Patents

Literature

311results about How to "Low market price" patented technology

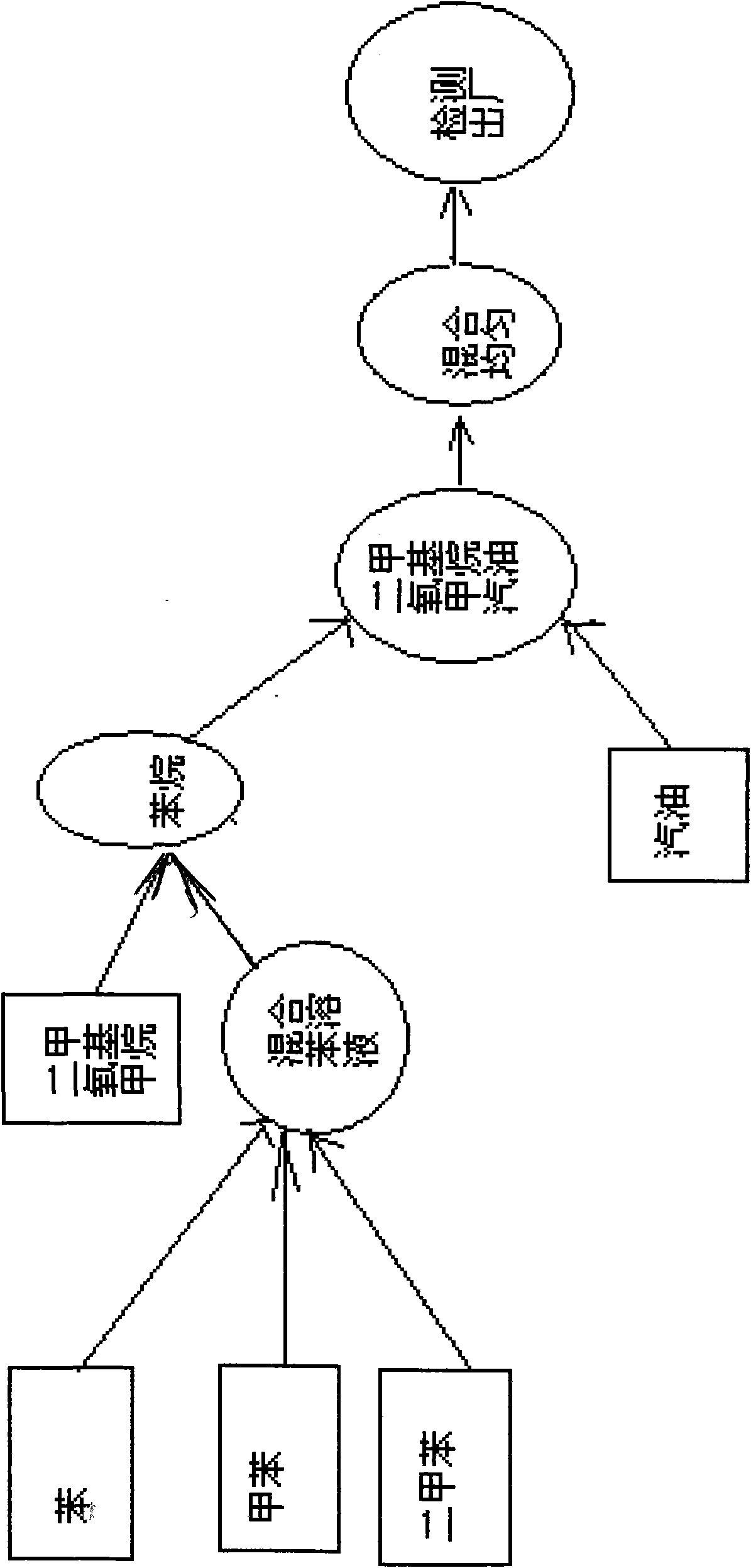

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gadolinium-containing Nd-Fe-B rare earth permanent magnetic material dn its manufacturing method

ActiveCN101071667ALow costImprove heat resistanceInorganic material magnetismNeodymium iron boronSintered magnets

The present invention provides the Nd-Fe-B gadolinium-containing rare earth permanent magnet materials and manufacturing methods. Nd-Fe-B described in the gadolinium-containing rare earth permanent magnet material for the composition: Re alpha Gd beta B gamma MxNyFe100 - alpha-beta - gamma - xy, including: Re for REE, including from Nd, Pr, Dy, Tb and in at least one Ce elemental or more elements; M to add elements, including Co and Cu; N to add elements, including from Al, Ga, Nb, Zr, Ti and Sn one or more elements; alpha, beta, gamma , x, y percentage of weight for each element content; Fe Fe and unavoidable impurities of which, 29 =< alpha =< 35,0.05 =< beta =< 0.50,0.95 =< gamma =< 1.20,0 =< x =< 10,0 =< y =< 1.50. Manufacturing methods described by melting, casting, grinding, molding and sintering of a continuous process manufacturing sintered magnets. The Nd-Fe-B Gd rare earth permanent magnet material added after its Hcj has improved, and to improve its temperature .

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Rubber powder-asphalt emulsion for concrete asphalt mortar and method for producing the same

ActiveCN101173106AImprove stabilityLow market priceBuilding insulationsPolymer scienceBitumen emulsion

The invention relates to a rubber powder-asphalt emulsion for cement asphalt mortar and a preparation method thereof. The rubber powder-asphalt emulsion is prepared from the following components in parts by mass: emulsifier: 0.1-3%, asphalt: 20-60%, rubber powder: 5-40%, stabilizer: 0.1-0.5%, thickener: 0.1-0.3%, auxiliary agent for adjusting pH value: 0-0.2%, and the balance is water. The preparation method includes first modifying asphalt with rubber powder, and then emulsifying; first emulsifying asphalt, then emulsifying rubber powder; first emulsifying rubber powder, and then emulsifying asphalt. The invention makes full use of solid waste—rubber powder, has the characteristics of environmental protection and energy saving, not only significantly improves the stability of CA mortar, but also reduces the cost of preparing CA mortar.

Owner:JIANGSU SOBUTE NEW MATERIALS

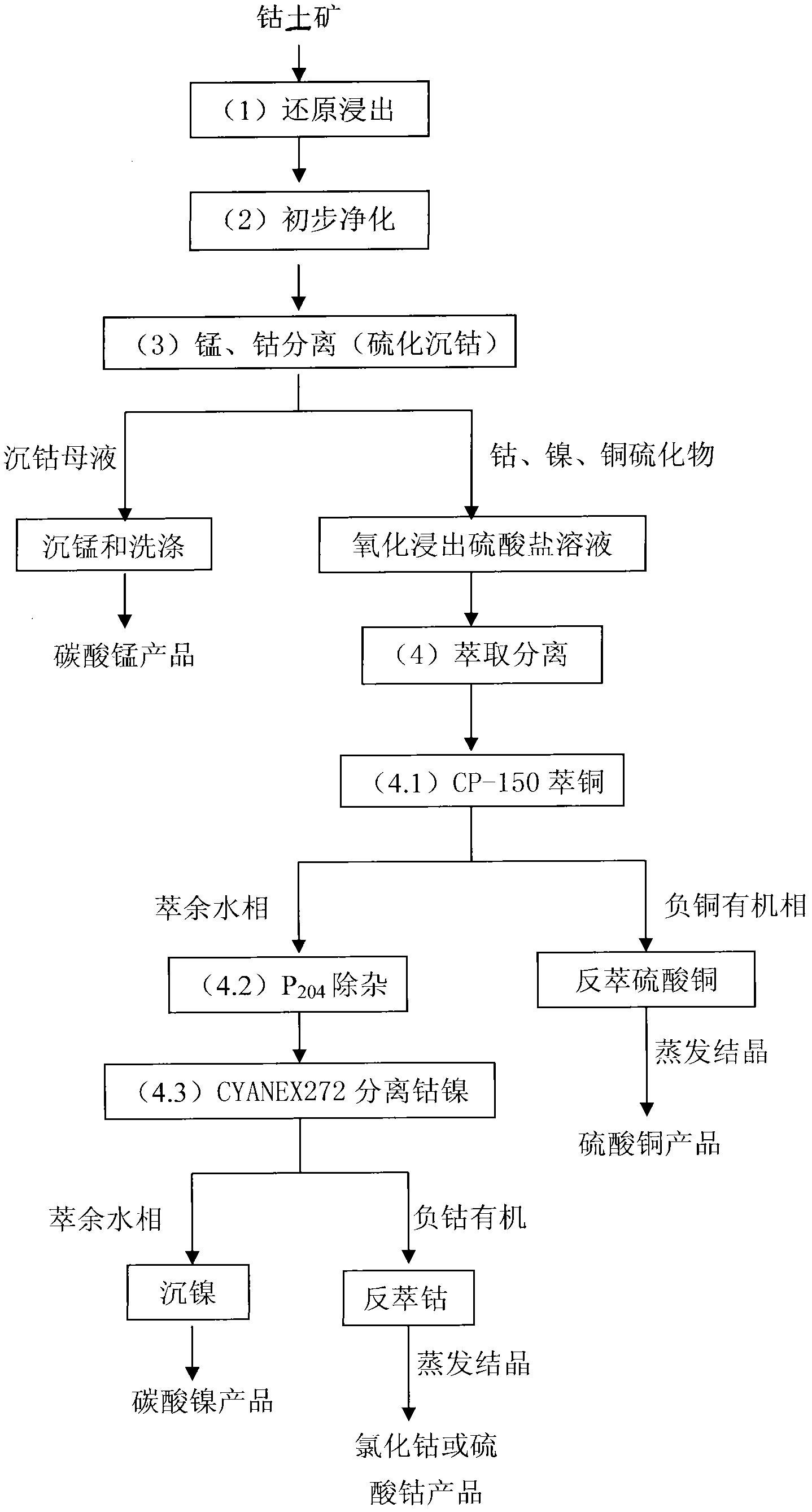

Processing method for comprehensively recovering high manganese asbolite

InactiveCN102021331AIncrease costLow recovery rateProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a processing method for comprehensively recovering high manganese asbolite, belonging to the field of hydrometallurgy. In the processing method, the high manganese asbolite is processed through four processing steps comprising (1) reduction leaching, (2) primary cleaning, (3) manganese and cobalt separation and (4) extraction separation to obtain a product manganese carbonate, copper sulfate, nickel carbonate or cobaltous sulfate. The processing method has the advantages that the source of raw materials is wide, the process and equipment are simple, the operation is stable, the energy consumption is low, the production cost is low, the practicability is wide, and the economic effect and the society effect are obvious.

Owner:HAINAN ZHONGDAO ENERGY DEV

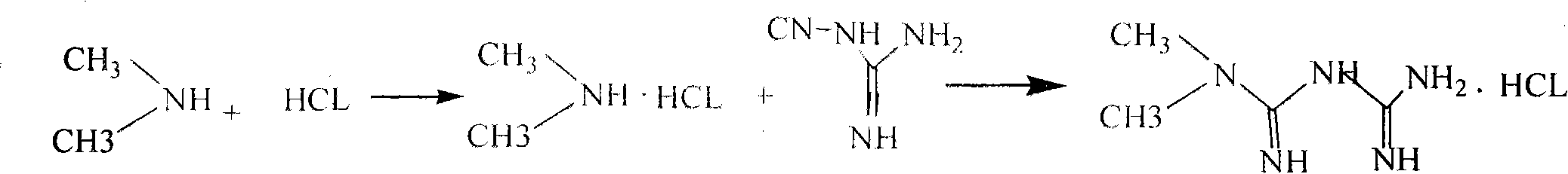

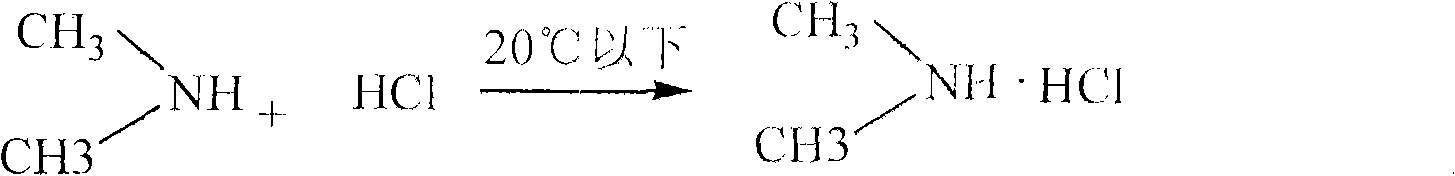

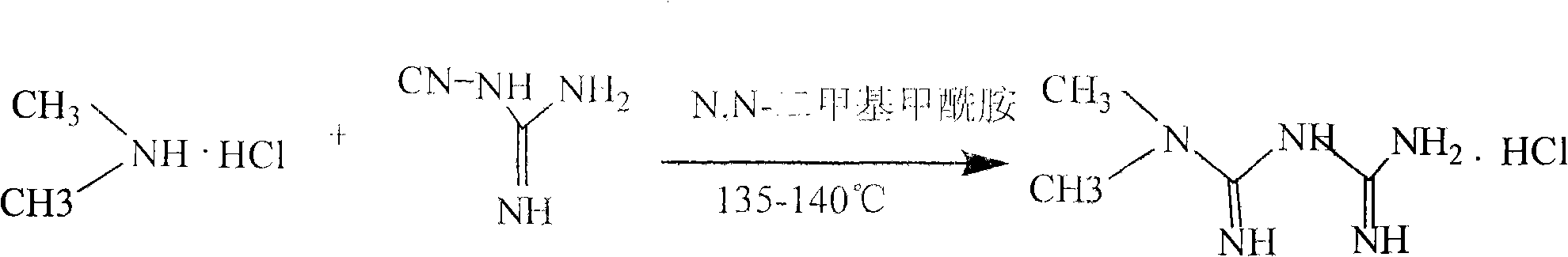

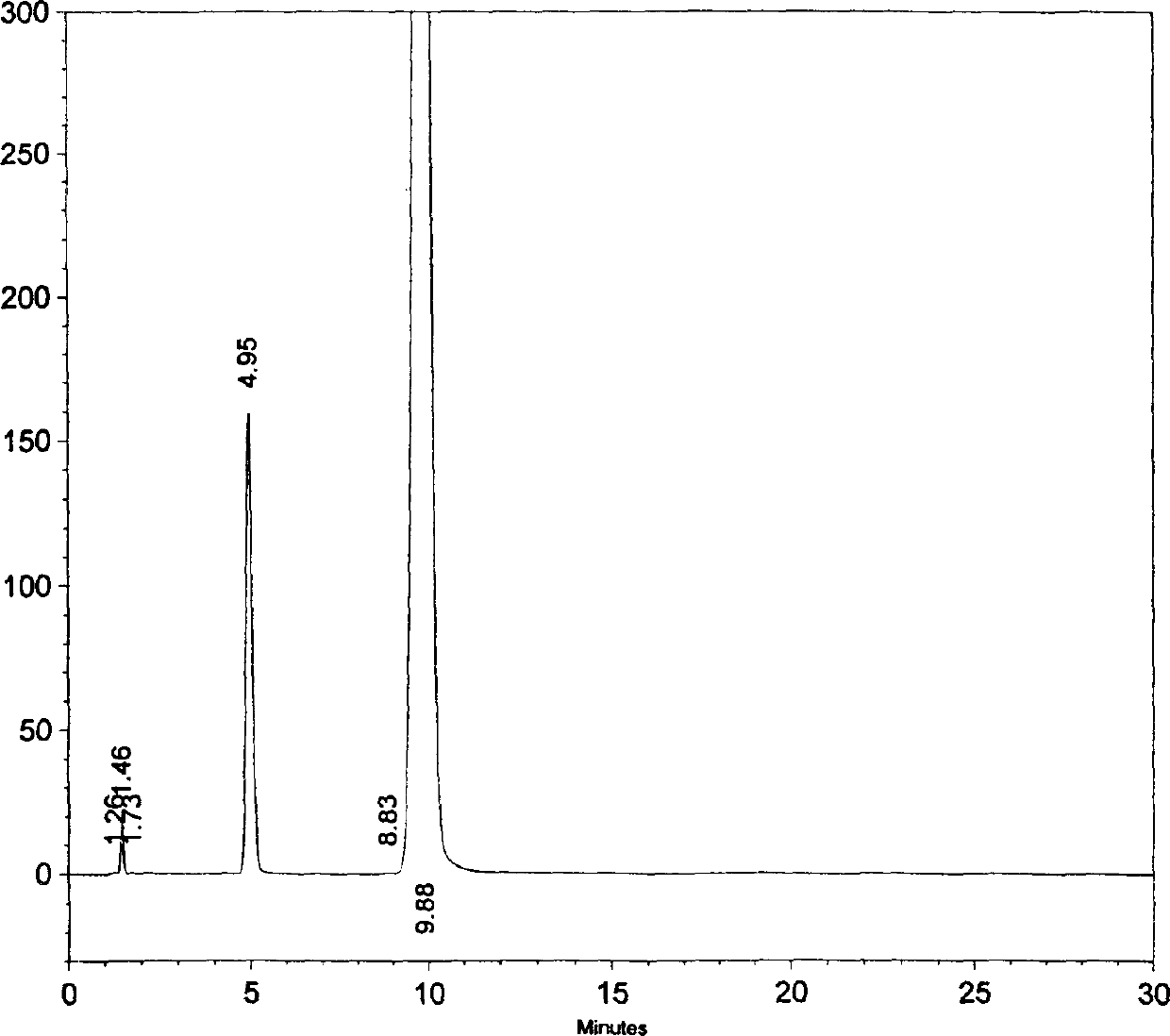

Preparation method of metformin hydrochloride

InactiveCN102516130ASimple production operationHigh purityOrganic chemistryOrganic compound preparationDimethyl formamideMetformin Hydrochloride

The invention discloses a preparation method of metformin hydrochloride. The method comprises: taking 40% dimethylamine as a starting material, which is subjected to a salification reaction with hydrochloric acid salt forming reaction of dimethylamine hydrochloride, subjecting the dimethylamine hydrochloride and dicyandiamide to an addition reaction in solvent N, N-dimethylformamide so as to generate a metformin hydrochloride crude product, then conducting refining, thus obtaining metformin hydrochloride. The solvent of the invention has viscosity insusceptible to temperature, and is easy to be separated from the product. Besides, the solvent can dissolve the reactant dicyandiamide, and even if dicyandiamide is not fully reacted, it cannot be separated out during separation of the product and the solvent, so that the production operation can be easier, and the purity of the final product can be very high. The method of the invention has the advantages of simple and easy production operation, high raw materialutilization rate, and cheap as well as easily available solvent, the market price of which is 2-3 times lower than prices of solvents in prior, and the synthesis cost is reduced by about 30%, so that the preparation method of the invention is very suitable for industrial production of metformin hydrochloride.

Owner:赤峰万泽药业股份有限公司

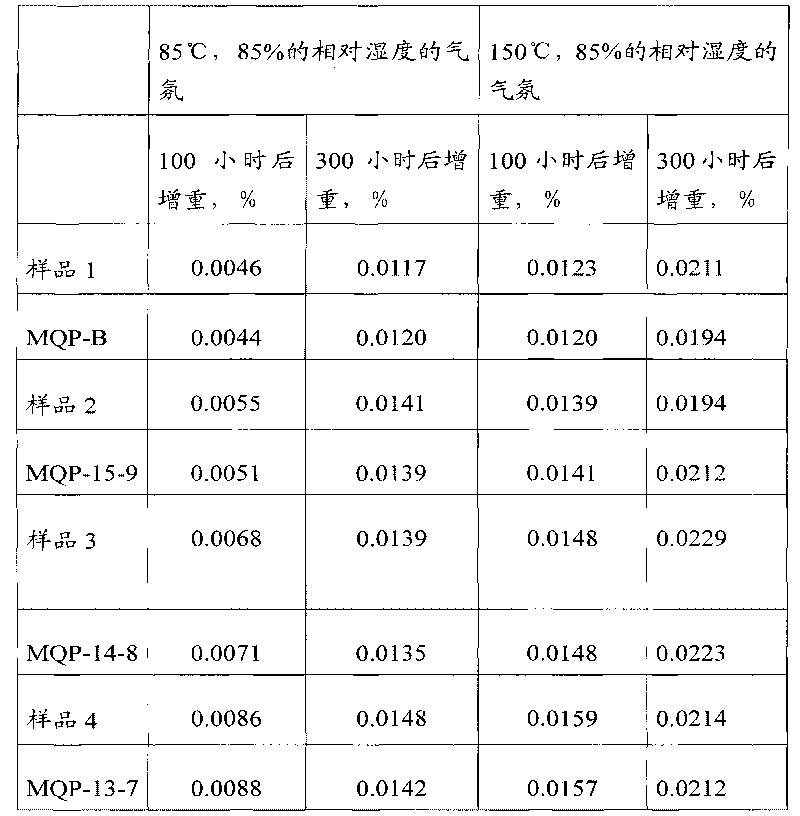

Novel neodymium iron boron magnetic material

The invention discloses a novel neodymium iron boron magnetic material, which is characterized in that the general molecular formula of the neodymium iron boron magnetic material is RExNd(0.27-x)Fe0.72B0.01, wherein the RE is selected from at least one of lanthanide / actinium metals except neodymium, and x is the weight ratio of the RE and is about 0.027-0.108. For the novel neodymium iron boron magnetic material preferably selected in the invention, rare earth element cerium (Ce) replaces the partial neodymium (Nd), good magnetism and corrosion resistance can be still kept basically, and has remarkable cost and price advantages are realized.

Owner:麦格昆磁(天津)有限公司

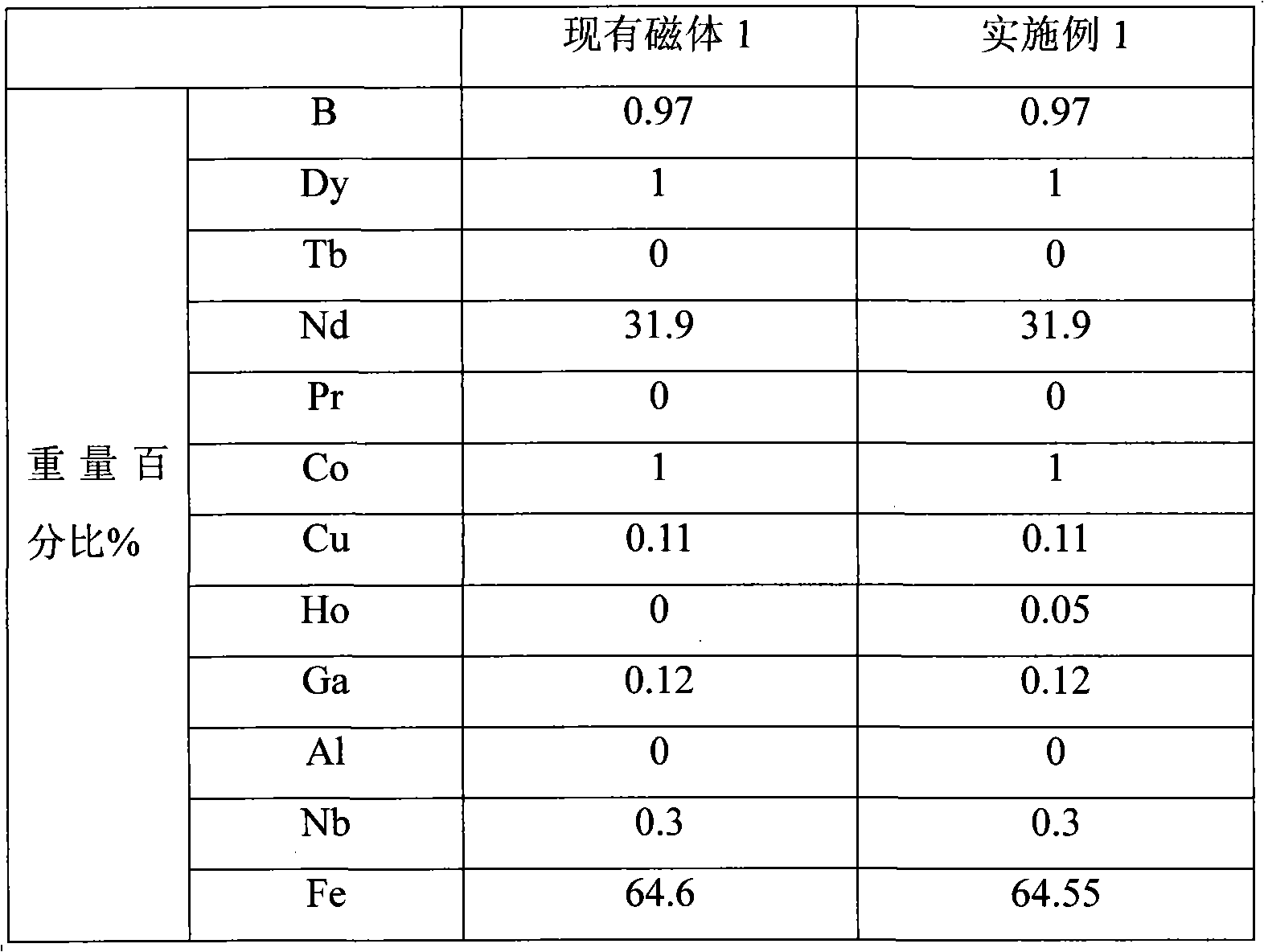

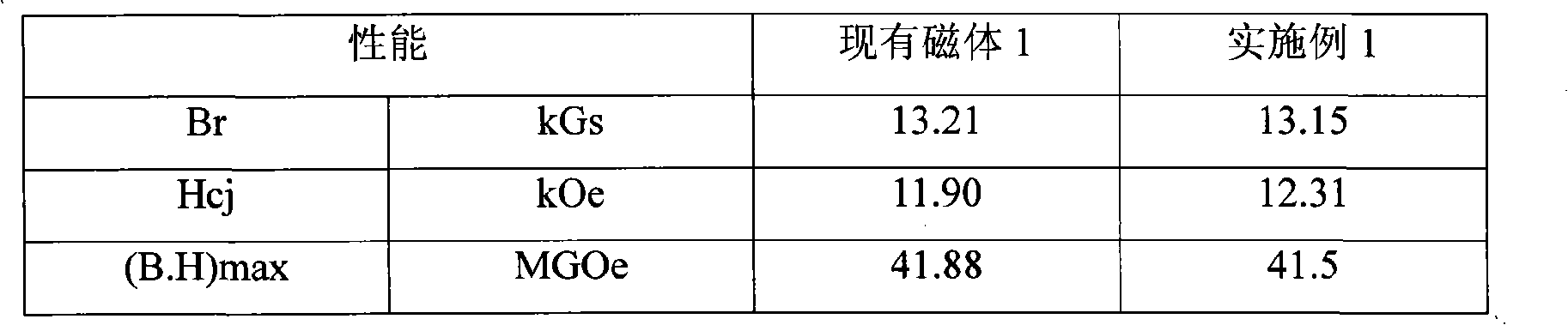

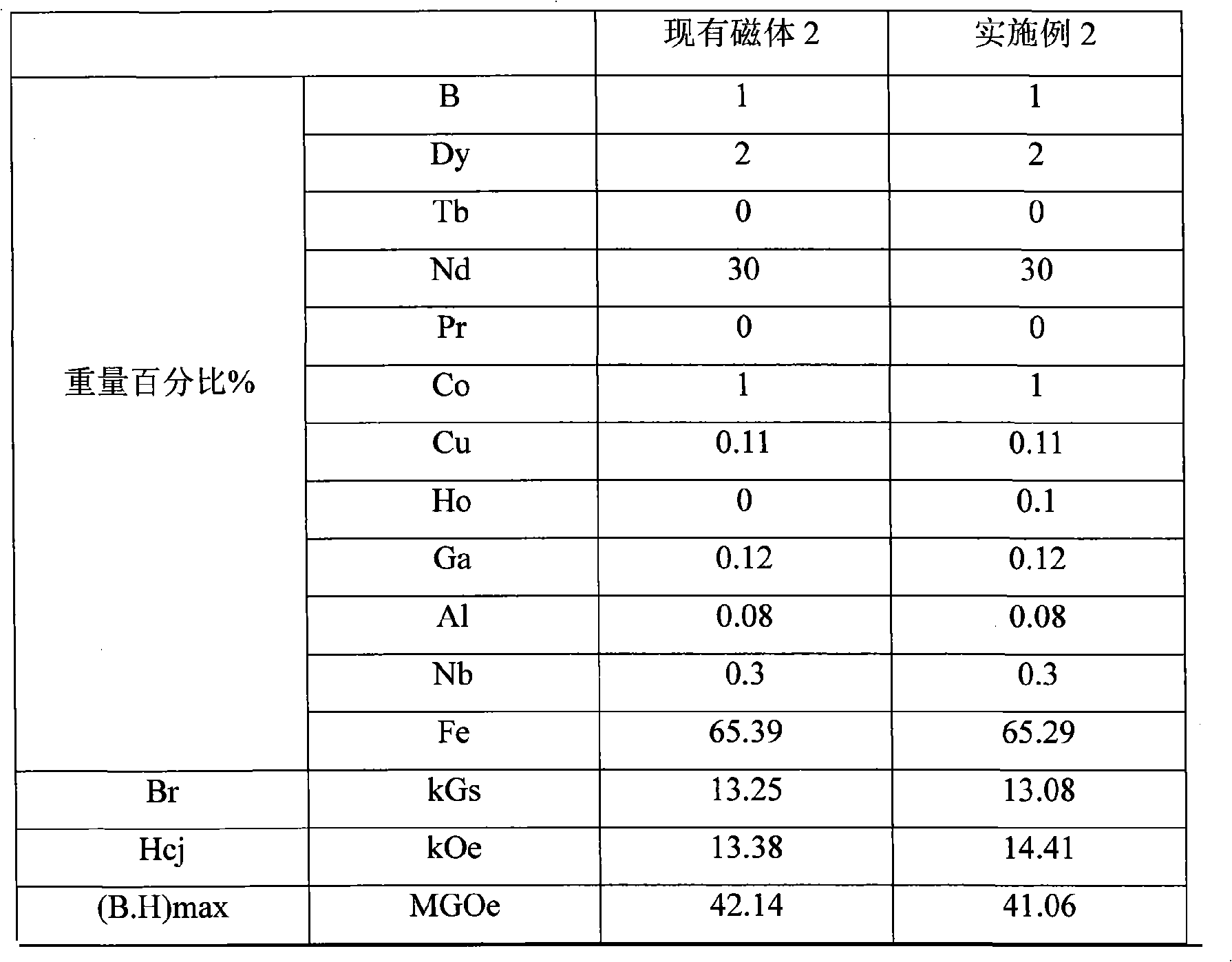

Holmium-contained Nd-Fe-B rare earth permanent magnetic material and manufacturing method thereof

InactiveCN101404196AIncreased coercive force HcjReduce manufacturing costMagnetic materialsRare-earth elementHolmium

The invention provides an Nd-Fe-B rare earth permanent magnet material containing Ho and a preparation method thereof; the composition of the Nd-Fe-B rare earth permanent magnet material containing Ho comprises Re Alpha Ho Beta B Gama MxNyFe 1-Alpha-Beta-Gama-x-y; wherein, Re is rare earth element and comprises Nd or Nd as well as one or more elements out of La, Ce, Pr, Pm, Sm, Eu, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y and Sc; M is addition element and comprises Co and Cu; N is addition element and comprises one or more elements out of Al, Ga, Nb, Zr, Ti and Sn; Alpha, Beta, Gama, x and y are respectively weight percentage of all elements; Fe is iron and unavoidable impurities; wherein, Alpha is not more than 35% and not less than 29%; Beta is not less than 0.05% and not more than 0.5%; Gama is not more than 1.20% and not less than 0.95%; x is not more than 10% and is not less than 0; y is not more than 1.50% and not less than 0. The preparation method adopts the continuous procedures such as smelting, casting, crushing, forming and sintering to prepare a magnet. The Hcj of the Nd-Fe-B rare earth permanent magnet material is improved and the production cost thereof is reduced after Ho is added in the Nd-Fe-B rare earth permanent magnet material.

Owner:ZHEJIANG SHENGHUA MAGNETIC MATERIALS

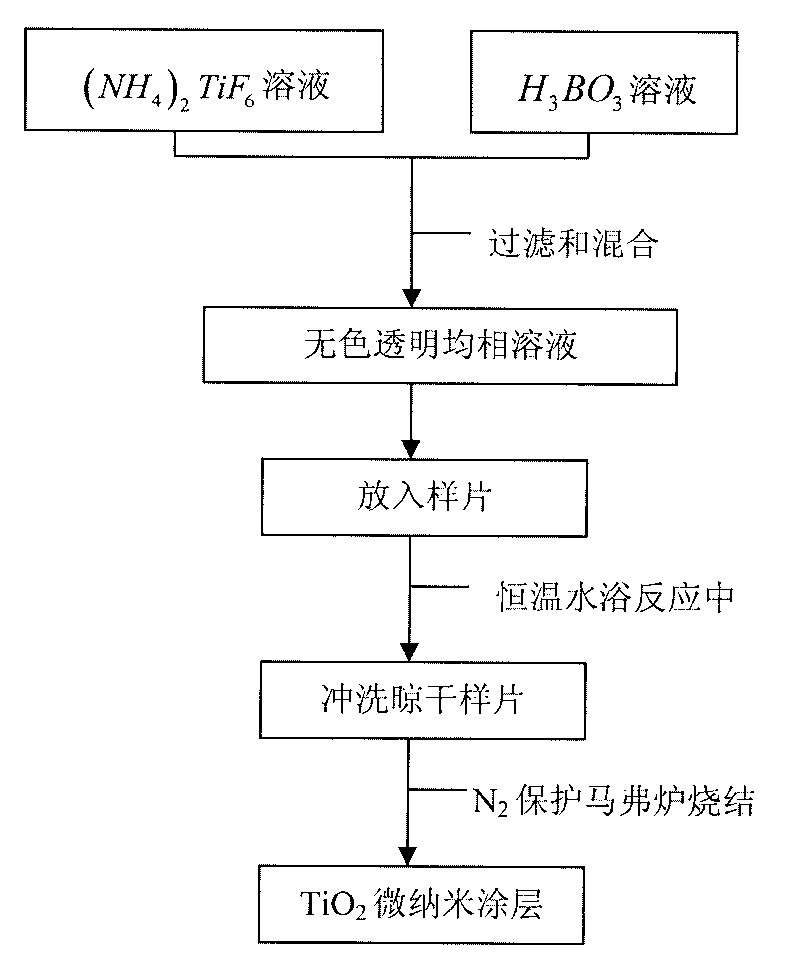

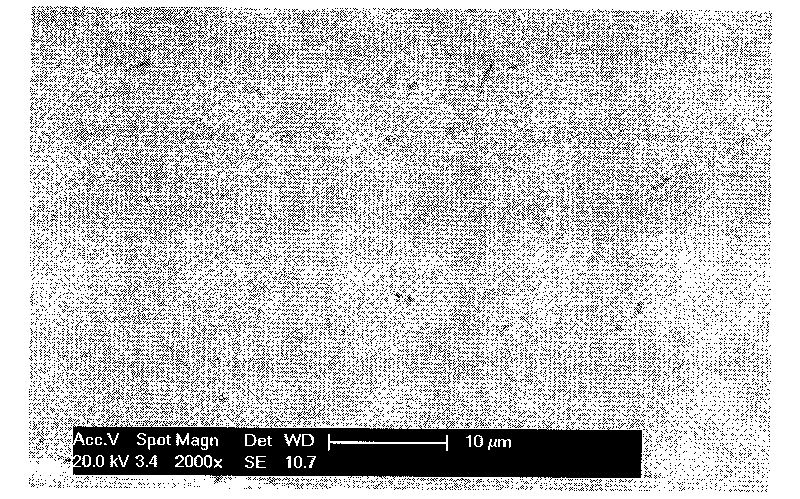

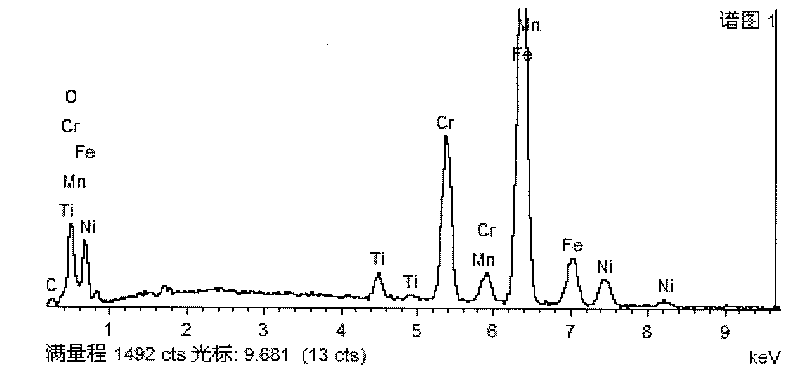

Method for preparing enhanced heat-transfer and scale prevention coating of micron/nanometer titanium dioxide on stainless steel substrate

InactiveCN101760737AUniform and dense appearanceLow market priceMetallic material coating processesPre treatmentTitanium dioxide

The invention discloses a method for preparing an enhanced heat-transfer and scale prevention coating of micron / nanometer titanium dioxide on a stainless steel substrate, comprising the following steps of: (a) pre-treating the stainless steel substrate; (b) preparing ammonium fluorotitanate and boric acid into uniform solutions, and mixing the two solutions uniformly; (c) placing the prepared mixed solution in a water bath and controlling the temperature thereof at 20-80 DEG C, suspending the stainless steel substrate perpendicularly in the mixed solution and starting to deposit to prepare the substrate coated with TiO2 thin film after the temperature of the mixed solution is stable; (d) after deposition, picking the substrate out and washing the surface of the substrate with distilled water; and (e) drying the substrate naturally, then placing the substrate in a resistance furnace to heat to obtain the micron / nanometer TiO2 surface coating. The coating prepared by adopting the method is compact and uniform in appearance and the Ra value of the sintered surface coating is substantially equal to that of the polished surface coating. The coating is high-temperature resistant and is combined with the substrate more firmly.

Owner:TIANJIN UNIV

Cultivation method for good-quality flower mushrooms

The invention discloses a cultivation method for good-quality flower mushrooms. Cultivation is completed in the mode of compounding, bagging, sterilizing, cooling, inoculating, cultivating, mushroom producing managing and harvesting. Ingredients include 78 percent of hard and mixed wood bit, 20 percent of wheat bran or rice bran, 1 percent of gypsum powder and 1 percent of white sugar; or ingredients include 42 percent of hard and mixed wood bit, 42 percent of corncob powder, 15 percent of wheat bran or rice bran and 1 percent of gypsum powder. According to the cultivation method, low-temperature and late-maturing mushroom breeds are inoculated and generate mushrooms, a mushroom stick is arranged on a cultivation frame to produce mushrooms, the low-temperature and dry weather conditions in spring and autumn are used for growth of the good-quality flower mushrooms, and the rate of the flower mushrooms can reach 60 percent or higher.

Owner:JILIN AGRICULTURAL UNIV

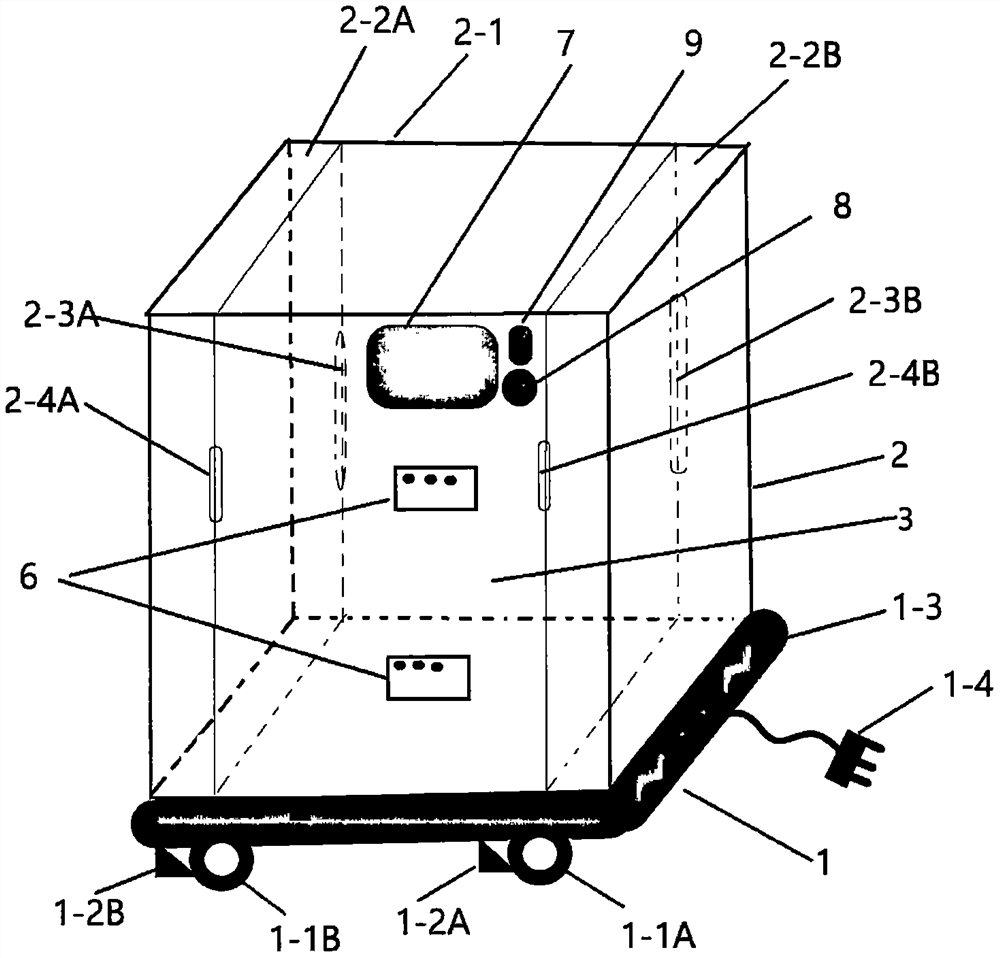

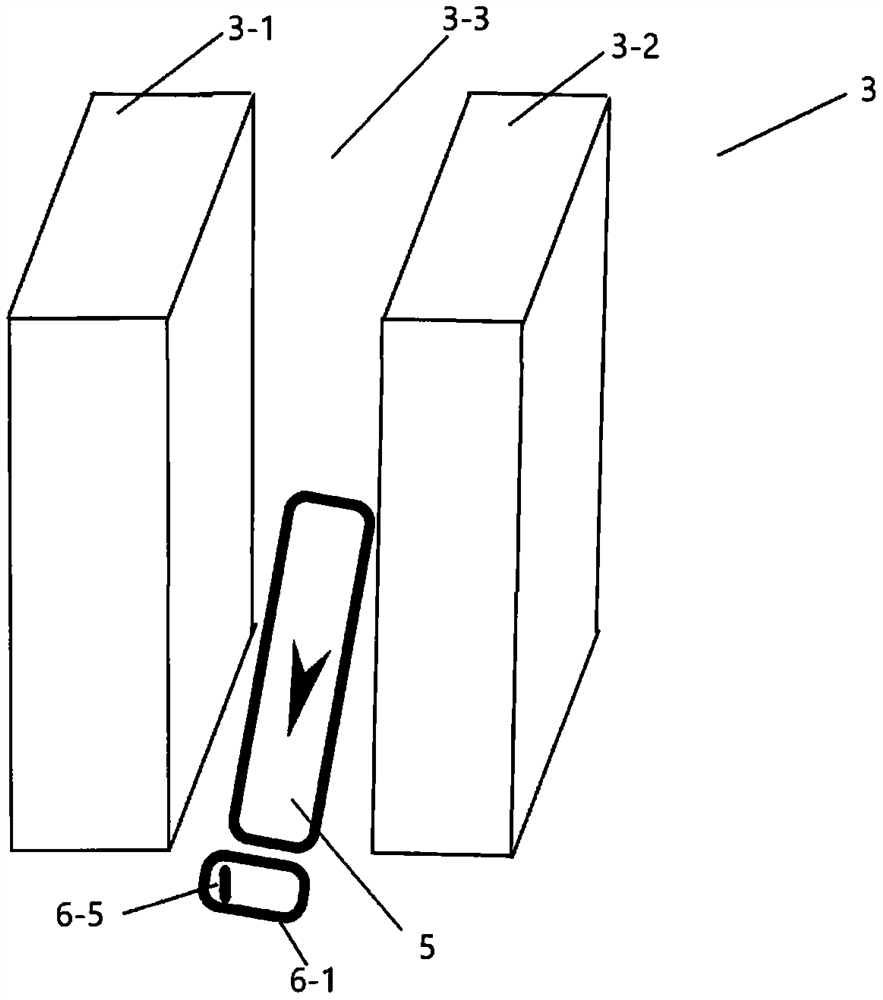

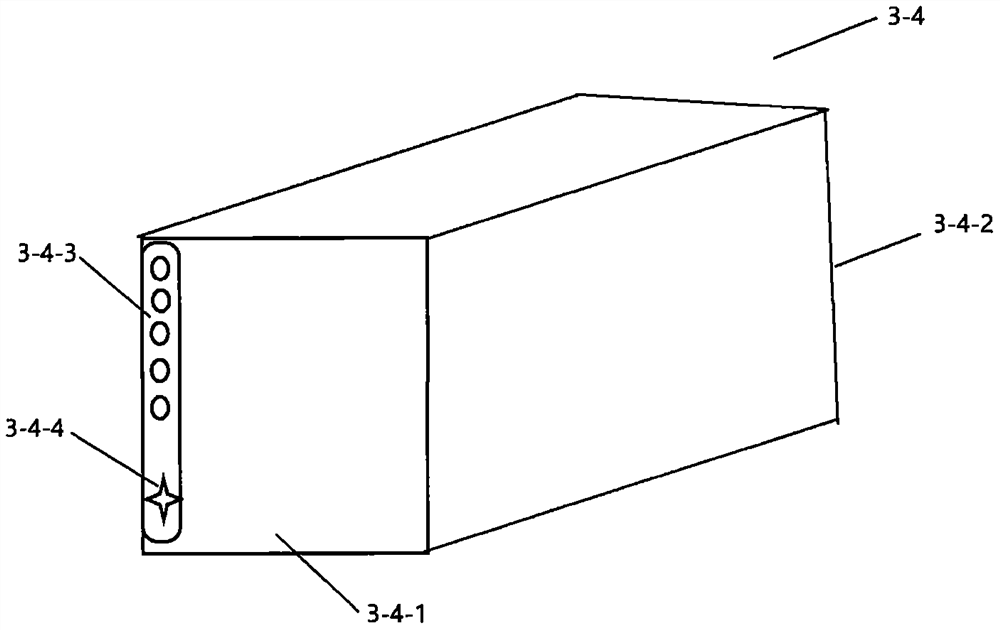

Pharmacy robot device, method and system

ActiveCN111846721AIntensive storageFull use of spaceConveyorsStorage devicesDispensaryPhysical medicine and rehabilitation

A pharmacy robot device comprises a chassis, a pharmacy, push rod equipment, a conveyor belt and an induction door, and is used for executing the functions of drug replenishment, delivery and inventory, and an AI verification system and an intelligent diagnosis system are combined to realize physician service, pharmacist service and pharmaceutical affair service of the pharmacy. According to requirements, a plurality of pharmacy robot devices can be linked in parallel or in series, the variety and number of stored drugs are increased, the device is simple in structure and flexible to deploy and configure, and therefore, the operation cost of a pharmacy shop is reduced.

Owner:XIAMEN BONAI MOLD DESIGN CO LTD

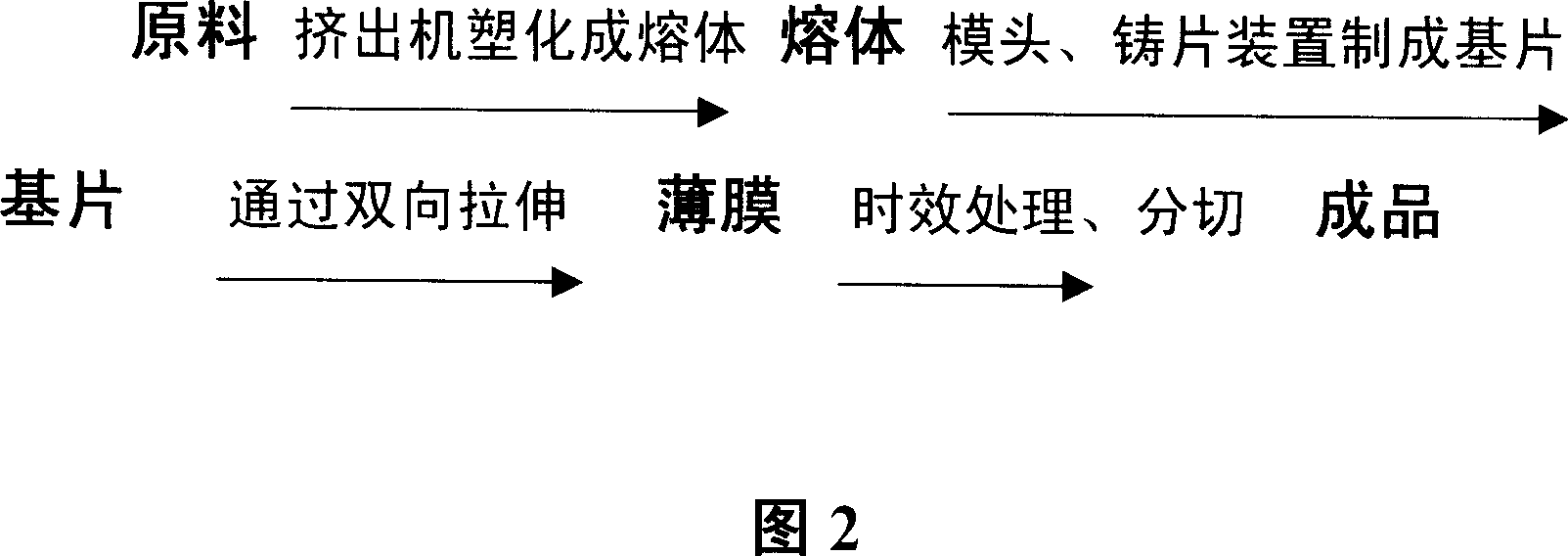

Vacuum aluminium coating laser bidirection drawed BOPP film and its production method

InactiveCN1948000ALow market priceIncrease productivitySynthetic resin layered productsSurface layerOptoelectronics

A bidirectionally stretched polypropene film substrate with high aluminum-plating effect, transfer effect and laser effect is composed of upper surface layer, core layer and lower surface layer, which are combined through heat fusing and co-extruding. It is prepared from cheap homopolypropene. Its preparing process is also disclosed.

Owner:DAQING PETROLEUM ADMINISTRATION

Culture mediums for producing doramectin through fermentation of mutant streptomyces avermitilis and material supplement method

ActiveCN104561180ALow market priceIncrease productionMicroorganism based processesFermentationBiotechnologyPolystyrene

The invention relates to culture mediums for producing doramectin through fermentation of mutant streptomyces avermitilis and a material supplement method. The culture mediums comprise a seed culture medium and a fermentation culture medium, and are characterized in that the seed culture medium comprises corn lees and low-temperature pressing soya bean cake powder; the fermentation culture medium comprises corn lees, low-temperature pressing soya bean cake powder, polystyrene non-polar adsorbent resins and nonionic surfactants. The cost problem of raw materials and auxiliary materials are solved, the environment influence on sources of the raw materials and the auxiliary materials is reduced to the hilt, the supplying of the raw materials and the auxiliary materials is sufficient, the stable and efficient production of the doramectin is realized, and at the same time, the fermentation unit can be improved by using the culture mediums and the material supplement method.

Owner:宁夏泰瑞制药股份有限公司

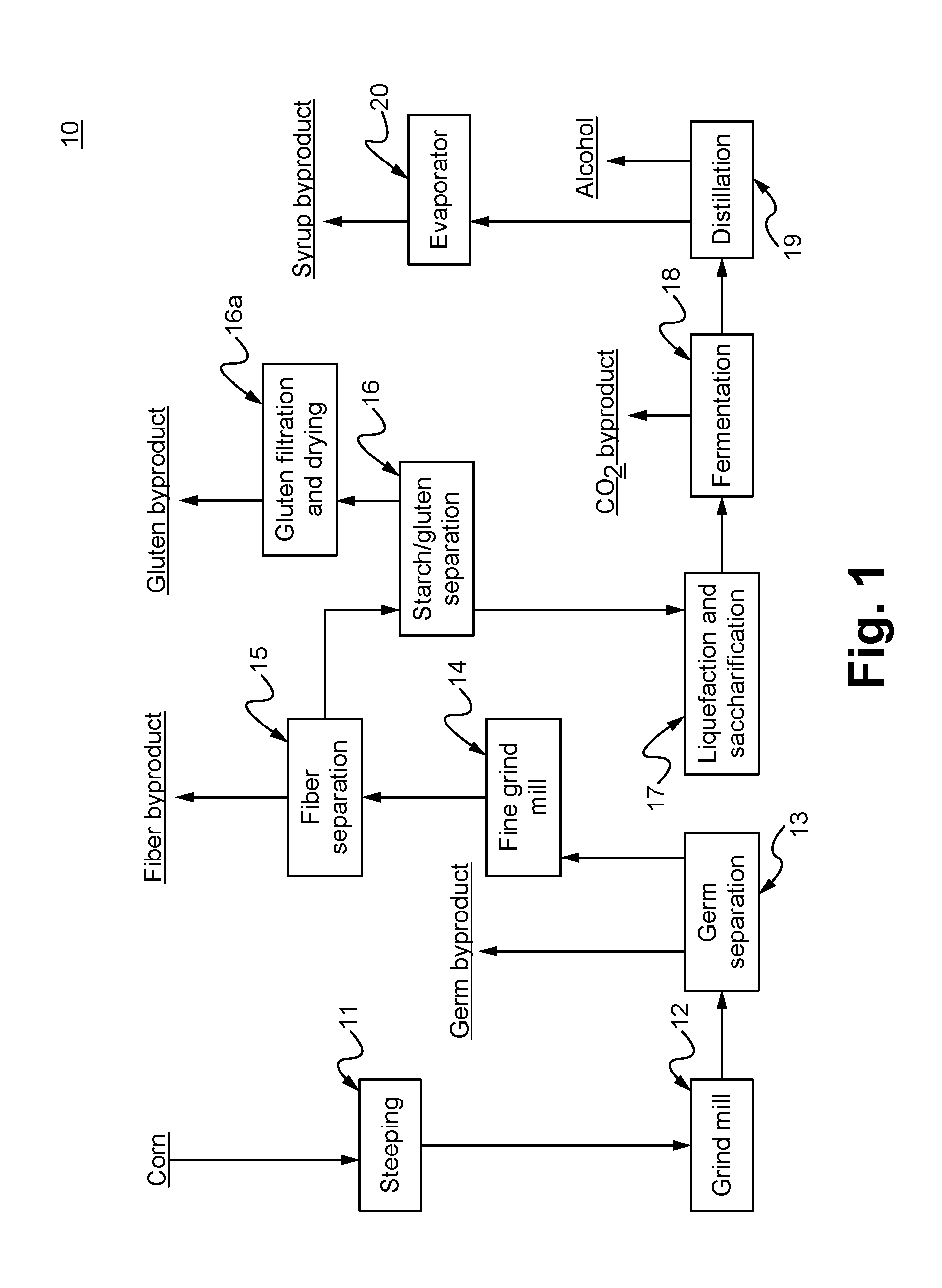

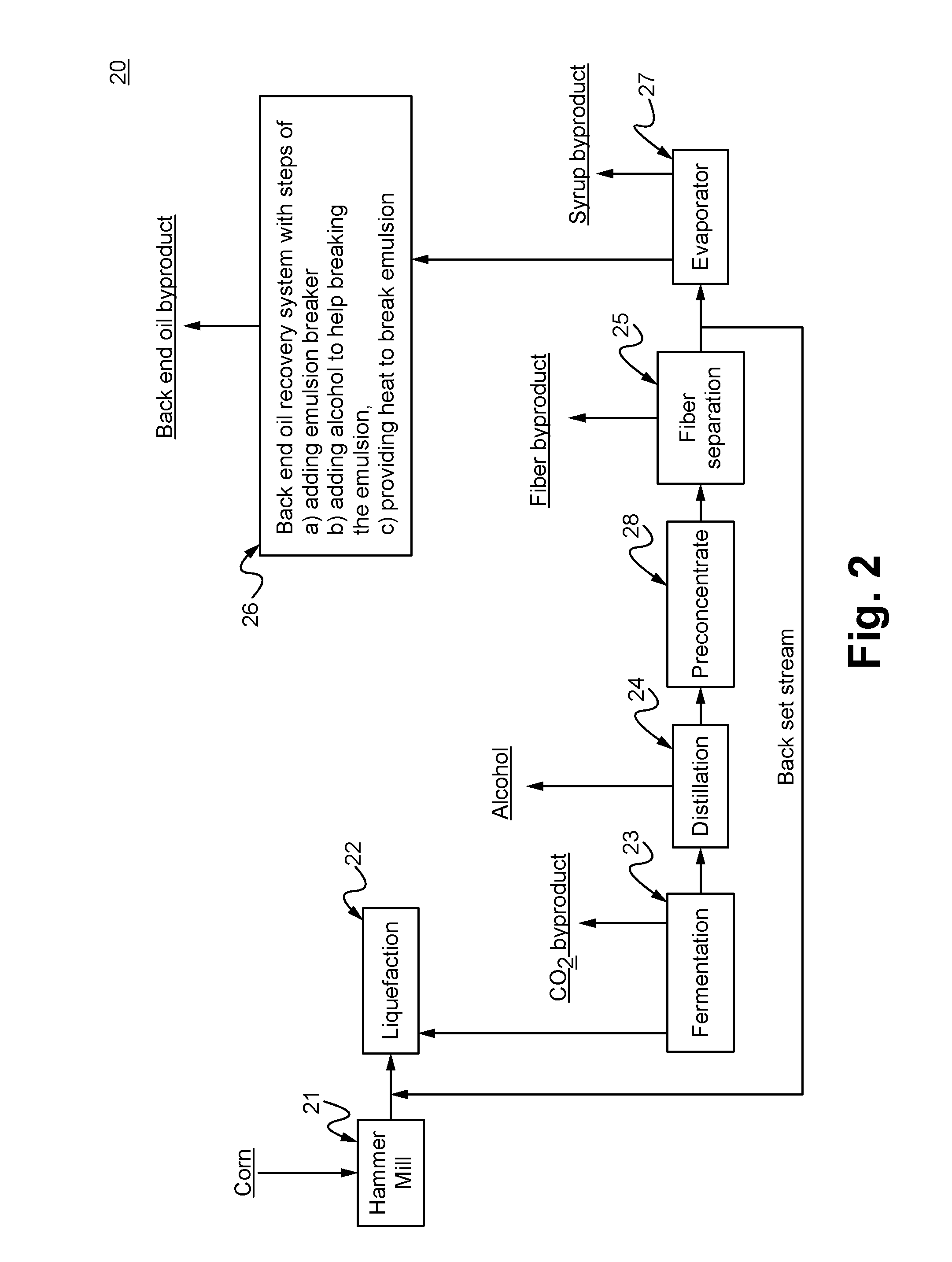

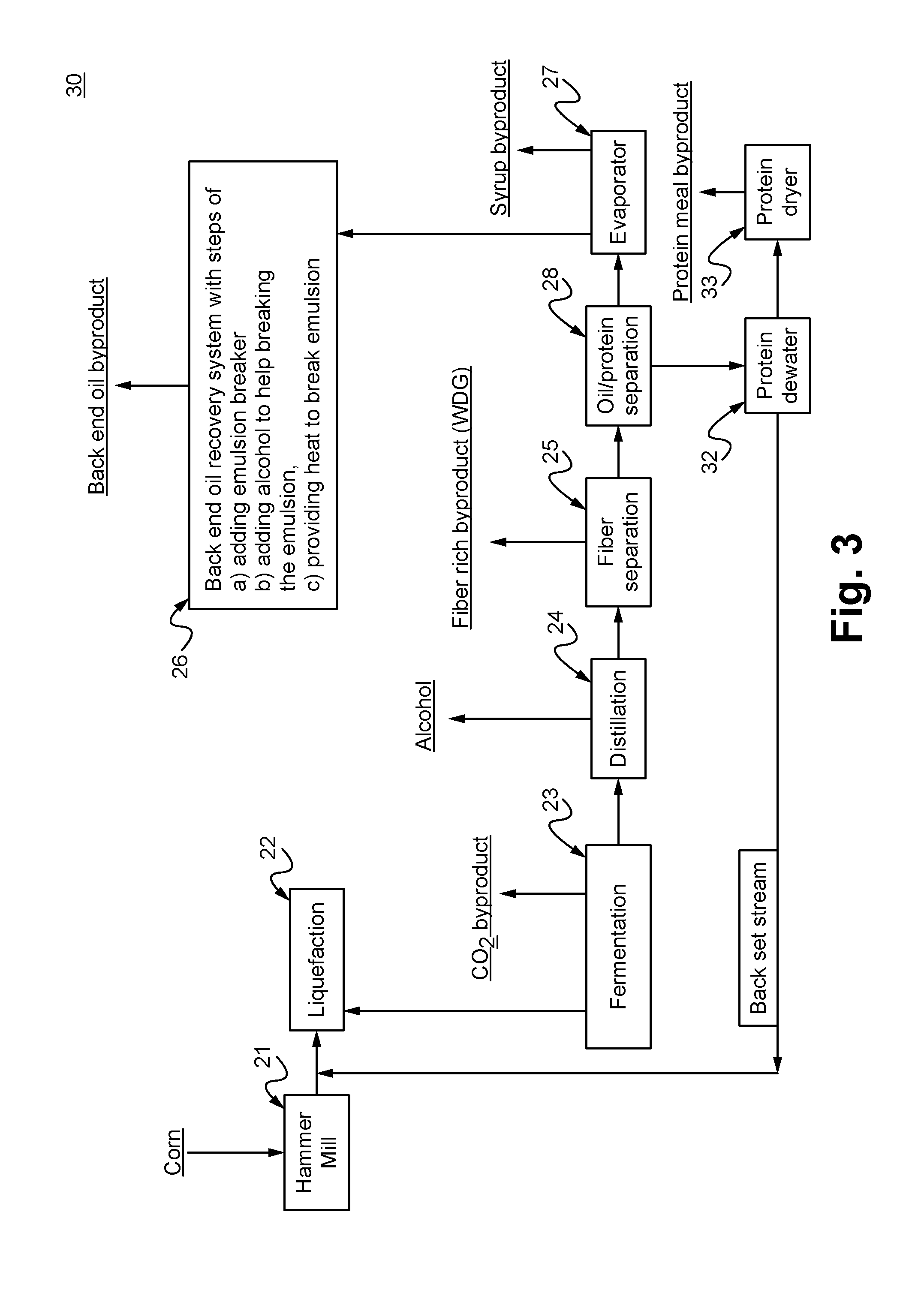

Method of and system for producing a high value animal feed additive from a stillage in an alcohol production process

InactiveUS20160374364A1Extended shelf lifeLow transportation costBy-product recoveryFeeding-stuffCo productOrganic acid

A method of and a system for controlling the culture growth of high value feed organisms in a co-fermented system that produces ethanol and for the culture to consume both nonprotein and carbohydrate based products. The method and system produce products that enhance the nutritional value of the co-products. The method further provides a system to grow unique value added co-products, including a mycotoxin-free animal feed, for the monogastric and ruminant animal feed markets including aquaculture, poultry, swine, companion animals and livestock animals. The method includes the production of organic acids to enrich animal feed for enhanced animal performance with reduced antibiotic components in the feed. The method includes the production and incorporation of probiotics in the animal feed product.

Owner:LEE TECH LLC

Method for preparation of m-aminobenzenesulfonic acid by catalytic hydrogenation

ActiveCN103804242ALow market priceReduce loadChemical recyclingSulfonic acid preparationChemistryActivated carbon

Belonging to the field of fine chemical industry, the invention in particular relates to a method for preparation of m-aminobenzenesulfonic acid by catalytic hydrogenation. The method includes: taking sodium m-nitrobenzene sulfonate as the raw material, adding water for dissolving, boiling the mixture by activated carbon, conducting hot filtration, adjusting the pH value of the filtrate to 7.5-8.5 by a sodium hydroxide aqueous solution, employing Pt-Ru / C as a catalyst to perform hydrogenation reduction for preparation of m-aminobenzenesulfonic acid, ending the hydrogenation reduction reaction when the hydrogen pressure no longer changes, filtering out the Pt-Ru / C catalyst at the end of the reaction, firstly washing the catalyst by ethanol, then carrying out washing recycling, with the recycled catalyst being able to be applied over 50 times and still having a conversion rate and selectivity up to 99%; and subjecting the obtained filtrate to acid precipitation to pH of 2, thus obtaining a white crystal, i.e. the target product m-aminobenzenesulfonic acid. The method provided by the invention lowers the catalyst cost, improves the utilization rate of equipment, and also overcomes the problems of pollution and energy consumption in the regeneration process of the catalyst.

Owner:中国中化股份有限公司 +1

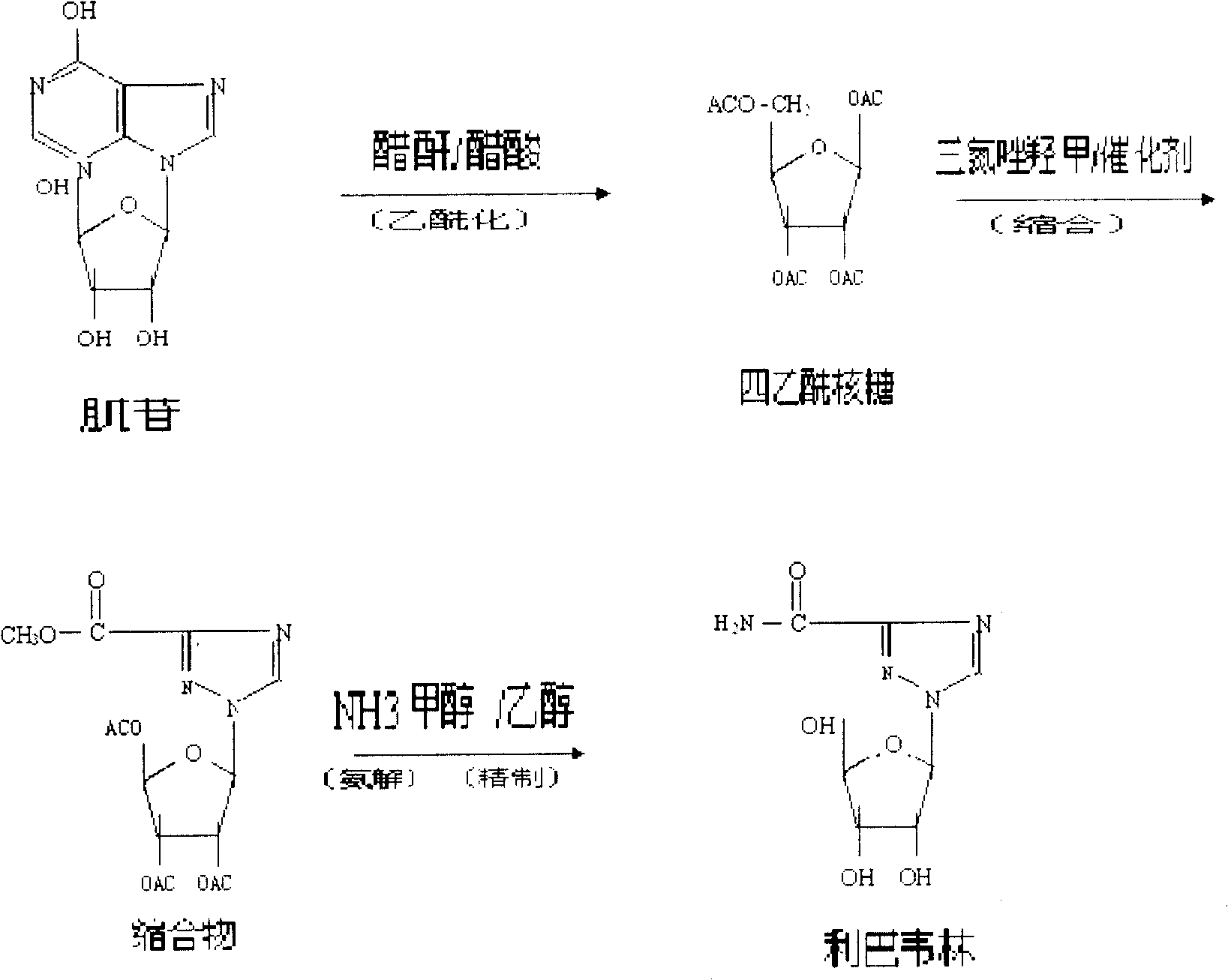

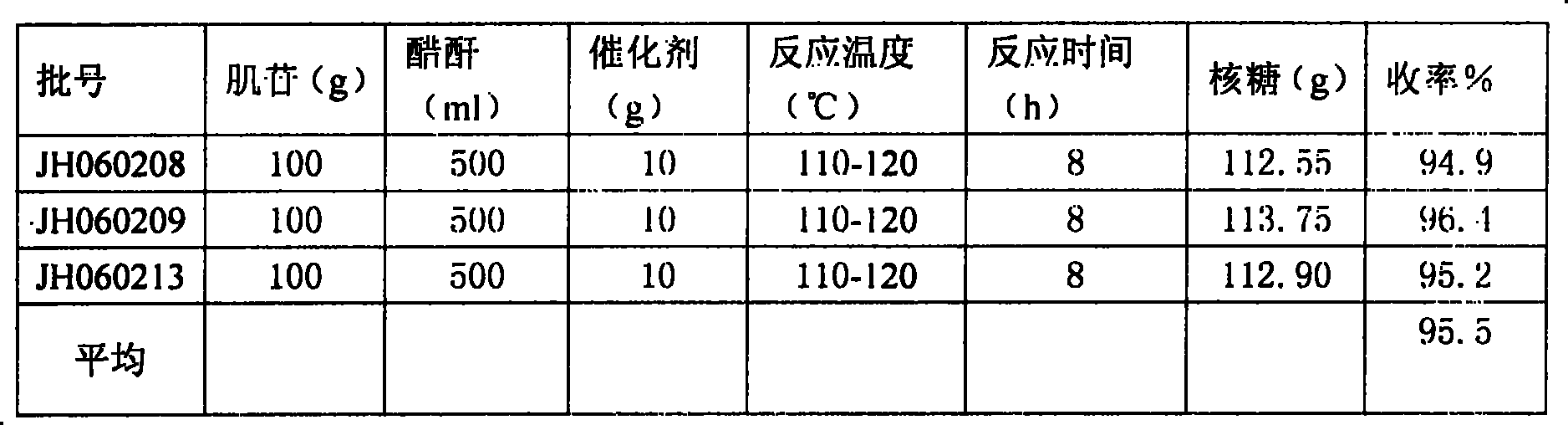

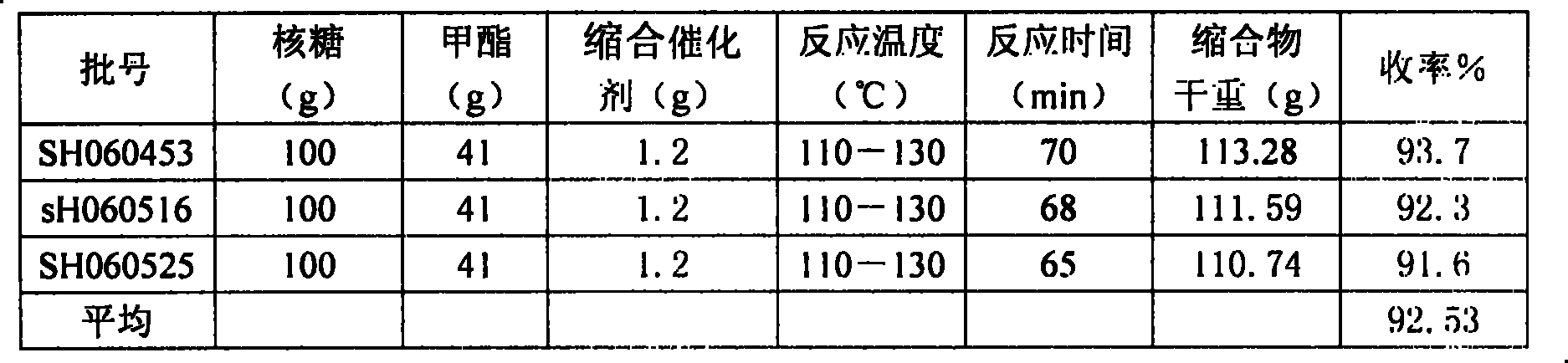

A kind of preparation method of ribavirin

ActiveCN102286046ARaise the level of industrial productionLow market priceSugar derivativesSugar derivatives preparationInosineAlcohol

The invention discloses a preparation method of ribavirin, comprising the following steps: A, by taking inosine as a raw material, adding acid and a catalyst I for acylation reaction to generate ribofuranose tetraacetate; B, respectively treating the ribofuranose tetraacetate obtained in the step A and 1,2,4-triazole-3-carboxylic acid methyl ester by using active carbon firstly, then uniformly mixing the ribofuranose tetraacetate and the 1,2,4-triazole-3-carboxylic acid methyl ester, and then adding a catalyst II for condensation reaction to obtain a condensation compound; C, subjecting the condensation compound obtained in the step B to ammonolysis in ammonia and methyl alcohol to generate crude ribavirin; and D, carrying out refinement on the crude ribavirin obtained in the step C to obtain pure ribavirin. The method is simple in operation, good in selectivity, clean and environment friendly and high in yield of ribavirin.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

Treatment method of bird's nests

The invention discloses a treatment method of bird's nests. The treatment method mainly comprises the following steps of cleaning, sterilizing, soaking, dehydrating, quick-freezing and vacuum drying, the bird's nests are obtained through the treatment steps and are hygienic, safe, bacteria-free and free from additives, nutrient components in bird's nest raw materials are reserved, and users can eat favorable bird's nests in a short time through the manners of brewing and stewing. According to the treatment method disclosed by the invention, the problem that the bird's nests are difficult to process, preserve or transport is perfectly solved, and the bird's nests have high market values.

Owner:杨新远

Fabric dirt pretreatment agent containing steady biological enzyme complex and low-activity substance and preparation method thereof

ActiveCN101514306ALow cost performanceLow market priceSurface-active detergent compositionsDetergent perfumesFatty alcoholPollution

The invention relates to a fabric dirt pretreatment agent containing a steady biological enzyme complex and a low-activity substance and a preparation method thereof. A product of the invention takes fatty alcohol polyoxyethylene ether (7), fatty alcohol polyoxyethylene ether (9), sodium fatty alcohol-polyoxyethyleneether sulfate (70 percent), fatty alcohol polyoxyethylene ether (JFC), polyacrylate, sodium citrate, boric acid, propylene glycol, prolease, calcium chloride, isothiazolinone, essence, and deionized water as raw materials; and the method adopts a polymer to ensure that the prolease forms a polymer complex in a system by researching biological enzyme stabilization technology, which ensures the long-term effective activity of biological enzyme, ensures that the product can achieve stronger detergency when the content of an active substance is 10 percent or so and has steady quality during the storage, and achieves the aims of saving resources and protecting environment. The product is neutral, and has unique advantages in preventing fading, reducing the damage of clothes, protecting skin, and reducing pollution.

Owner:北京绿伞科技股份有限公司

Formula and preparation method of cationic polymer

InactiveCN101817912ALow costLow market priceWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationIonic polymerizationPolymer

The invention provides a formula and a preparation method of a cationic polymer. The raw material formula of the cationic polymer comprises the following components in part by weight: water 5-50, acetone 3-25, amine 5-30, aldehyde 5-40, alkaline regulator 3-12 and acidic regulator 5-20. In the method, a water soluble cationic polymer is prepared from aldehyde, acetone and amine by a nucleophilic addition reaction, an aldol condensation reaction and a Michael addition reaction in the presence of acid and alkali catalysts in turn and by a two-step feeding process. The method has the advantages that: the raw material cost is low, the synthesis process is simple and easy to implement; the preparation conditions are mild and safe; and the obtained product has high cation content and has high decolorizing and flocculating effects on anionic dye waste water.

Owner:FUZHOU UNIV

Method for quickly breeding large-size cherry blossom seedlings

The invention relates to the technical field of asexual reproduction of plants, in particular to a method for quickly breeding large-size cherry blossom seedlings. The method comprises the processes of time selection of grafting, selection and preparation of scions, grafting method and management after grafting, wherein the grafting method comprises the following steps of: selecting vigorous living cherry trees which have the ground diameters of 10 to 20 centimeters, have the heights of 2 to 2.5 meters and are not damaged by diseases and insects as stocks; treating the branches to be grafted in the cherry trees, cutting out smooth cross sections, and longitudinally cutting from the 1 / 4 to 1 / 3 of the sections and from top to bottom, wherein the cuts are flat and smooth, and the lengths of the cuts are 2 to 3 centimeters; inserting the cut scions into the cuts to ensure that the cambium of the long inclined plane of each scion is aligned with and tightly attached to the cambium of each stock, and fastening with a plastic film strip from bottom to top; and covering a plastic bag on each scion, and pricking 5 to 6 holes in different parts of each plastic bag by using a fine nail, wherein 2 to 3 scions are grafted to the side branch of each stock.

Owner:江苏八达园林有限责任公司

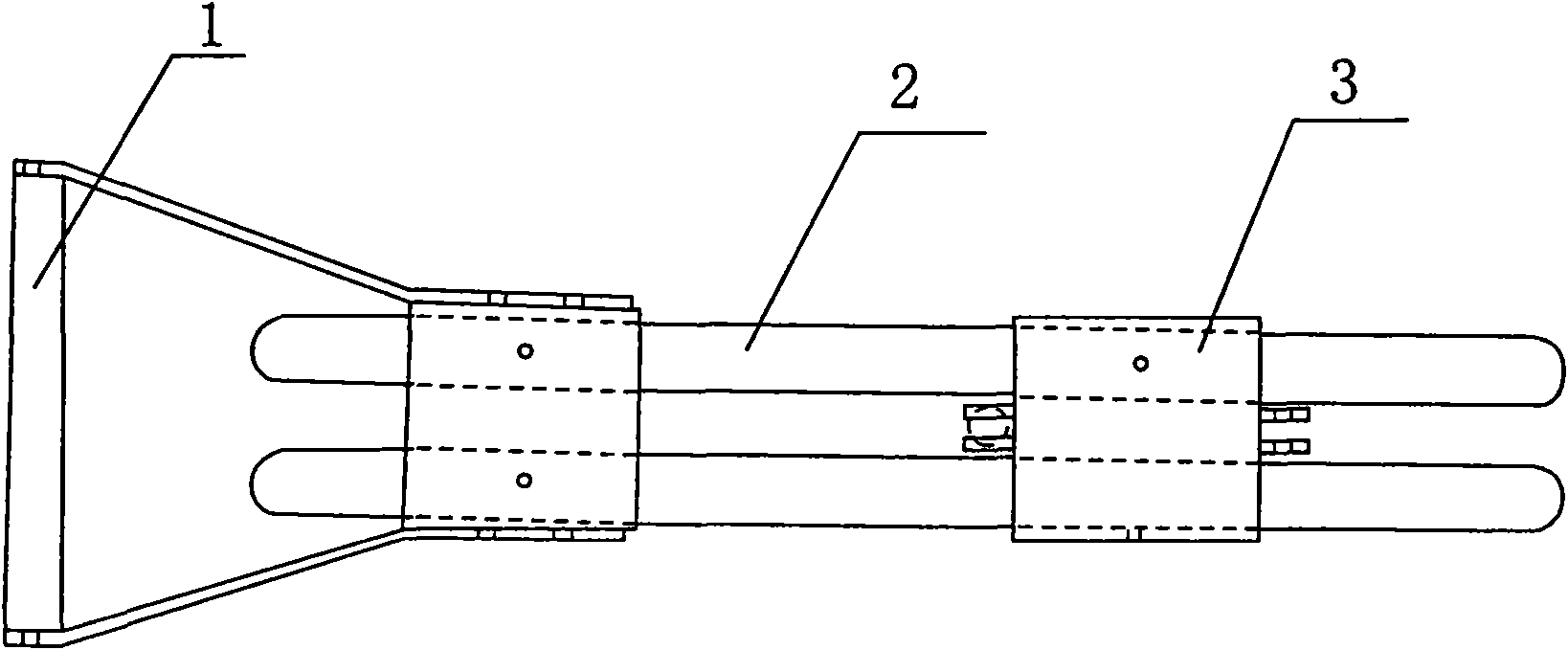

Voice prompt manual cardiopulmonary resuscitator

InactiveCN101612090AAirway patencyAvoid direct contactElectrotherapyArtificial respirationCardiorespiratory arrestEngineering

The invention relates to a medical appliance, in particular to a voice prompt manual cardiopulmonary resuscitator used in first aid and rescue of cardiac arrest cases. The major technology adopts manual operation that: a user can hold a handle by hand to press down an adjustable pressing rod at a frequency of 100times / minute; thus, a pressing column is driven to move up and down 4 to 5cm, and a pressing rubber head presses the lower part of a breastbone to move up and down 4 to 5cm in the same way, thereby reaching the goal of cardiac compression; moreover, when moving up and down, the pressing column pulls an air-compressing rack and an air sac cover to move downwards periodically at a frequency of 10times / minute; and a ventilation change-over switch at the upper end of the air-compressing rack can be adjusted to ensure that 300 or 600ml air in an air sac enters the respiratory tract of a patient through a chassis air sac blow vent, an air division check valve, and the like; thus, an inspiratory process of the patient is completed. The voice prompt manual cardiopulmonary resuscitator has the advantages of simple structure, easy manufacturing, low price and no restriction on using condition.

Owner:刘大志

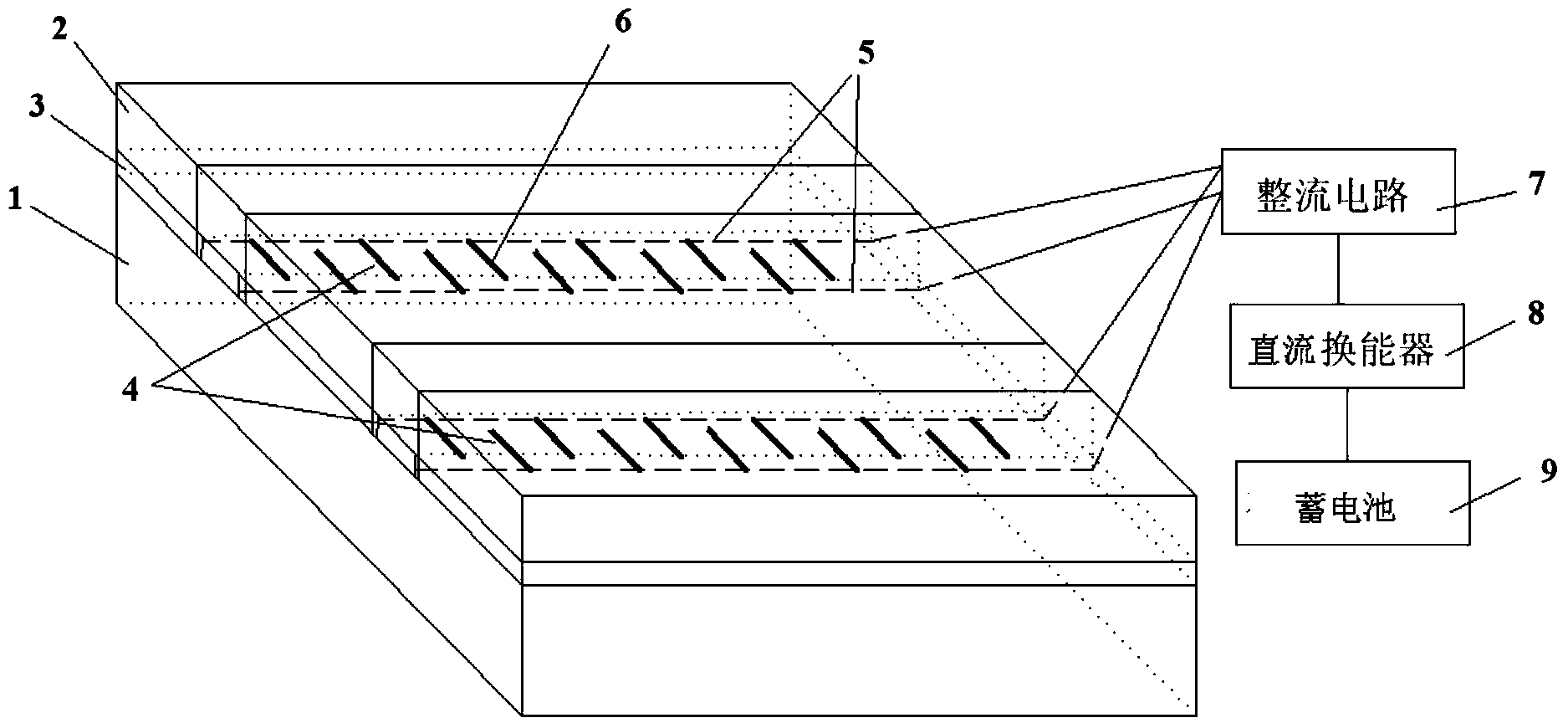

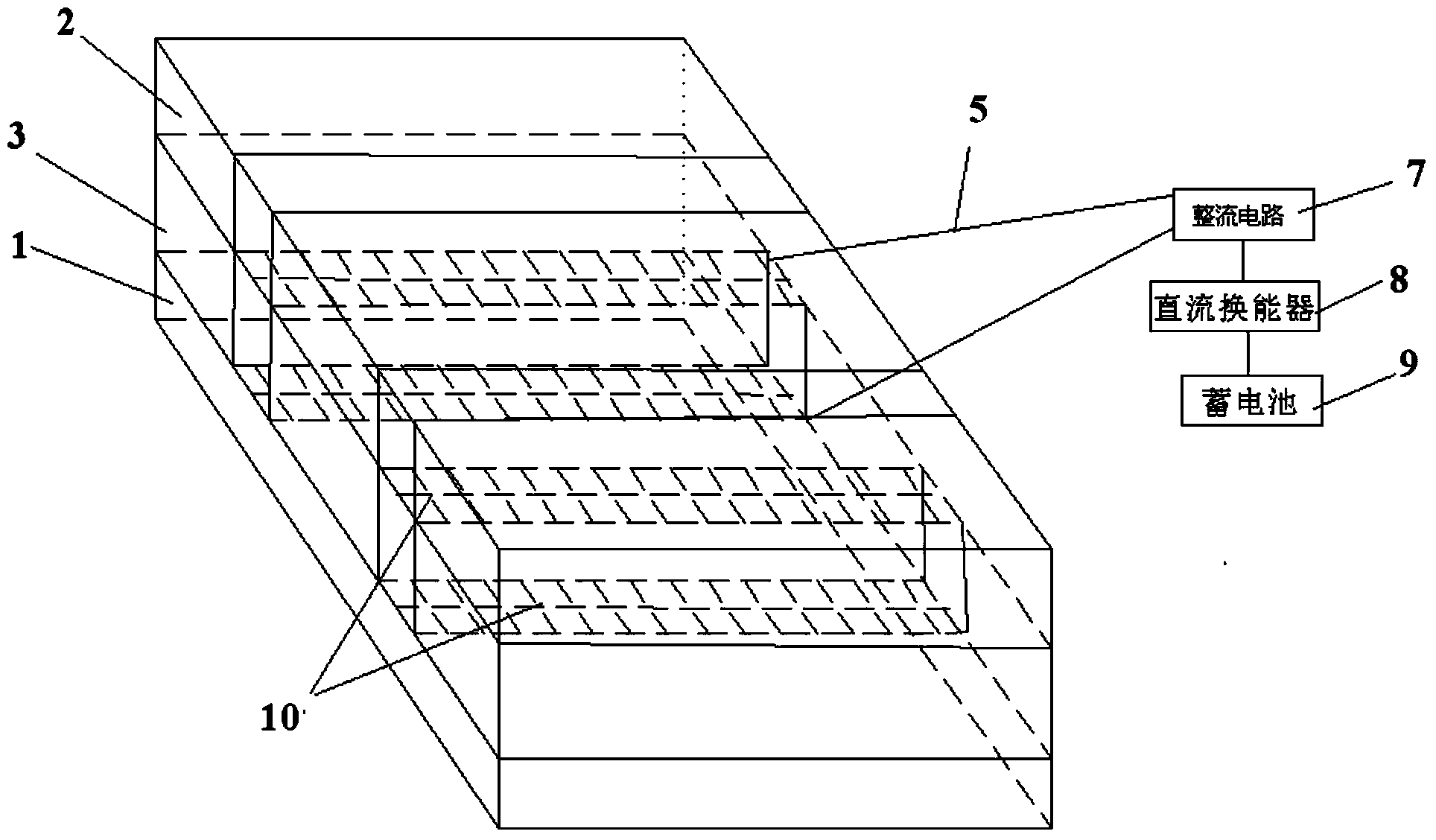

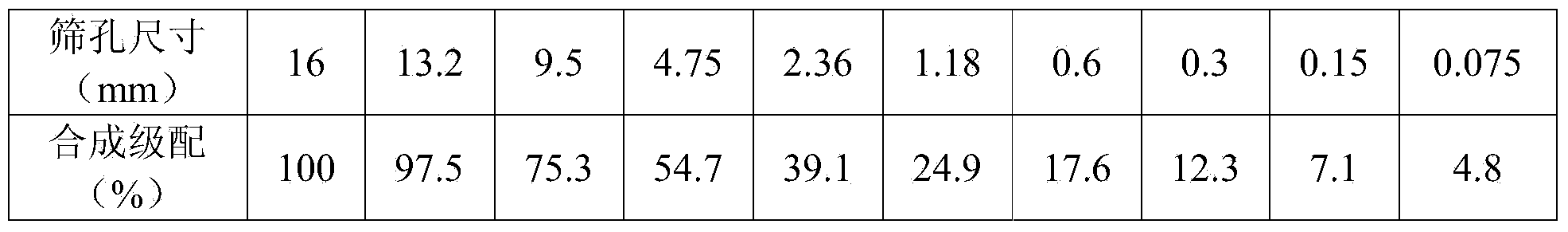

Piezoelectric asphalt concrete and power generation pavement structure thereof

ActiveCN103669151AImprove economyIncrease storage capacityIn situ pavingsTemporary pavingsElectricityConductive materials

The invention provides a piezoelectric asphalt concrete, which is composed of the following raw materials in parts by weight: 83 to 90 parts of aggregate, 4 to 6 parts of mineral powder, 2 to 4 parts of piezoelectric material, 1 to 2 parts of conductive material, and 3 to 5 parts of asphalt, wherein the total raw material part number is 100. The invention also provides two power generation pavement structures based on the piezoelectric asphalt concrete. The two power generation pavement structures utilize cooperation between the piezoelectric asphalt concrete and rod-shaped electrode or metal net electrode to achieve the electric energy collection. The piezoelectric asphalt concrete has a good economic property, and is suitable for being widely promoted and applied.

Owner:CHANGAN UNIV

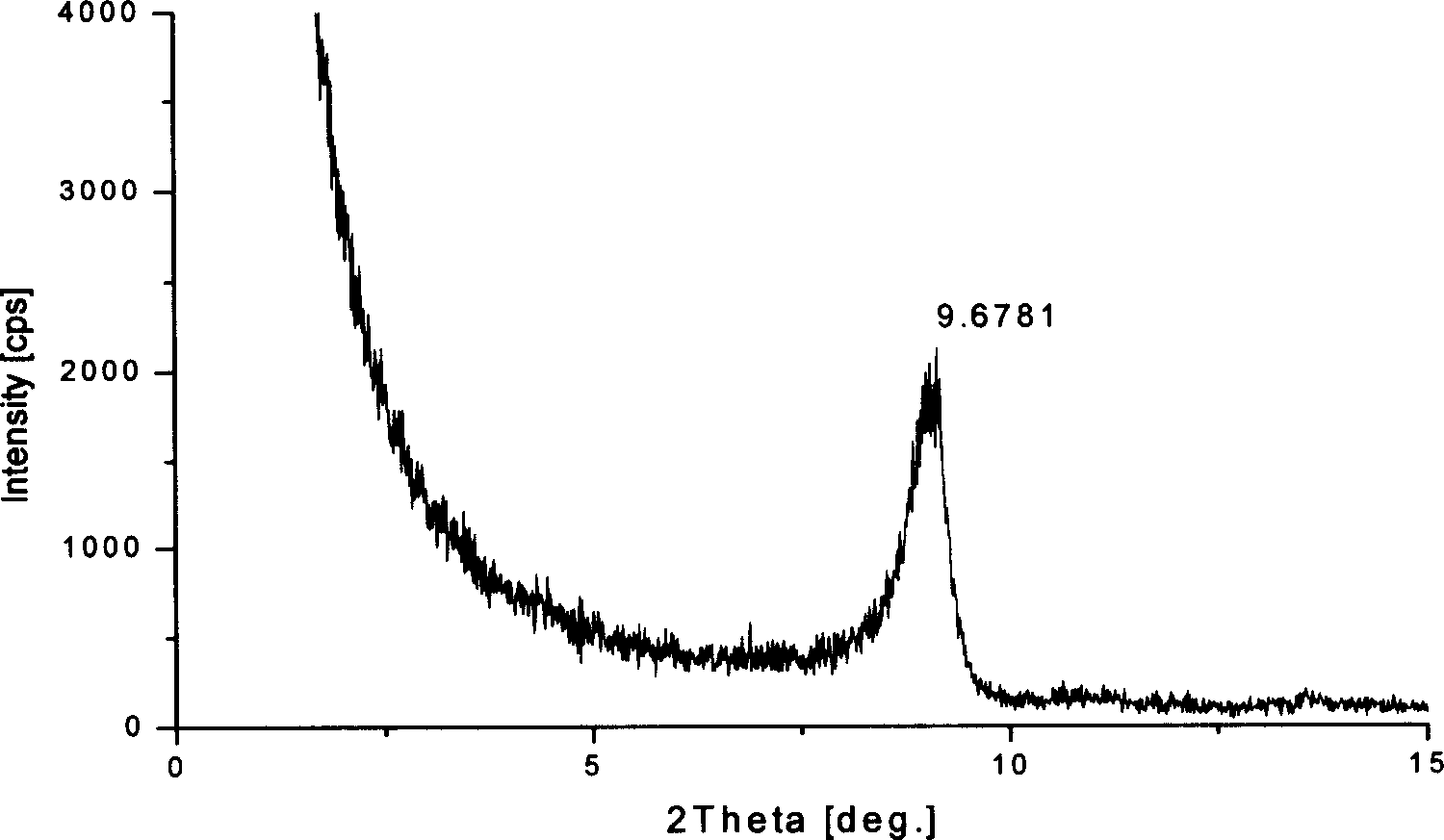

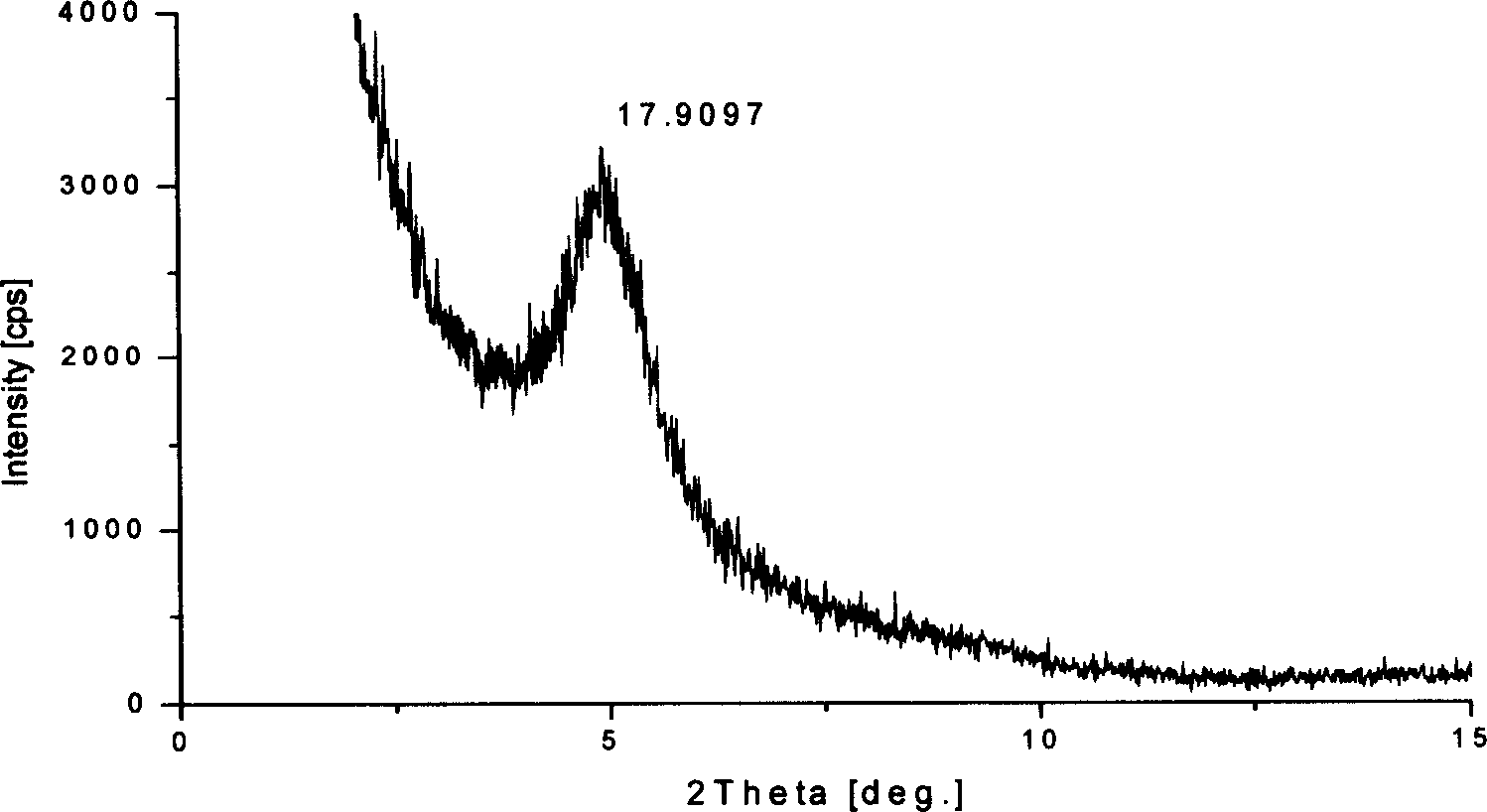

Inorganic clay compound material, its preparation and use

InactiveCN1736586AEfficient photocatalytic performanceWide wavelength response rangeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlcohol

The invention relates to inorganic clay composite and the method for preparation and the utility, belonging to the catalyst art. The material comprises rare-earth element, titanium oxide and clay, the rare-earth element being one or two from Ce, La, Nd, Pr, Yt, Eu and Er, the clay being montmorillonite, the mass ratio of every component being: montmorillonite 54- 90%, titanium oxide 8- 45%, and rare-earth oxide 0.1- 4.0%; and the technique contains the following steps: the mass ratio of material being: titanate 0.6- 1.8%, absolute ethyl alcohol 45- 90%, rare-earth salt 0.013- 0.08% clay 0.8- 1.8%, deionized water 3- 30% and glycerin 4- 35%, using titanate, absolute ethyl alcohol and glycerin solution to prepare titanium oxide sol, using rare-earth salt and absolute ethyl alcohol to prepare rare-earth solution, adding said sol and solution separately into the suspension of clay- absolute alcohol, mixing, aging, filter-pressing, drying in 60- 80Deg. C, and at last roasting 4- 10 hours to prepare the product. The material is added into coating as an additive. And the material has a high catalysis property and a short preparation process.

Owner:HEBEI UNIV OF TECH

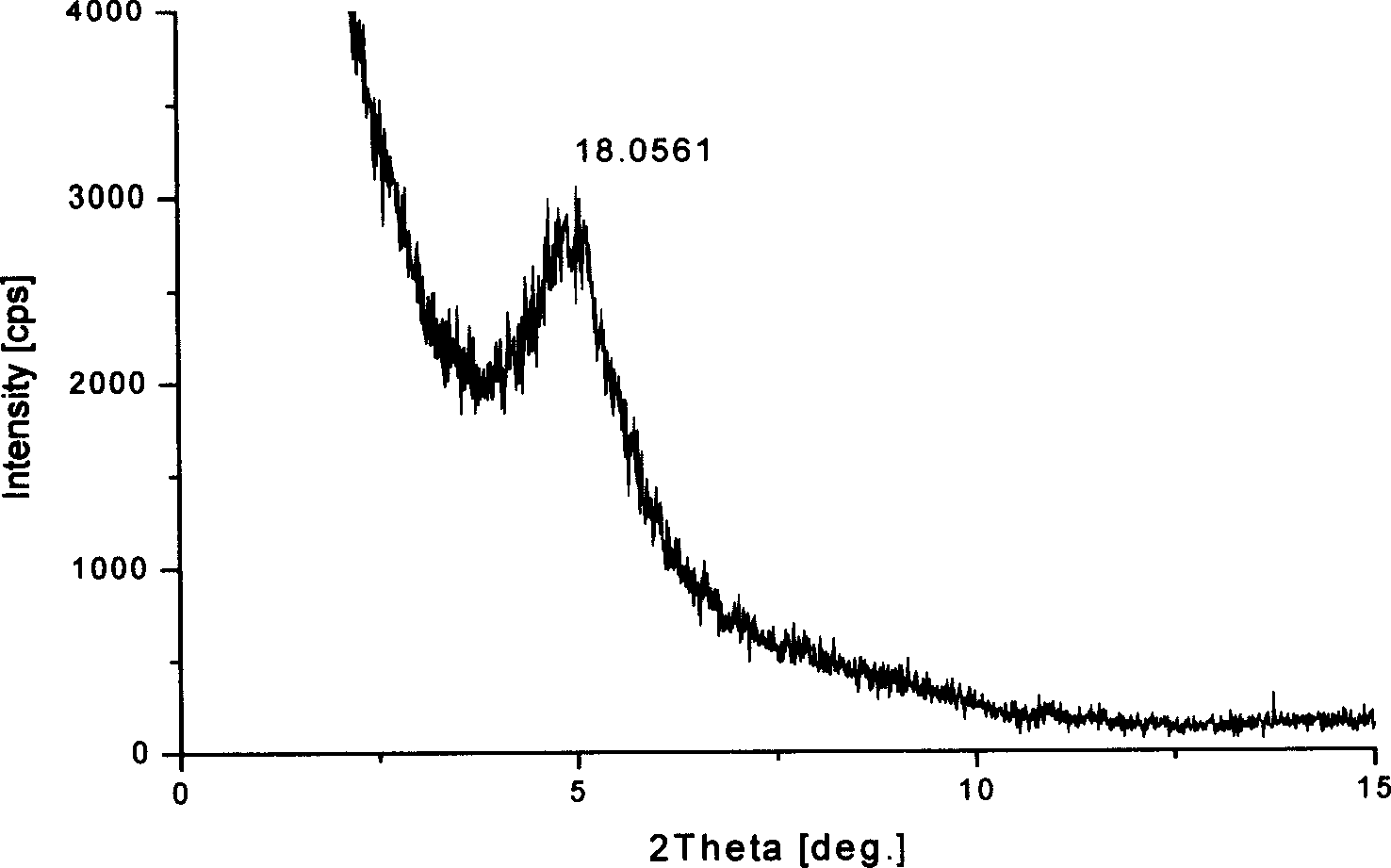

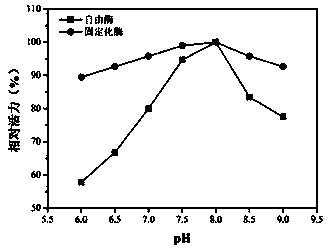

Immobilized composite unhairing enzyme with leather-making secondary waste as carrier and preparation method thereof

InactiveCN103525954AReduce the degree of actionMinimize or avoid damagePre-tanning chemical treatmentFiberNeutral protease

The invention discloses a preparation method of an immobilized composite unhairing enzyme with leather-making secondary waste as a carrier. The method is characterized by: firstly soaking the leather-making secondary waste in deionized water at room temperature, then reacting the leather-making secondary waste with glutaraldehyde, conducting filtration and washing off the residual glutaraldehyde on the leather-making secondary waste by deionized water; reacting the glutaraldehyde treated carrier with the composite unhairing enzyme, performing filtration and washing off the residual composite enzyme on the carrier, thus obtaining the immobilized composite unhairing enzyme with leather-making secondary waste as the carrier. Specifically, every 100 parts of the composite unhairing enzyme comprise 55-80 parts of neutral protease, 10-25 parts of alpha amylase and 5-15 parts of pancreatin. The immobilized composite unhairing enzyme prepared by the method involved in the invention has a high immobilized enzyme amount and high enzyme activity yield, and has good stability and reusability. The immobilized composite unhairing enzyme can be used for raw hide unhairing and collagen fiber dispersion, the production conditions are mild, high controllability can be achieved on a hide collagen hydrolysis process and the separation and loose degree of collagen fibers, and also the product quality fluctuation can be avoided in production.

Owner:SICHUAN UNIV

Dimethoxymethane gasoline

The invention relates to dimethoxymethane gasoline, which consists of dimethoxymethane, benzene, methylbenzene, dimethylbenzene and gasoline, wherein the benzene, the methylbenzene and the dimethylbenzene can be replaced by coked mixed benzene; the dimethoxymethane gasoline is not added with methanol and alcohol; and the dimethoxymethane and the gasoline are not delaminated at low temperature or delaminated when meeting water. The dimethoxymethane gasoline has high combustion efficiency and prevents the automobile power from falling. A coal product is applied to the dimethoxymethane gasoline so as to develop a novel kind of gasoline. The dimethoxymethane in the dimethoxymethane gasoline has a high component ratio and is used as a fuel so as to save the gasoline and reduce the cost.

Owner:SICHUAN JUNHONG ENVIRONMENTAL PROTECTION TECH +1

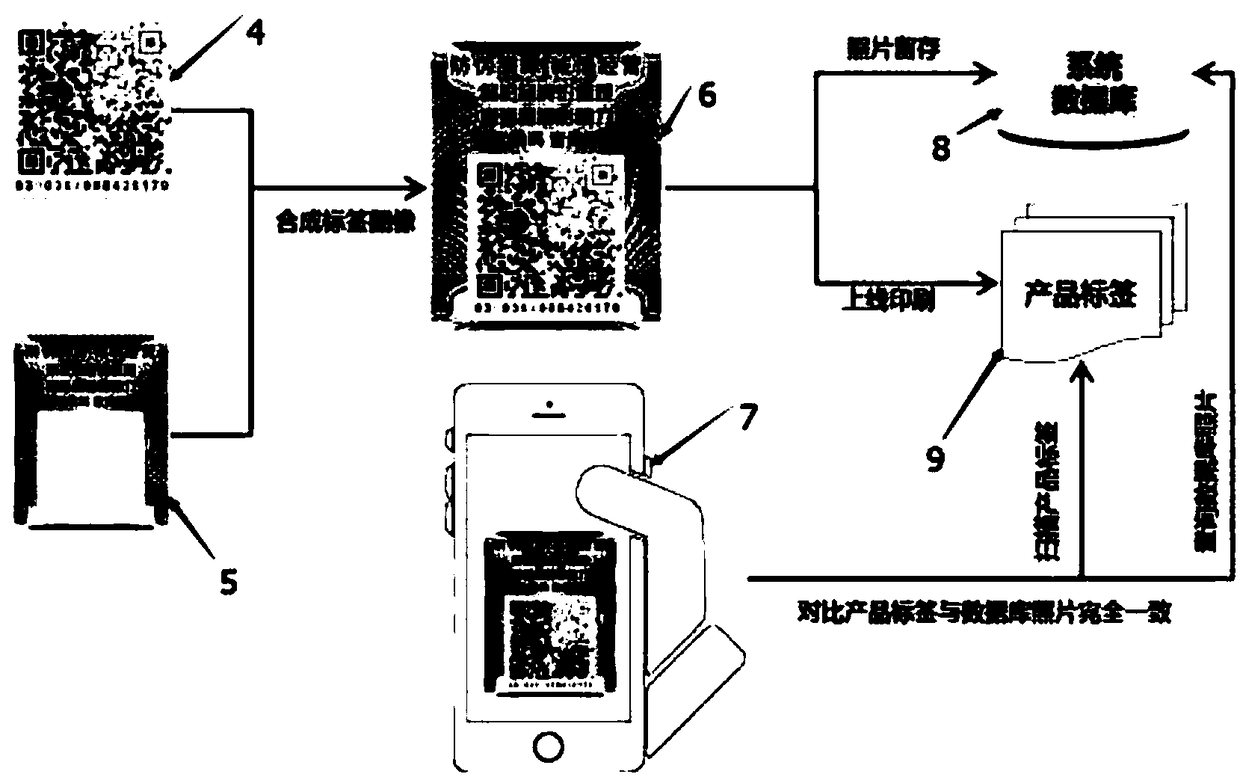

Random color dot matrix label anti-counterfeiting system

The invention belongs to the anti-counterfeiting technology field and discloses a random color dot matrix label anti-counterfeiting system. The system comprises anti-counterfeiting code dot matrix images and a composite image, wherein software generates the anti-counterfeiting code dot matrix images with a variable quantity, size and position, and multiple random colors around a two-dimensional code; and the software guarantees the reliability of code scanning, and simultaneously, the two-dimensional code is divided into four color areas, the colors of the four color areas are changed randomly, the anti-counterfeiting code dot matrix images and an original anti-counterfeiting base plate are synthesized so as to generate an image format used for a printing machine and send to the printing machine for printing, an independent label can be printed or the image can be directly printed to a product package, and simultaneously, the complete image is stored in a system database for backup sothat query and comparison can be performed. A simple and operable mode with low cost is adopted, and the counterfeiting cost of a counterfeiting enterprise is increased so as to protect the brand andthe fame of an enterprise. The products of the enterprise are reliable and competitive in a marketplace.

Owner:CHONGQING YANSHEN TECH DEV CO LTD

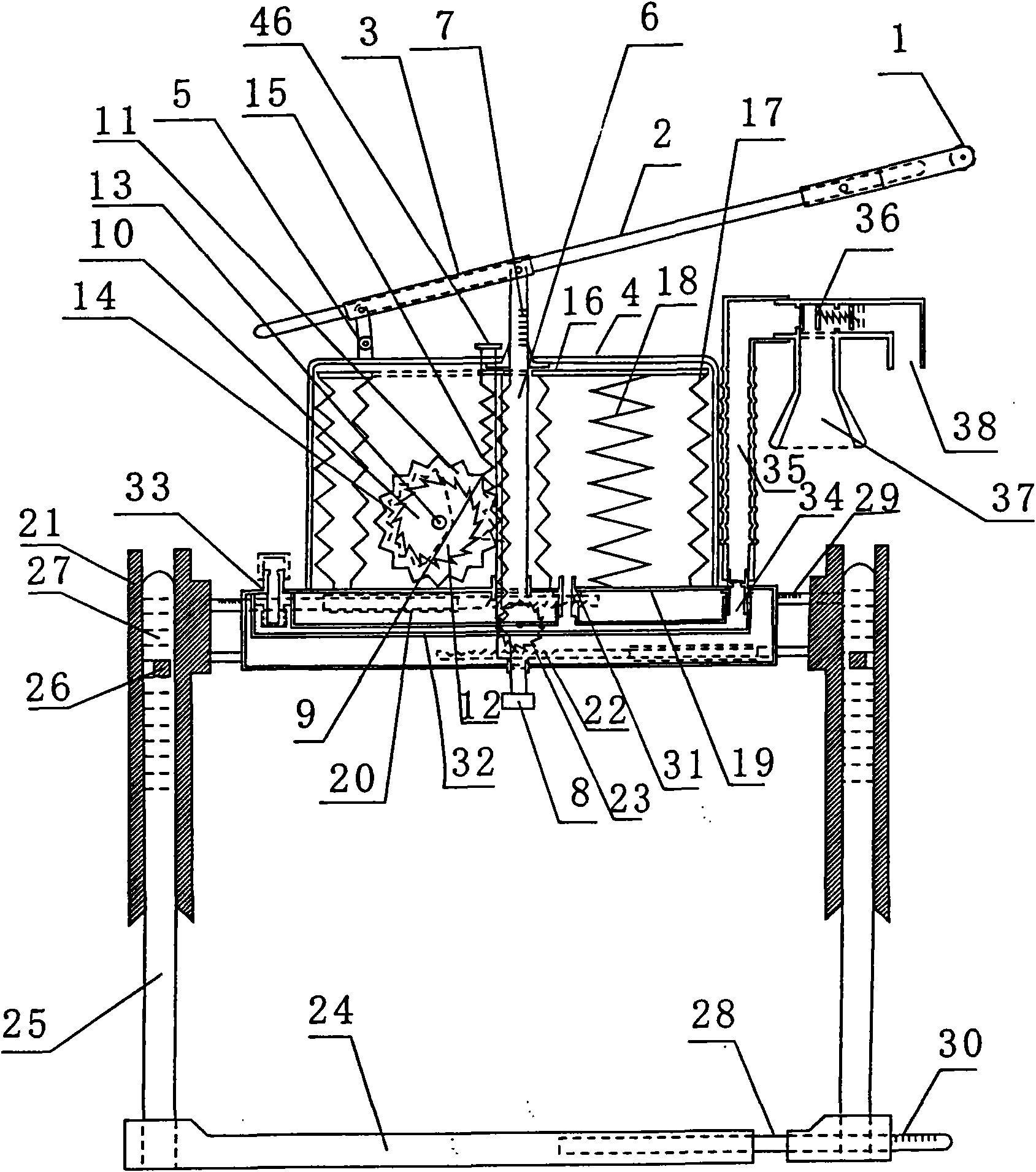

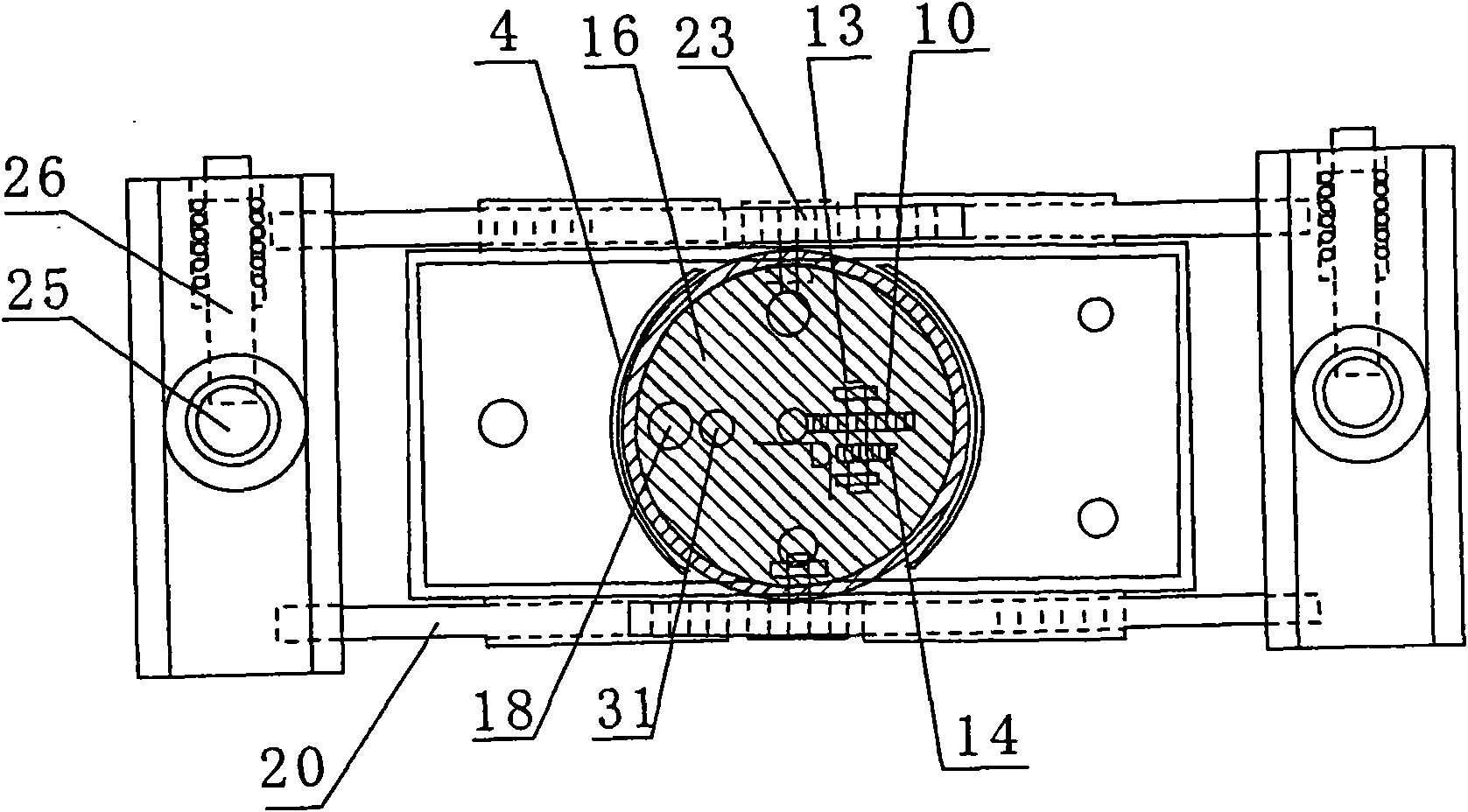

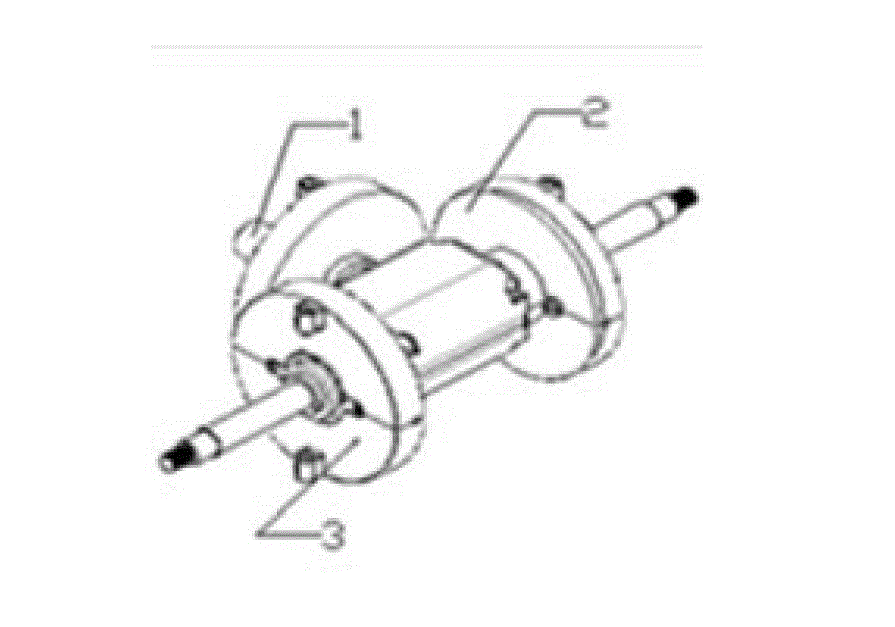

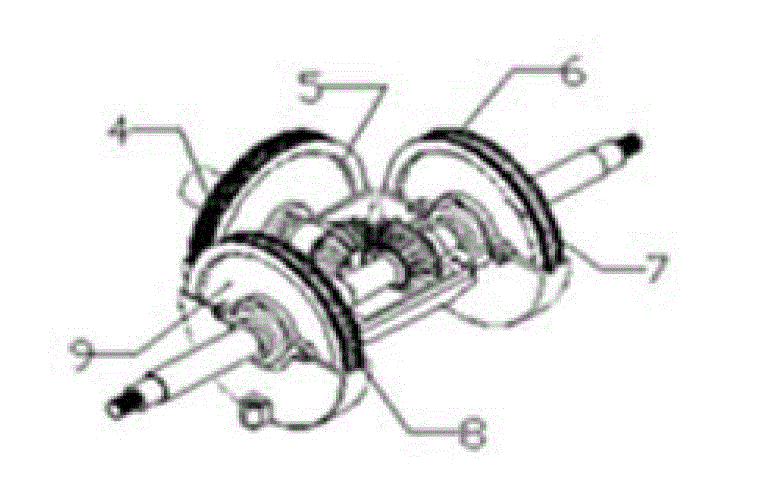

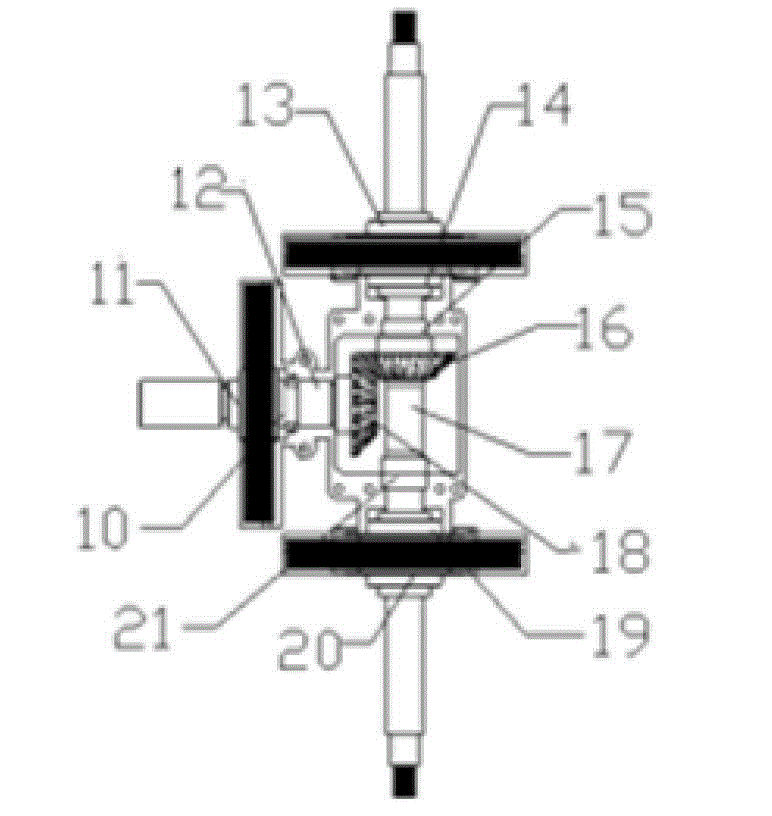

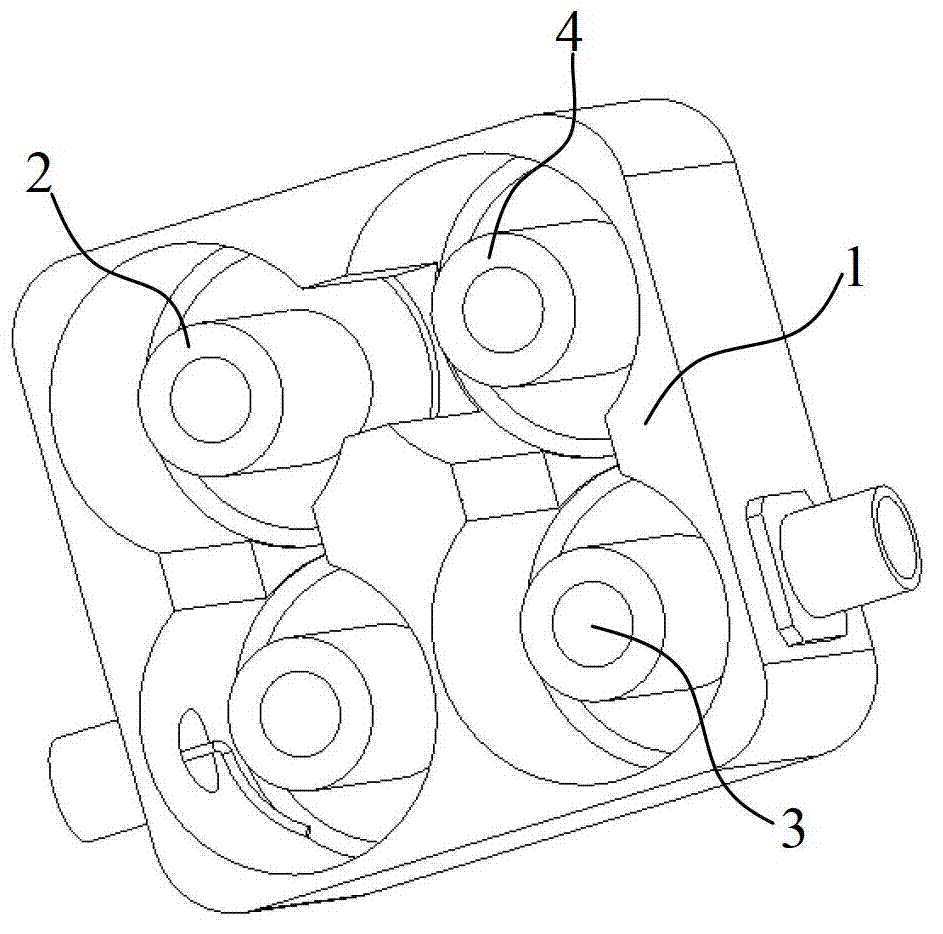

Magneto-rheological clutch, brake and variable speed control drive assembly device

The invention belongs to the technical field of drive assembly devices, in particular to a magneto-rheological clutch, brake and variable speed control drive assembly device, which is formed by assembling a coupling, an upper shell, a lower shell, a clutch coil, a clutch shell, a brake coil, a brake shell, a clutch holder shaft, a clutch disc shaft, a clutch bearing, a brake pad bracket, a reversing bearing, a reversing gear, a reversing shaft and a power gear; when a vehicle starts, the coupling inputs power to the clutch disc shaft; when the vehicle runs, current is input into the clutch coil, a magneto-rheological material is subjected to phase change, and the power is transmitted to the reversing shaft from the clutch disc shaft through the power gear and the reversing gear; and when the vehicle is braked, the current input into the clutch coil and the brake coil is cut off, the magneto-rheological material is subjected to phase change, and the brake pad bracket and the reversing shaft are in a brake locking state. The device solves technical problems to achieve light-weight product, simple structure, material reduction and intelligent control, and powerful support is provided for promoting new materials, new technologies, new processes and technical upgrade of products.

Owner:山东格新精工有限公司

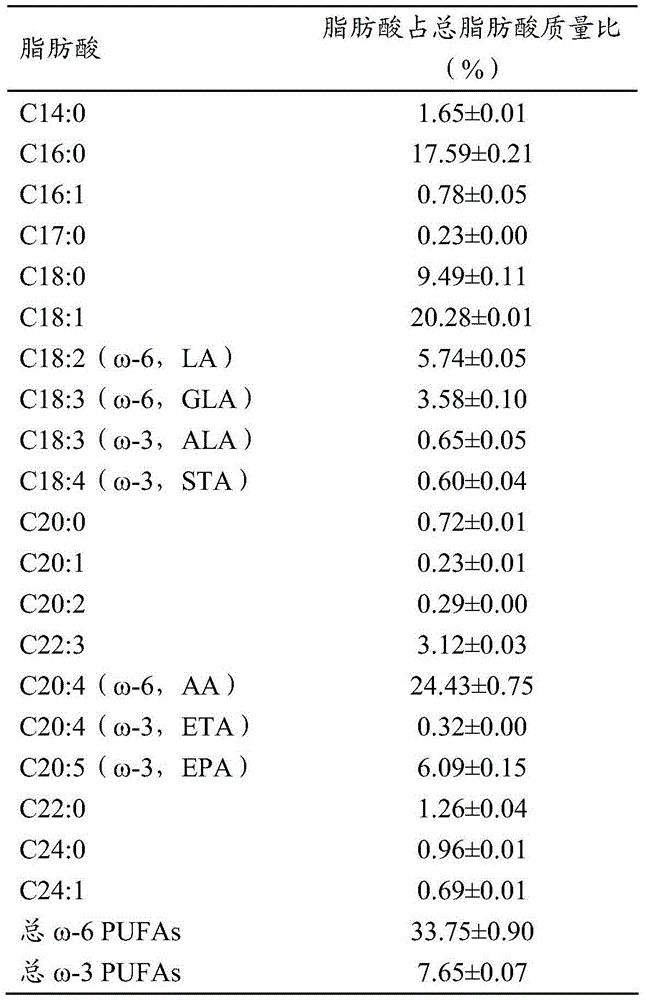

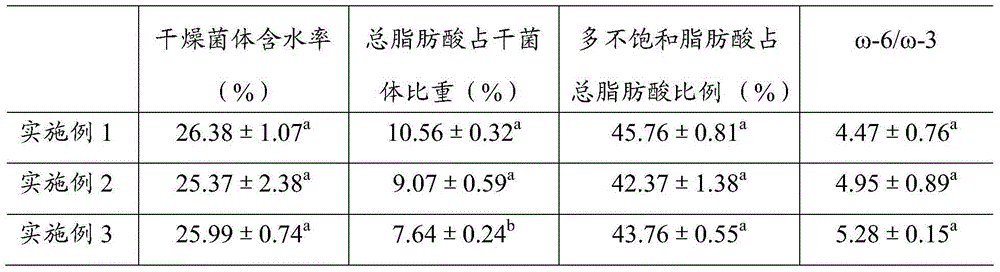

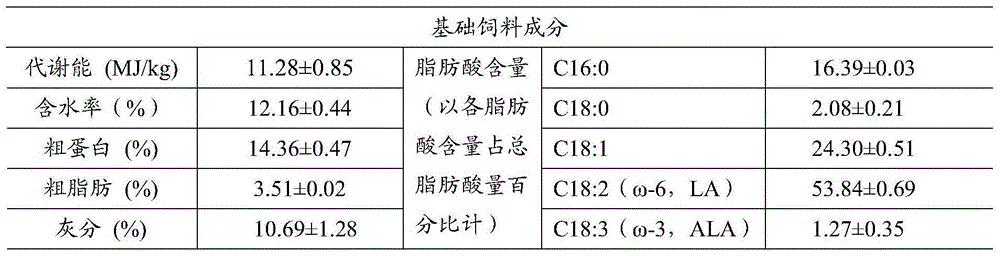

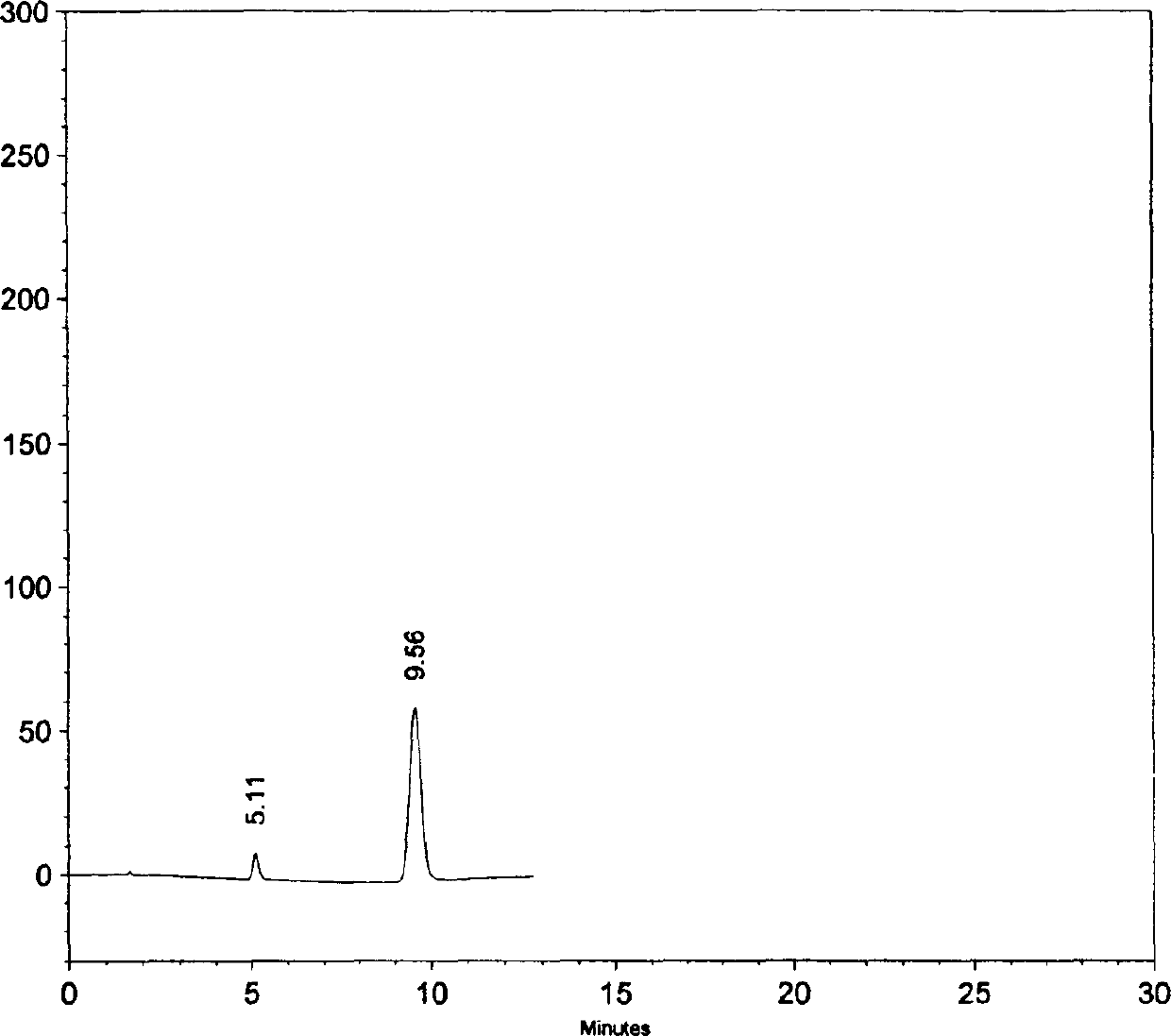

Mortierella alpine CCFM442 strain and use thereof

ActiveCN104630077AImprove the safety of useReasonable compositionFungiAnimal feeding stuffBiotechnologyD-Glucose

The invention relates to a mortierella alpine CCFM442 strain and use thereof. The mortierella alpine CCFM442 strain is used for producing thalli feed additive, the method for producing the thalli feed additive comprises the steps of slant cultivation, seed cultivation, fermentation cultivation and post treatment. The thallis feed additive is high in security. The fatty acid in the thallis feed additive is reasonable in compositions, the content of the polyunsaturated fatty acid in the total fatty acid achieves 42.4-45.8%, omega-6 / omega-3 ratio is 4.5-5.3, and meets the recommendation standard of WHO and FAO. Cheap glucose and bean pulp which are low in market price and easy to obtain, are adopted asa culture medium for producing the thallis feed additive, so that the production cost is low.

Owner:JIANGNAN UNIV

Pharmaceutical composition containing amoxicillin trihydrate and clavulanate potassium

InactiveCN1634044ALow priceRaw materials are easy to getAntibacterial agentsPharmaceutical delivery mechanismAdjuvantMethyl cellulose

The invention discloses a slow release medicament three-layer tablet which comprises Amoxicillin hydrate, clavulanate potassium and pharmaceutically acceptable excipient or carrier, the layer 1 is a rapid release layer comprising Amoxicillin hydrate and clavulanate potassium, the layer 2 is a rapid release layer comprising a portion of Amoxicillin hydrate, the layer 3 is a rapid release layer comprising rest portions of Amoxicillin hydrate, the slow release layer contains not only common medicinal adjuvant, but also slow release material of hydroxy propyl methyl cellulose E30.

Owner:北京泛美华医药科技发展有限公司

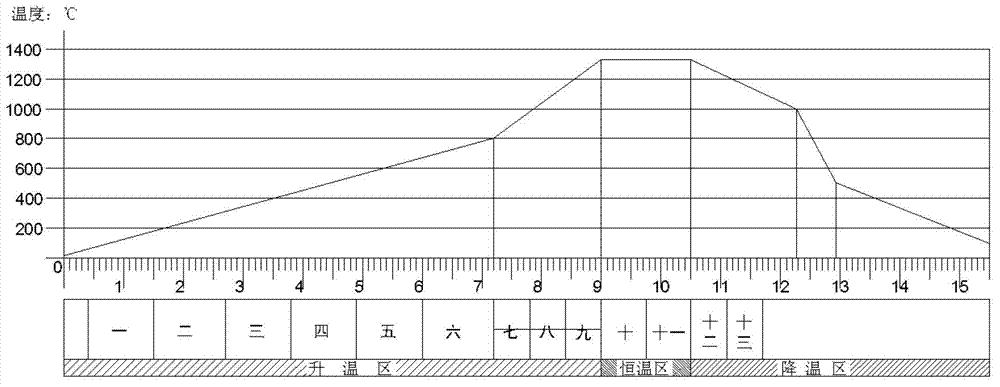

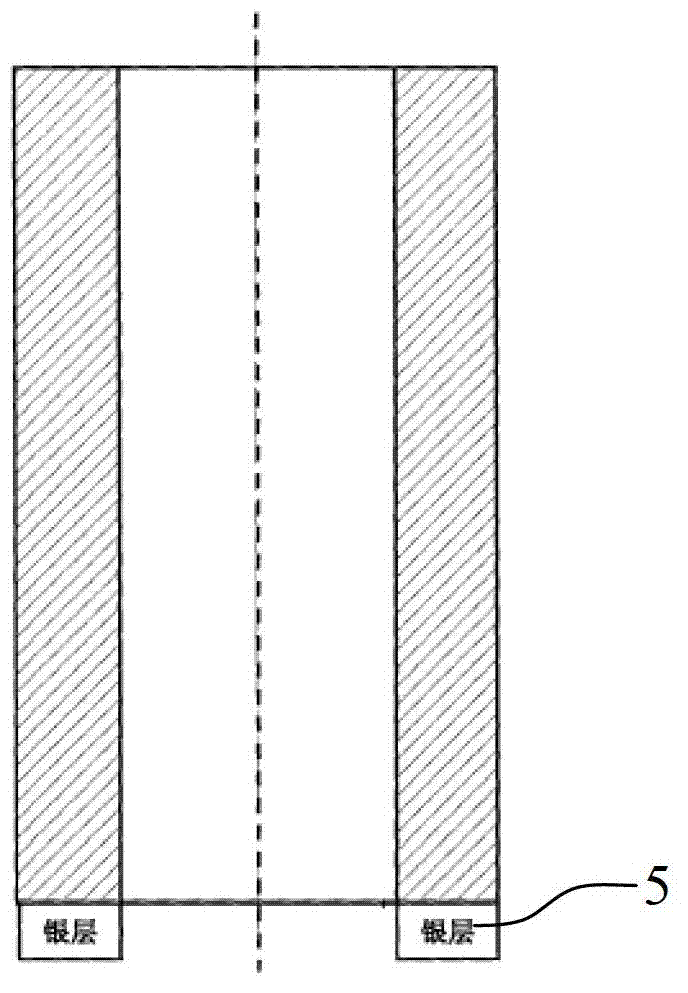

Novel medium cavity filter with cavity

ActiveCN102969549AReduce lossSteep frequency characteristicResonatorsThermal expansionTemperature coefficient

The invention discloses a novel medium cavity filter with a cavity. The novel medium cavity filter comprises the cavity and medium resonators, wherein each medium resonator is a cylinder with a through hole and is prepared from the following components according to mass percent: 29%-32% of calcium carbonate with purity of 97.5%, 9%-11% of aluminum oxide with purity of 97.5%, 21%-25% of neodymium oxide with purity of 99.5%, and 35%-38% of titanium dioxide with purity of 99.6%; a silver layer is coated at one end of each medium resonator, and the other end of the medium resonator is welded inside the cavity; the cavity is prepared from the following components according to mass percent: 95%-96% of aluminum oxide, 2%-3% of calcium carbonate, 0.8%-1.5% of lanthanum oxide, and 0.2%-0.5% of samarium oxide; and the dielectric constant of the cavity is 9.5. The medium cavity filter disclosed by the invention is high in Q value, small in size and adjustable in temperature coefficient, and can ensure high reliability of a product structure and good consistency of thermal expansion coefficients of the cavity and the medium resonators.

Owner:江苏灿勤科技股份有限公司

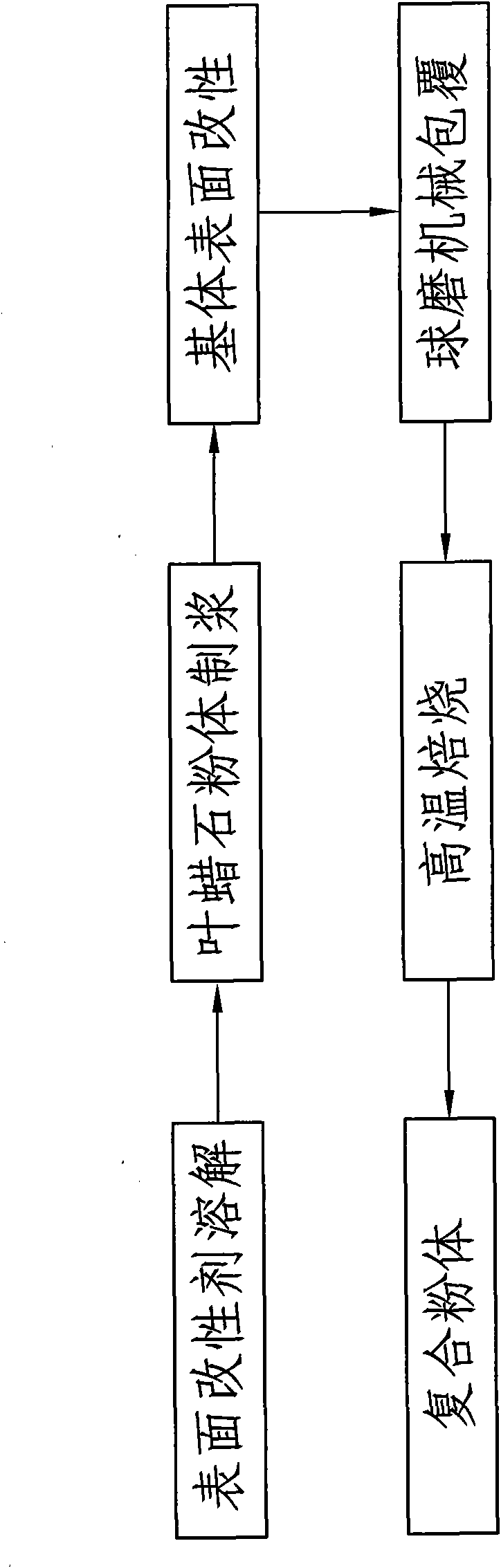

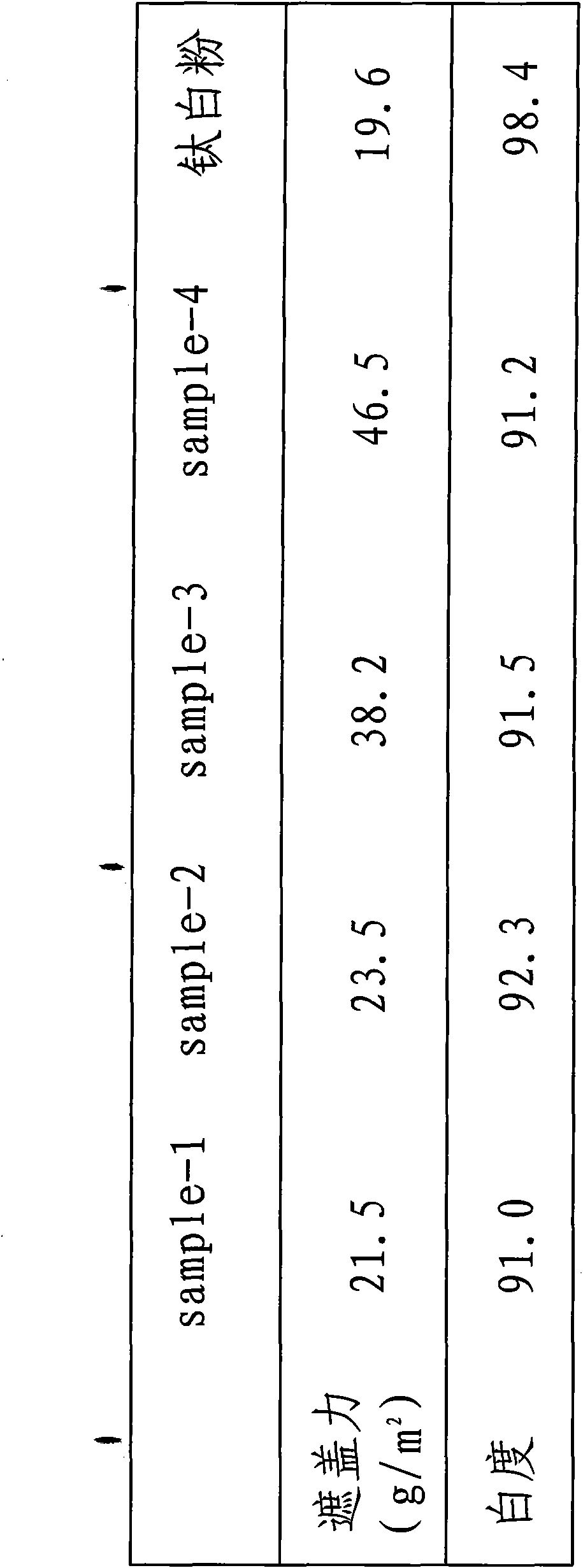

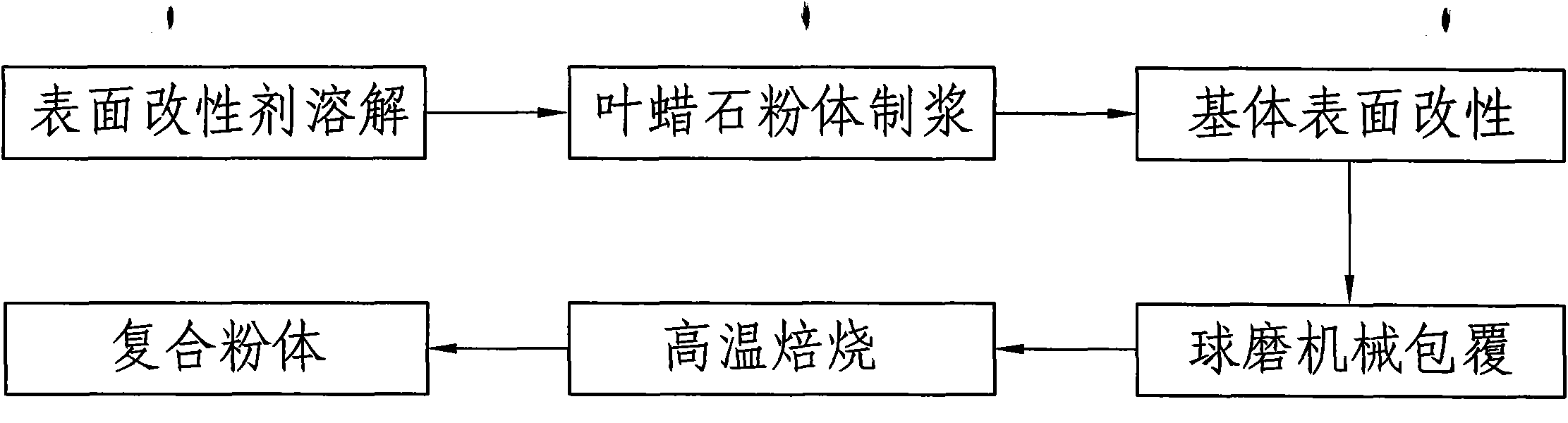

Pyrophyllite-based composite titanium white powder and preparation method thereof

ActiveCN101851437ALow market priceLow investment costPigment physical treatmentPigment treatment with non-polymer organic compoundsPyrophylliteWhite powder

The invention relates to a powder pigment, in particular to a pyrophyllite-based composite titanium white powder and a preparation method thereof. The invention provides the following technical scheme that: the pyrophyllite-based composite titanium white powder comprises pyrophyllite and rutile-type titanium white powder which have the mass ratio of 50-90:50-10, and the blue-white luminosity of the pyrophyllite is 75-84. By adopting the technical scheme, the invention provides the pyrophyllite-based composite titanium white powder which has low cost and simple technique, and the preparation method thereof.

Owner:浙江皓翔矿业有限公司

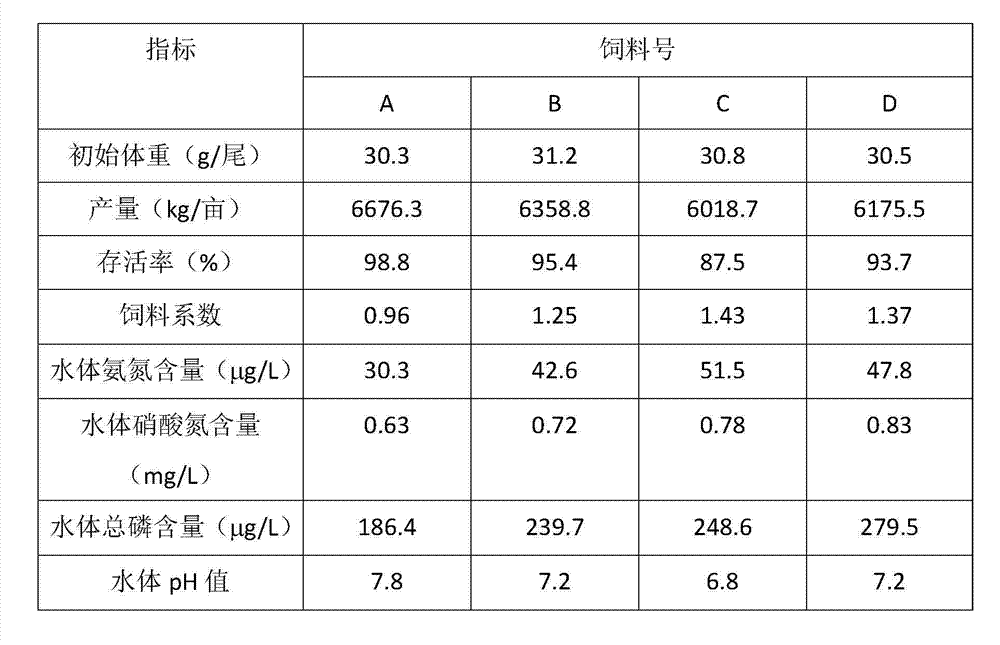

Novel environment-friendly and nutritional efficient clarias fuscus feed

InactiveCN103202405AHarm reductionImprove digestion utilizationAnimal feeding stuffPhytaseWater quality

The invention discloses a novel environment-friendly and nutritional efficient clarias fuscus feed and aims to provide the novel environment-friendly and nutritional efficient type clarias fuscus feed which can effectively improve the feed utilization rate of clarias fuscus, reduce the disease damages to the clarias fuscus, improve the water quality and increase the benefits. The technical scheme is that the feed is formed by the following components in mass percentage: 20-25% of flour, 6-16% of rapeseed meal, 2-6% of meat meal, 10-25% of fish meal, 4-8% of peanut meal, 5% of corn protein powder, 22-30% of bean pulp, 1-2% of cuttlefish cream, 5% of DDGS (Distillers Dried Grains with Soluble) feed, 1-2% of fish oil, 2-4% of soybean lecithin oil, 1-2.0% of monocalcium phosphate, 0.2-0.5% of compound vitamin, 1-2% of compound mineral, 0.03-0.05% of mould-proof agent, 0.1% of choline chloride and 0.2-0.4% of phytase; and the sum of all the components is 100%. The novel environment-friendly and nutritional efficient clarias fuscus feed belongs to the technical field of fish feed.

Owner:GUANGDONG TONGWEI FEED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com