Hard-wire constructed safety protection device of wind generating set

A technology for wind turbines and safety protection devices, which is applied to wind turbines, wind turbine control, wind power generation, etc., and can solve problems such as extreme abnormality of grid power, inability to classify and sequence input points, and loss of control of safety systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

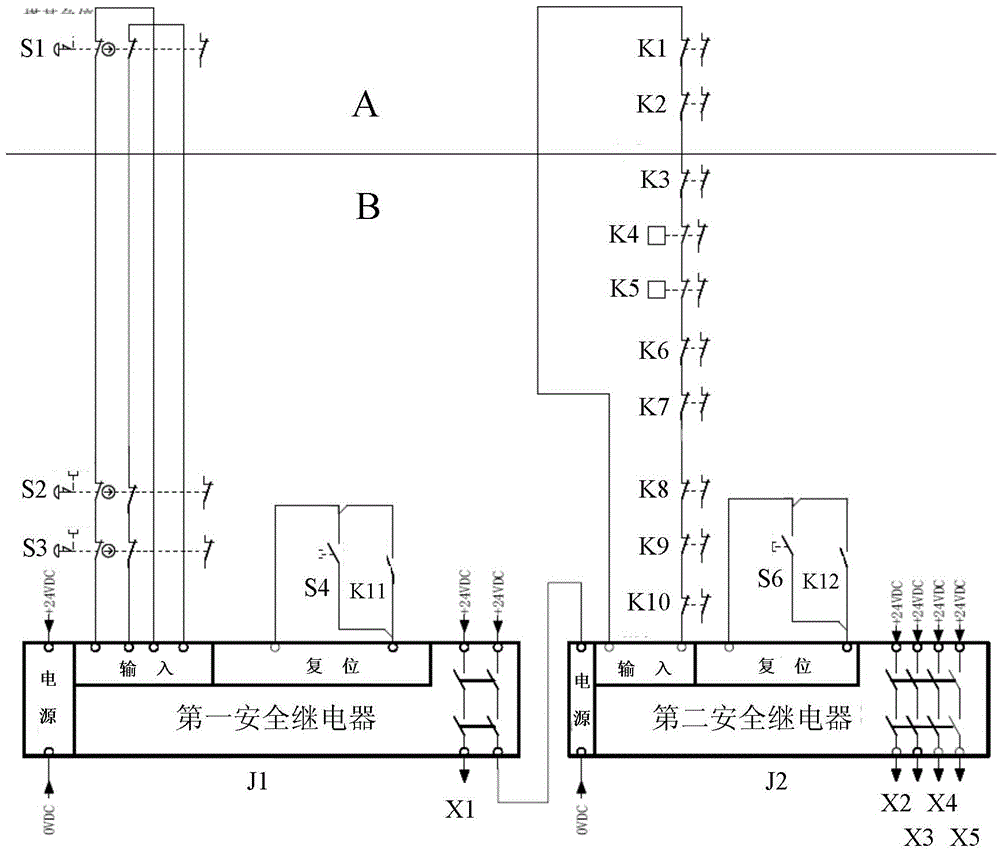

[0012] The hardwired safety protection device for wind power generating sets provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, the hard-wired wind turbine safety protection device provided by the present invention is mainly composed of the first safety relay J1 and the second safety relay J2 placed in the cabin cabinet, wherein: the two input circuits of the first safety relay J1 The normally closed contacts of the emergency stop button S1 of the tower base main control cabinet, the emergency stop button S2 of the engine room main control cabinet, and the emergency stop button S3 of the frequency converter are connected in series to the two input terminals of the first safety relay J1 in a two-way redundant manner. Composition, to prevent the emergency stop button from being invalid due to the failure of a certain contact of the emergency stop button, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com