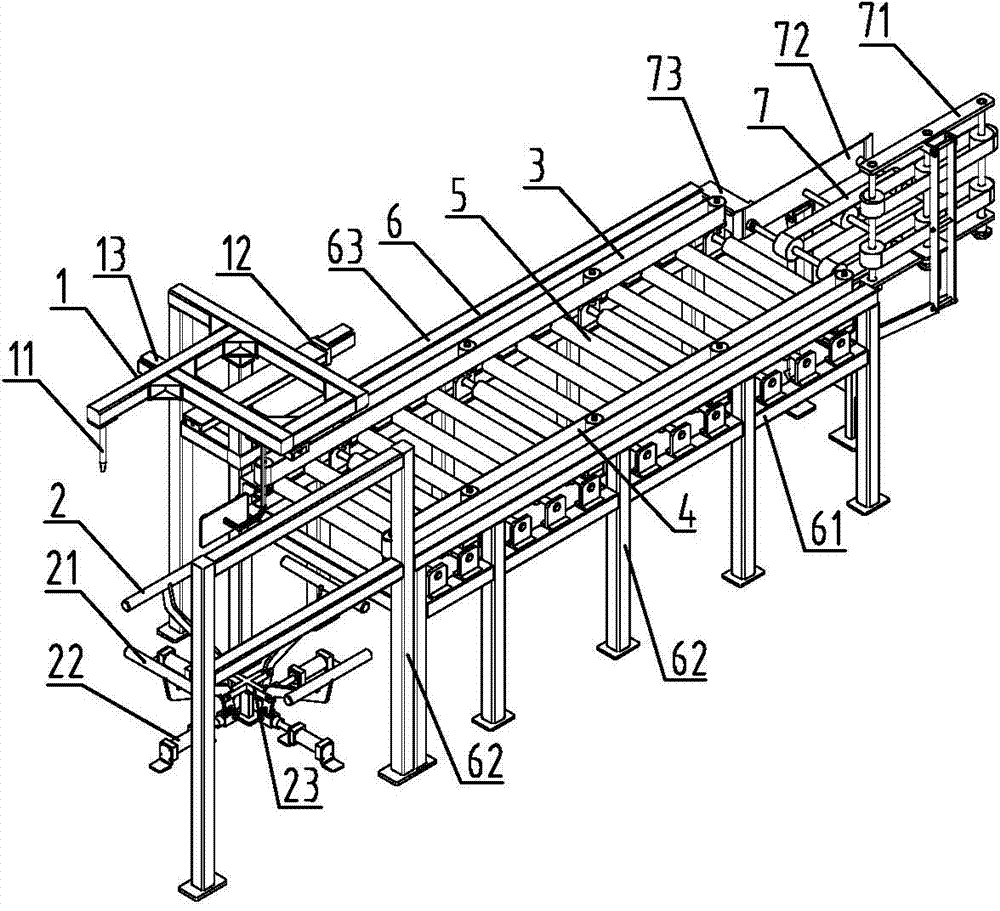

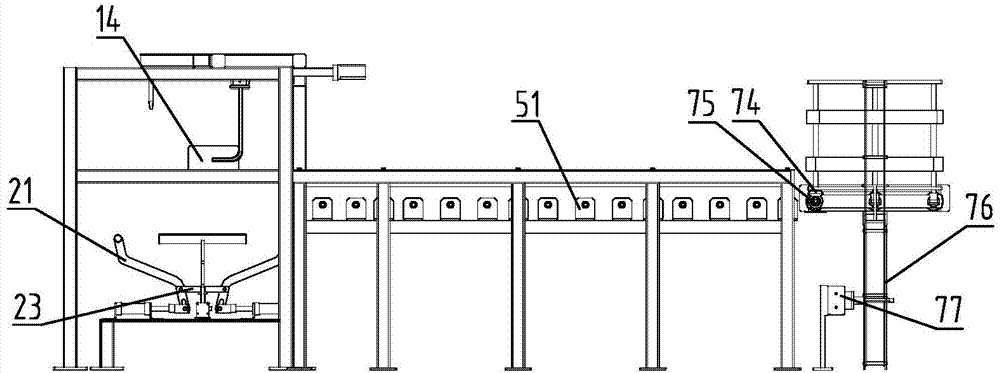

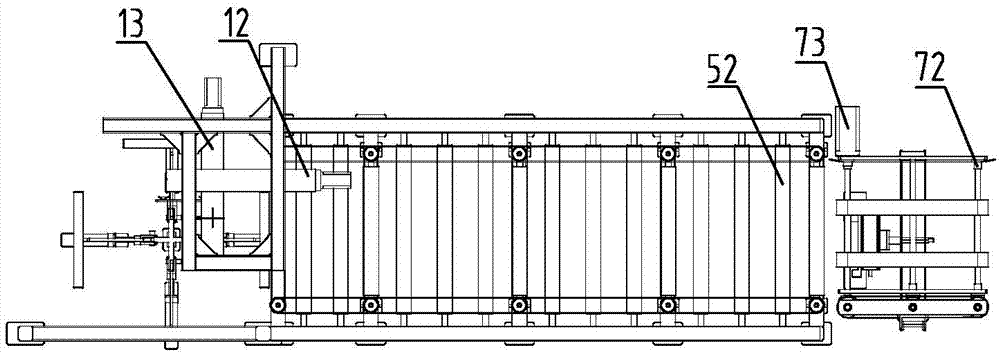

[0018] Such as figure 1 -- Figure 5 As shown, the lower folding transport mechanism of the carton of the unmanned packaging equipment in the storage battery rear road of this embodiment includes a retrieving mechanism, a lower folding mechanism, a main frame, a non-powered rolling table, and two lateral belt transportation device, an overturning transport frame mechanism, the material retrieving mechanism is installed outside the front end of the frame, the lower folding mechanism is installed on the same straight line as the unpowered rolling table, and is in the Below the reclaiming mechanism, the two-sided belt transport device is installed on the left and right sides of the frame, and is higher than the unpowered rolling table, and the overturning transport frame mechanism is installed on the machine the rear end of the rack.

[0019] In the above structure, the retrieving mechanism includes a reclaiming frame, a horizontal KK module, a longitudinal KK module, a retriev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com