Polyvinylidene fluoride composite membrane and method for preparing same

A polyvinylidene fluoride and composite film technology, applied in the field of composite materials, can solve the problems of low surface energy and difficult bonding of films, and achieve the effects of reducing difficulty, novel and unique preparation methods, and high cost advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

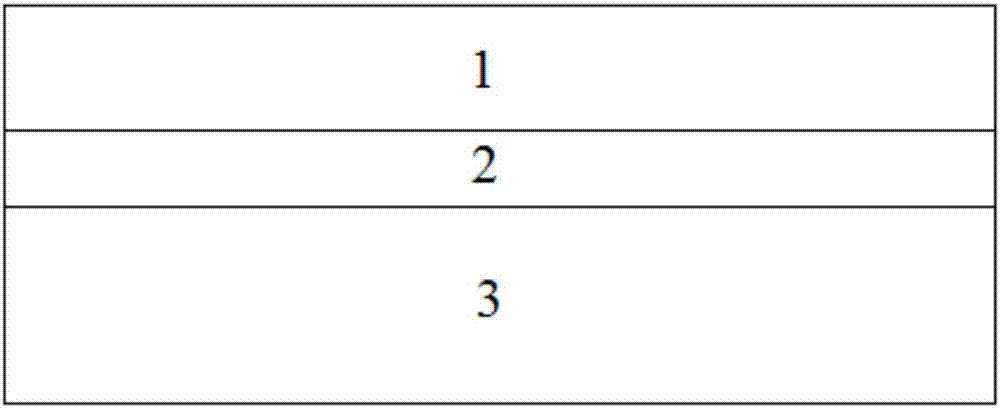

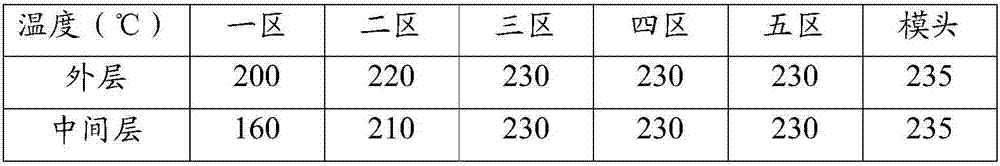

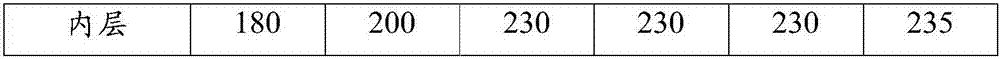

[0027] Among the raw materials used in the three-layer co-extruded cast film, PVDF is modified, and the mass-number ratio of the modified PVDF raw material is 90 parts of PVDF, 10 parts of PMMA, 0.5 part of antioxidant, and 0.7 part of ultraviolet absorber. The modified PVDF pellets, EMA pellets and LDPE pellets were placed in their respective single-screw extrusion stages, and re-cast in three layers of die heads to form a film. By adjusting the extrusion volume, the thickness of the outer layer was 5 μm, and the thickness of the middle layer was The layer is 5 μm and the inner layer is 5 μm in thickness. The temperature settings in each zone of the three single-screw extruders are as follows:

[0028] temperature(°C)

Embodiment 2

[0030] Among the raw materials used in the three-layer co-extruded cast film, PVDF is modified, and the mass-number ratio of the modified PVDF raw material is 90 parts of PVDF, 10 parts of MBS, 0.3 part of antioxidant, and 0.5 part of ultraviolet absorber. The modified PVDF pellets, EMA pellets and LDPE pellets were placed in their respective single-screw extrusion stages, and re-cast in three layers of die heads to form a film. By adjusting the extrusion volume, the thickness of the outer layer was 5 μm, and the thickness of the middle layer was The layer is 10 μm and the inner layer is 15 μm in thickness. The temperature settings in each zone of the three single-screw extruders are as follows:

[0031]

[0032]

Embodiment 3

[0034] Among the raw materials used in the three-layer co-extruded cast film, PVDF is modified, and the mass fraction ratio of the modified PVDF raw material is 90 parts of PVDF, 10 parts of acrylate toughening agent, 0.6 part of antioxidant, and ultraviolet absorber 0.9 servings. The modified PVDF pellets, EMA pellets, and LDPE pellets were put into their respective single-screw extrusion stages, and re-cast in three layers of die heads to form a film. By adjusting the extrusion volume, the thickness of the outer layer was 8 μm, and the thickness of the middle layer was The layer is 8 μm, the inner layer is 20 μm in thickness. The temperature settings in each zone of the three single-screw extruders are as follows:

[0035] temperature(°C)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com