Patents

Literature

65results about How to "High cost advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

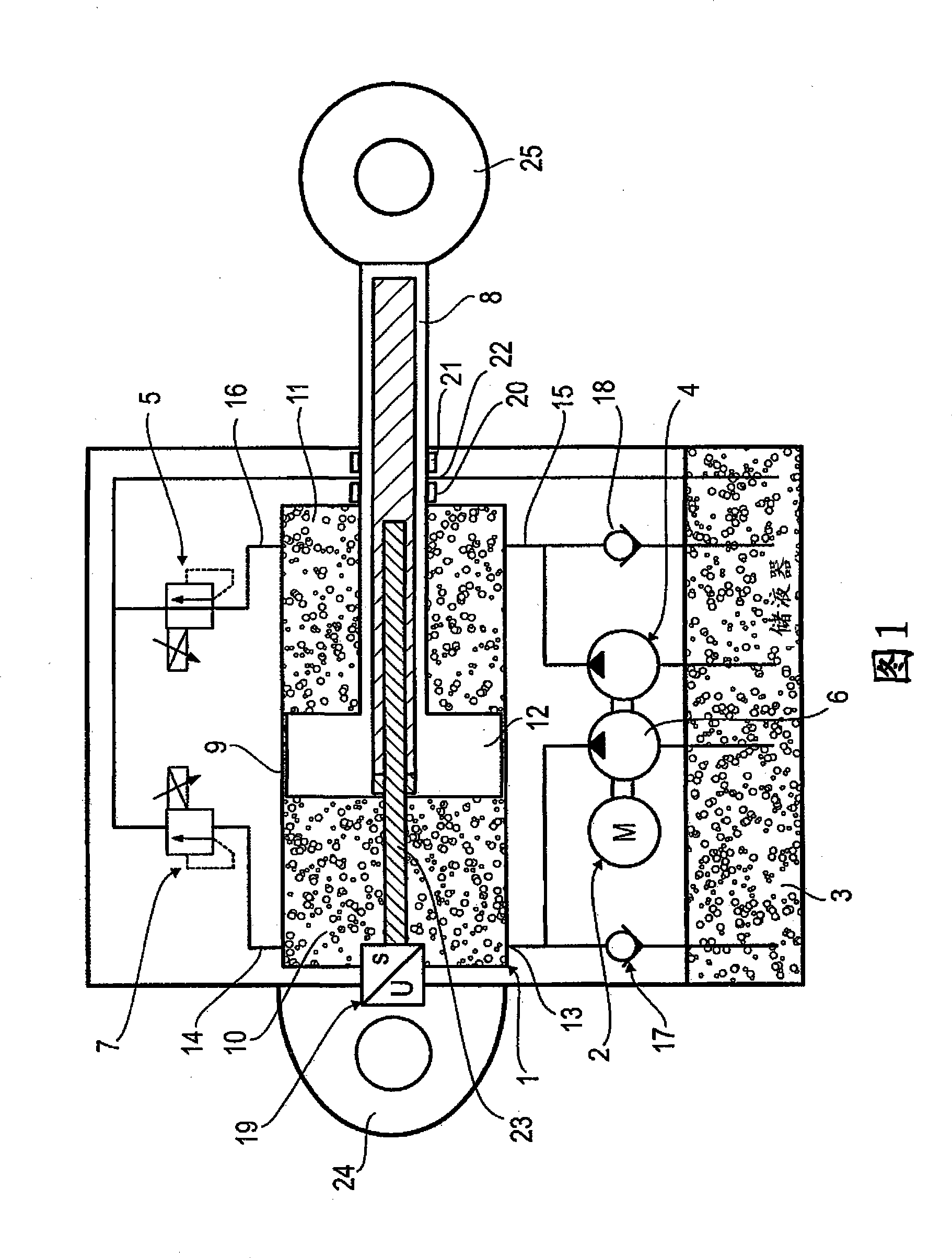

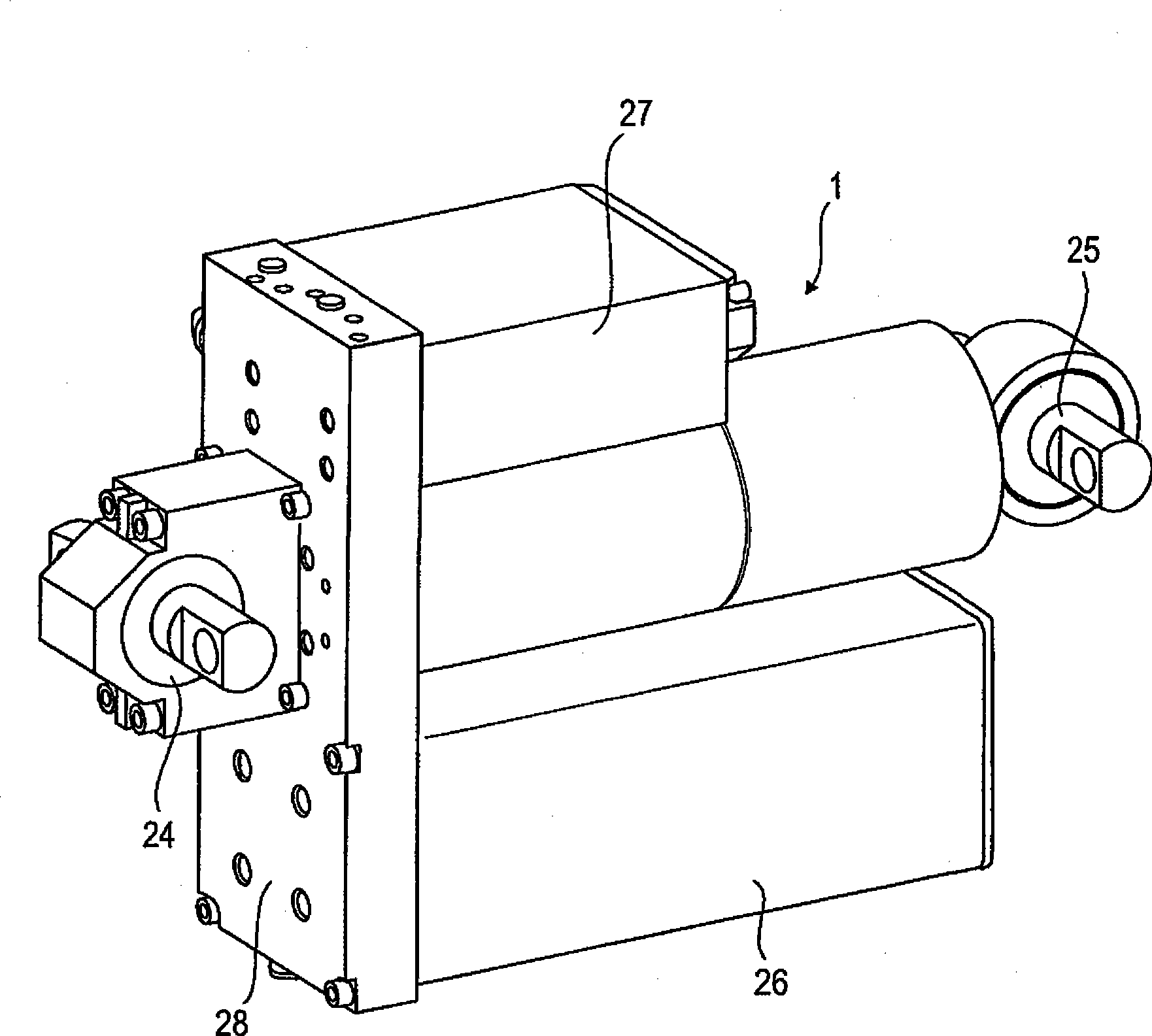

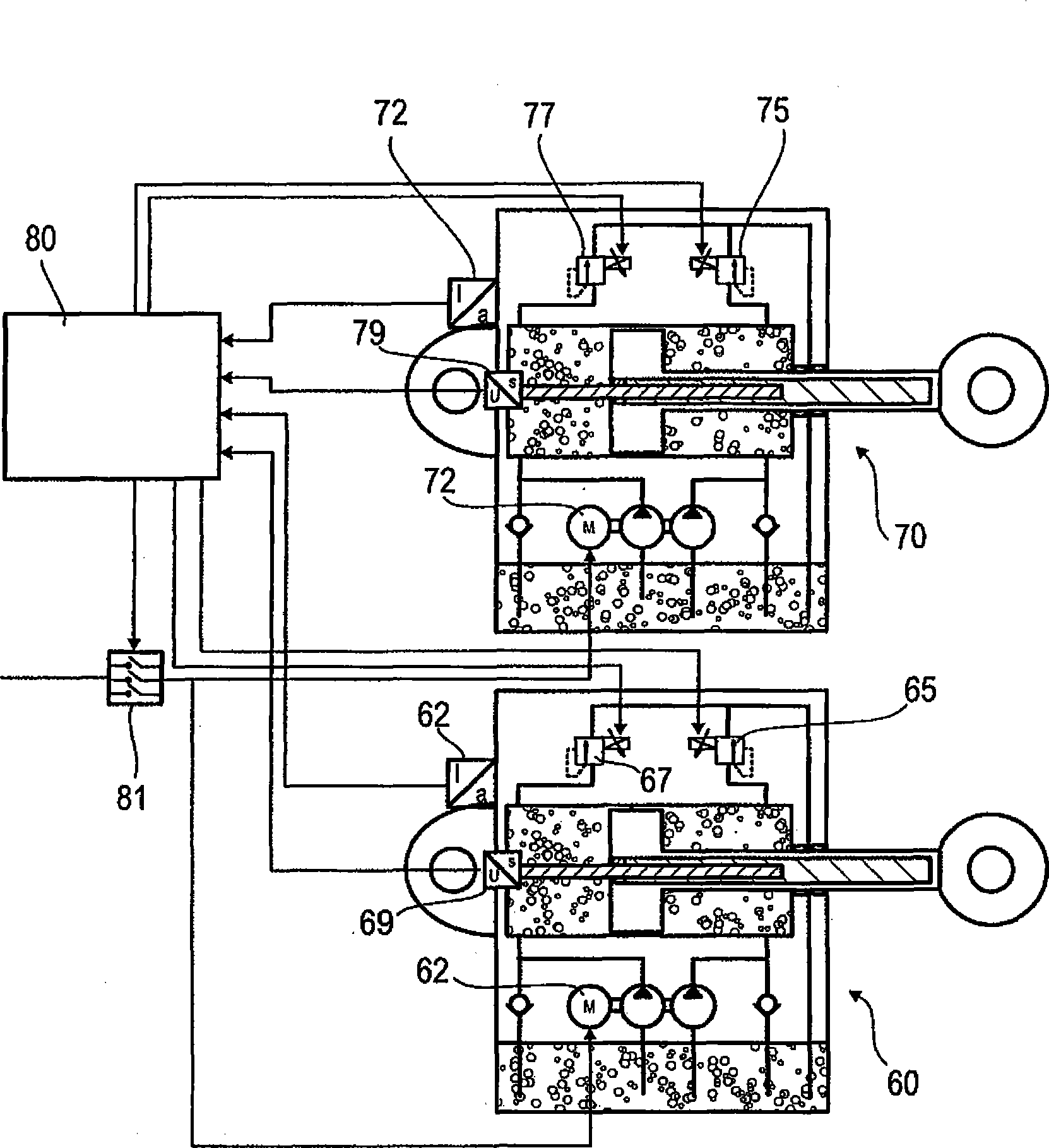

Active hydraulic damper and hydraulic actuator

ActiveCN101392809ASave packing spaceReduce weightSpringsLiquid based dampersHydraulic cylinderActuator

The invention relates to an active hydraulic damper specially for railway vehicles, comprising a hydraulic cylinder, an electric motor, a hydraulic accumulator, at least a pump and at least a control valve. According to the invention, all components of the active hydraulic damper are arranged at the hydraulic cylinder.

Owner:利勃海尔运输系统股份有限公司

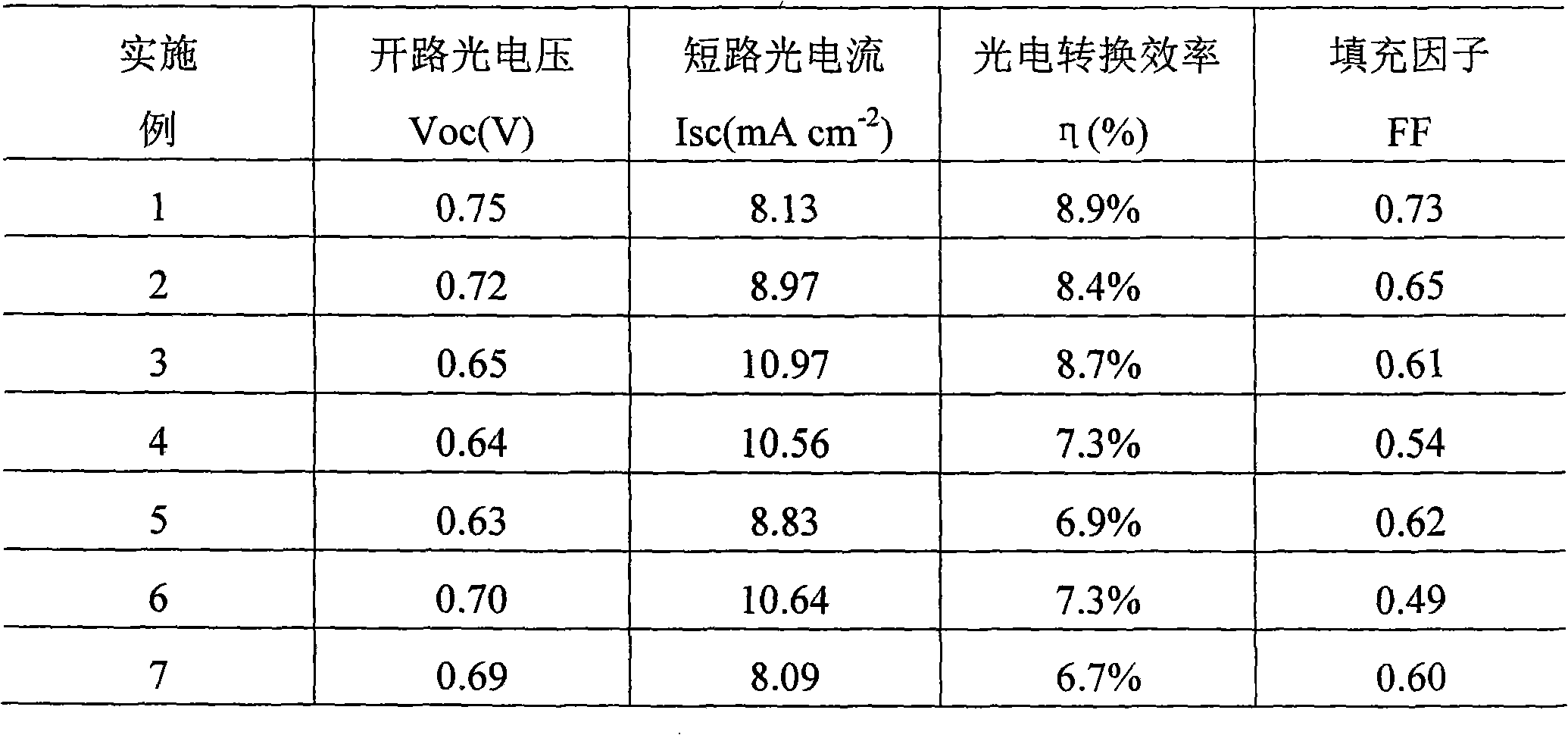

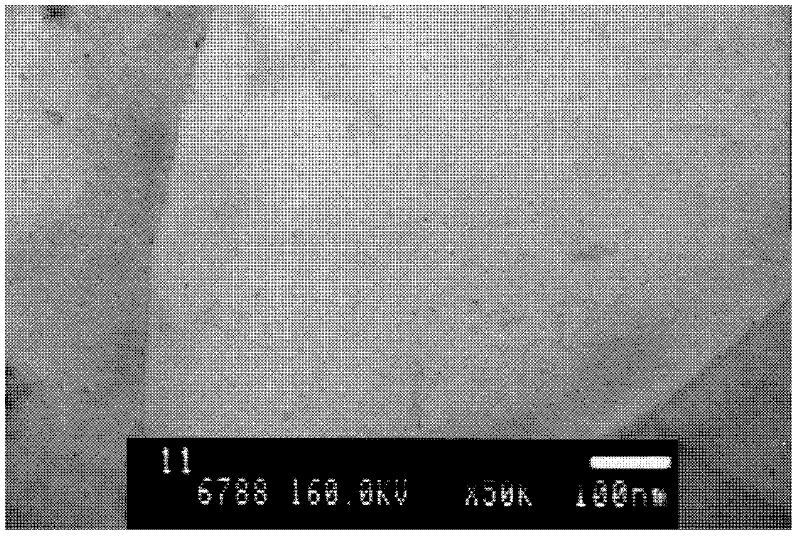

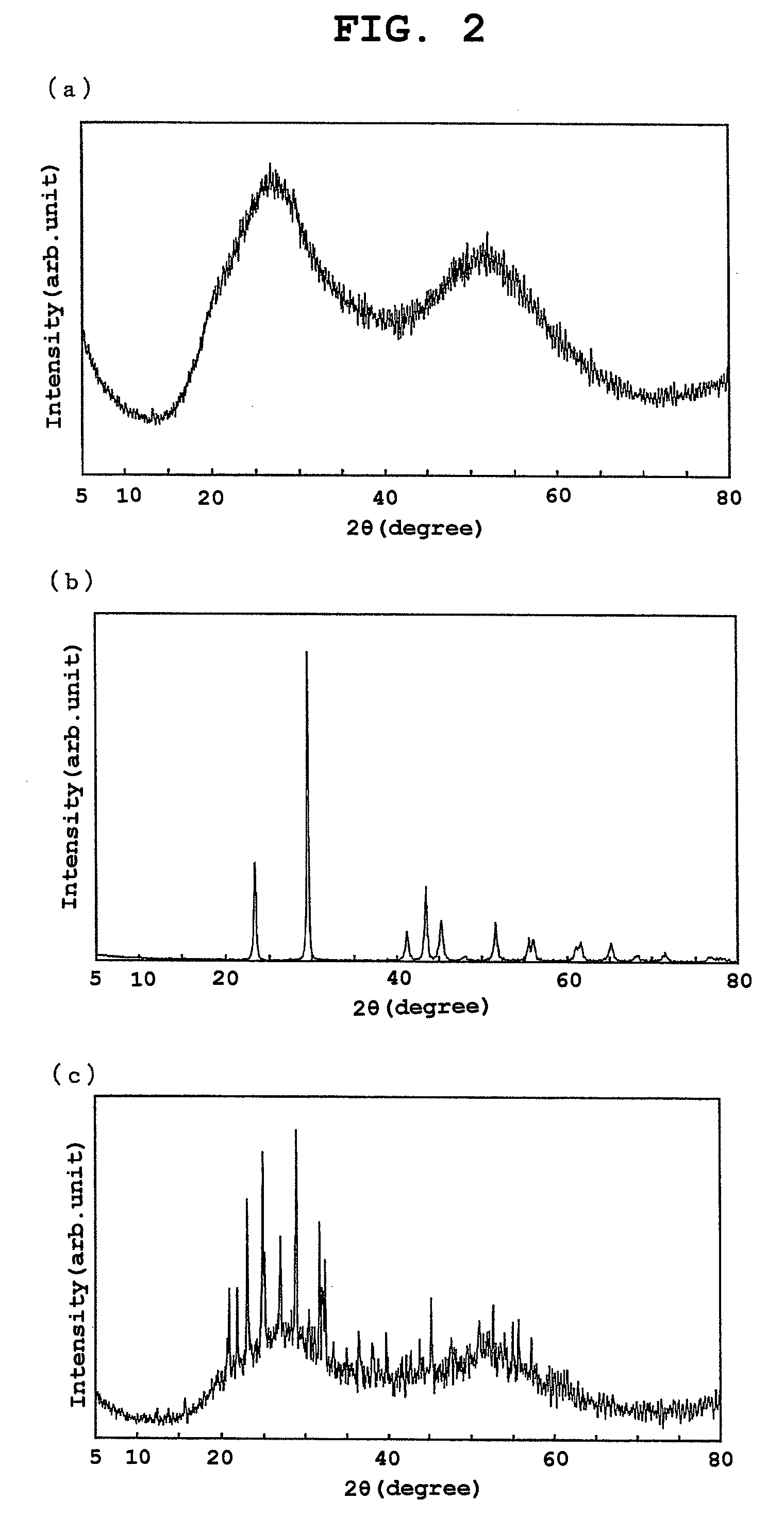

Preparing method of non-metal doped dye sensitization TiO2 nano-crystal thin film photoelectrode

InactiveCN101587779AImprove photovoltage and light absorption efficiencyImprove photoelectric conversion efficiencyElectrolytic capacitorsFinal product manufactureChemistrySensitization

The invention belongs to the preparing field of TiO2 nano-crystal thin film photoelectrode of dye sensitization solar cell, especially relates to a preparing method of non-metal doped dye sensitization TiO2 nano-crystal thin film photoelectrode which is prepared by colloids containing non-metal doped large granule TiO2 nano-crystal and non-metal doped TiO2 nano-crystal granule. The photoelectrode prepared by the invention is prepared by rotary coating the non-metal doped TiO2 colloidal sols and non-metal doped TiO2 power body slurry in order on a conductive substrate; after naturally drying, performing heat-treatment to obtain a nano-crystal thin film photoelectrode with porous structure. On one hand, the non-metal doped TiO2 nano-crystal granule changes the performance of the semiconductor, and is used as almsgiver to provide more carriers to improve the electric conductivity; on the other hand, the non-metal doped TiO2 nano-crystal granule changes the position of TiO2 energy band to improve the photovoltage and the photo absorption efficiencies. The preparing method of the invention is simple and is easy to operate, is suitable for the industrial production preparation of the dye sensitization TiO2 nano-crystal thin film photoelectrode, and also is suitable for the fields of photochemical catalysis electrode and self-cleaning glass and so on.

Owner:BEIJING UNIV OF CHEM TECH +1

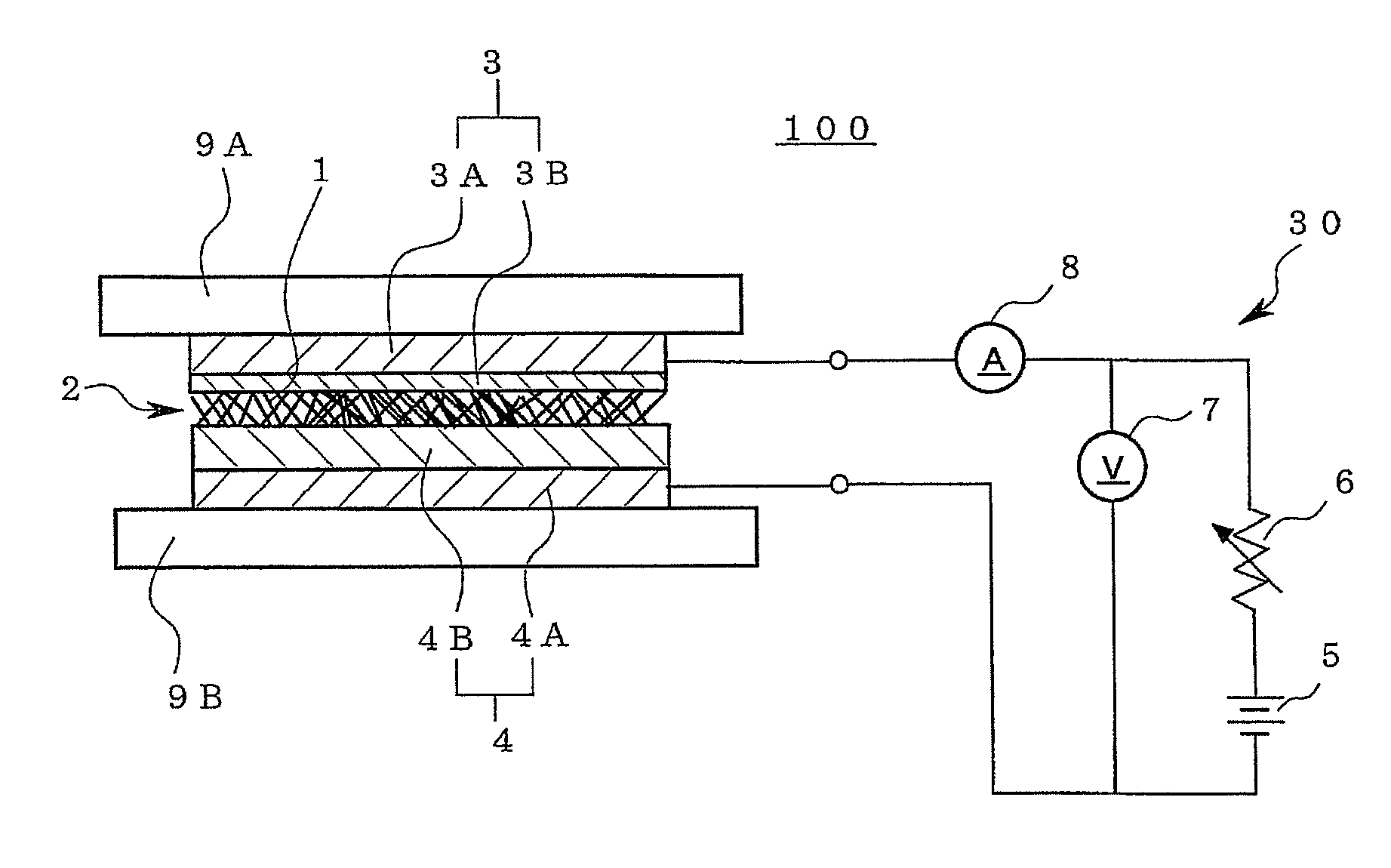

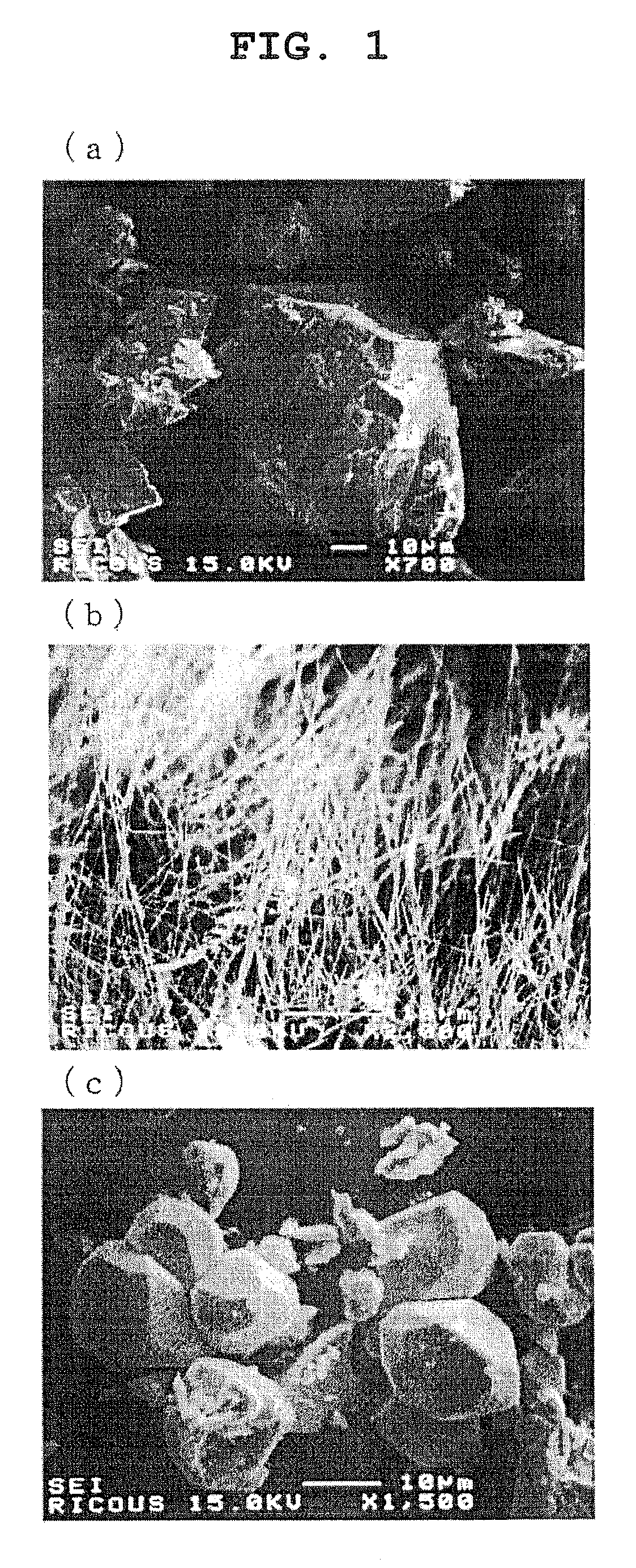

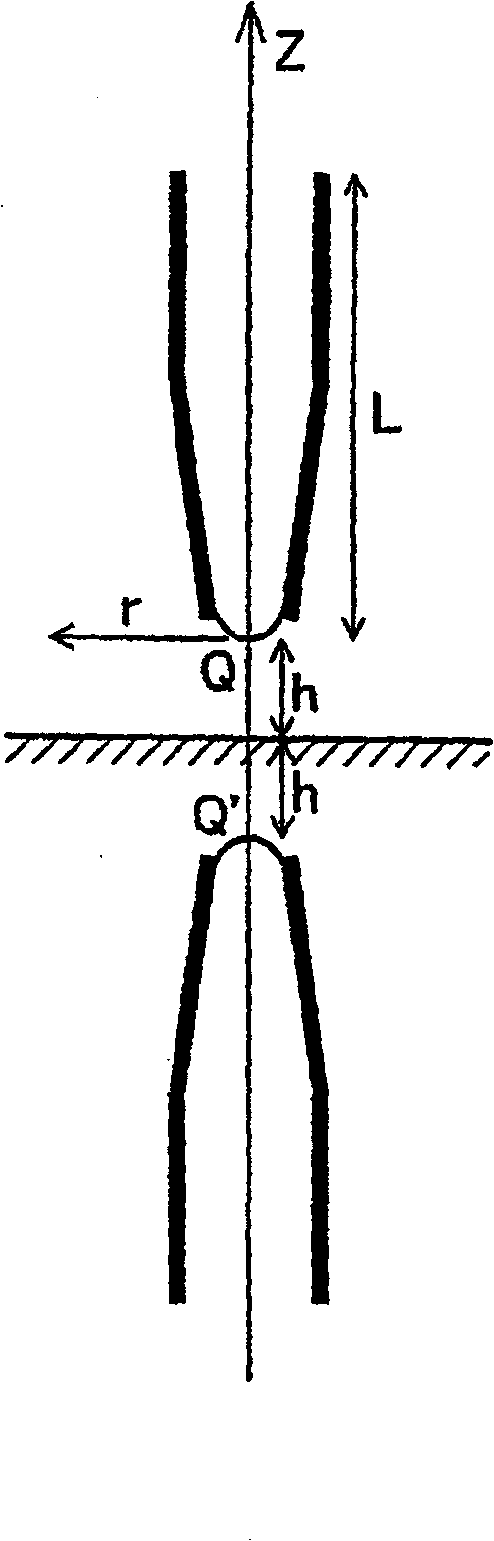

Gas sensitive material comprising microcrystalline selenium and gas sensor using same

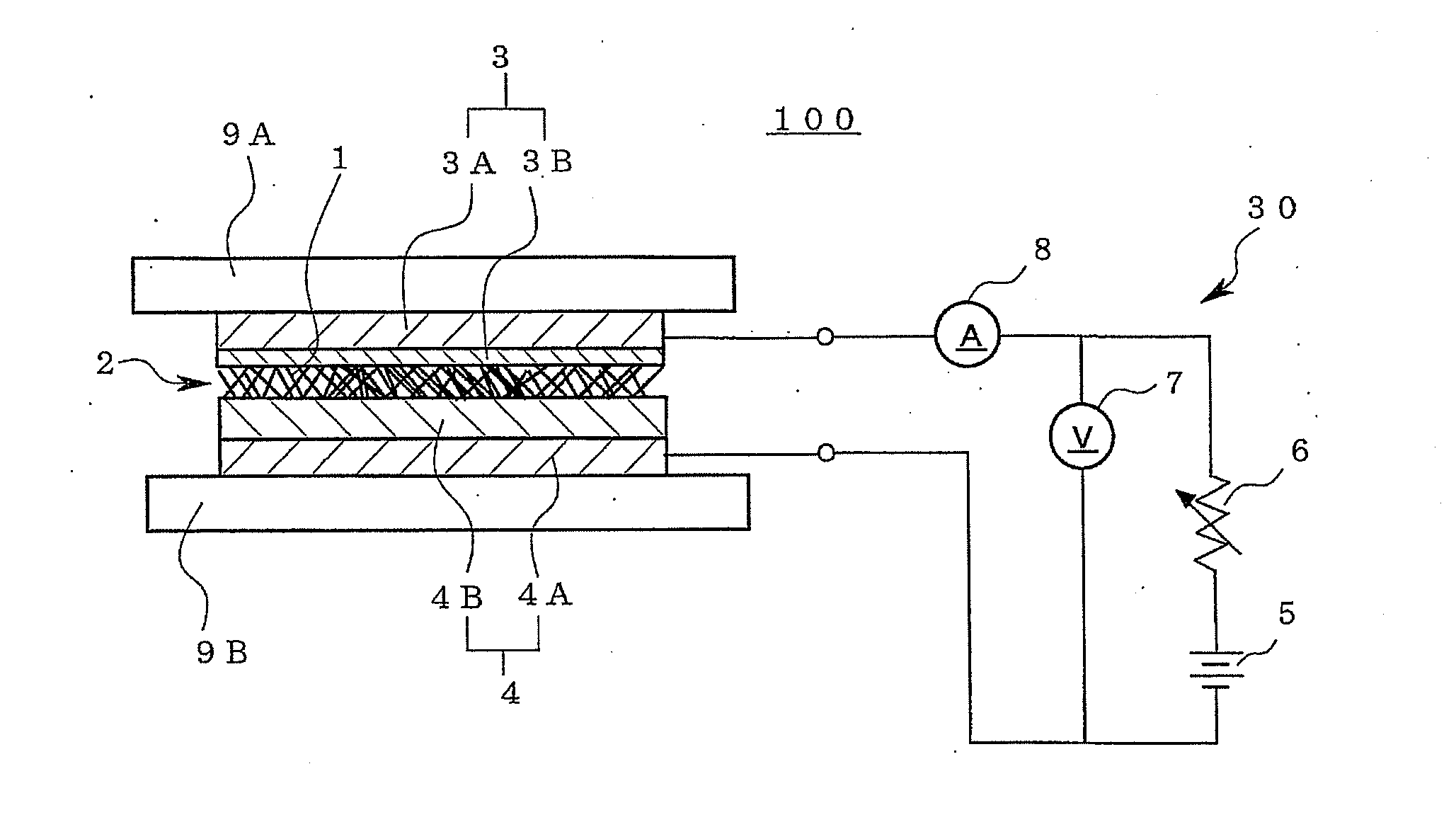

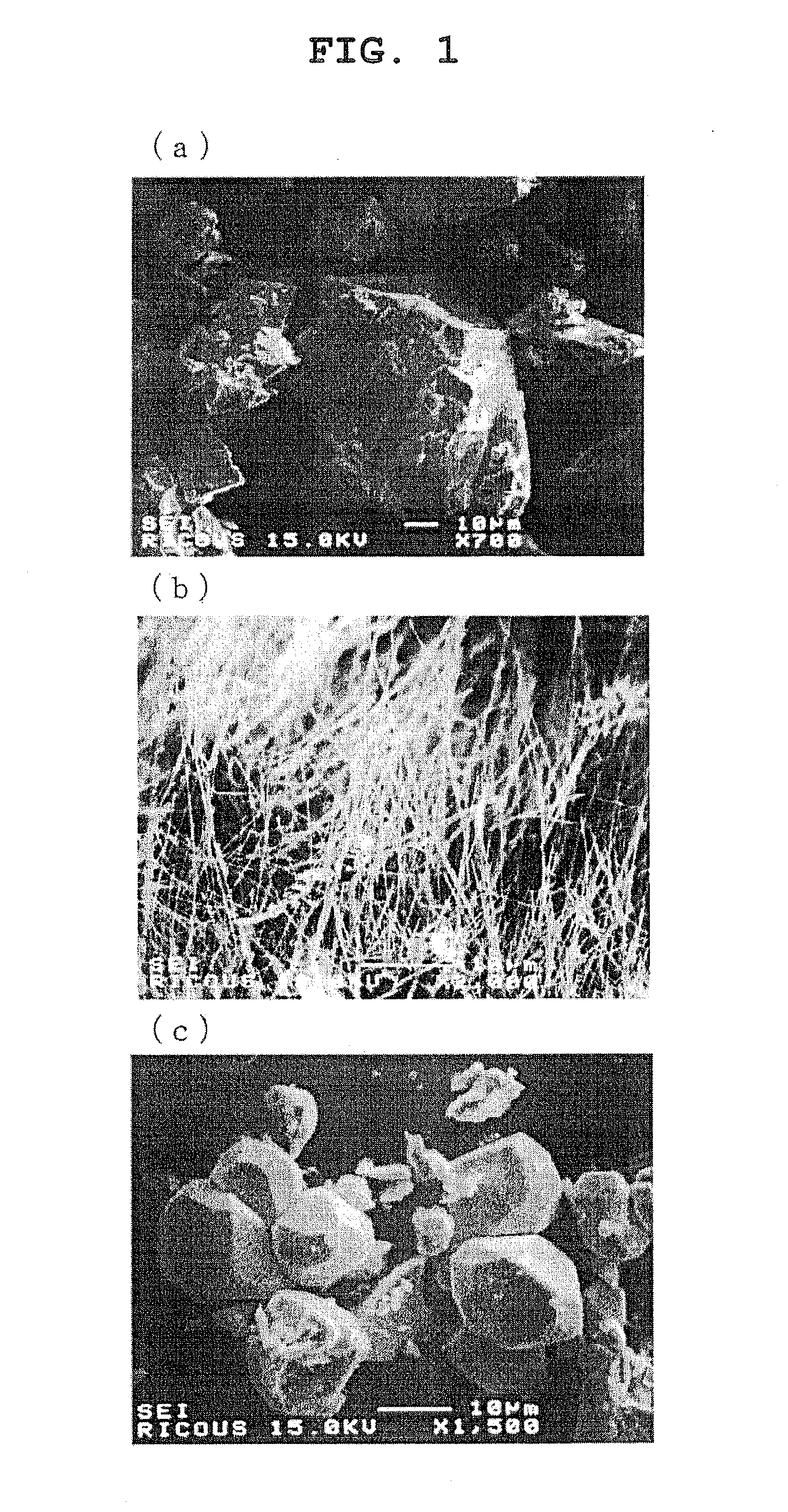

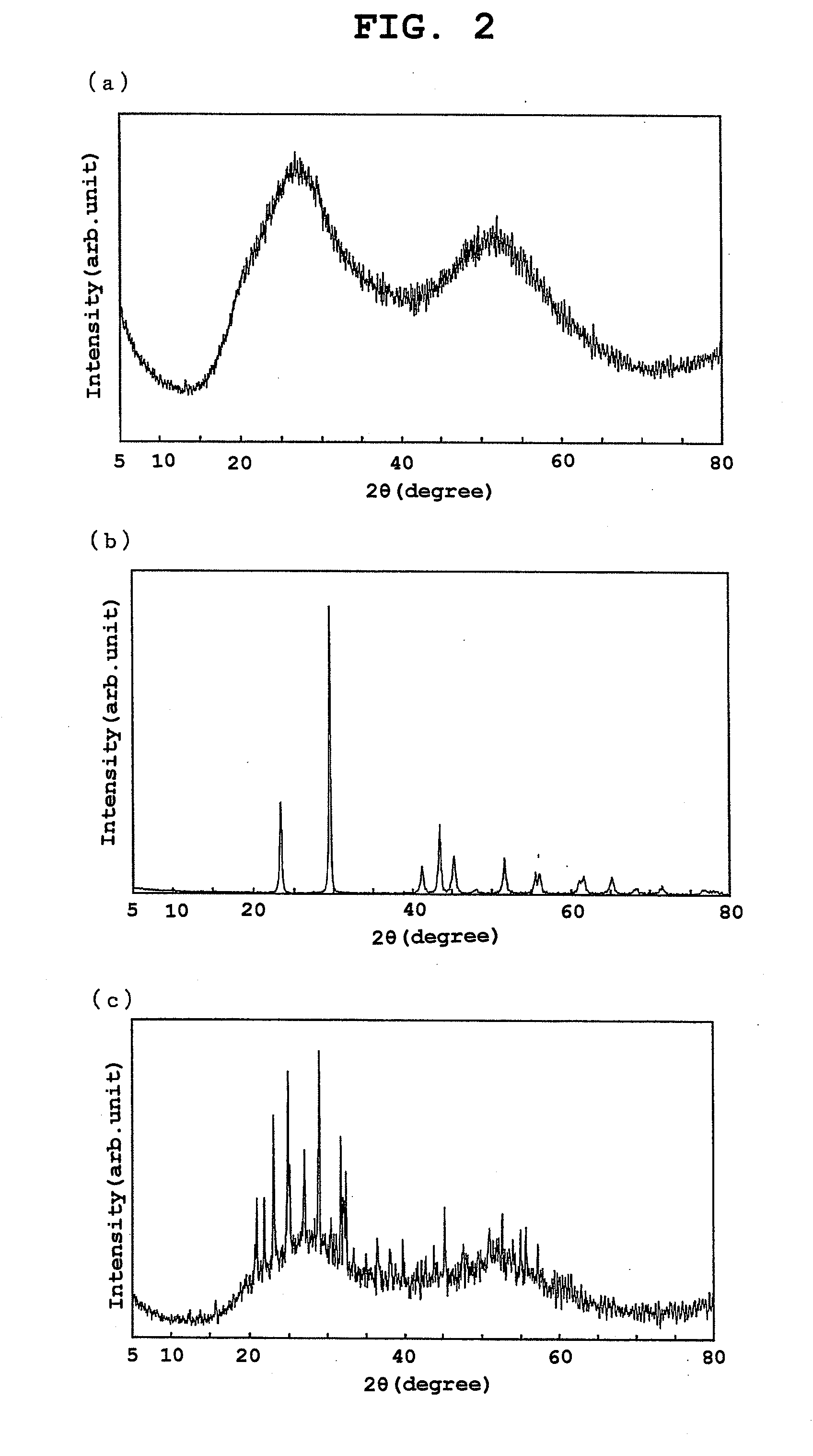

ActiveUS20120266658A1Easy to produceHigh cost advantageMaterial nanotechnologyMaterial resistanceNanowirePhysical chemistry

The invention provides a gas sensitive material made from microcrystalline selenium (preferably selenium nanowire) and a gas sensor having an element structure wherein the gas sensitive material is disposed between two electrodes. The invention allows for the kind of organic gas to be distinguished, because microcrystalline selenium reacts with organic gas molecules with high sensitivity at room temperature without being influenced by humidity, and the magnitude of change of the value of the current flowing at a fixed voltage varies depending on the kind of an organic gas to be sensed.

Owner:KAKE EDUCATIONAL INSTITUTION

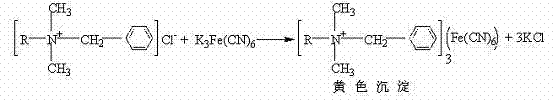

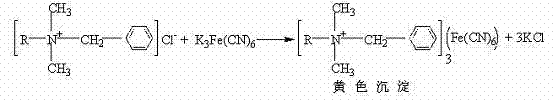

Formula and preparation method of cationic polymer

InactiveCN101817912ALow costLow market priceWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationIonic polymerizationPolymer

The invention provides a formula and a preparation method of a cationic polymer. The raw material formula of the cationic polymer comprises the following components in part by weight: water 5-50, acetone 3-25, amine 5-30, aldehyde 5-40, alkaline regulator 3-12 and acidic regulator 5-20. In the method, a water soluble cationic polymer is prepared from aldehyde, acetone and amine by a nucleophilic addition reaction, an aldol condensation reaction and a Michael addition reaction in the presence of acid and alkali catalysts in turn and by a two-step feeding process. The method has the advantages that: the raw material cost is low, the synthesis process is simple and easy to implement; the preparation conditions are mild and safe; and the obtained product has high cation content and has high decolorizing and flocculating effects on anionic dye waste water.

Owner:FUZHOU UNIV

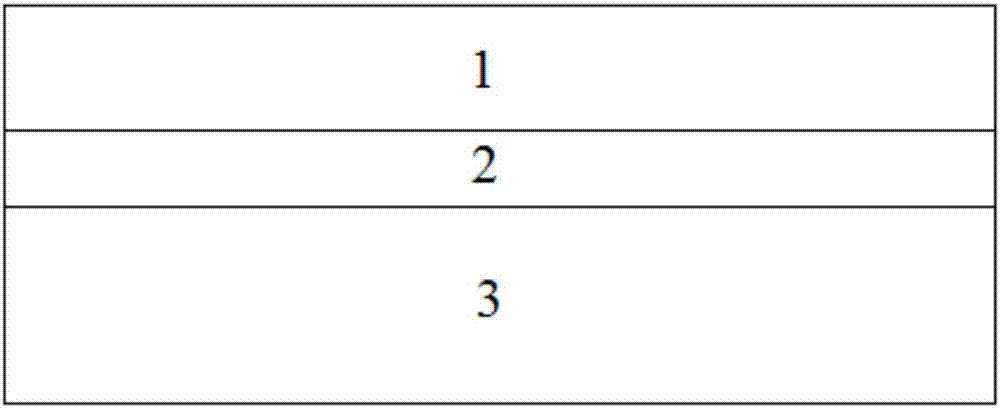

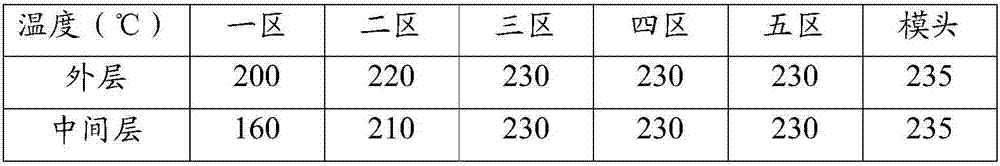

Polyvinylidene fluoride composite membrane and method for preparing same

InactiveCN107199752AImprove adhesionImprove aging resistanceSynthetic resin layered productsElectrical equipmentElastomerPolyolefin

The invention relates to a polyvinylidene fluoride composite film and a preparation method thereof, wherein the polyvinylidene fluoride composite film comprises: an outer PVDF layer, a middle layer and an inner polyolefin layer, wherein the middle layer is acrylic acid Copolymer layer or olefinic copolymer layer, wherein said acrylic acid copolymer comprises ethylene-acrylate EMA, ethylene-acrylic acid EAA, ethylene-ethyl acrylate EEA, ethylene-methacrylic acid copolymer EMAA and ethylene-methyl acrylate One or more of the copolymer EMAC; the olefinic copolymer layer is one or more of the graft-modified ethylene-vinyl acetate EVA and the graft-modified polyolefin elastomer POE. The polyvinylidene fluoride composite film and its preparation method in this invention are adopted, and the solar battery back plate prepared adopts the modified PVDF composite film, which has good bonding performance and good aging resistance effect, greatly reduces the production cost of the fluorine film, and The preparation method is simple and practical, and reduces the difficulty of compounding it with other substrates.

Owner:SHANGHAI HIUV NEW MATERIALS

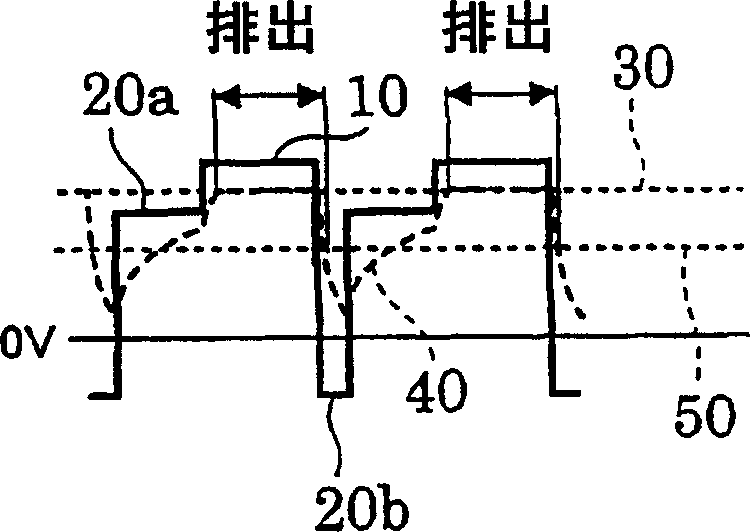

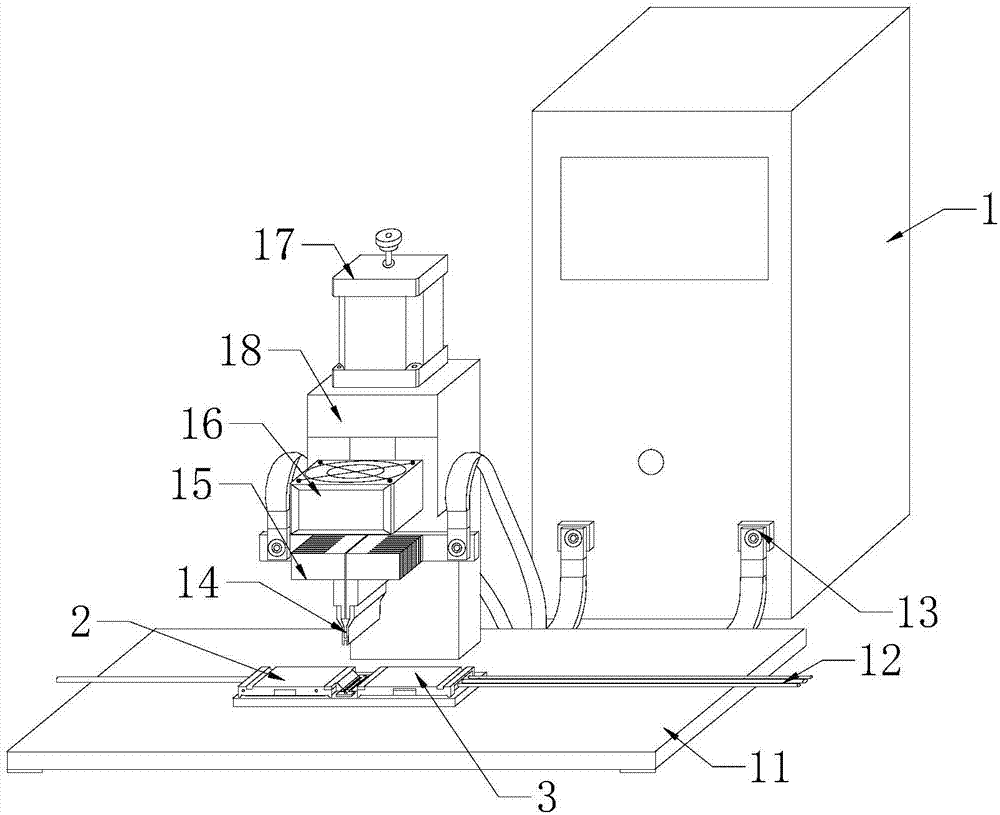

Electrostatic suction-type fluid discharging method and device

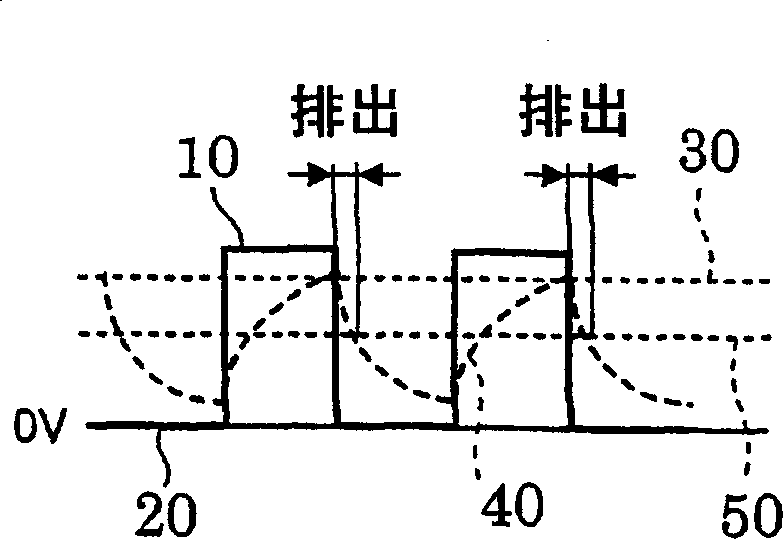

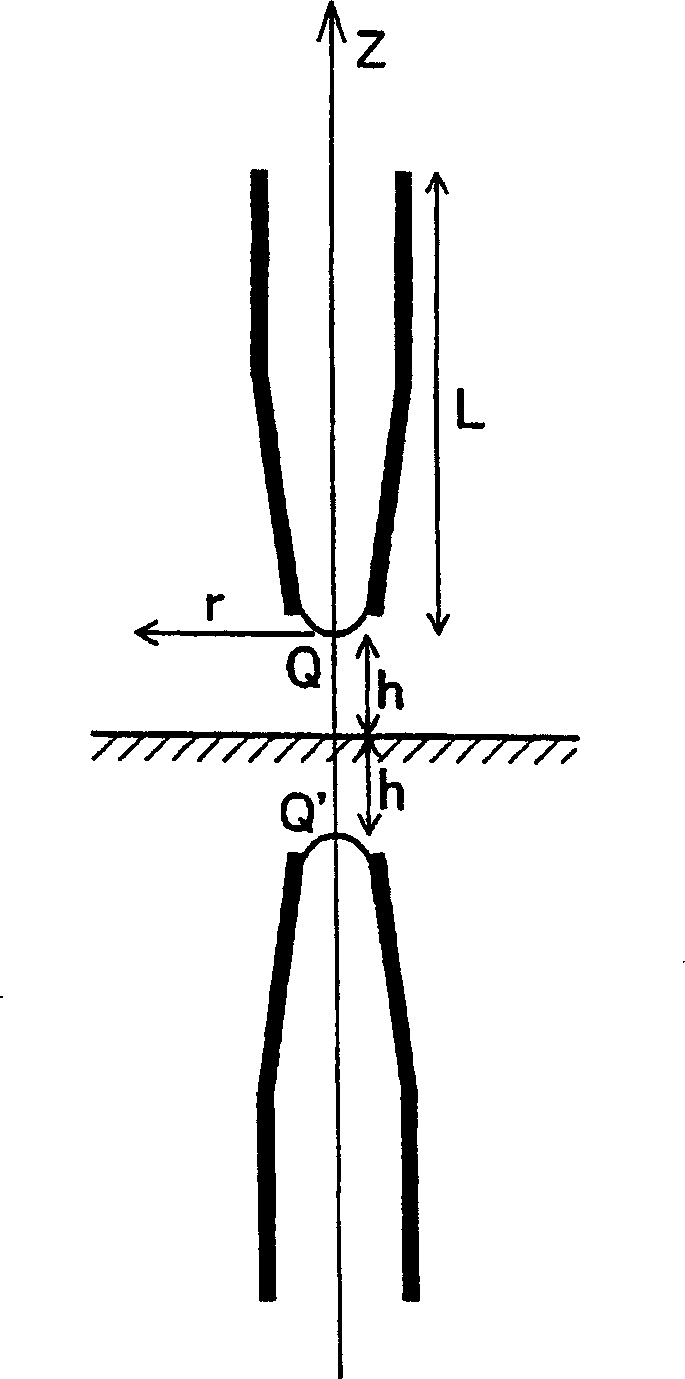

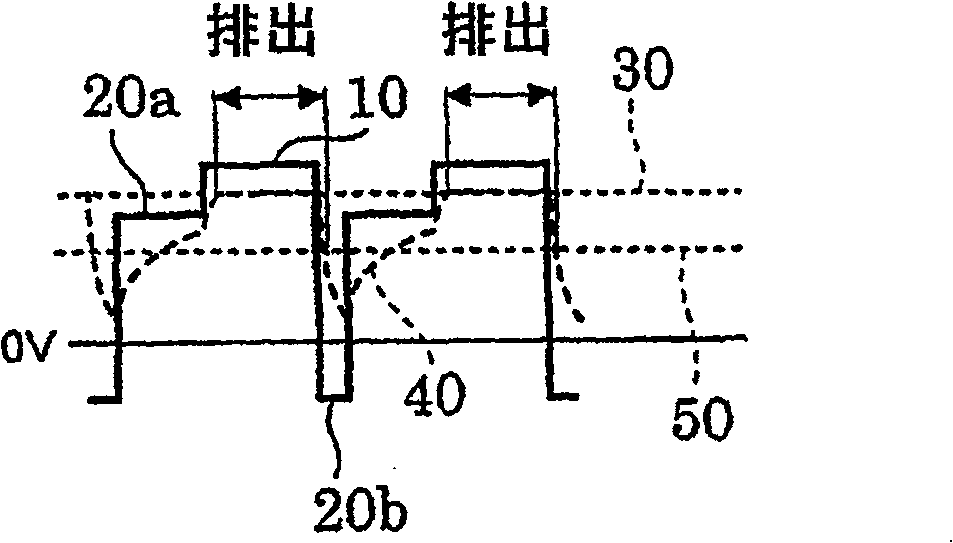

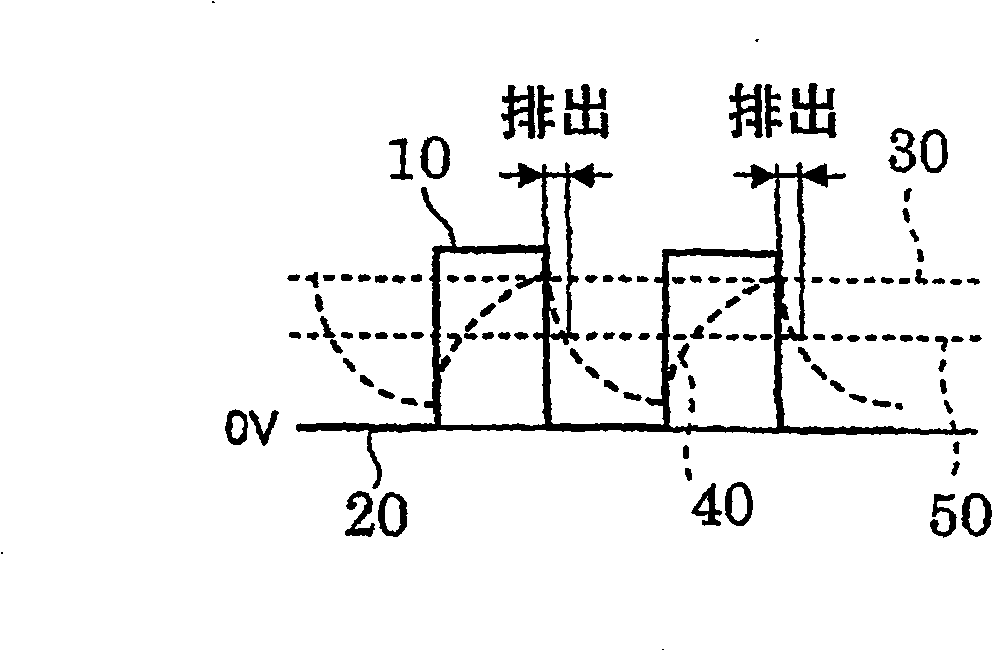

InactiveCN1849178AImprove reliabilityHigh cost advantageLiquid surface applicatorsCoatingsLower limitStart stop

The discharge hole diameter of the nozzle is 0.01 to 25 μm, and the upper limit voltage (10) set to be greater than or equal to the minimum dischargeable voltage (30) as a voltage condition for starting fluid discharge is applied between the nozzle and the substrate by a voltage applying unit the pulse voltage. Before the rising edge of the pulse voltage, set the first lower limit voltage (20a) whose polarity is the same as the upper limit voltage (10) and whose absolute value is smaller than the lowest dischargeable voltage (30), and immediately after the rising edge of the pulse voltage, set A second lower limit voltage (20b) having a polarity opposite to the upper limit voltage (10). Therefore, it is possible to provide an electrostatic attraction type fluid discharge method and device, which can achieve miniaturization of nozzles, discharge of tiny fluids, high accuracy of impact position, and low voltage of driving voltage, while improving discharge start-stop characteristics and driving frequency. And it can control the pulse time of the discharge volume.

Owner:NAT INST OF ADVANCED IND SCI & TECH

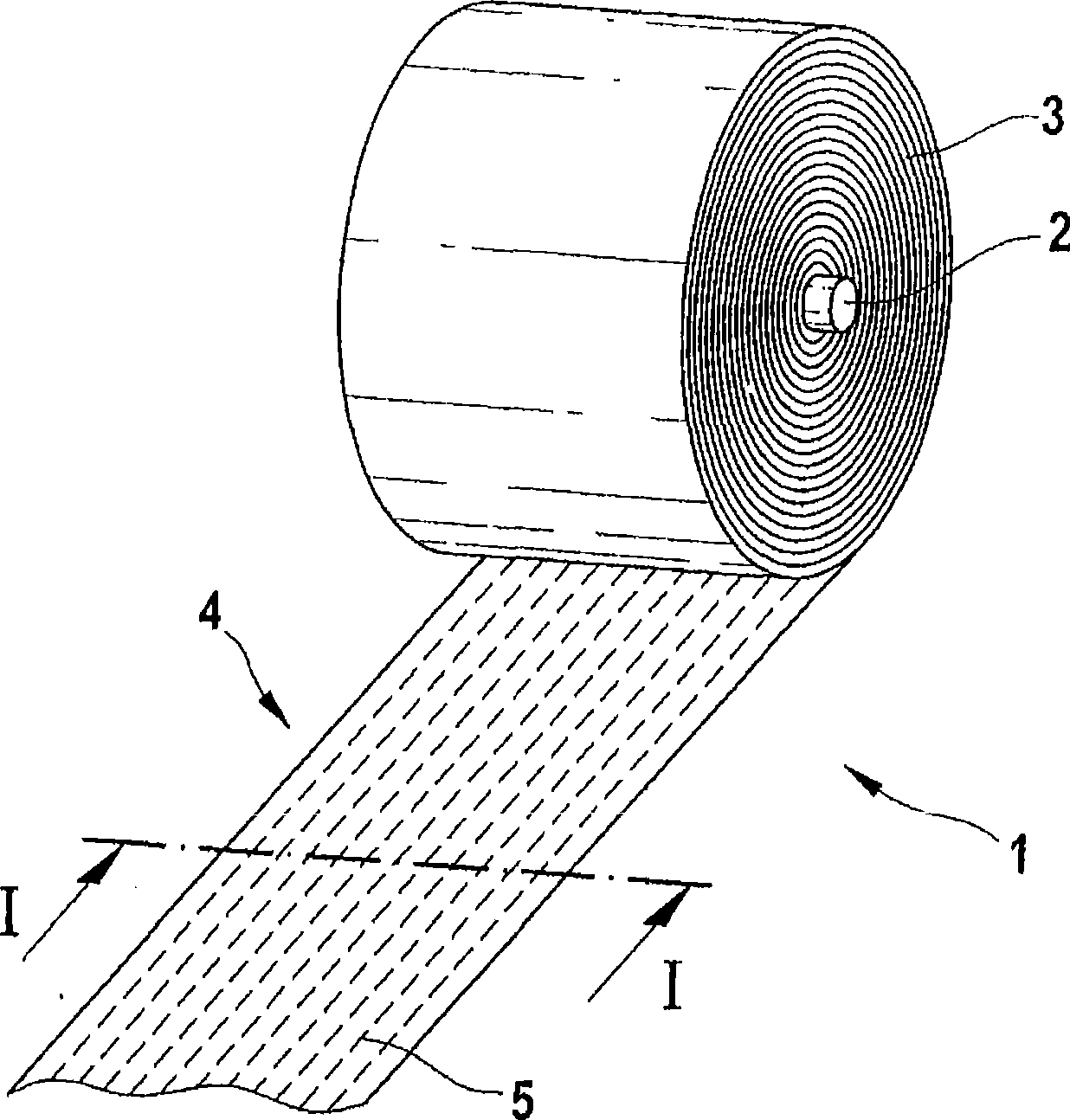

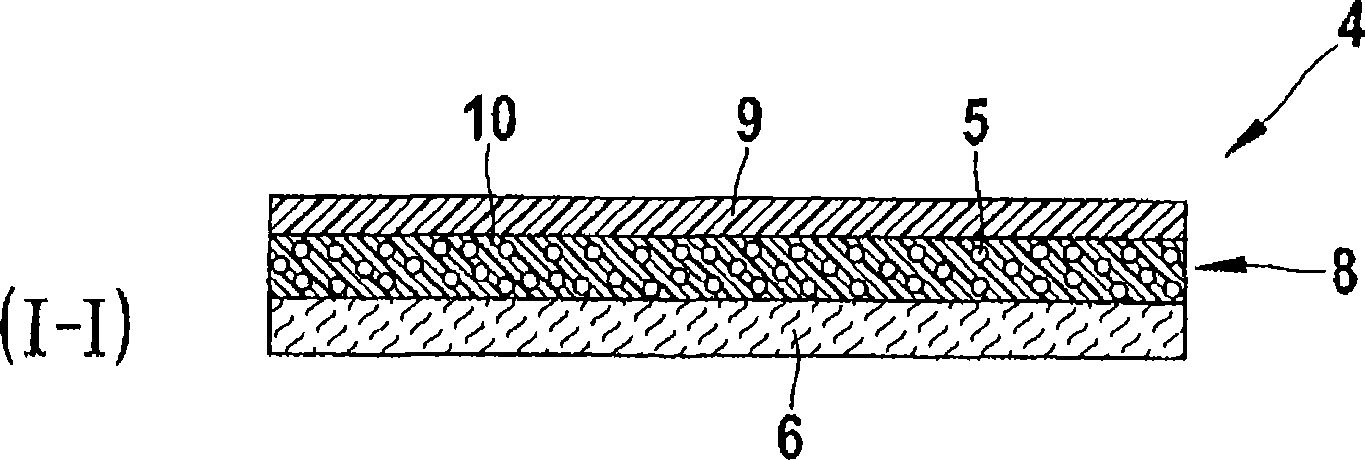

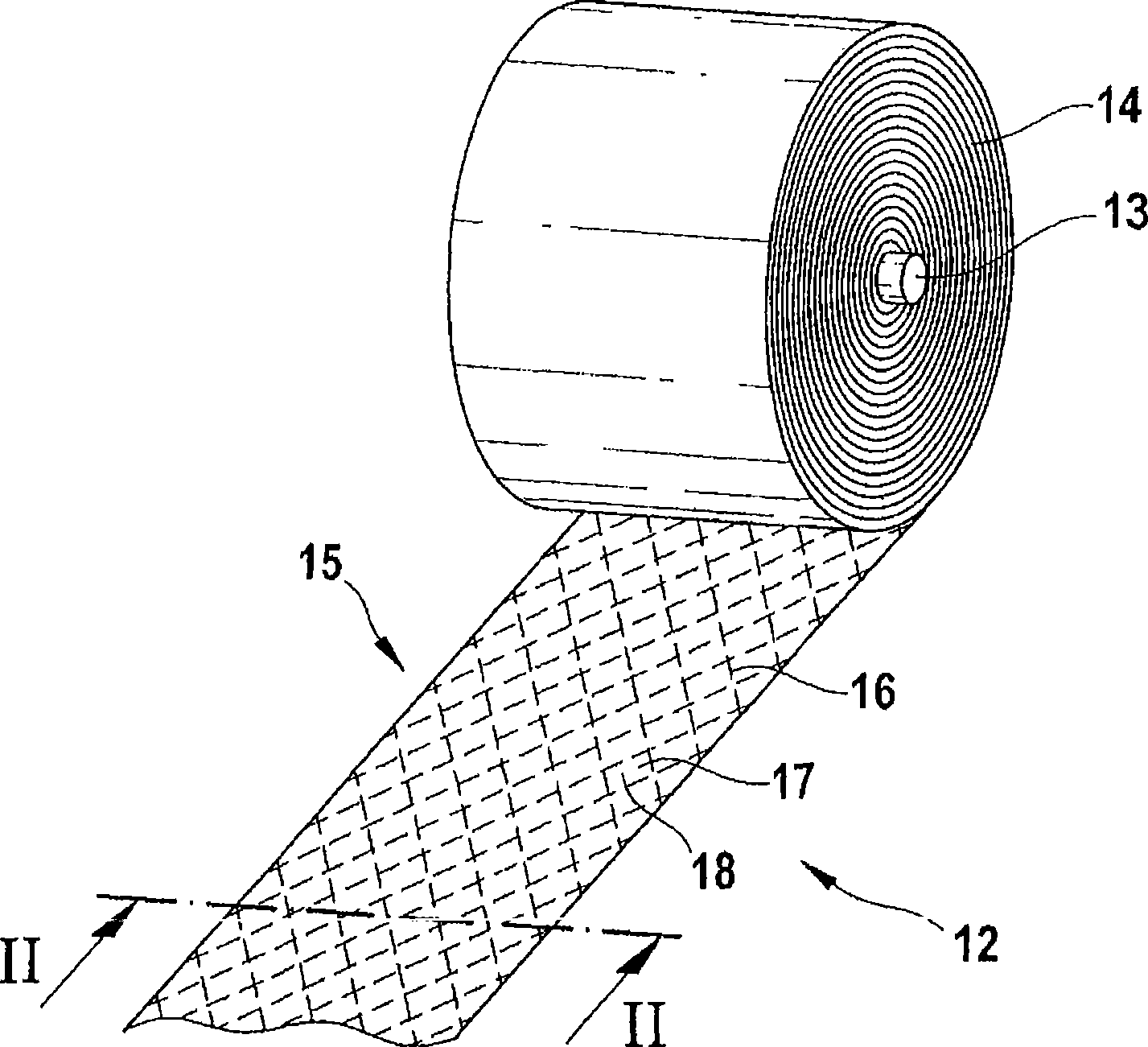

Lay-up arrangement and structural arrangement and method for producing a component for aerospace

ActiveCN101500796ALow costHigh cost advantageAircraft lighting protectorsSynthetic resin layered productsGlass fiberResin matrix

The invention provides a method for producing a component for aerospace, with the following method steps: supplying a lay-up arrangement (1) to be laid by means of a tape-laying machine (25), with a glass-fibre lay-up (8), which is preimpregnated with a resin matrix, and / or supplying a structural arrangement (12) to be laid by means of a tape-laying machine (25), with a structure (16) which is made of metal and is preimpregnated with a resin matrix, laying the lay-up and / or structural arrangement (1; 12) on a laminating apparatus (23) by means of a tape-laying machine (25), and curing the lay-up and / or structural arrangement (1; 12) and therefore forming the component (37).

Owner:AIRBUS OPERATIONS GMBH

Flame-proof glass fibre reinforced polycarbonate material and method for making same

The present invention discloses one kind of fire retardant glass fiber reinforced polycarbonate material and its preparation process. The fire retardant glass fiber reinforced polycarbonate material is prepared with polycarbonate 10-80 wt%, polycarbonate / catalyst 8-40 wt%, bromide fire retardant 2-10 wt%, toughening agent 4-10 wt%, antioxidant 0.1-1 wt%, lubricant 0.1-5 wt% and glass fiber 5-30 wt%. The addition of the catalyst makes the stable polycarbonate produce chemically active end hydroxyl radical and end carbonyl radical to enhance the compatibility between polycarbonate and long glass fiber. The product of the fire retardant glass fiber reinforced polycarbonate material has high surface smoothness and no floated glass fiber.

Owner:SHENZHEN KEJU NEW MATERIAL

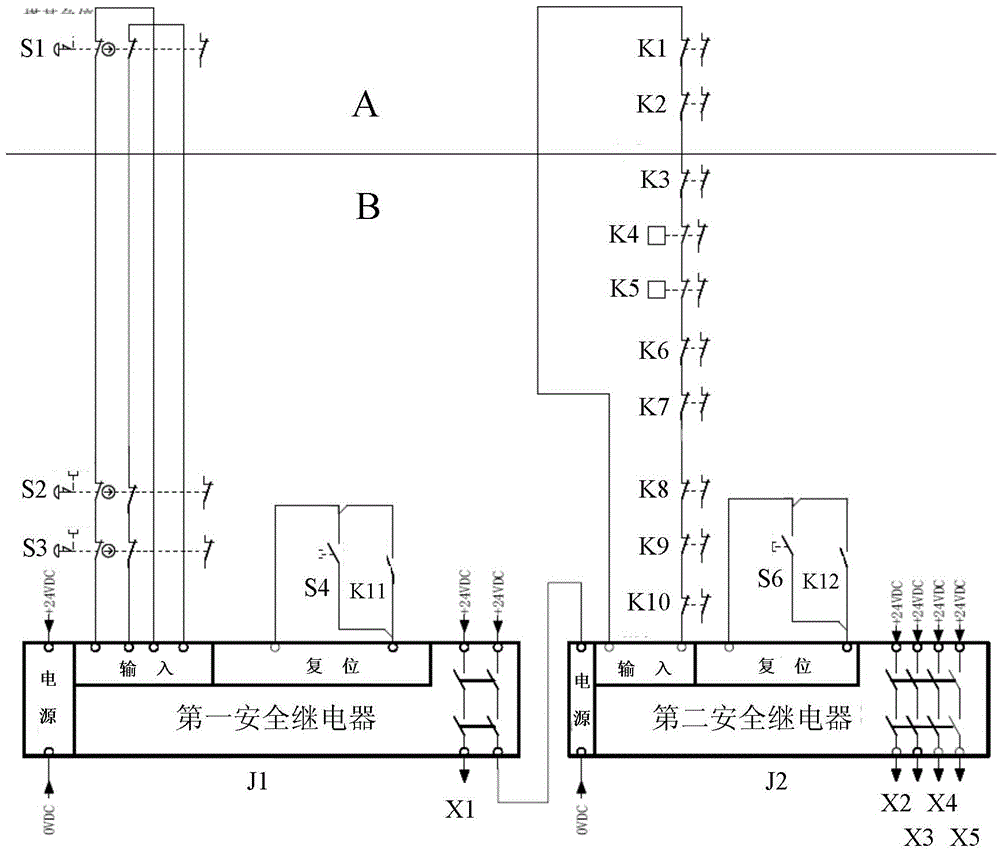

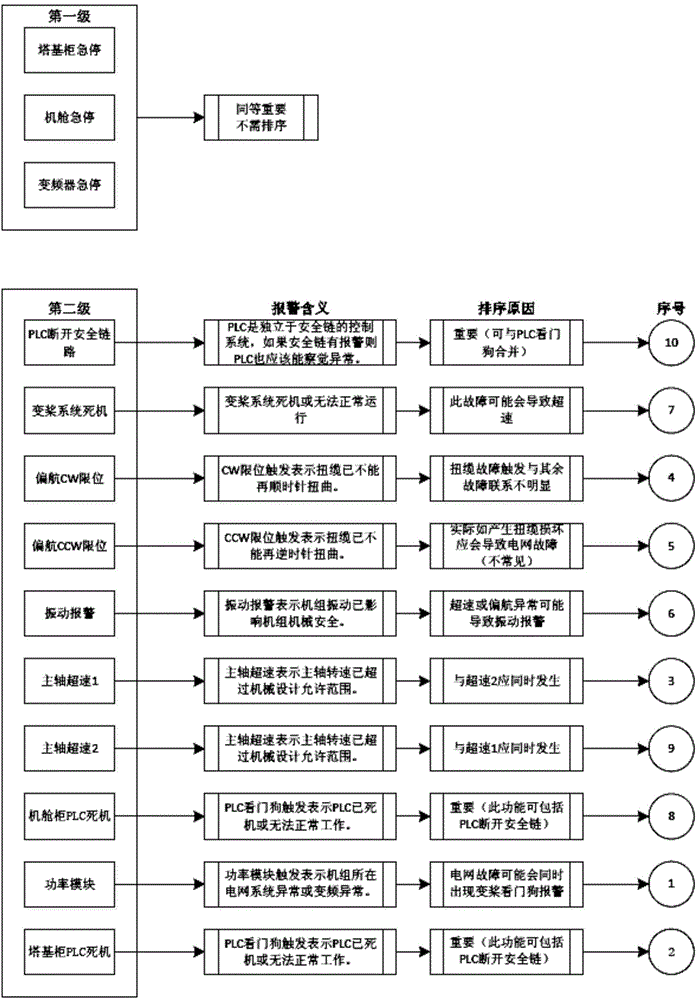

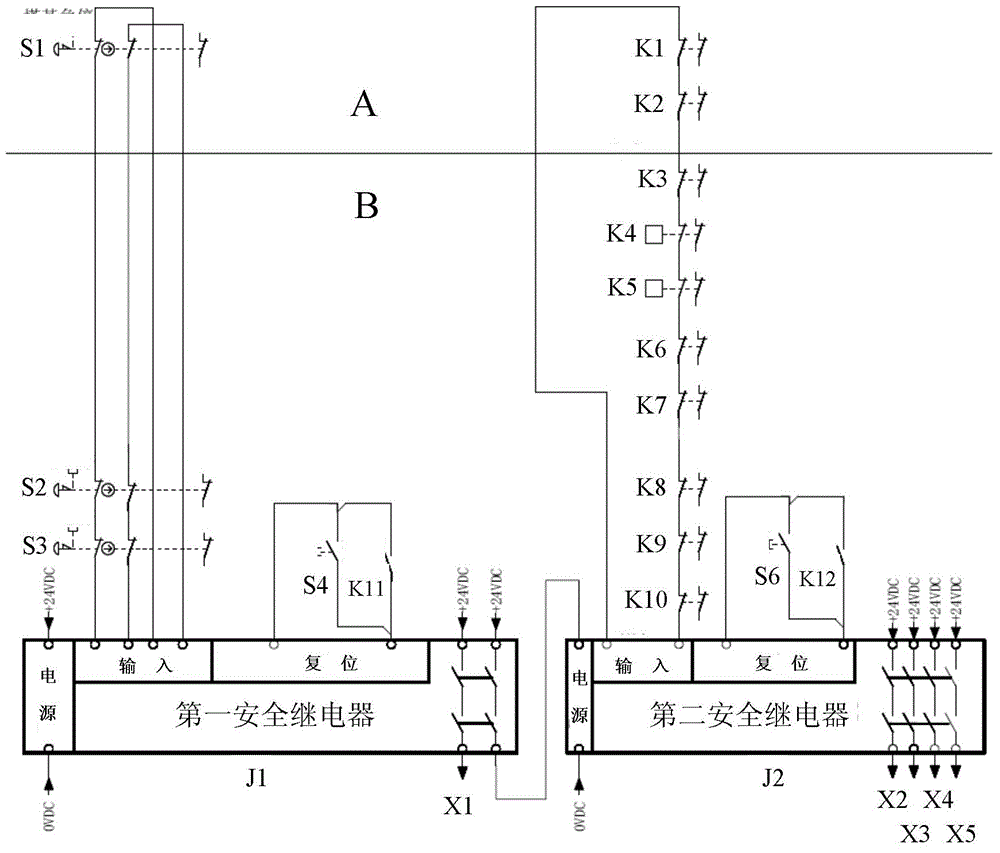

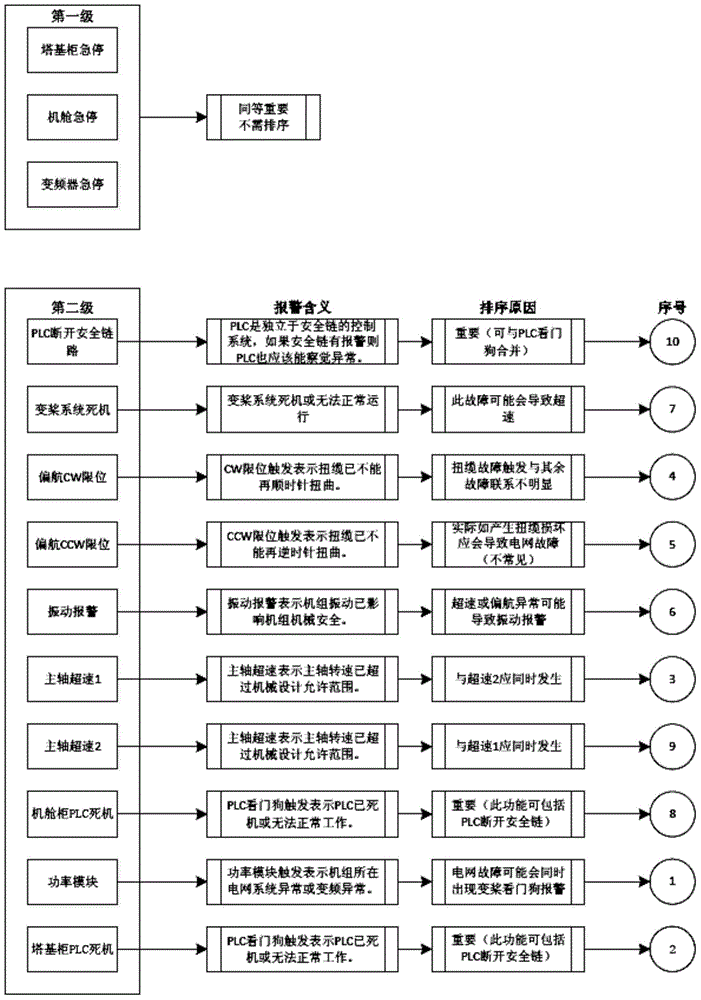

Hard-wire constructed safety protection device of wind generating set

ActiveCN103557116AEnsure safetyEasy diagnosisWind motor controlEnergy industryControl systemProgrammable logic controller

The invention relates to a hard-wire constructed safety protection device of a wind generating set. According to the technical solution, the safety protection device is mainly composed of a first safety relay and a second safety relay, and input, output and reset of the safety protection device completely depend on hard wires to be connected to the two safety relays special for safety loops in a cabin cabinet so that the whole safety protection device is divided into two levels, the function and a control loop of the safety protection device are completely separated from a programmable logic controller (PLC) control system, safety of a unit can be still guaranteed in the condition of dead halt of a PLC, communication interruption or failure to normally operate, and the safety protection device has a fail-safe function; signals from each input contact and each output contact of the safety protection device are simultaneously input into the PLC in a mode of independent switching value digital signals, so that fault points of the unit can be conveniently diagnosed, requirements for PLC factories and types are absent, and the universality is high; only the two safety relays, signal cables and a plurality of auxiliary contacts are added, and the advantage of low costs is achieved.

Owner:天津瑞源电气有限公司

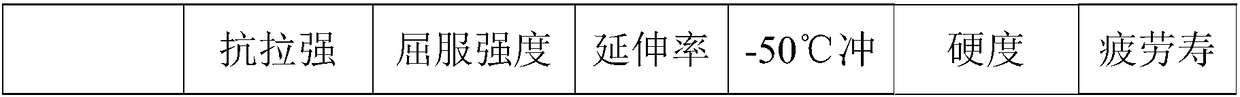

Steel for superhigh-strength hot rolling automobile structure and preparation method thereof

The invention relates to steel for a superhigh-strength hot rolling automobile structure and a preparation method thereof, belonging to the field of alloy steel production processes. The steel comprises the following components: 0.08 percent to 0.12 percent of carbon, 0.10 percent to 0.50 percent of silicon, 1.5 percent to 2.50 percent of manganese, less than 0.02 percent of phosphorus, less than 0.01 percent of sulfur, 0.02 percent to 0.05 percent of aluminum, 0.08 to 0.25 percent of vanadium, 0.03 percent to 0.06 percent of nitrogen and the balance of Fe and other inevitable impurities. The production process comprises the following steps of: converter smelting; external refining; continuous casting; hot rolling and reeling. The main process parameters are as follows: the heating temperature of continuous casting slabs is between 1,150 and 1,220 DEG C, the reeling temperature is between 500 and 650 DEG C, and the hot rolling total reduction ratio is more than 85 percent. According to the steel, vanadium-nitride micro alloying is adopted, vanadium precipitation is promoted by enhancing nitrogen, grains are refined, and precipitation strengthening and fine-grain strengthening are used as main strengthening measures, so that the yield strength is more than 700 MPa, the tensile strength is more than 800 MPa, the total elongation rate after fracture is more than percent, and the steel is used for high-strength automobile structures with high plasticity and good cold bending properties.

Owner:UNIV OF SCI & TECH BEIJING +1

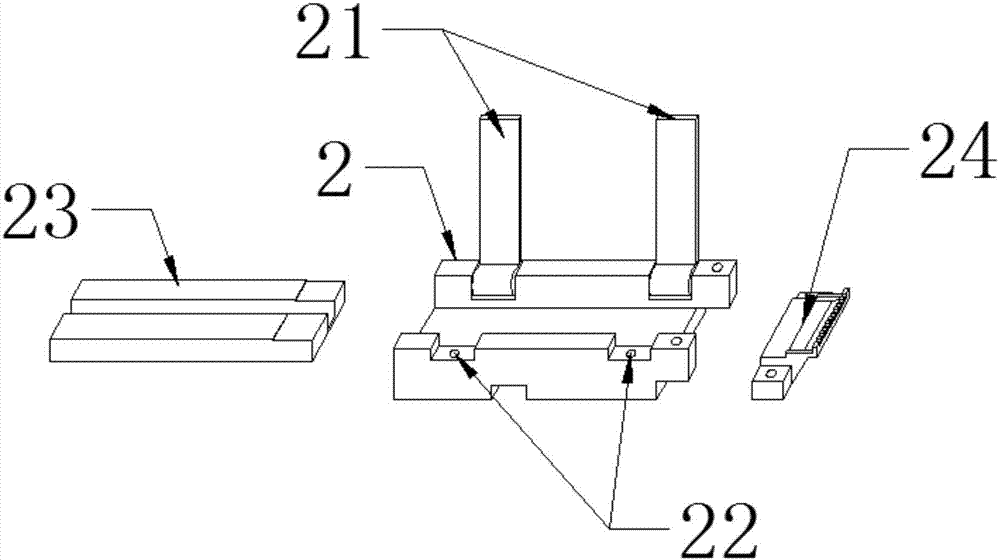

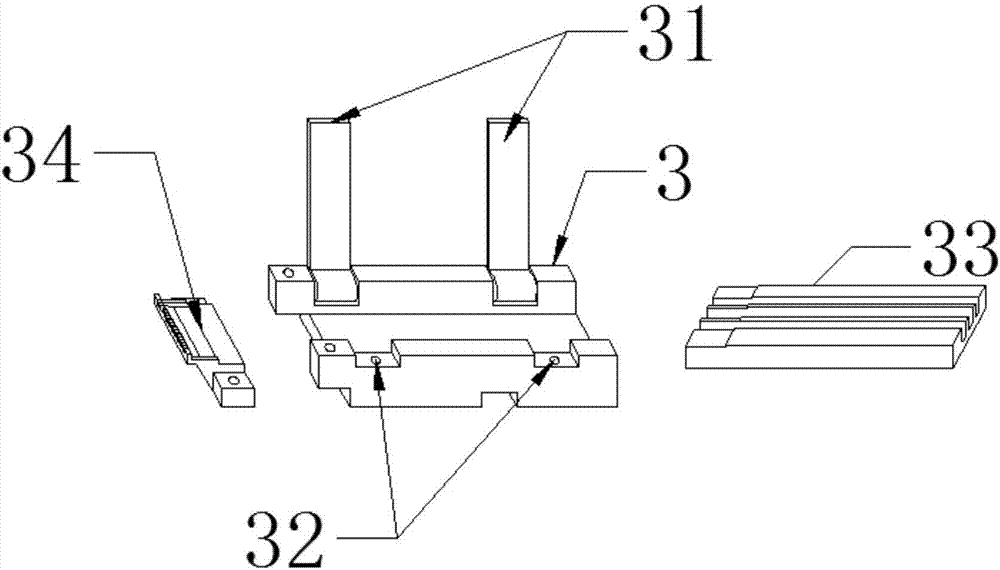

Automatic combined wire welding equipment and welding method thereof

PendingCN107096975AConnector Size ShortImprove the excellent rateConductorsSoldering ironEngineeringHeat spreader

The invention provides automatic combined wire welding equipment. The equipment comprises a main case, a left wire arranging jig and a right wire arranging jig, wherein a welding machine base is arranged at the front end of the main case; welding machine power supply electrodes are arranged on the front surface of the main case; the main case is connected with a welding structure through the welding machine power supply electrodes; the welding structure comprises a welding head with double rows of knives, an electrode radiator, a cooling fan, a stepping moving motor and a welding machine rail running mechanism; the stepping moving motor is arranged above the welding machine rail running mechanism; the welding head with double rows of knives is arranged at the front side of the welding machine rail running mechanism; the electrode radiator is arranged on the top of the welding head with double rows of knives; and the cooling fan is arranged on the top of the electrode radiator. The equipment provided by the invention has the following beneficial effects that joint size is short, so that the requirements for SR appearance and wire end fixing are met; the space between the wires is fixed and the wires are uncrossed, so that the high-frequency characteristic is stable and good; and the wire welding operation is standard and easy to learn.

Owner:惠州市升华科技有限公司

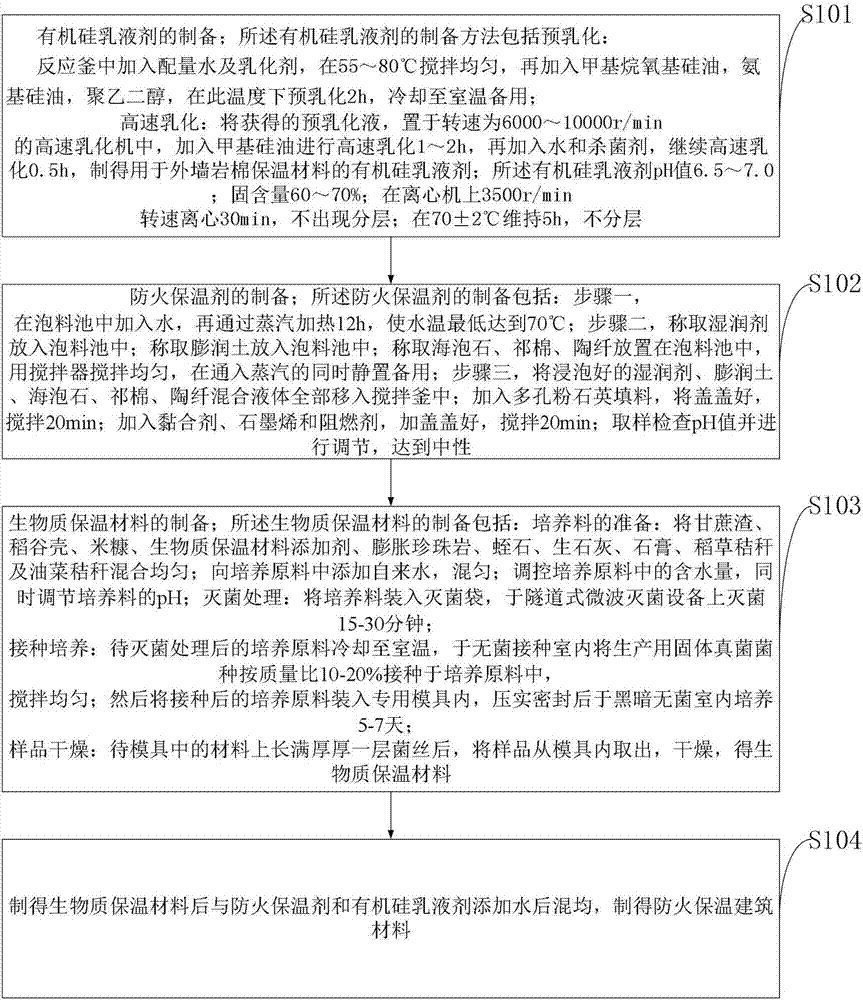

Fireproof heat insulation building material and preparation method thereof

The invention discloses a fireproof heat insulation building material and a preparation method thereof. The fireproof heat insulation building material comprises, by weight, 20-30 parts of expanded perlite, 9-15 parts of blast furnace slag, 15-20 parts of clay, 3-10 parts of dolomite powder, 5-18 parts of rubber, 7-18 parts of plant fiber powder, 4-10 parts of aluminum silicate fiber cotton, 10-17 parts of flame retardants, 2-15 parts of color master batches and 2-13 parts of auxiliary raw materials. The fireproof heat insulation building material has good effects of insulating heat and retarding flame, fire resistance of the building material is improved, energy storing and temperature adjusting functions of the material are achieved, indoor heat loss is prevented, and the heat insulation material takes the expanded perlite as a main raw material, so that the heat insulation material has the advantages that the material is light in apparent density, low in heat conductivity coefficient, good in chemical stability and free from toxicity and taste. The flame retardants of the building material are tetrabromobisphenol A which is one of flame retardant products subjected to the most scientific tests on the market and with the highest cost advantages.

Owner:合肥市晨雷思建筑材料科技有限公司

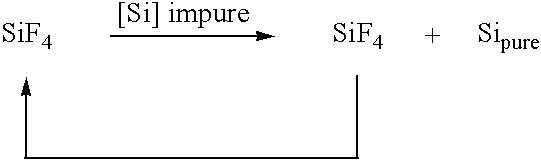

Method for producing halosilanes by impinging microwave energy

InactiveUS7265235B2Reduce energy inputHigh selectivitySilicon organic compoundsHalogenated silanesMicrowaveHalogen

Silanes containing halogen which is bound to silicon are prepared using microwave energy. Silicon is reacted with mixtures of elements or compounds selected from the group consisting of halogen or halogen and organohalogen compounds or halogen and hydrogen or halogen and halogen hydrogen or organohalogen compounds or organohalogen compounds and hydrogen or organohalogen compounds and halogen hydrogen or halogen hydrogen or fluorosilanes and hydrogen, or fluorosilanes and halogen hydrogen or hydrogen containing chlorosilanes and hydrogen or hydrogen containing chlorosilanes and halogen hydrogen or organohalogensilanes and hydrogen or organohalogensilanes and halogen hydrogen or hydro-carbons and halogen hydro-carbons.

Owner:WACKER CHEM GMBH

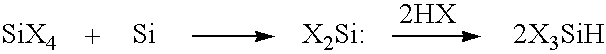

Gas sensitive material comprising microcrystalline selenium and gas sensor using same

InactiveUS9134265B2Easy to produceHigh cost advantageMaterial resistanceElemental selenium/telluriumNanowireRoom temperature

The invention provides a gas sensitive material made from microcrystalline selenium (preferably selenium nanowire) and a gas sensor having an element structure wherein the gas sensitive material is disposed between two electrodes.The invention allows for the kind of organic gas to be distinguished, because microcrystalline selenium reacts with organic gas molecules with high sensitivity at room temperature without being influenced by humidity, and the magnitude of change of the value of the current flowing at a fixed voltage varies depending on the kind of an organic gas to be sensed.

Owner:KAKE EDUCATIONAL INSTITUTION

Semitransparent closed solvent-free epoxy prime coat compound

ActiveCN113462261AGood cross-cut performanceGood adhesionEpoxy resin coatingsCalcium silicatePolymer science

The invention discloses a semitransparent closed type solvent-free epoxy prime coat compound. The component A of the compound is composed of epoxy resin, a bifunctional reactive diluent, crystalline silicon micro-powder and an auxiliary agent, and the component B is composed of a cardanol modified phenolic aldehyde amine curing agent, a coupling agent and a waterproof agent. The closed solvent-free epoxy prime coat is solvent-free, has the characteristics of strong bonding force with a base material, excellent sealing performance on a calcium silicate board and a concrete base surface, high transparency and low total heat value, and has a stronger cost advantage and a better application prospect.

Owner:MIANYANG HUILI EPOXY ENG

Electrostatic suction-type fluid discharging method and device

InactiveCN100429005CHigh cost advantageReduce the driving voltageLiquid surface applicatorsCoatingsLower limitElectrical polarity

The diameter of a discharge hole of a nozzle is 0.01-25 mum. A pulse voltage is applied by voltage applying means to between the nozzle and a substrate, where an upper limit voltage (10) of the pulse voltage is set equal to or higher than a dischargeable minimum voltage (30) that is a voltage condition at which a fluid discharge starts. Immediately before the pulse voltage is built up, a lower limit first voltage (20a) having the same polarity as the upper limit voltage (10) and having an absolute value smaller than the dischargeable minimum voltage (30) is set, and immediately after the pulse voltage is built up, a lower limit second voltage (20b) having the opposite polarity to the upper limit voltage (10) is set. This provides an electrostatic suction-type fluid discharging method and device where the nozzle is fine, fine fluid can be discharged, hit positions are precise, and a drive voltage is lower. Further, discharge start / end characteristics are enhanced to improve drive frequency, and pulse time control of a discharge amount is enabled.

Owner:NAT INST OF ADVANCED IND SCI & TECH

A safety protection device for wind power generator set built by hard wiring

ActiveCN103557116BEnsure safetyEasy diagnosisWind motor controlEnergy industryProgrammable logic controllerControl system

The invention relates to a hard-wire constructed safety protection device of a wind generating set. According to the technical solution, the safety protection device is mainly composed of a first safety relay and a second safety relay, and input, output and reset of the safety protection device completely depend on hard wires to be connected to the two safety relays special for safety loops in a cabin cabinet so that the whole safety protection device is divided into two levels, the function and a control loop of the safety protection device are completely separated from a programmable logic controller (PLC) control system, safety of a unit can be still guaranteed in the condition of dead halt of a PLC, communication interruption or failure to normally operate, and the safety protection device has a fail-safe function; signals from each input contact and each output contact of the safety protection device are simultaneously input into the PLC in a mode of independent switching value digital signals, so that fault points of the unit can be conveniently diagnosed, requirements for PLC factories and types are absent, and the universality is high; only the two safety relays, signal cables and a plurality of auxiliary contacts are added, and the advantage of low costs is achieved.

Owner:天津瑞源电气有限公司

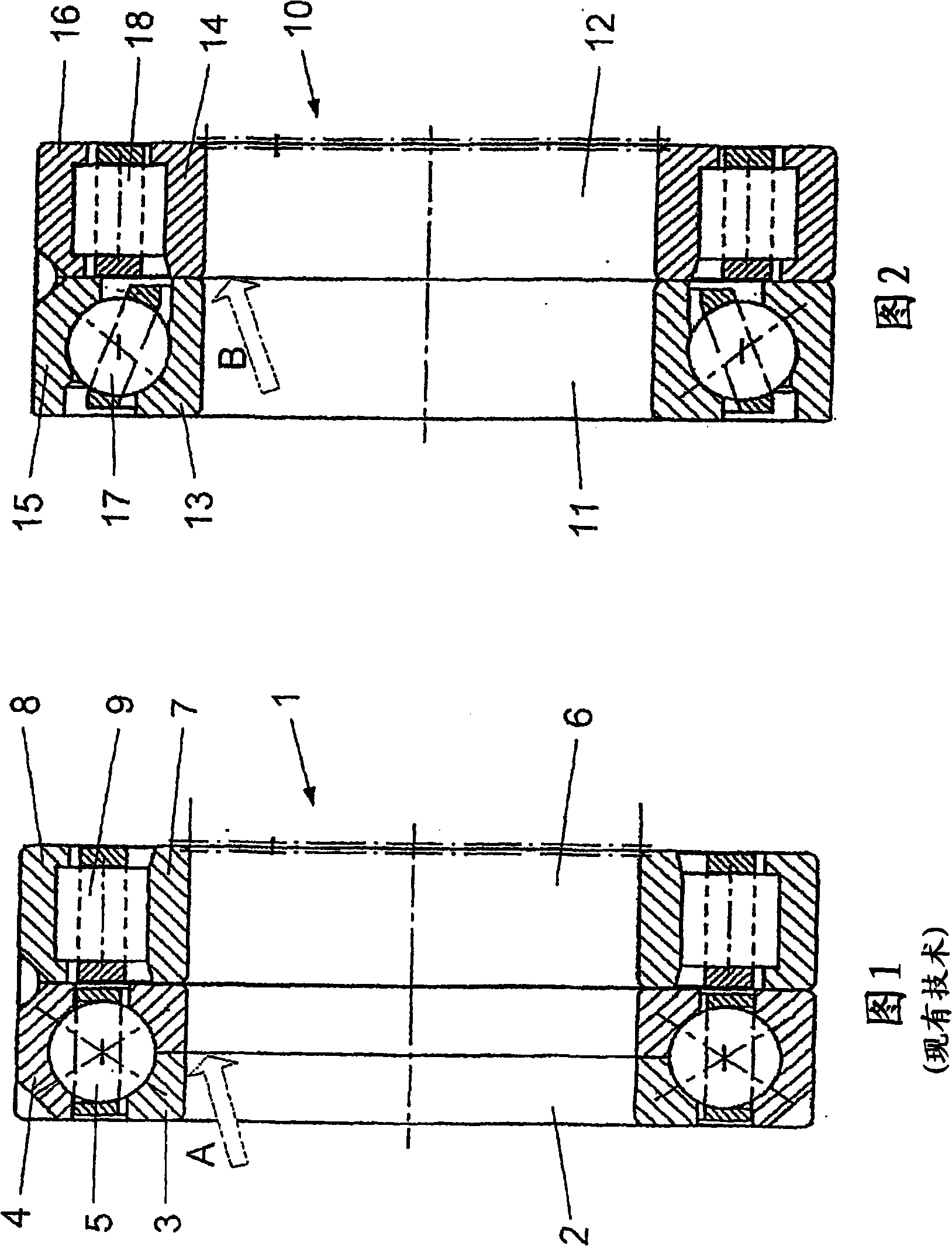

Bearing set with an angular ball bearing and cylinder roller bearing receiving axial forces

InactiveCN101310118AReduce axial playOrientation is accurateRoller bearingsBall bearingsAxial forceEngineering

The invention relates to a bearing set (10) for a shaft to be guided in an axially restricted and exact manner, a running wheel or the like for machine units. The aim of the invention is to devise less expensive bearings for receiving comparatively low axial back pressure forces. The bearing set (10) consists of a ball bearing (11), especially an angular ball bearing, receiving axial back pressure forces due to operation, and a ring slide bearing receiving axial back pressure forces or a cylinder roller bearing configured as a support bearing and receiving axial back pressure forces.

Owner:SCHAEFFLER TECH AG & CO KG

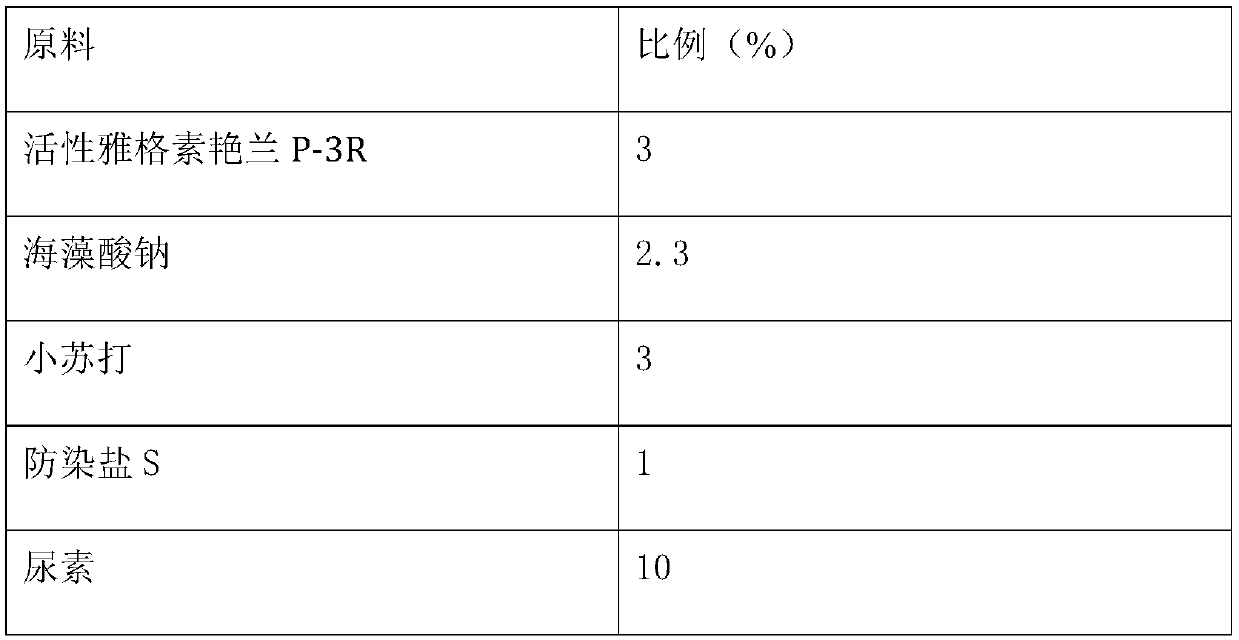

Activity imitation adhesive composition and preparation method thereof

ActiveCN109629263AImprove self-thickening performanceGood flexibilityDyeing processAdhesiveCopolymer

The invention discloses an activity imitation adhesive composition and a preparation method thereof. The novel activity imitation adhesive is prepared from, by weight, 0.5-10% of inorganic nanopowder,15-35% of clay, 2-15% of alkyd resin, 15-45% of silicon- acrylic copolymer and 25-40% of water according to the total weight of the novel activity imitation adhesive. The composition is good in stability and high in self-thickening performance, does not contain a formaldehyde agent, is applied to a pure cotton fabric, and has the advantages that the darkening effect is significant, the fastness is extremely high, and the hand feeling is quite soft, the comprehensive effect of the composition is same with the performance of reactive printing (dyeing), and the effect of activity imitation printing is achieved.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

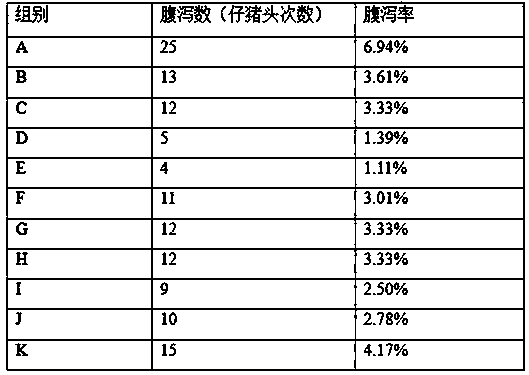

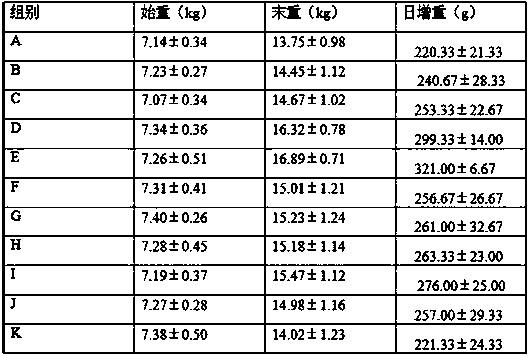

Preparation method of grease for weaned pig and application thereof in piglet feed

ActiveCN109077186APromote growthPromote absorptionFatty acid esterificationFatty-oils/fats refiningOil and greaseStress syndrome

The invention discloses an application of compound grease comprising freshwater fish oil or the freshwater fish oil after fractionation treatment or combination of the above two types of the grease and other grease in a piglet feed. A dosage of the grease in the feed is 0.5-10%. The other grease is coconut oil and modified deep sea fish oil. The modified deep sea fish oil is obtained by ester exchange of the deep sea fish oil and the coconut oil, especially, on the basis of improvement of grease properties. The invention further relates to a fractionation method for fractionation freshwater fish oil and an ester exchange method, so oil which is better in quality and suitable for piglet growth is obtained. The feed grease is capable of reducing generation of a stress syndrome, and has an apparent function for promoting the piglet growth.

Owner:广东至润油脂食品工业有限公司

Fireproof thermal insulation building material and preparation method thereof

The invention belongs to the field of building decoration materials, and discloses a fireproof thermal insulation building material and a preparation method thereof. The material is prepared from sepiolite, Qi cotton, porous powder quartz, ceramic fiber, bentonite, a wetting agent, a binding agent, graphene, fire retardant, methyl silicone oil, methyl alkoxy silicone oil, amino silicon oil, polyethylene glycol, an emulsifier, fungicide, bagasse, rice hulls, rice bran, biomass insulation material additives, expanded perlite, vermiculite, quicklime, gypsum, straw stalk and rape stalk. The material has the thermal insulation and cold insulation effects, by using the building material, the thickness of the wall can be reduced, the thermal insulation and cold insulation effects are achieved, and the building material can be greatly saved. The paint is excellent in performance, good in freezing resistance and free of cracking and deformation; the fire retardant adopted by the building material adopts tetrabromobisphenol A, and the fire retardant is one of the fire retardant products which are most scientifically tested and have the highest cost advantage in the market.

Owner:CHANGAN UNIV +1

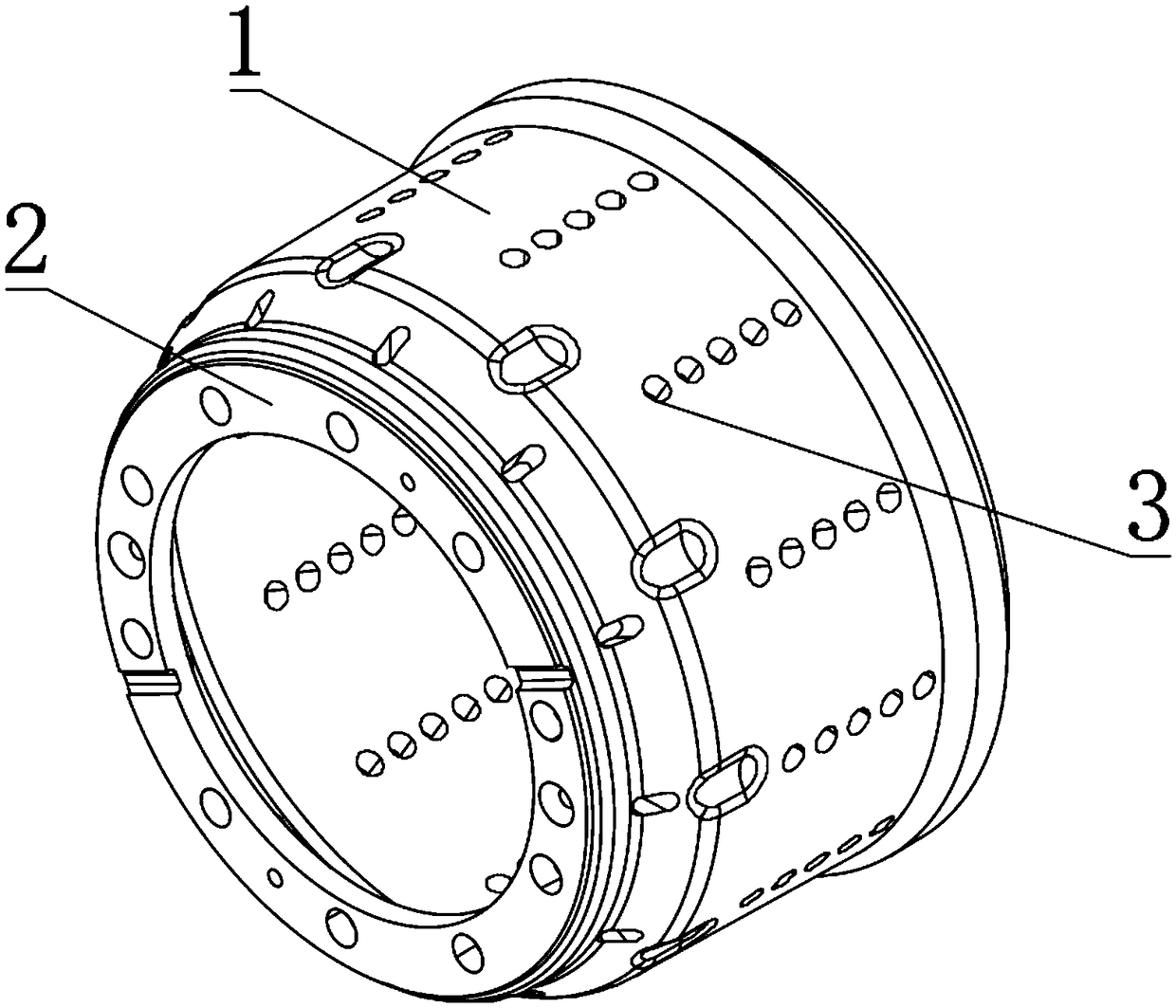

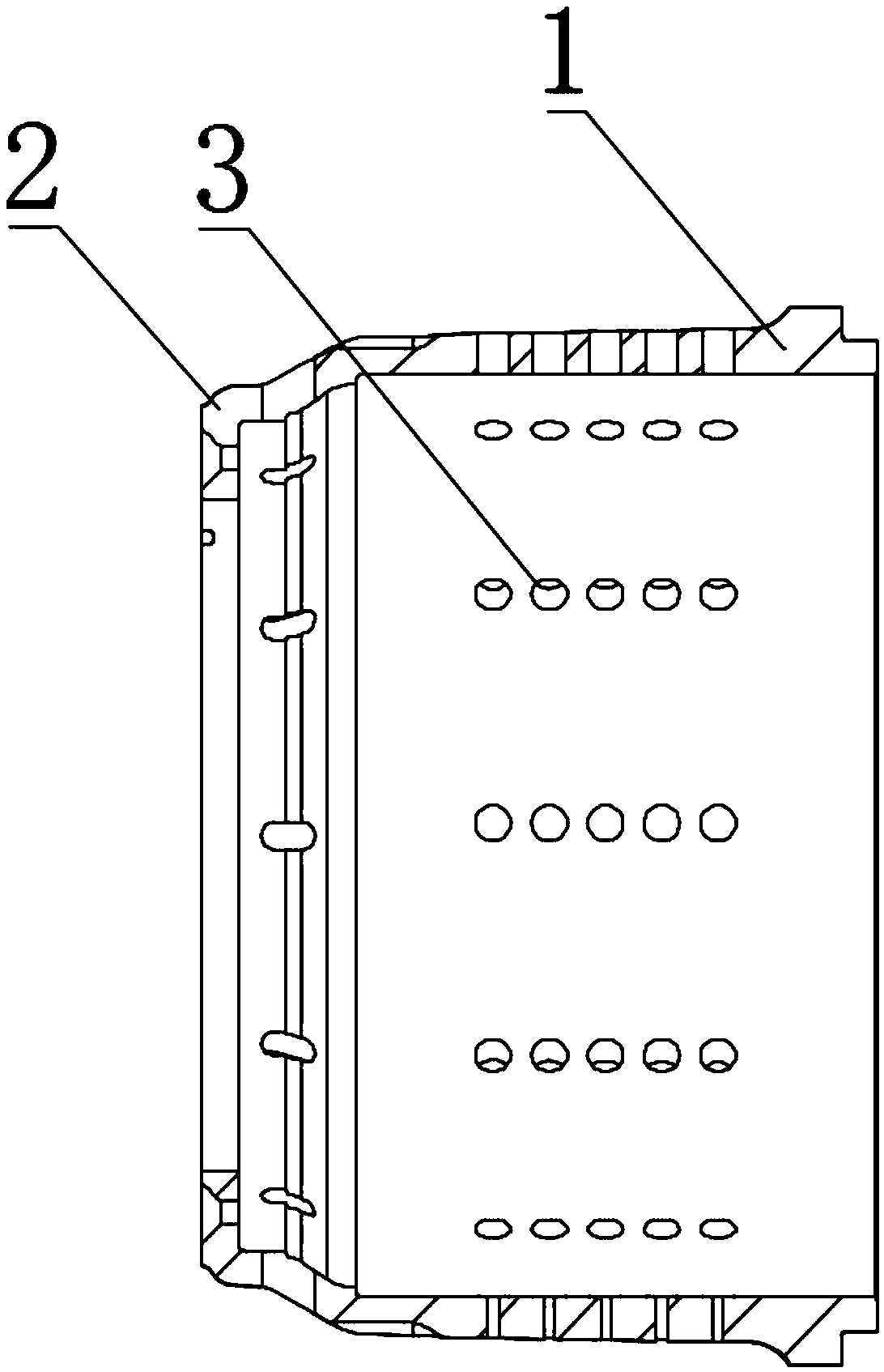

Alloy material, lightweight brake drum with alloy material applied, and lightweight brake drum preparation method

InactiveCN109371327AImproved dimensional stabilityImproves Strength and ToughnessBraking drumsFurnace typesQuenchingDriving safety

The invention relates to the technical field of brake materials, in particular to an alloy material, a lightweight brake drum with the alloy material applied, and a lightweight brake drum preparationmethod. The alloy material is prepared from, by weight, C: 0.23-0.28%, Si: 0.45-0.55%, Mn: 1.05-1.10%, S: no greater than 0.007%, P: no greater than 0.008%, Ni: 1.05-1.20%, Cr: 0.8-0.95%, Mo: 0.5-0.62%, Al: no greater than 0.04%, and the balance Fe. The alloy material has better mechanical properties and thermal fatigue resistance. The annealing and quenching and tempering processes are added in the casting process of the lightweight brake drum, so that the mechanical property of the lightweight brake drum is enhanced. In addition, the wall thickness can be thinned and the structure of the lightweight brake drum can be optimized so as to enhance the braking stability of the lightweight brake drum and increase the driving safety performance.

Owner:天宜上佳(天津)新材料有限公司

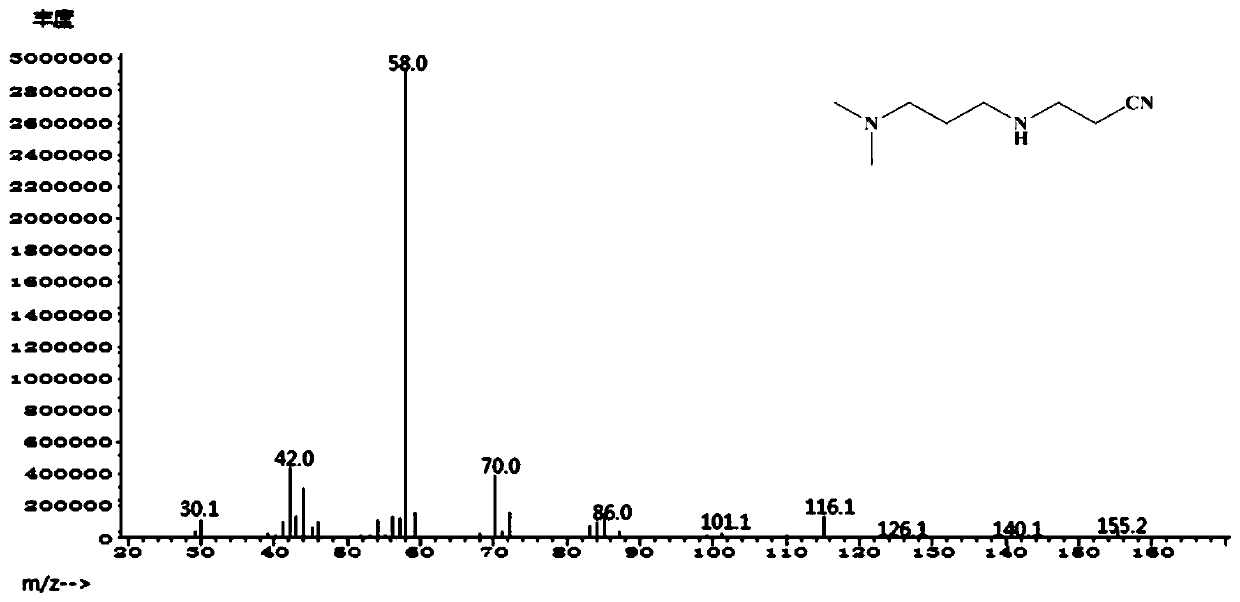

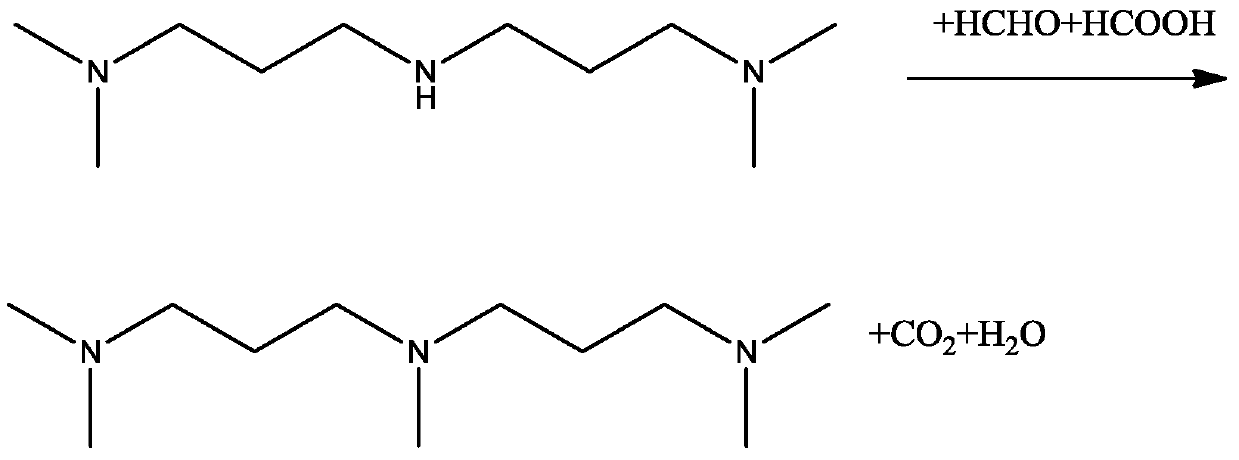

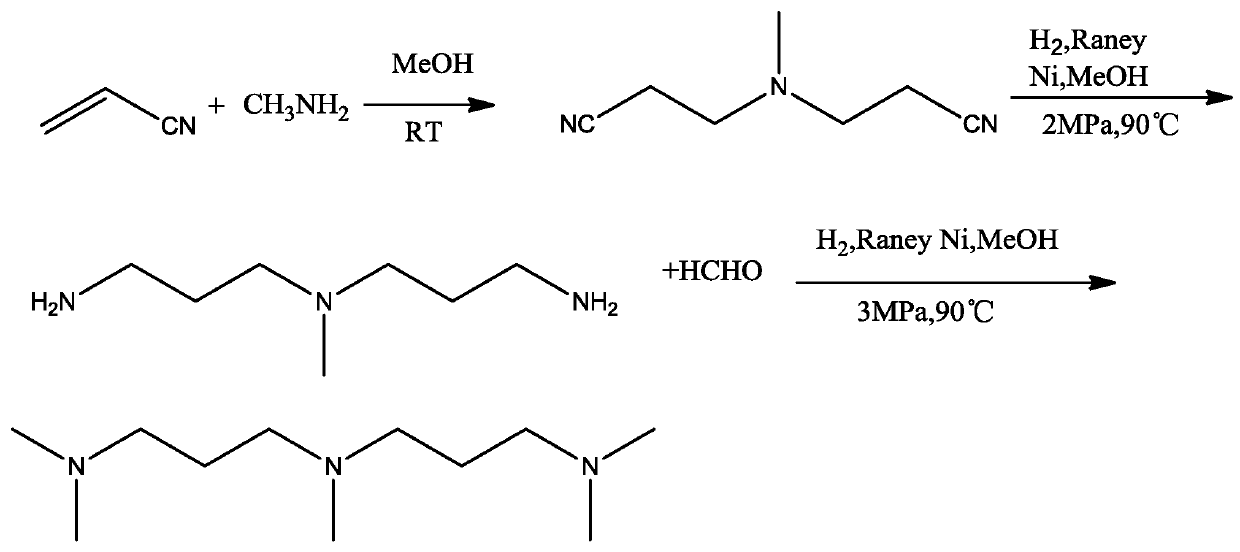

Method for preparing pentamethyldipropylene triamine

ActiveCN110437102AHigh yieldHigh cost advantageCarboxylic acid nitrile preparationAmino preparation from aminesHydrogenation reactionAcrylonitrile

The invention provides a method for preparing pentamethyldipropylene triamine. The method comprises the following steps: (1) performing a reaction on 3-dimethylaminopropylamine and acrylonitrile so asto form a 3-[[3-(dimethylamino)propyl]amino]propionitrile reaction solution, and performing separation so as to obtain a 3-[[3-((dimethylamino)propyl]amino]propionitrile pure product; (2) performinga hydrogenation reaction on 3-[[3-(dimethylamino)propyl]amino]propionitrile, hydrogen and a solvent under the action of a catalyst so as to obtain a N'-(3-aminopropyl)-N,N-dimethyl-1,3-propylene diamine reaction solution; and (3) performing a methylation reaction on the N'-(3-aminopropyl)-N,N-dimethyl-1,3-propylene diamine reaction solution obtained in the step (2), formaldehyde and hydrogen underthe action of a catalyst so as to obtain pentamethyldipropylene triamine. The method has the advantages of cheap and easily available starting materials, good selectivity to the product and high product yield, and the method is economical and effective, and has industrialization prospects.

Owner:WANHUA CHEM GRP CO LTD +1

Formula and preparation method of cationic polymer

InactiveCN101817912BLow costLow market priceWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationIonic polymerizationPolymer

The present invention provides a formula and a preparation method of a cationic polymer. The raw material formula of the cationic polymer comprises the following components in part by weight: water 5-50, acetone 3-25, amine 5-30, aldehyde 5-40, alkaline regulator 3-12 and acidic regulator 5-20. In the method, a water soluble cationic polymer is prepared from aldehyde, acetone and amine by a nucleophilic addition reaction, an aldol condensation reaction and a Michael addition reaction in the presence of acid and alkali catalysts in turn and by a two-step feeding process. The method has the advantages that: the raw material cost is low, the synthesis process is simple and easy to implement; the preparation conditions are mild and safe; and the obtained product has high cation content and has high decolorizing and flocculating effects on anionic dye waste water.

Owner:FUZHOU UNIV

Method for synthesizing methyl isopropyl ketone by one-step method

ActiveCN112209813AReduce the amount of exhaust gasReduce consumptionOrganic compound preparationCarbonyl compound preparationIsopropylBiochemical engineering

The invention provides a method for synthesizing methyl isopropyl ketone through a one-step method. The method comprises the steps of feeding, a first-stage heat preservation reaction process and a second-stage heat preservation reaction process. According to the synthesis method, the reaction yield and the production efficiency are improved, the yield is 70-80% (metered by formaldehyde), operations such as material turnover and separation are reduced, the amount of waste water and waste gas is obviously reduced, and the method is safe and easy to control. Compared with the traditional synthesis method, the method significantly reduces the use amount of equipment and the like, greatly shortens the reaction time and has simple and easily-controlled processes. Various expenses of material consumption, equipment investment, three-waste treatment, personnel and the like are reduced, and the cost advantage is obviously improved. According to the synthesis method disclosed by the invention,the yield of the methyl isopropyl ketone can be 80-85% (metered by formaldehyde) and the purity of the methyl isopropyl ketone is 99.5% or above by virtue of a preferable technical scheme.

Owner:山东智永化工产业技术研究院有限公司

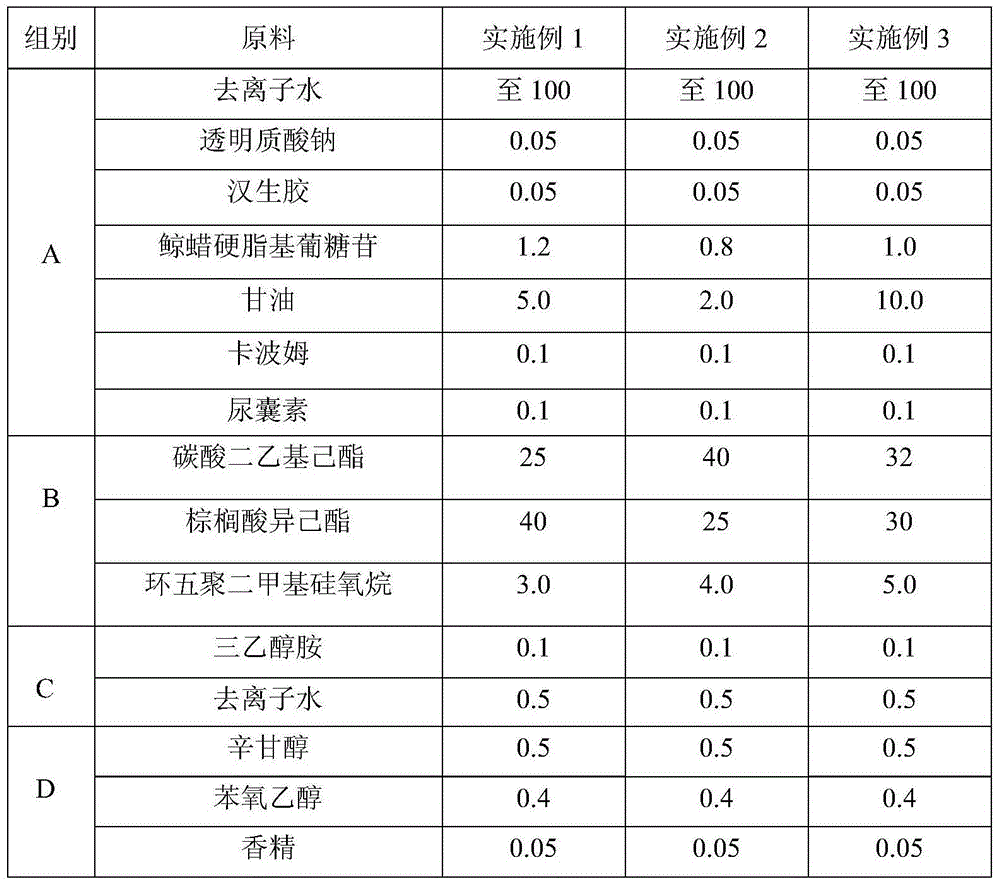

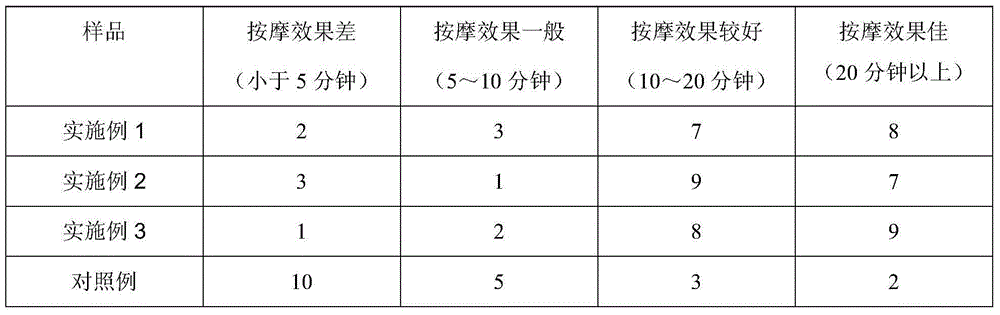

Oil outlet massage cream and preparation method thereof

InactiveCN104473784AMoisturizes and massages wellHigh cost advantageCosmetic preparationsToilet preparationsSodium hyaluronateCaprylyl Glycol

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

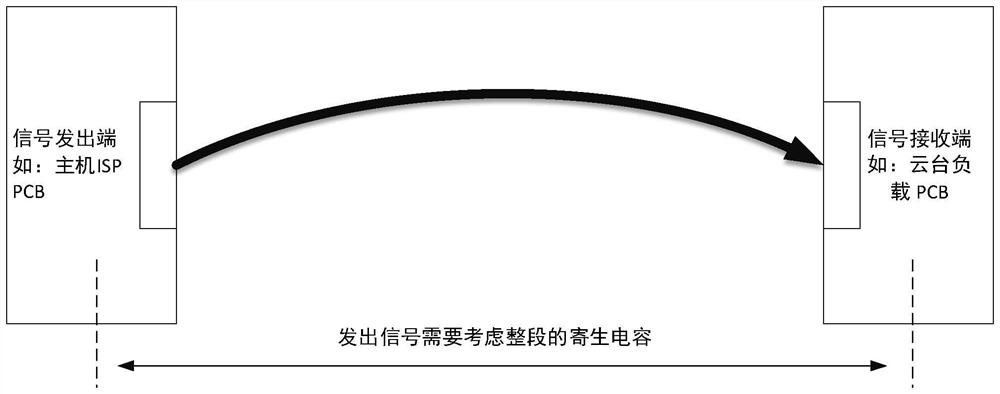

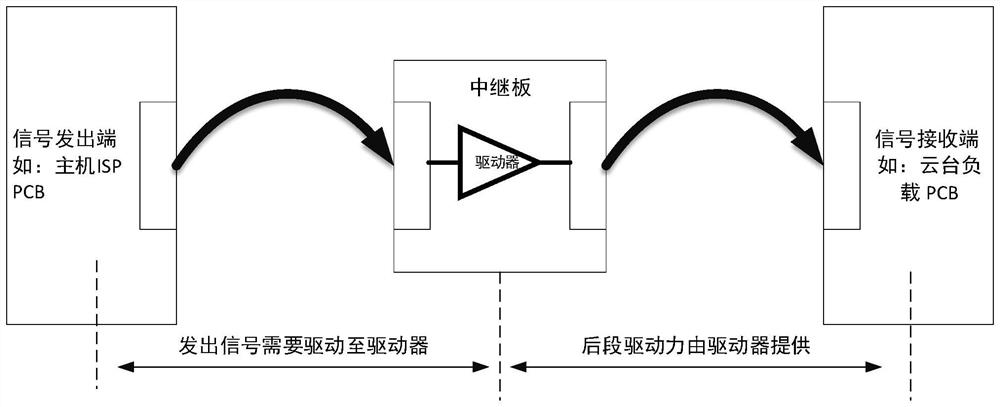

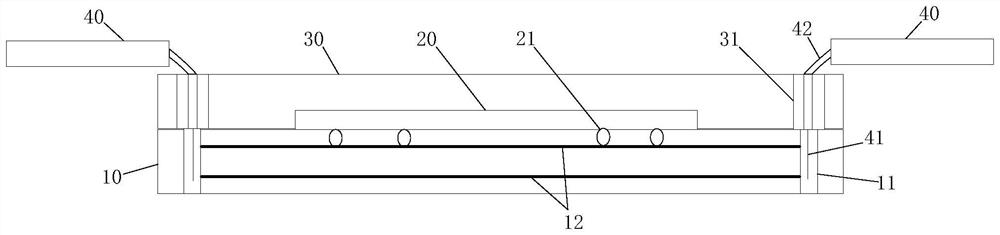

Chip packaging structure and packaging method

InactiveCN112640098ALow costHigh cost advantageSemiconductor/solid-state device detailsSolid-state devicesSignal qualityParasitic capacitance

The embodiment of the invention provides a chip packaging structure and packaging method. The structure comprises a substrate which is provided with a first connection part and a second connection part, wherein the first connection part and the second connection part are electrically connected through an internal circuit of the substrate, the second connection part is a through hole penetrating through the substrate, and an electroplated layer with a connecting hole is arranged in the through hole; a chip arranged on the substrate and electrically connected with the first connection part, so that a signal path is formed between the second connection part and the chip through the internal circuit of the substrate; a protective layer which is arranged on the substrate and wraps the chip and the second connection part, wherein a wire passing hole is formed in the position, corresponding to the second connection part, of the protective layer so that the signal wire can penetrate through the wire passing hole to be electrically connected with the second connection part. According to the technical scheme provided by the embodiment of the invention, the parasitic capacitance on the signal path can be reduced, the signal quality of a receiving end is effectively improved, the signal line connection reliability is improved, the size is reduced, and the cost is reduced.

Owner:SZ DJI TECH CO LTD

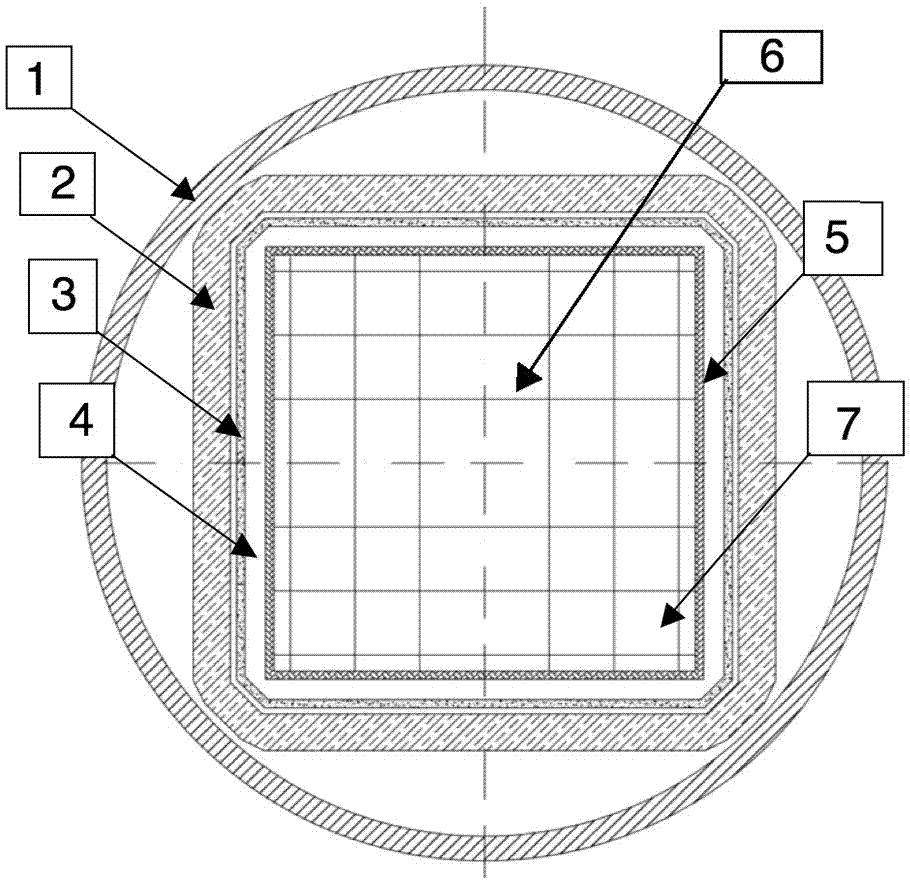

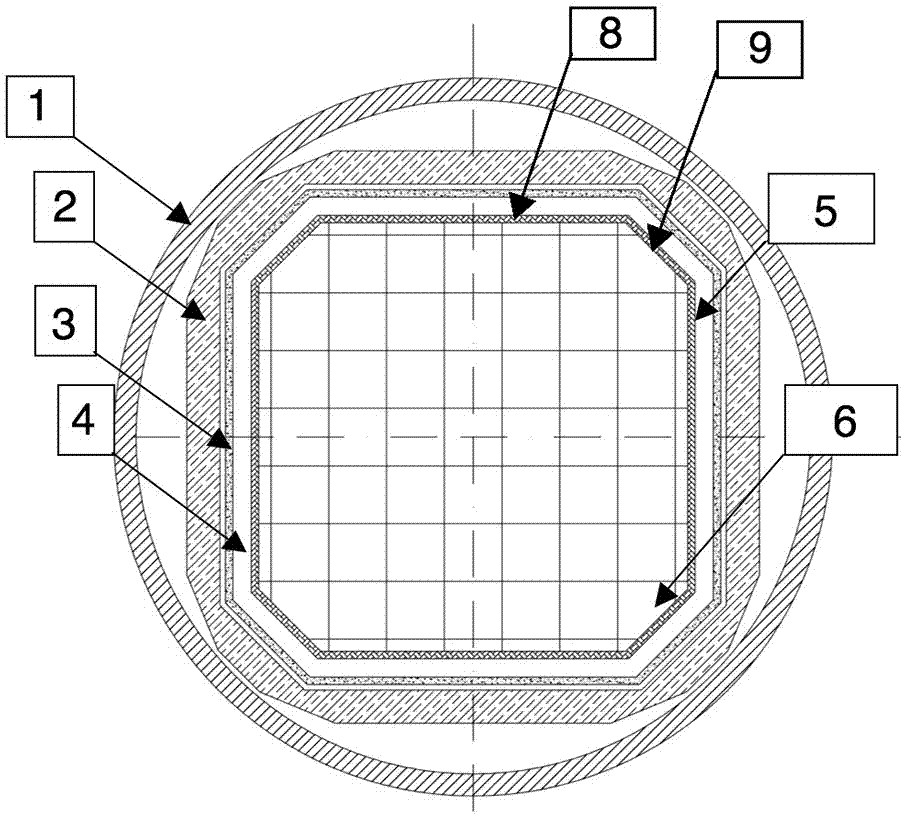

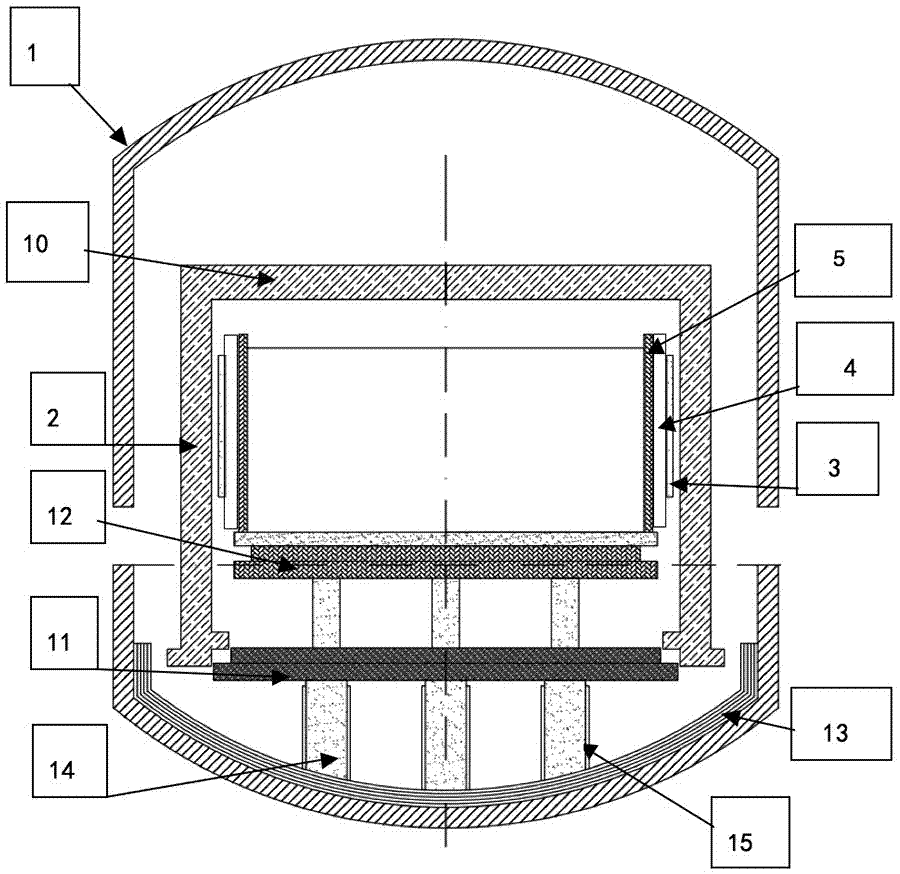

Ingot casting furnace capable of improving average conversion efficiency of silicon ingot

InactiveCN107326436AIncrease the thermal field sizeImprove average conversion efficiencyPolycrystalline material growthSingle crystal growth detailsEnergy conversion efficiencyCrucible

The invention discloses an ingot casting furnace capable of improving average conversion efficiency of a silicon ingot. The ingot casting furnace comprises a furnace body and a crucible, wherein the crucible is arranged in the furnace body; a graphite vertical column is vertically arranged at the bottom part of the interior of the furnace body; a heat exchange platform is horizontally arranged at the top part of the graphite vertical column; the crucible is placed on the heat exchange platform; a graphite protective plate layer, a heater layer and a heat insulation cover layer are sequentially arranged between the periphery of the furnace body and the wall surface of the interior of the furnace body; the cross section of the crucible is in an octagon shape; the octagon-shaped crucible comprises four crucible walls and four crucible chamfer walls; each crucible chamfer wall is positioned between the two adjacent crucible walls; the cross sections of the graphite protective plate layer and the heater layer have the same shape with the cross section of the crucible; the graphite protective plate layer and the heater layer are respectively formed with chamfer layer surfaces corresponding to the crucible chamfer walls. The ingot casting furnace has the advantages that the four corners of the existing quadrilateral heat field are chamfered, the size of the heat field is increased, the quadrilateral heat field is upgraded into the octagon-shaped heat field, the production of corner ingots is avoided, and the average conversion efficiency of the whole silicon ingot is improved.

Owner:扬州续笙新能源科技有限公司

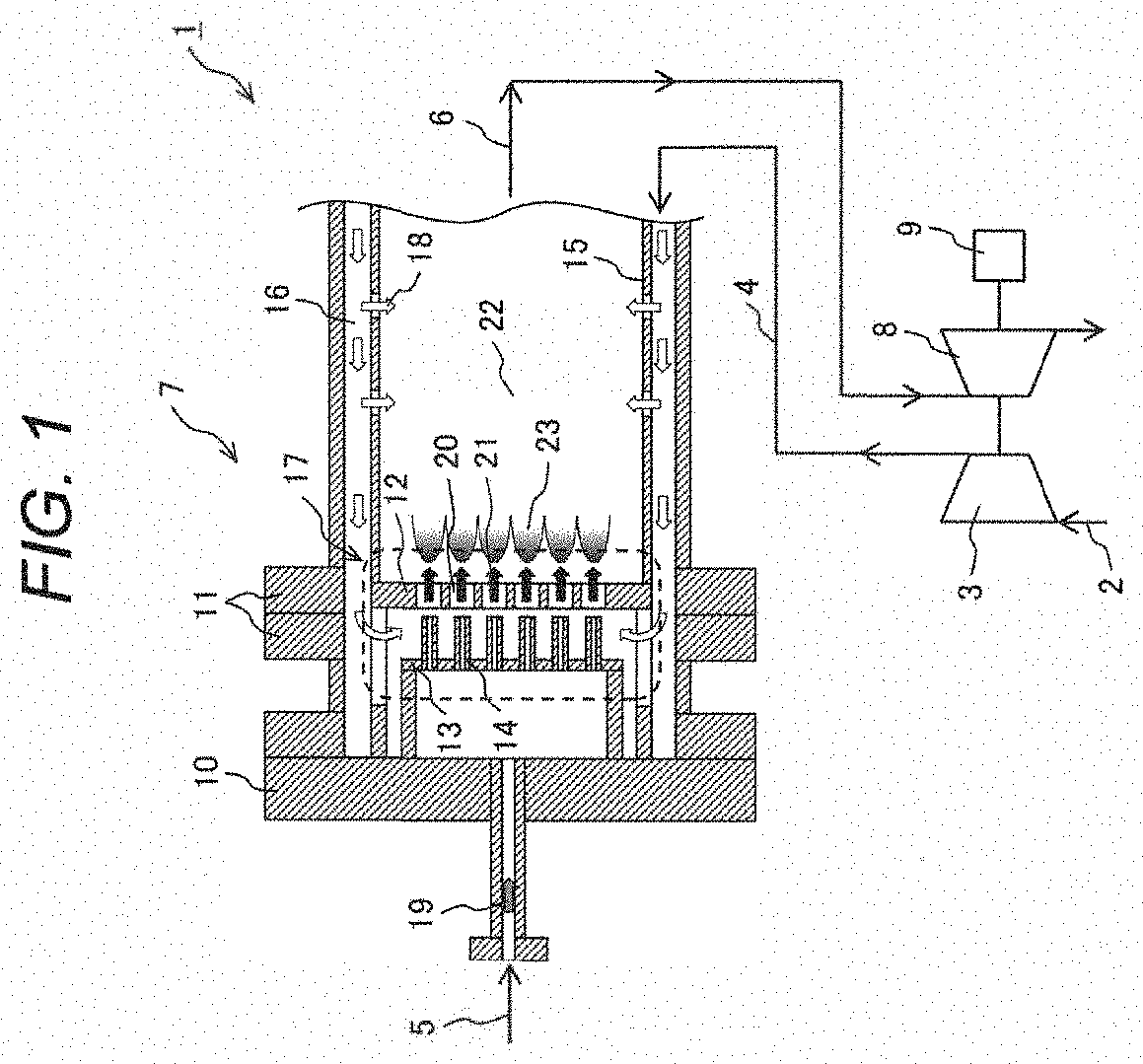

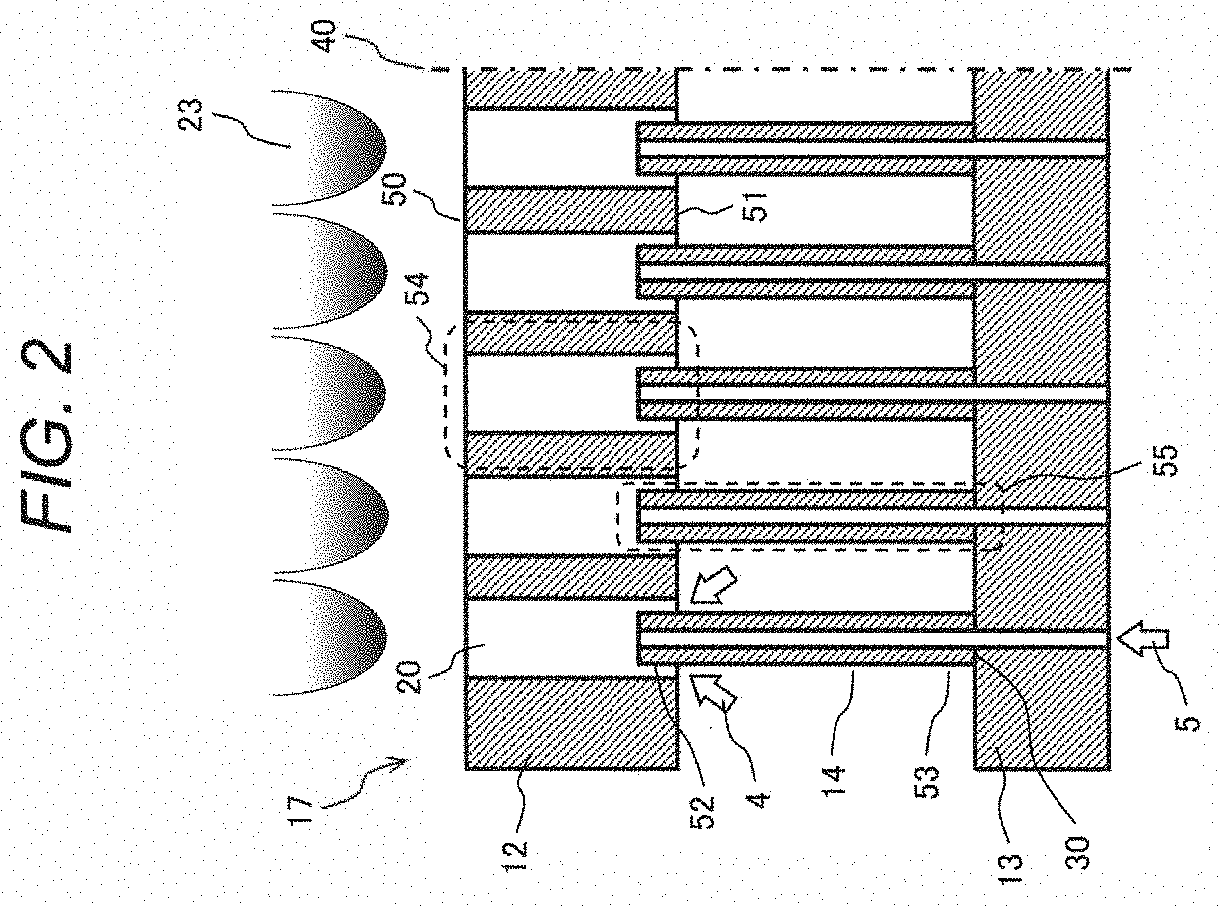

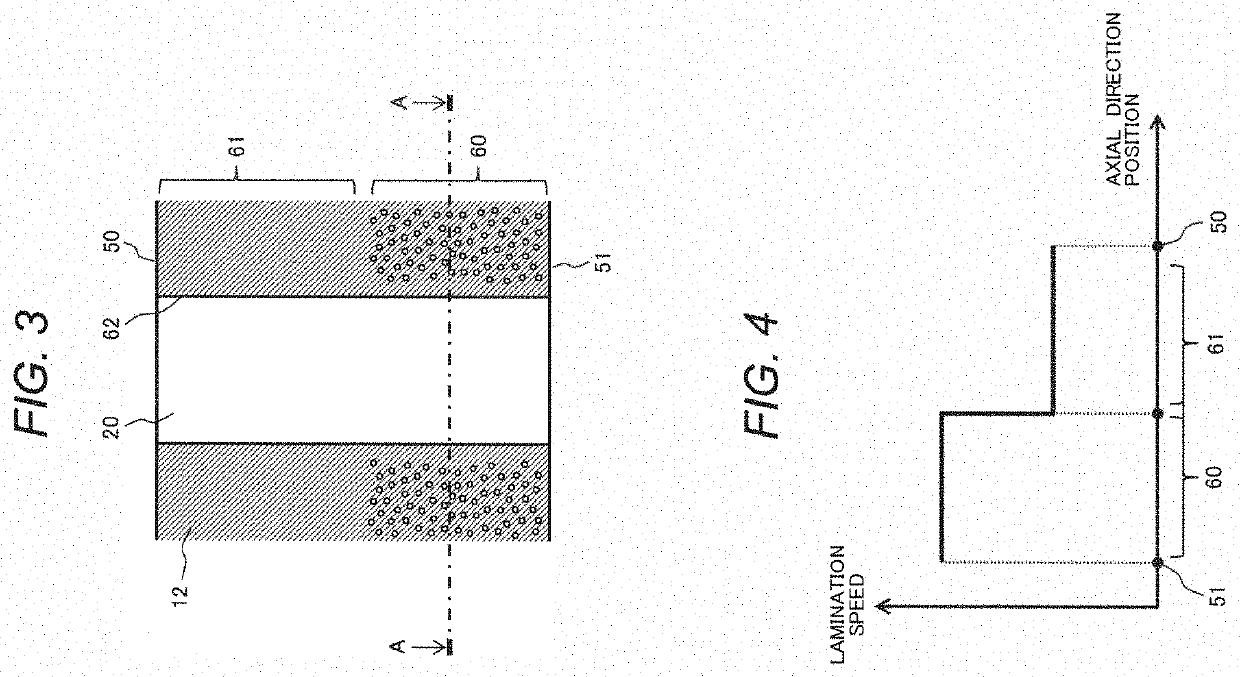

Gas Turbine Combustor and Method of Manufacturing Burner Component

ActiveUS20210302022A1High strengthHigh cost advantageTurbinesAdditive manufacturing apparatusCombustorMetallic materials

There is provided a gas turbine combustor which includes a burner component which is molded by 3D additive manufacturing and is optimized in material strength per part. The burner component includes a first part which is used within a first temperature range and / or a first stress range and a second part which is used within a second temperature range which is lower than the first temperature range and / or a second stress range which is lower than the first stress range, and a lamination speed at which a metal material is laminated on the first part by the 3D additive manufacturing is lower than a lamination speed at which the metal material is laminated on the second part.

Owner:MITSUBISHI HEAVY IND LTD

Fireproof thermal insulation building material

InactiveCN107759191AImprove insulation effectImprove flame retardant performanceThermal energyTetrabromobisphenol A

The invention discloses a fireproof and thermal insulation building material. The fireproof thermal insulation material comprises the following materials in parts by weight: 20-30 parts of expanded perlite, 9-15 parts of silicon dioxide, 15-20 parts of clay, and 3-10 parts of dolomite powder 5-18 parts of rubber, 7-18 parts of plant fiber powder, 4-10 parts of aluminum silicate fiber cotton, 10-17 parts of flame retardant, 2-15 parts of color masterbatch, 2-13 parts of auxiliary raw materials. The invention provides a fire-proof and heat-preserving building material, which has good heat-preserving and flame-retardant effects, improves the fire-proof performance of the building material, and also realizes the energy storage and temperature-regulating function of the material to prevent the loss of indoor heat energy; the heat-insulating material uses swelling Perlite is the main raw material, which makes the insulation material have the characteristics of light apparent density, low thermal conductivity, good chemical stability, non-toxic and tasteless. The flame retardant used in the building materials is tetrabromobisphenol A, which is one of the flame retardant products with the most scientific tests and the highest cost advantage in the market.

Owner:董丹丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com