Patents

Literature

70results about How to "Strong advanced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

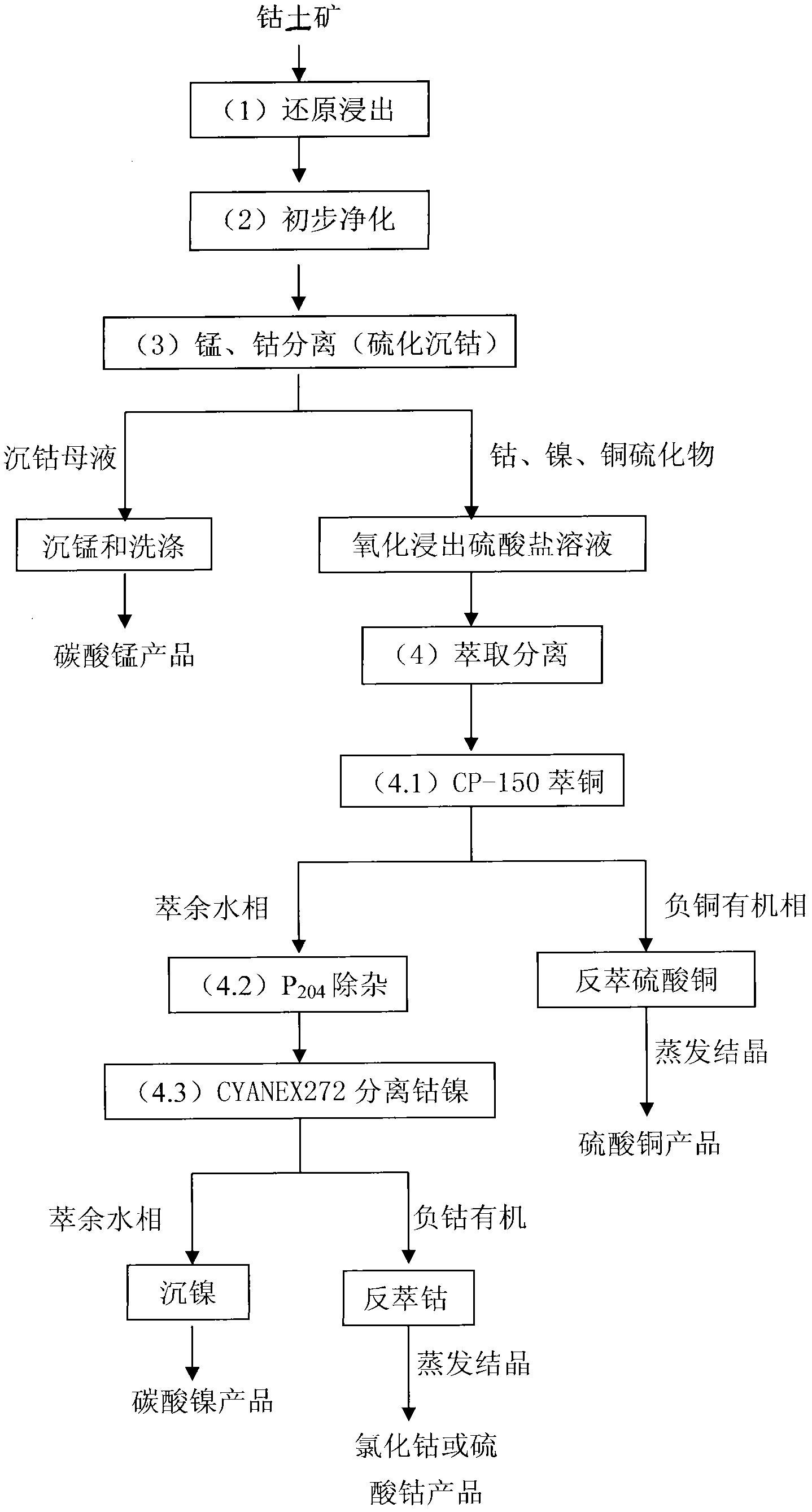

Processing method for comprehensively recovering high manganese asbolite

InactiveCN102021331AIncrease costLow recovery rateProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a processing method for comprehensively recovering high manganese asbolite, belonging to the field of hydrometallurgy. In the processing method, the high manganese asbolite is processed through four processing steps comprising (1) reduction leaching, (2) primary cleaning, (3) manganese and cobalt separation and (4) extraction separation to obtain a product manganese carbonate, copper sulfate, nickel carbonate or cobaltous sulfate. The processing method has the advantages that the source of raw materials is wide, the process and equipment are simple, the operation is stable, the energy consumption is low, the production cost is low, the practicability is wide, and the economic effect and the society effect are obvious.

Owner:HAINAN ZHONGDAO ENERGY DEV

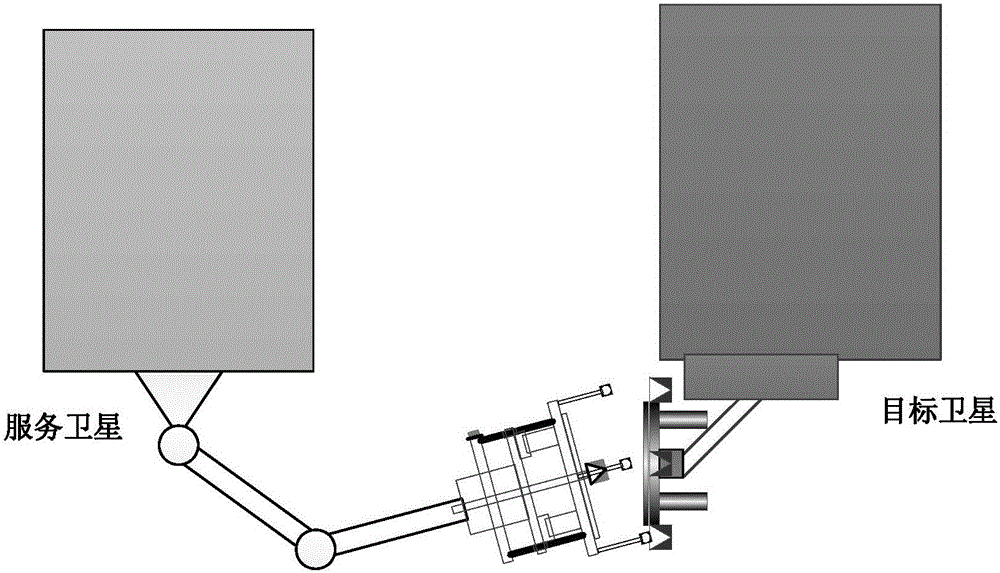

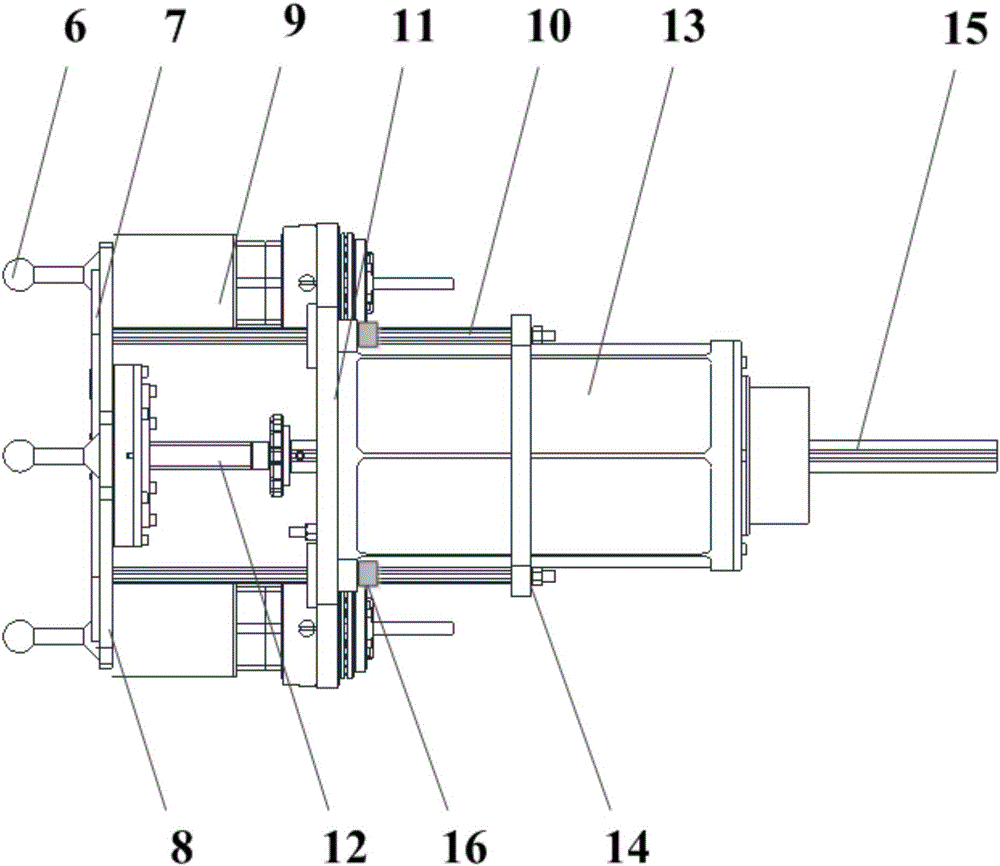

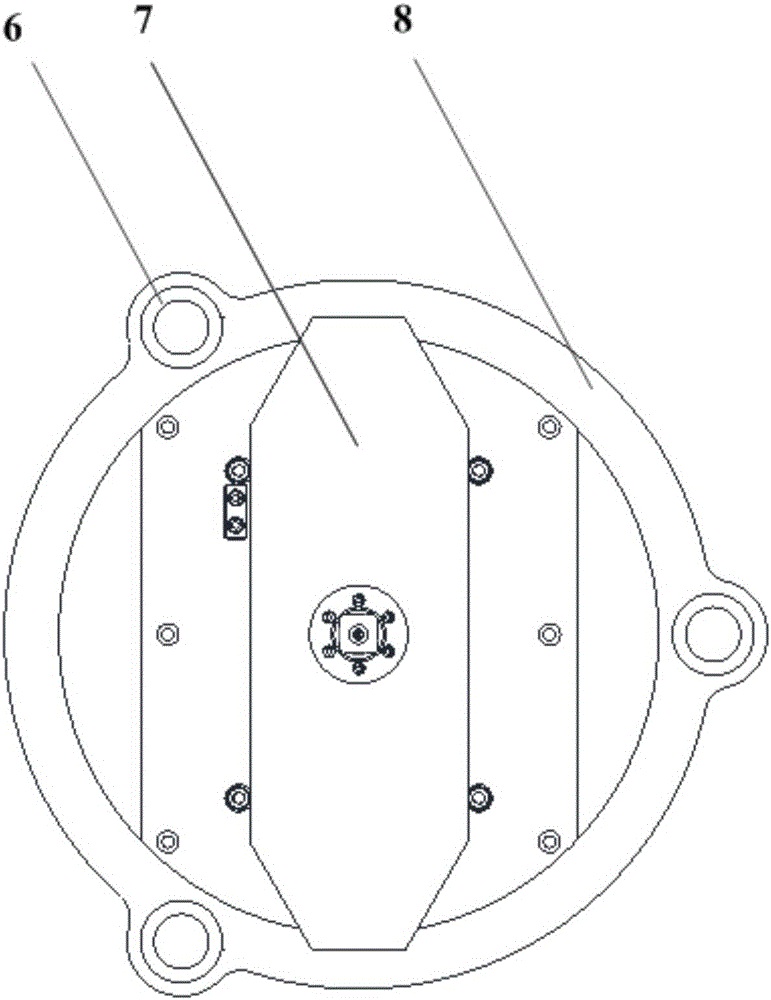

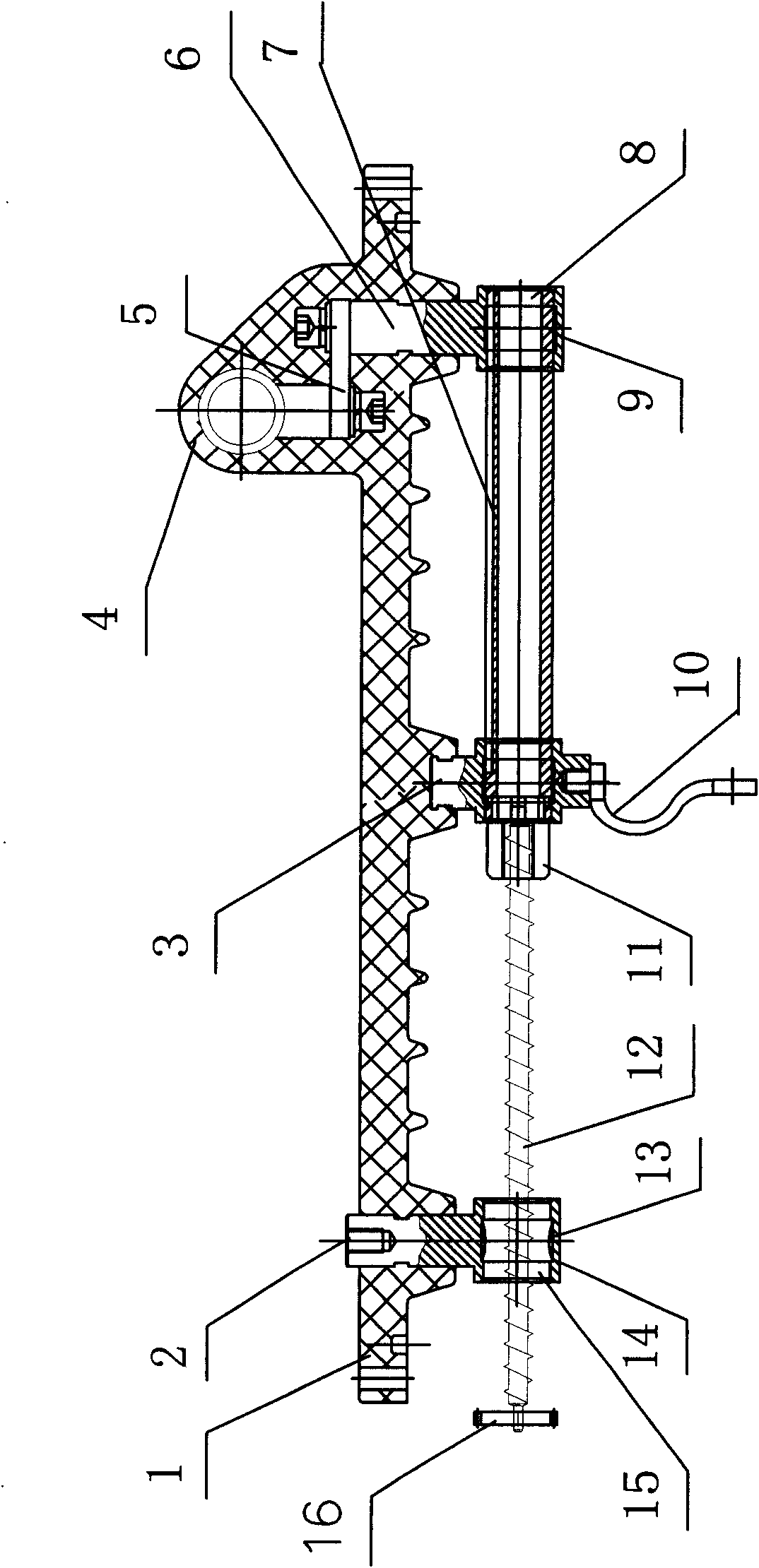

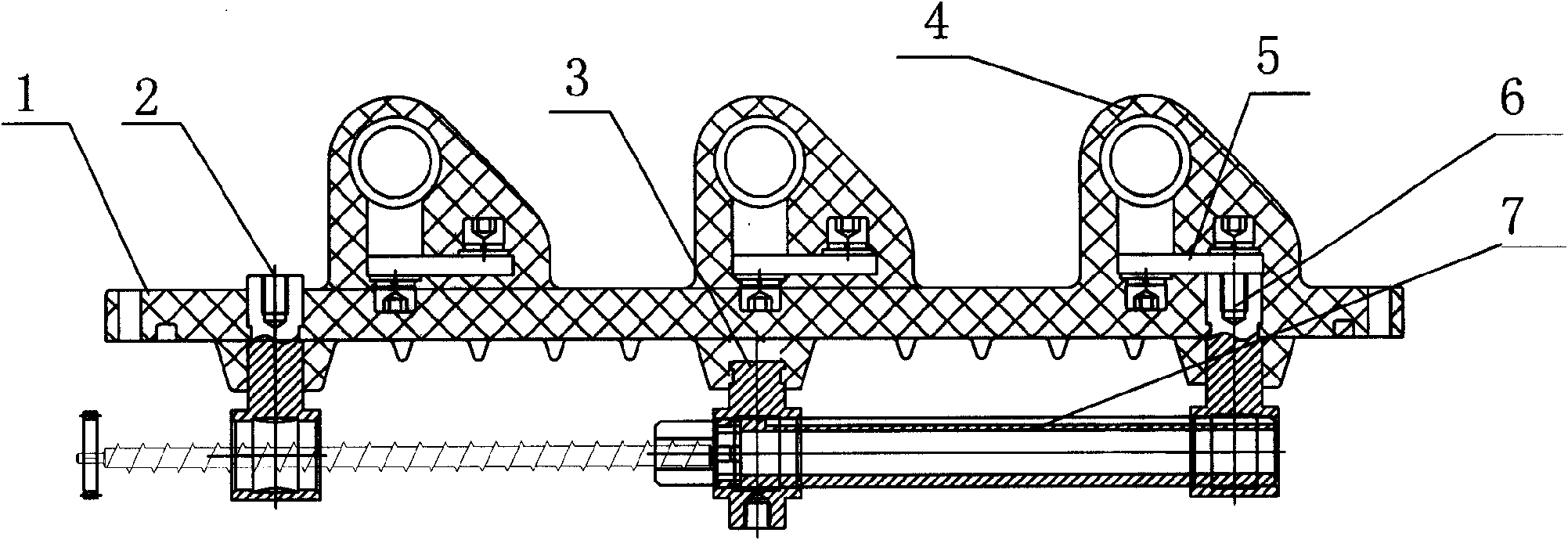

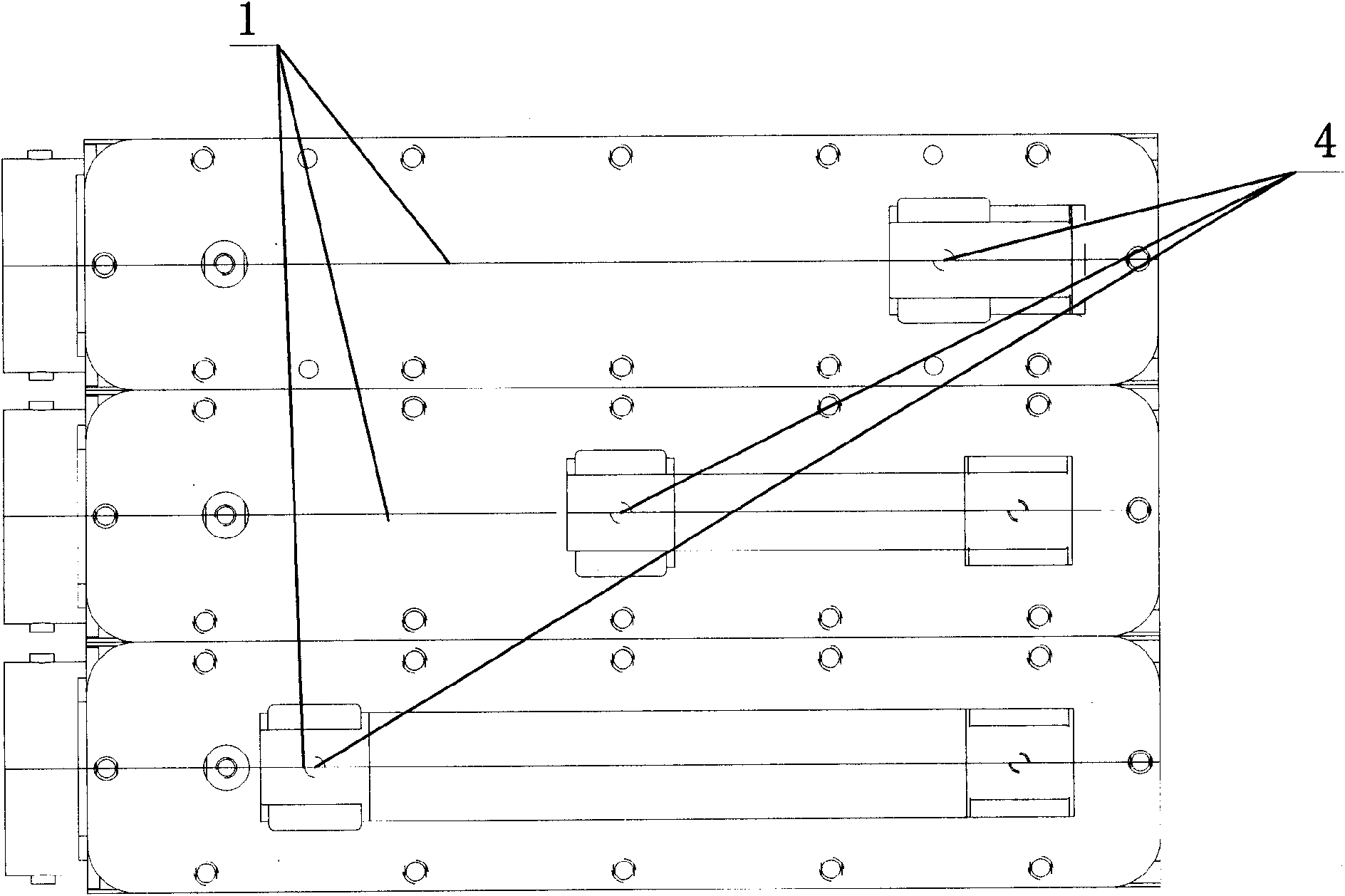

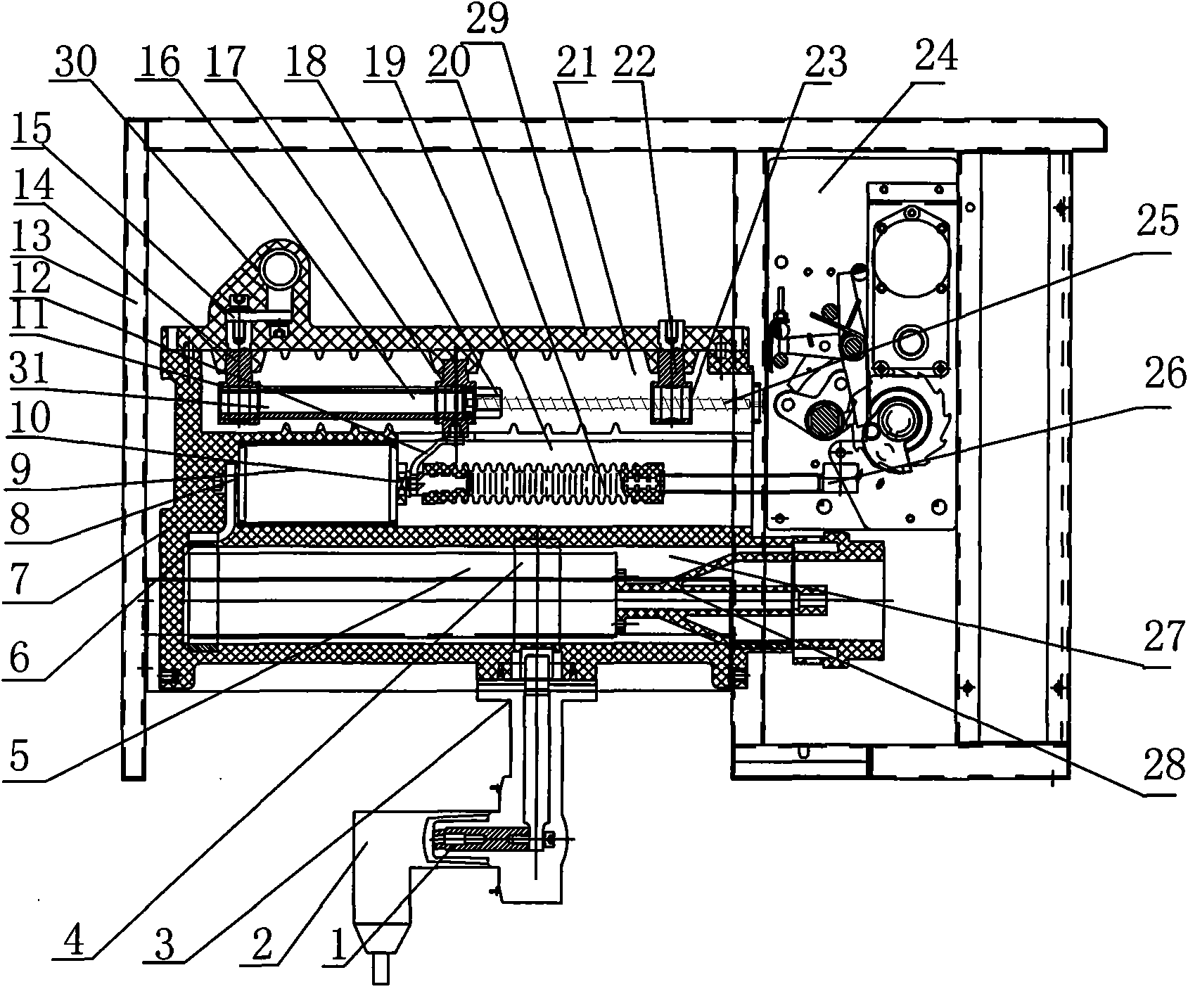

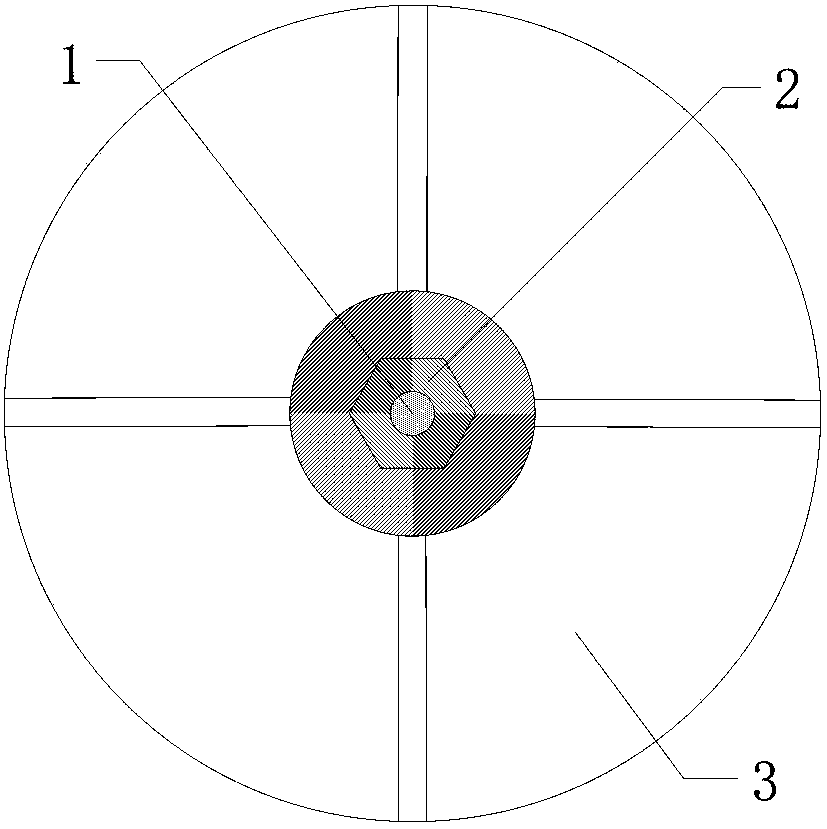

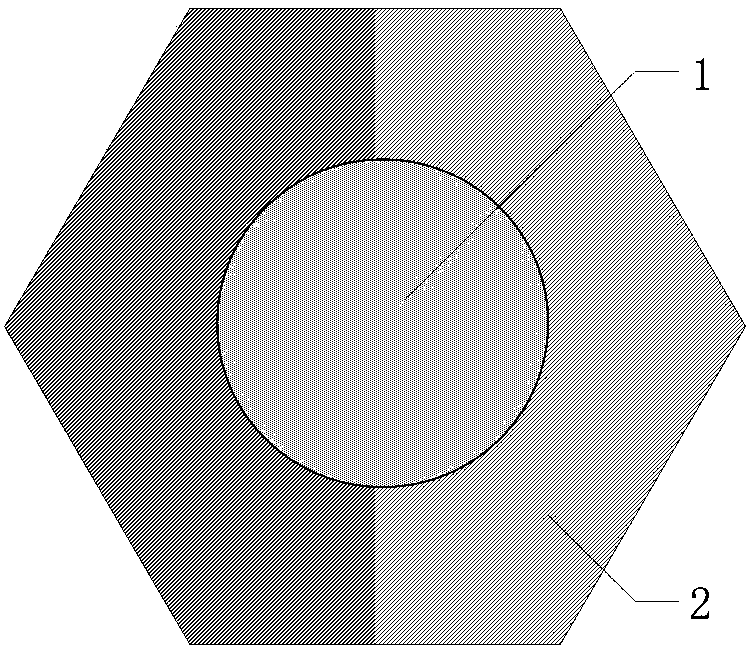

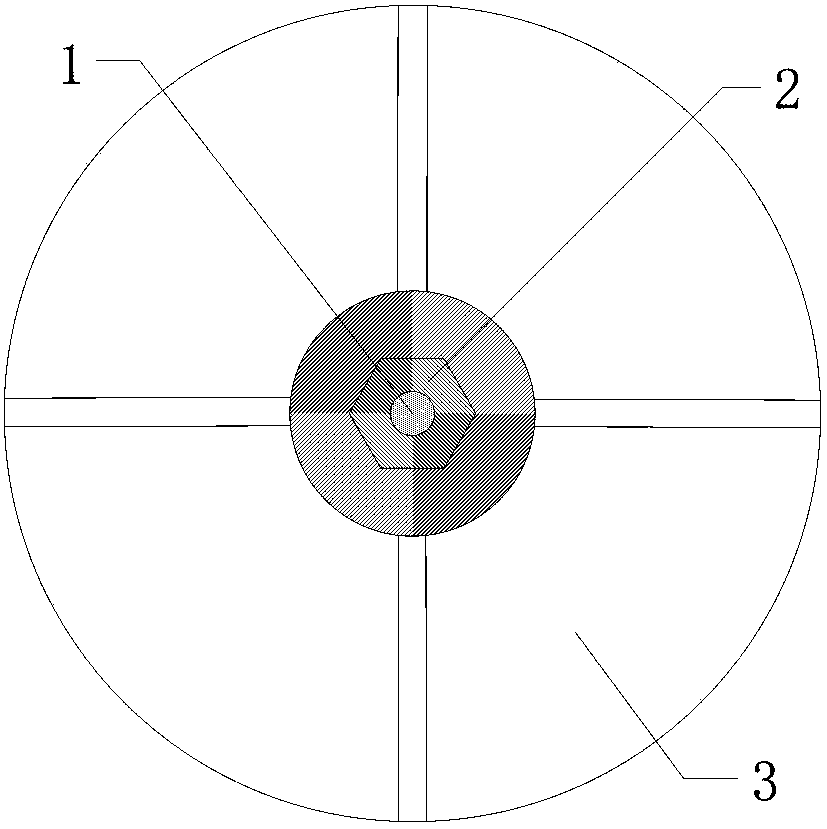

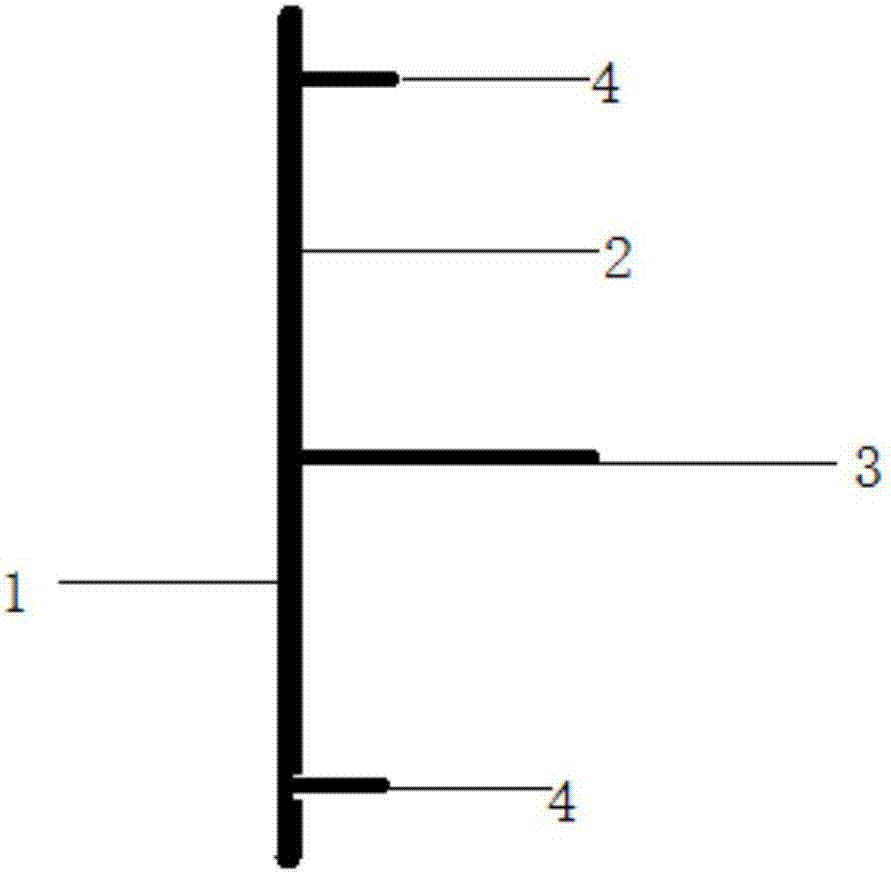

Connector device for replenishing gas and liquid on orbit

ActiveCN105059569AGood flexibilityStrong advancedCosmonautic component separationSatelliteFixed position

The invention relates to a connector device for replenishing gas and liquid on the orbit. The connector device is used for replenishing gas and liquid for a target satellite by a service satellite on the orbit. The connector device comprises an active mechanism and a passive mechanism. The service satellite and the target satellite are positioned and conveniently separated through guide devices on respective butt-joint surfaces of the active mechanism and the passive mechanism, the service satellite and the target satellite are caused to move relative to each other through a drive mechanism having the axial spacing function, and the service satellite and the target satellite are locked through a positioning locking structure, so that the service satellite and the target satellite are guaranteed to be at fixed positions relative to each other in the on-orbit gas-liquid replenishing process. Through the measures, the efficiency of the on-orbit gas-liquid replenishing process is improved, and the safety of the on-orbit gas-liquid replenishing process is guaranteed.

Owner:BEIJING INST OF CONTROL ENG

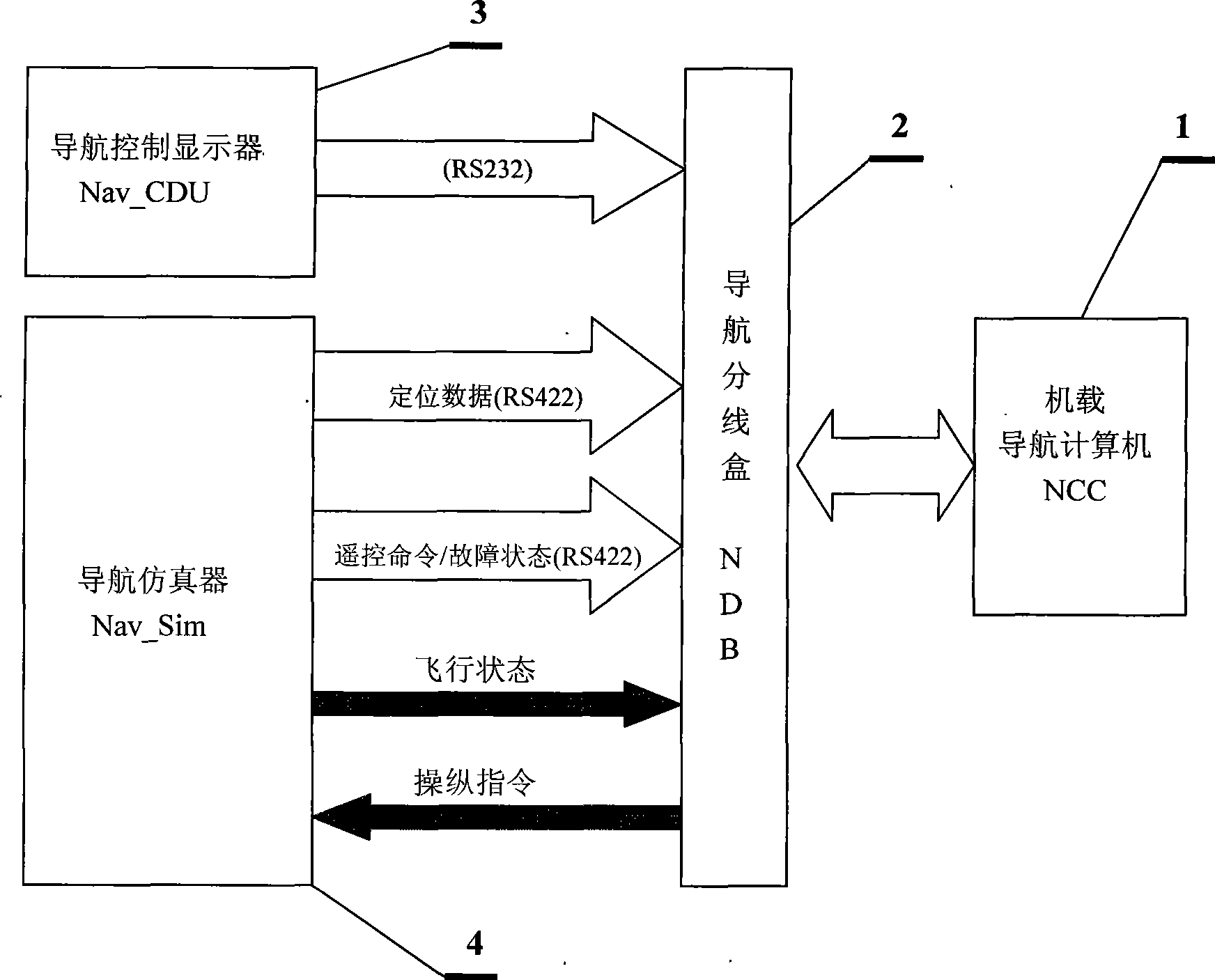

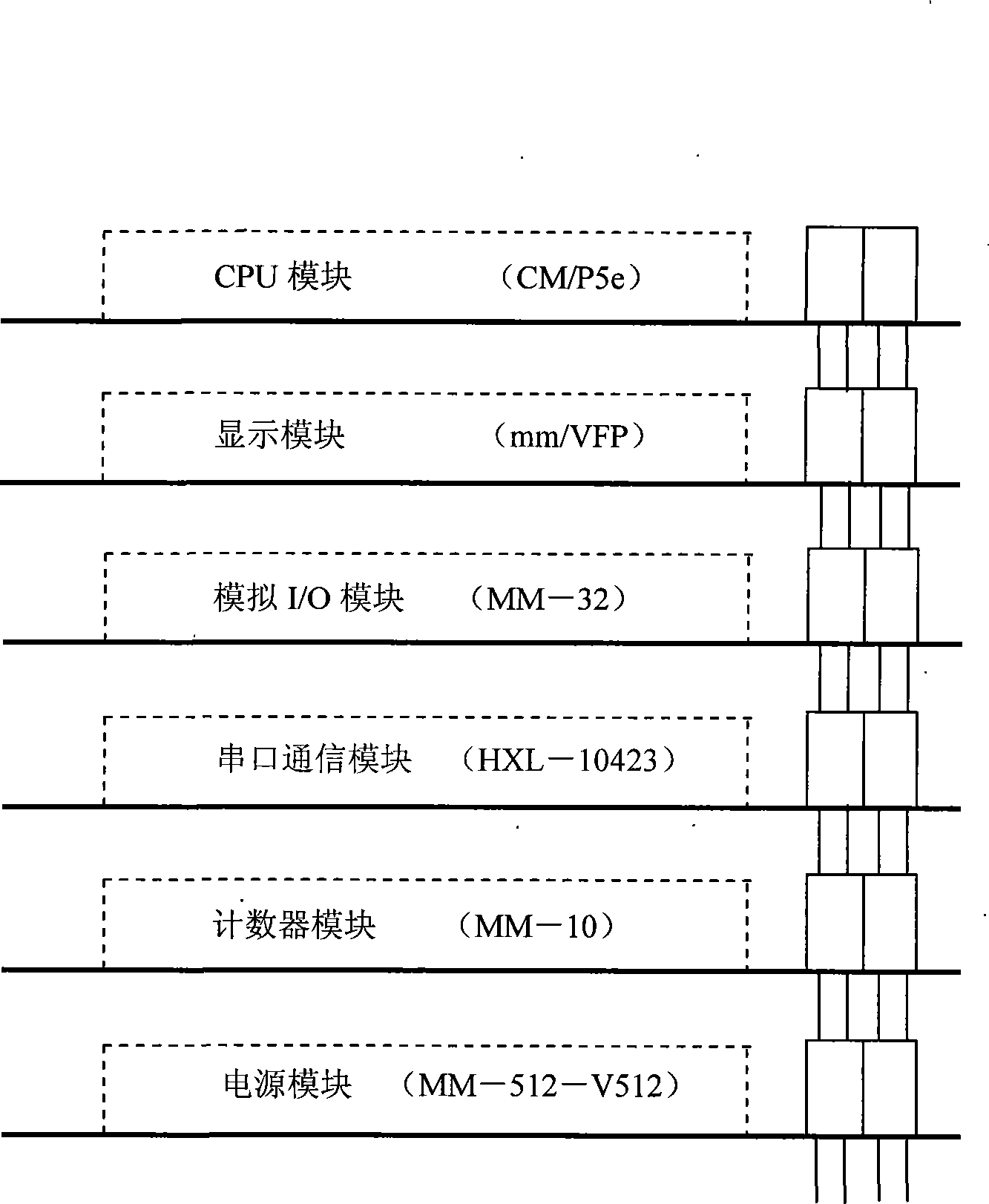

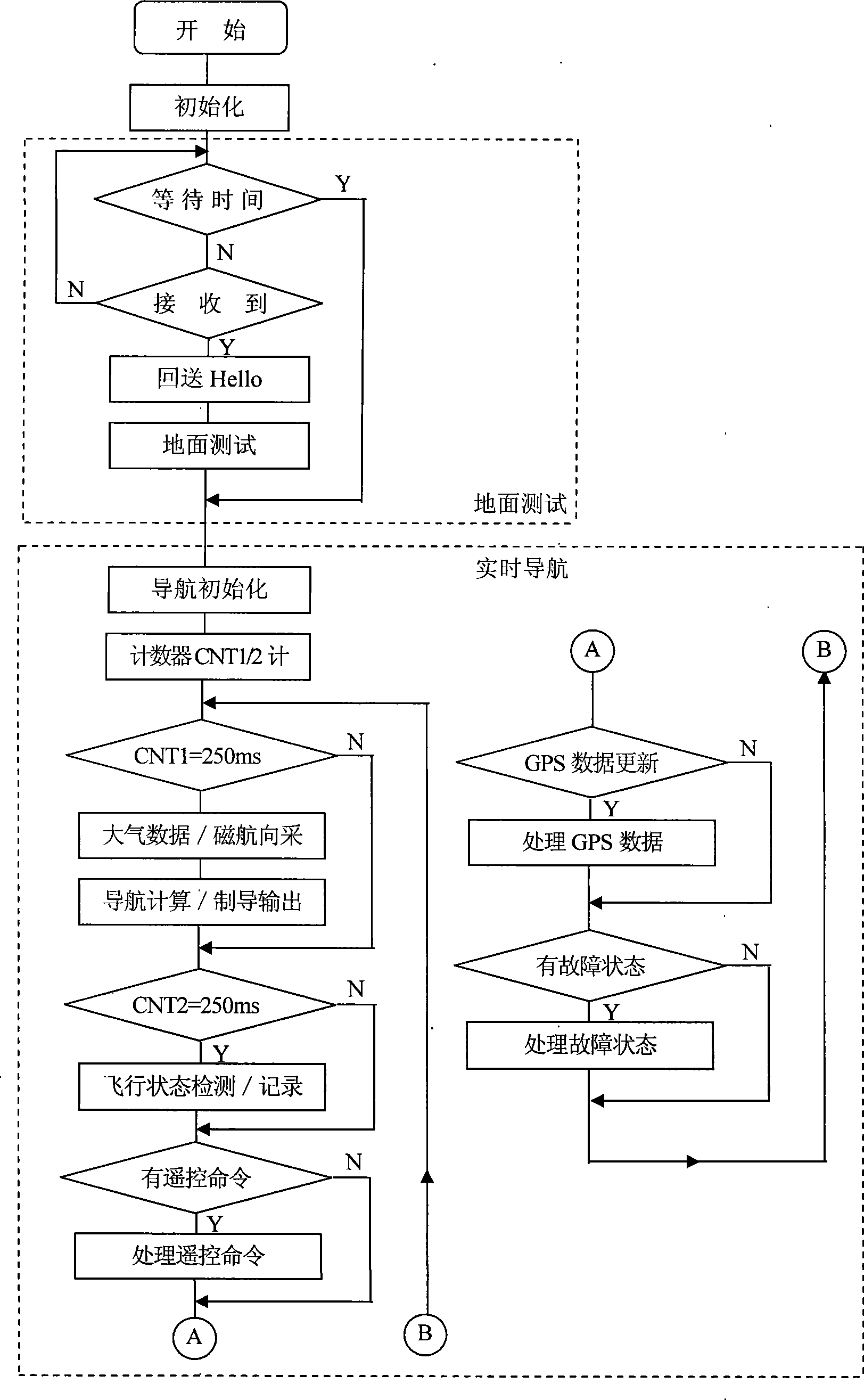

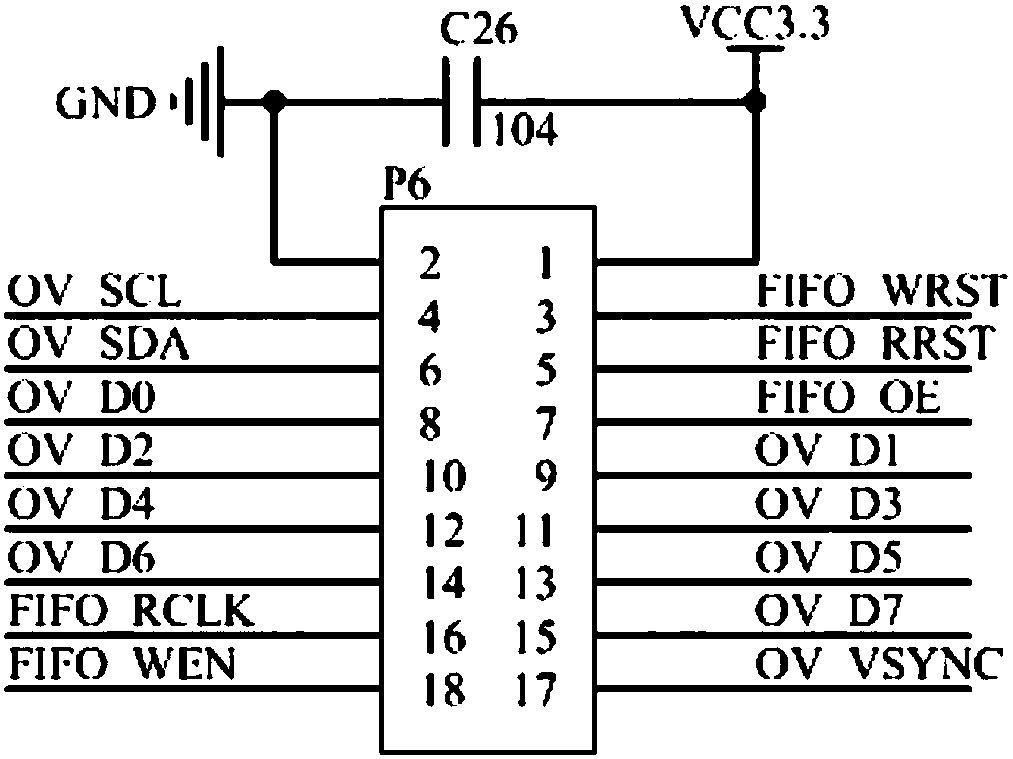

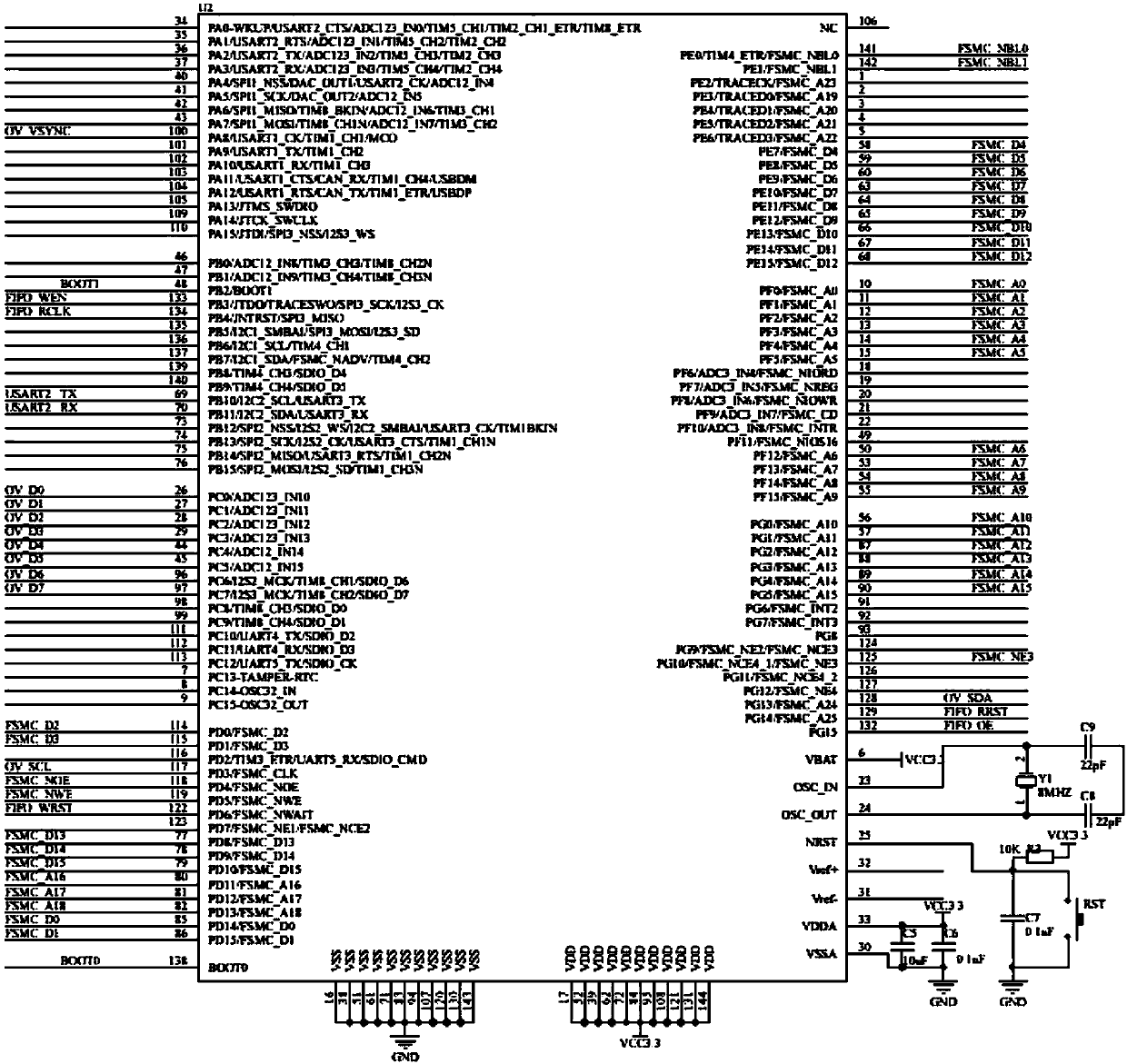

Semi-true object emulation technology apparatus of unmanned coaxal helicopter autonomous navigation system

InactiveCN101435703AStrong advancedWell designedNavigational calculation instrumentsSustainable transportationMarine navigationDisplay device

The invention provides a semi-physical simulation technique device for an autonomous navigation system of an unmanned coaxial helicopter. The device consists of a helicopter-mounted navigation computer, a helicopter-mounted navigation branch box, a navigation control displayer and a navigation simulator, wherein the helicopter-mounted navigation computer is crossed and linked with the navigation simulator by the navigation branch box to form an unmanned helicopter autonomous navigation simulation loop; and the helicopter-mounted navigation computer is also crossed and linked with the navigation control displayer by the navigation branch box to realize the control and test of the helicopter-mounted navigation computer. The device creates a general development platform for the unmanned helicopter navigation system, and can test the function / performance and reliability of the navigation system under conditions of simulating actual flight; the semi-physical simulation technique which the invention relates to has good advanced property, generality and practicability; and the semi-physical simulation environment which the invention relates to has the advantages of careful design, simple structure and good operability. Practice shows that the device reduces the development period and risk of the navigation system, and has good technical and economic benefits.

Owner:BEIHANG UNIV

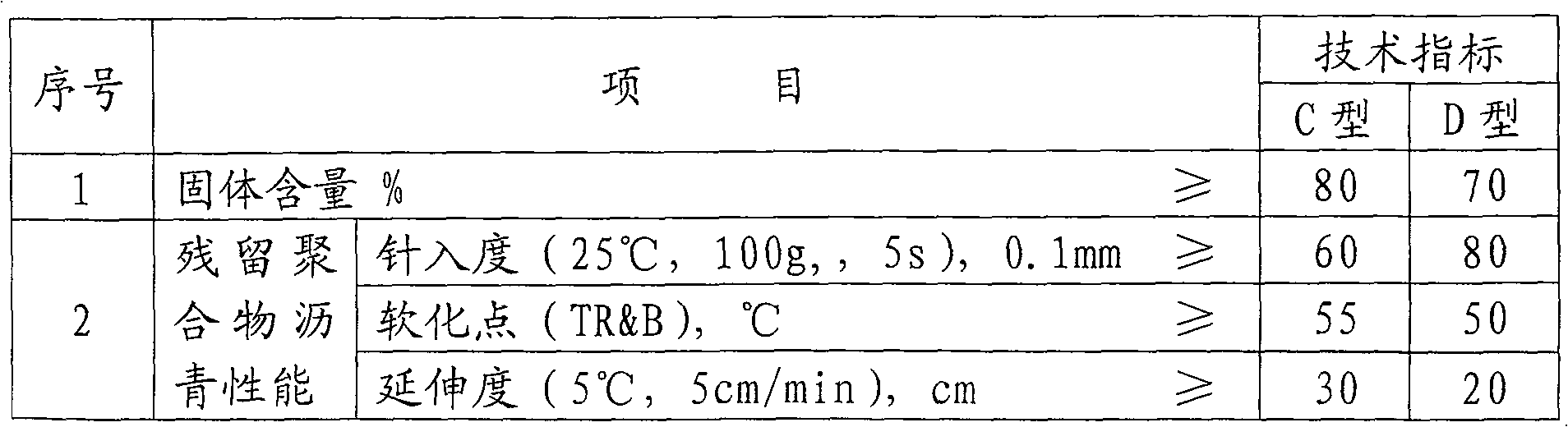

Cold-mixing repairing material SBS pitch liquid for pit or slot of pitch road surface, and its producing technology

InactiveCN1640939ATo overcome the construction affected by the climate environmentOvercoming many factors such as construction affected by climate and environmentIn situ pavingsBuilding insulationsGasolineRepair material

The present invention discloses SBS pitch fluid for repairing road pits and holes after cold mixing and its production process. The SBS pitch fluid has the material comprising diesel oil 7-10 wt%, glycol 4-5 wt%, gasoline 8-10 wt%, SBS 6-8 wt%, antiager 5-10 wt% and stripping resisting agent 0.3-0.4 wt% except pitch. The production process of the SBS pitch fluid is also disclosed. The SBS pitch fluid is liquid at normal temperature and low temperature and may be mixed directly before being used, so that it may be used conveniently all the year round without environmental pollution caused by heating pitch.

Owner:张坚

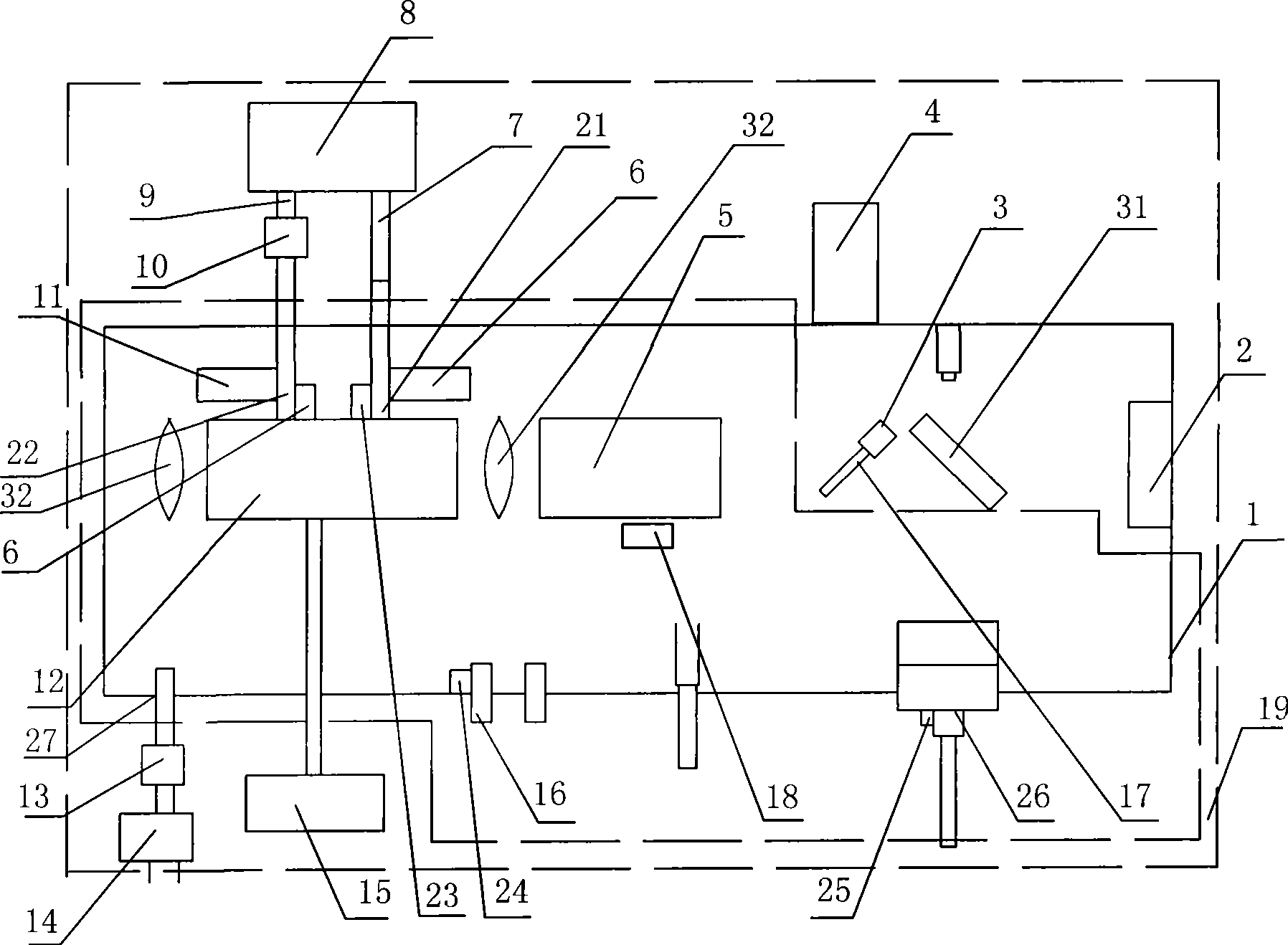

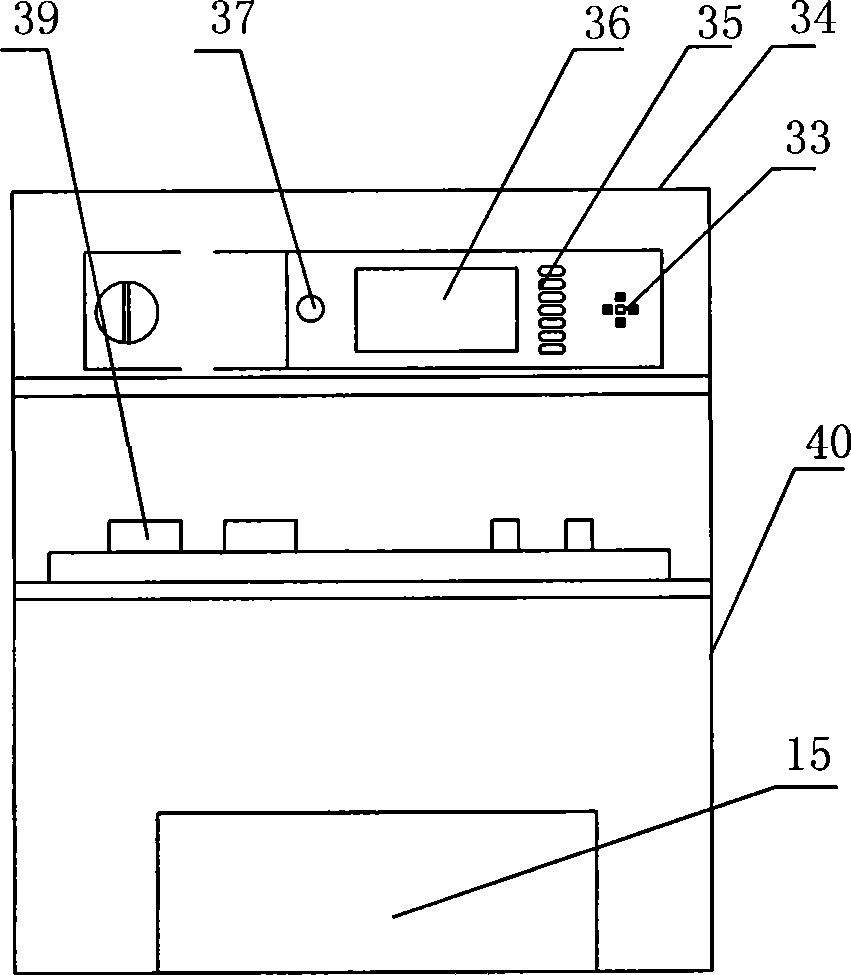

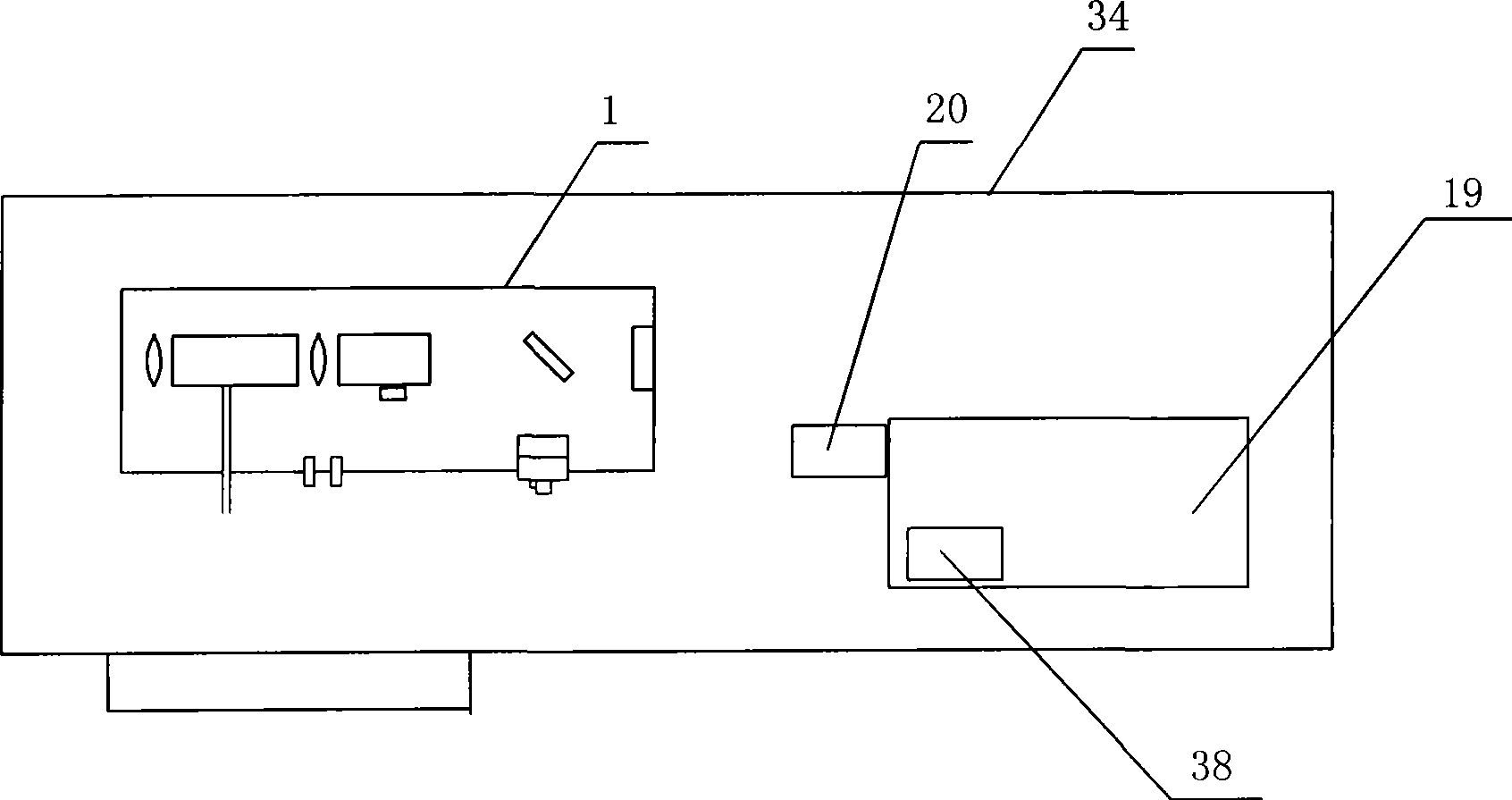

Universal controller for whole solid-state high-power laser

InactiveCN101465509AEasy to operateImprove protectionExcitation process/apparatusOperational costsWater leakage

The invention relates to a general purpose controller of an all-solid-state high power laser, which is composed of hardware and software; the hardware comprises a signal detecting and executing unit, an operating unit and a main control unit; the signal detecting and executing unit comprises a laser head power control and detecting mechanism, a cooling water control and detecting mechanism, a protecting gas control and detecting mechanism, an optic cavity water-leakage detecting mechanism, a optical gate switching control mechanism and a power detecting mechanism; the operating mechanism comprises a case body, a control panel, a liquid crystal display arranged on the control panel, seven control keystokes, seven status indicator lamps corresponding to the control keystokes, five setting keystokes and a dead-stop button; the main control unit comprises a power supply module and a main controller which adopts a double CPU structure. The software comprises a system main control procedure, an automatic on-off procedure and an alarming procedure. The design of the invention is scientific, the performance is stable and the operation is reliable, thus having high practicability and progressiveness; the installation is convenient, the operation is simple, and the operating cost is low, thus being suitable for being used in laser processing industry.

Owner:沈阳大陆激光工程技术有限公司

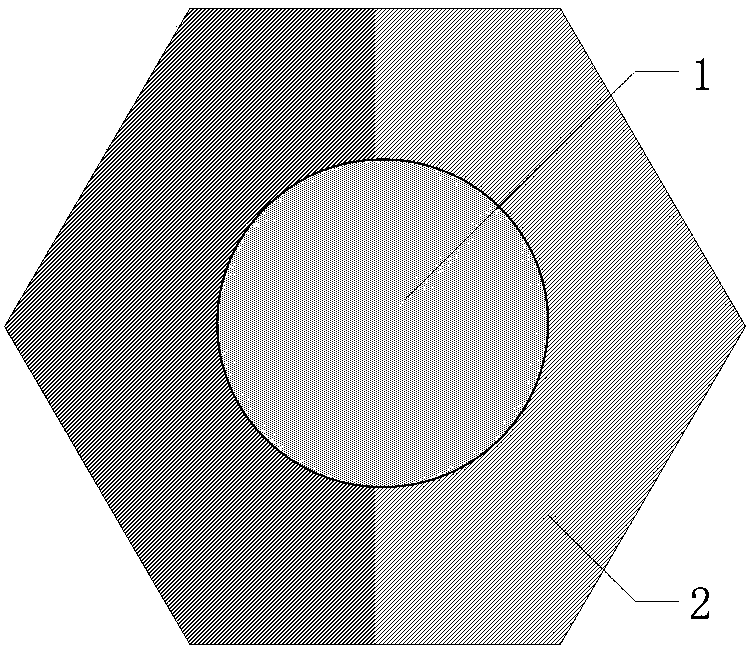

Epoxy-pouring full-insulation solid isolating switch

ActiveCN101620947AUnaffected by the surrounding environmentImprove electricity safetySwitches with movable electrical contactsEpoxyGround contact

The invention relates to an epoxy-pouring full-insulation solid isolating switch, which comprises an isolation body, a grounded contact, an isolation contact, a middle contact, an isolation moving contact, a driving screw rod, a fixed nut and a driving gear part, wherein the grounded contact and the isolation contact are arranged at two ends of the isolation body respectively, the middle part of the isolation body is provided with the middle contact, the upper end of the isolation contact is connected with a bus contact through a bus-bar, the bus contact is arranged on the top of the isolation body, and the isolation moving contact is always contacted with the middle contact through a watch chain sensing finger. The isolation switch slides between two positions of the middle contact and the isolation contact or the middle contact and the grounded contact to form the conduction or the isolation grounding of the isolating switch. The entire isolating switch is poured into a fully-sealed integral structure with epoxy resin.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

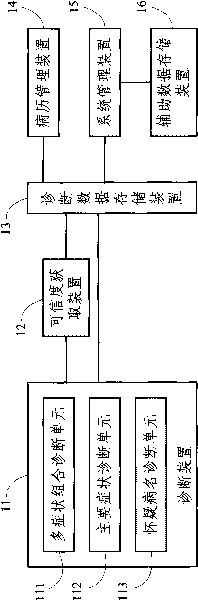

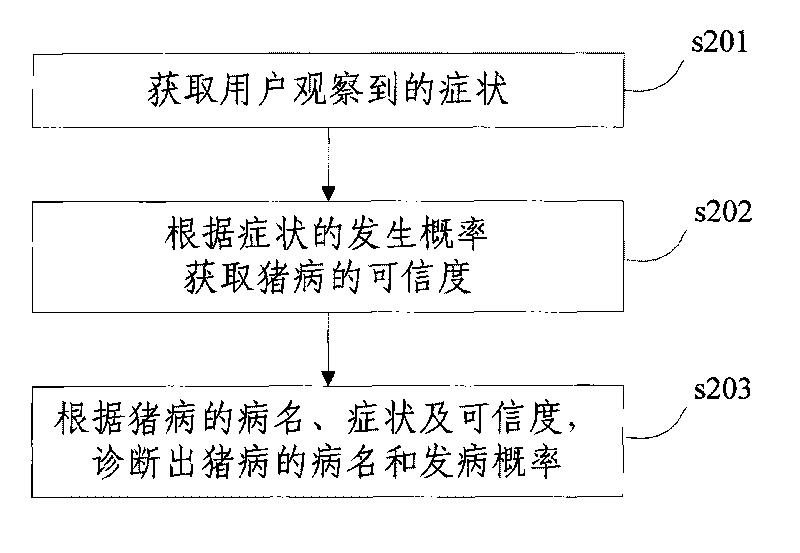

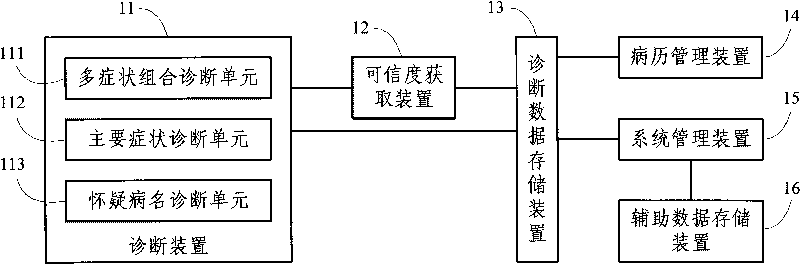

Swine disease diagnosis system and swine disease diagnosis method

InactiveCN101751509AImprove diagnostic accuracyHigh speedSpecial data processing applicationsKnowledge based modelsPig farmsInformation processing

The invention relates to a swine disease diagnosis system and a swine disease diagnosis method thereof and belongs to the technical field of the information processing. The system mainly comprises a diagnosis data storing device, a reliability acquisition device, a diagnosis device, an auxiliary data storing device, a medical record management device and a system management device. The diagnosis system has simple and convenient use, high diagnosis accuracy, rapid speed and strong scientificity, advancement and practicability. The system has various diagnosis methods and strong auxiliary functions. The diagnosis system has wide application range, not only is suitable for various pig farms and veterinary medical institutions, but also is suitable for various feed factories, veterinary medicines factories, feed and veterinary medicines dealers and the like to carry out after service. The popularization of the swine disease diagnosis system can greatly improve the clinical diagnosis level of the basic veterinaries, generate great social benefit and economic benefit, and provide strong guarantee for the animal husbandry production.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

Epoxy pouring type solid insulation switch with three-cabin

ActiveCN101677177ANo risk of leakageUndisturbedBus-bar/wiring layoutsSwitchgear arrangementsEngineeringElectrical and Electronics engineering

The present invention provides an epoxy pouring type solid insulation switch with three-cabin which is composed of three switch bodies having same structure. The switch body comprises an isolation cabin, a vacuum explosion-chamber cabin and a fuse cabin; a bus contact is arranged on the top of the isolation switch, the bus contact fixedly connects with an isolation contact through a master row; agrounding contact and the isolation contact are arranged on two ends of the isolation switch, a middle contact is in the middle; three contacts have same contact bases, sliding guide holes are arranged on the centre of the bases; the front connects with an insulation nut, the rear end connects with an operating mechanism. a through hole is arranged on the centre of the isolation moving contact andfixedly connects with the insulation nut, the insulation nut is sheathed on the nut and rotately connects with the nut; the vacuum explosion-chamber cabin and the fuse cabin are arranged below the isolation cabin respectively. The switch provided by the invention has advantages of reasonable design, higher electric safety performance, little volume, light weight, stable performance, reliable motion, stronger practicability and advancement. The switch provides assurance for reliability of electric supply, which is a precondition condition for reducing user investment.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

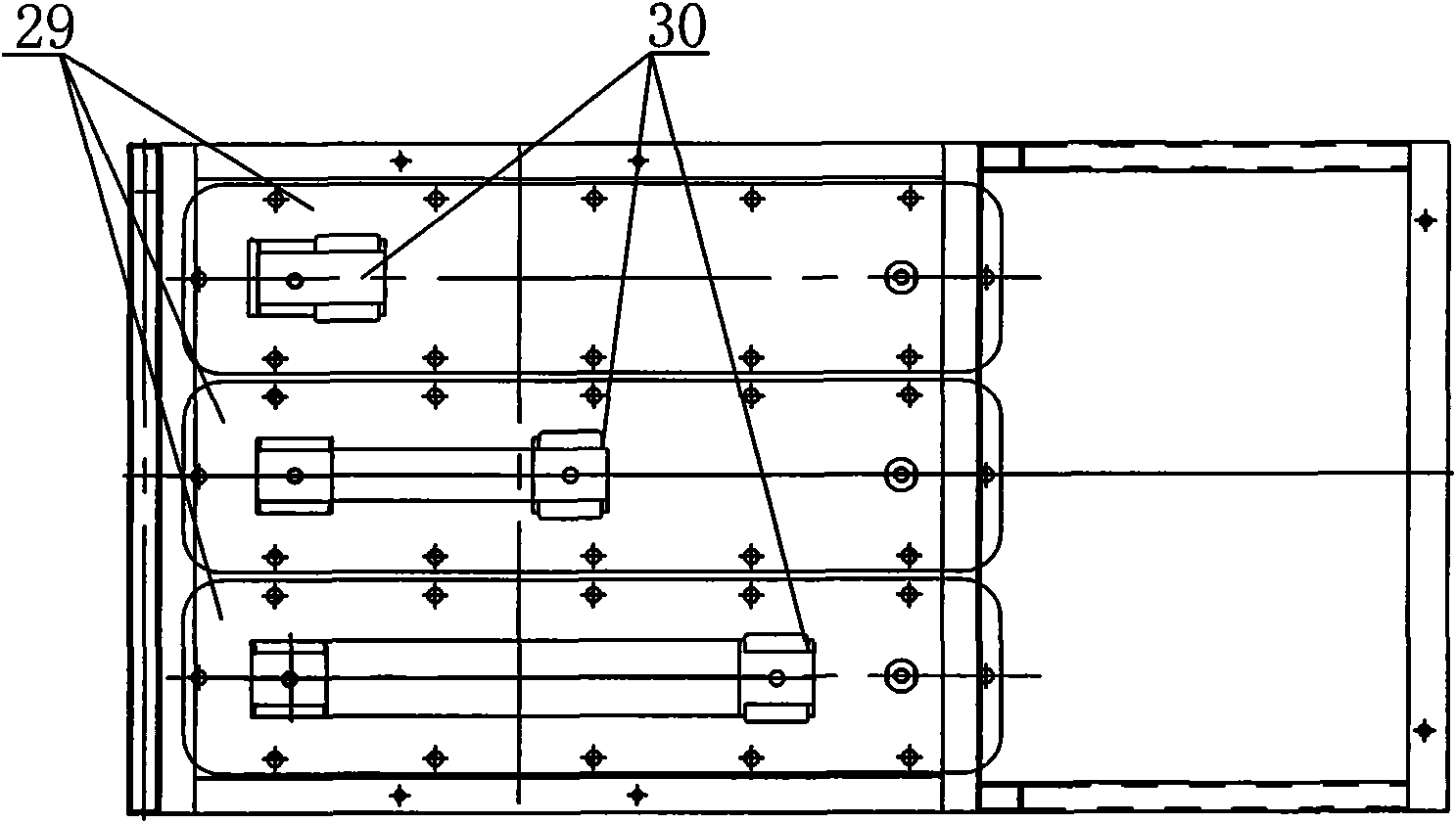

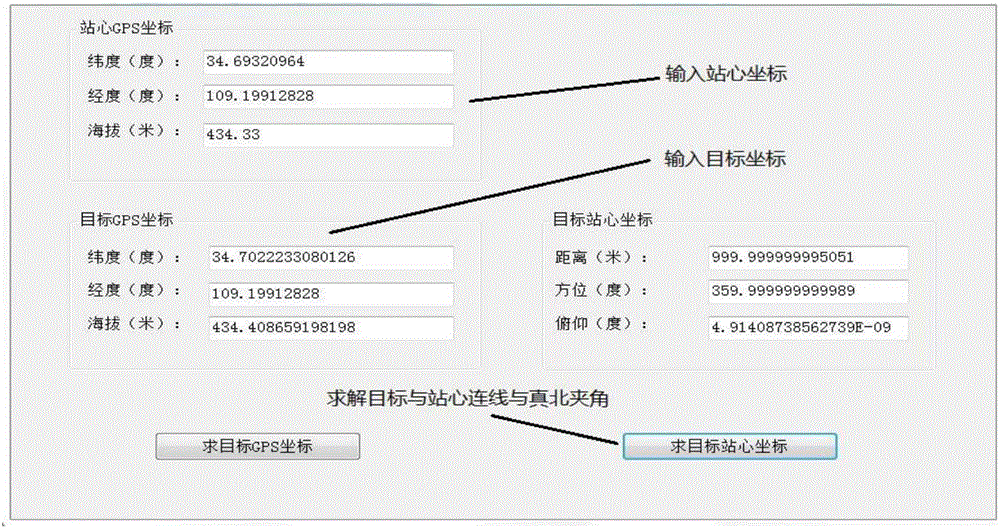

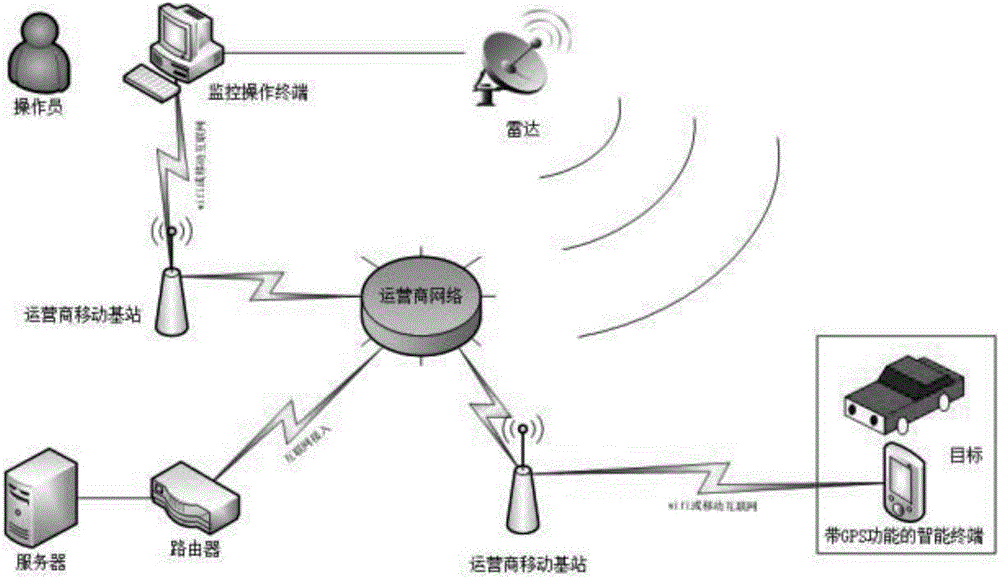

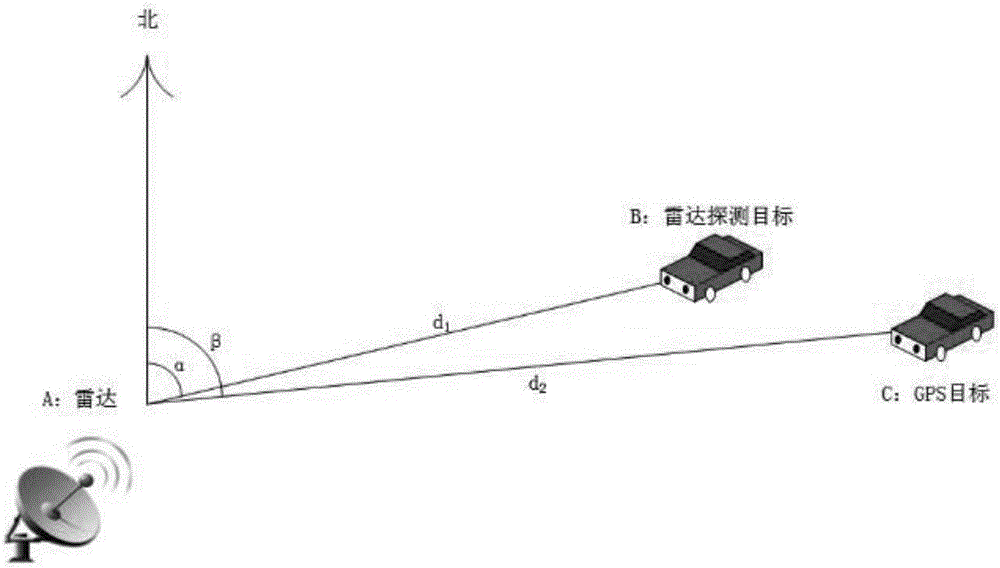

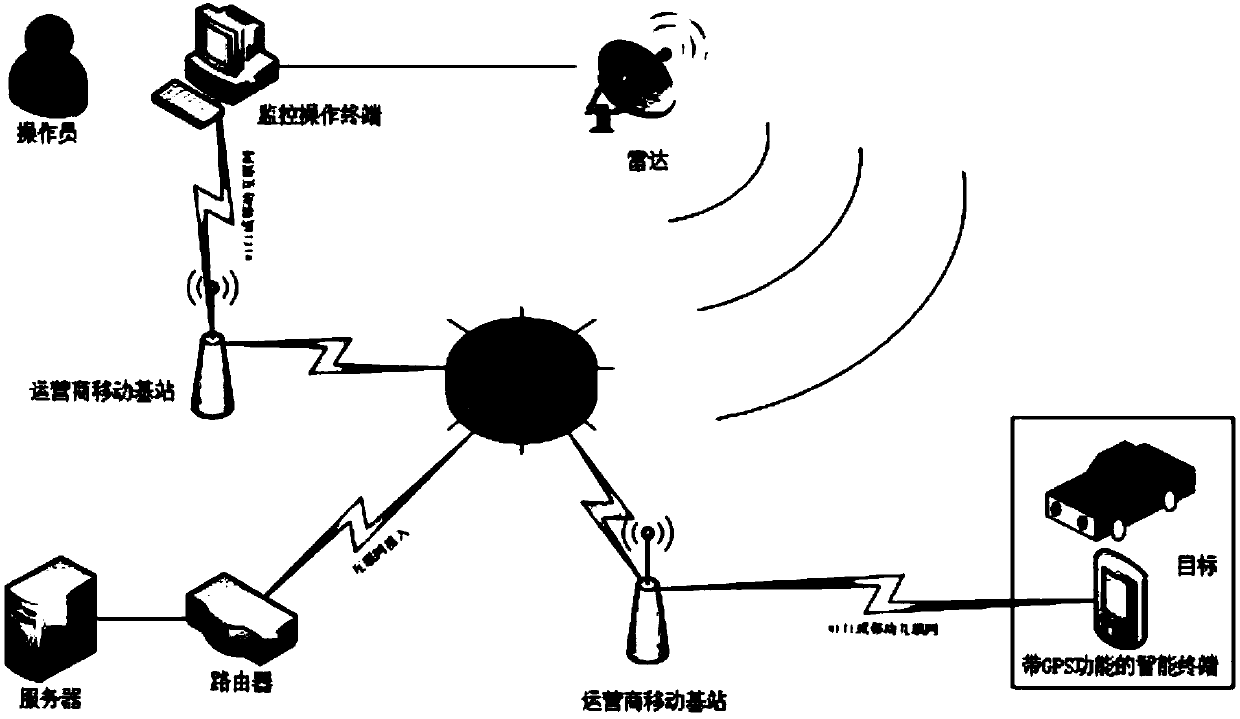

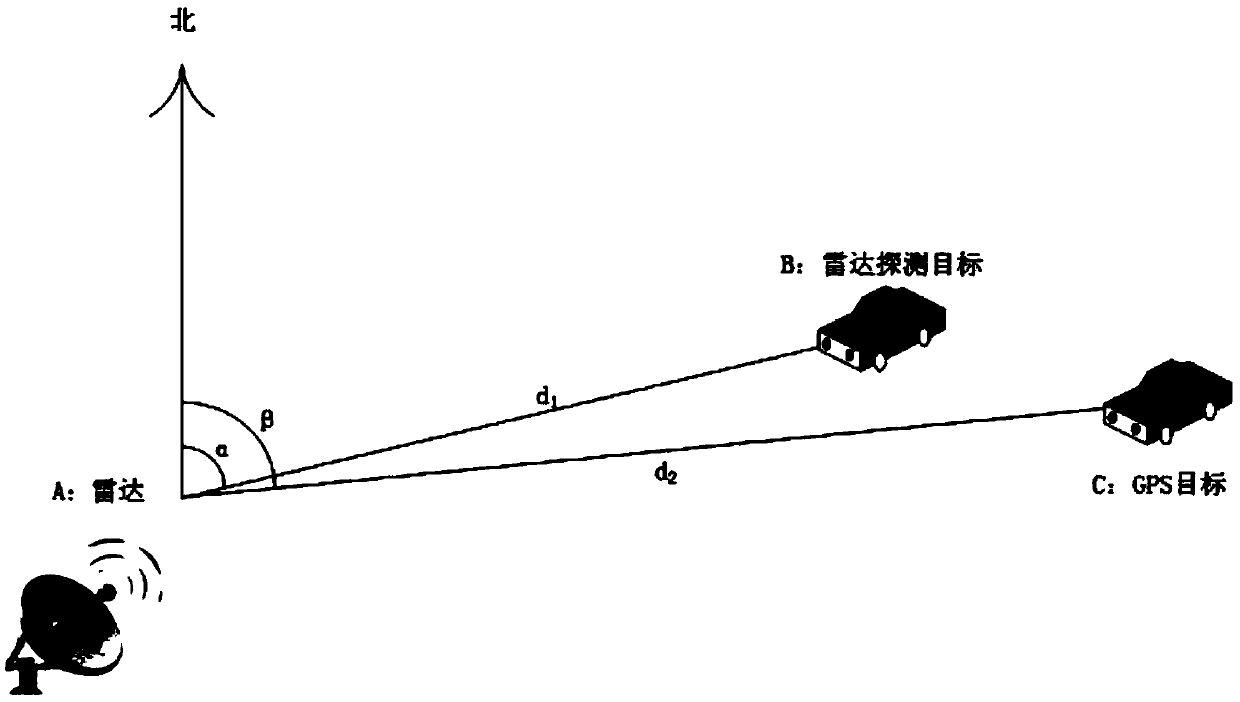

System for high-precision correction of monitoring radar measurement error and correction method

InactiveCN106814349ACorrect measurement errorFit closelyWave based measurement systemsThe InternetComputer terminal

The invention relates to the field of a radar measurement error modification technology, more particularly to a system for high-precision correction of a monitoring radar measurement error and a correction method. The system is composed of a server, a radar, a monitoring operation terminal, and an intelligent terminal. The server is based on the Internet and is provided with a public coordinate forwarding module. The monitoring operation terminal and a radar carry out information exchange and is superposed with a digital map. The intelligent terminal including a coordinate obtaining and reporting module reports coordinate information of the location point of the intelligent terminal to the server by a mobile base station; and the server forwards the received location point coordinate information to the monitoring operation terminal by the internet. With cooperation with a target, pure radial movement and pure tangential movement are made to correct an angle and a distance error. The system has the following advantages: when a mobile carrier carries the intelligent terminal, a geodetic coordinate system and radar coordinate system are normalized to realize high-precision positioning displaying of a target trace point in a practical map, so that monitoring information outputted by a radar terminal becomes precise.

Owner:西安寰达导航科技有限公司

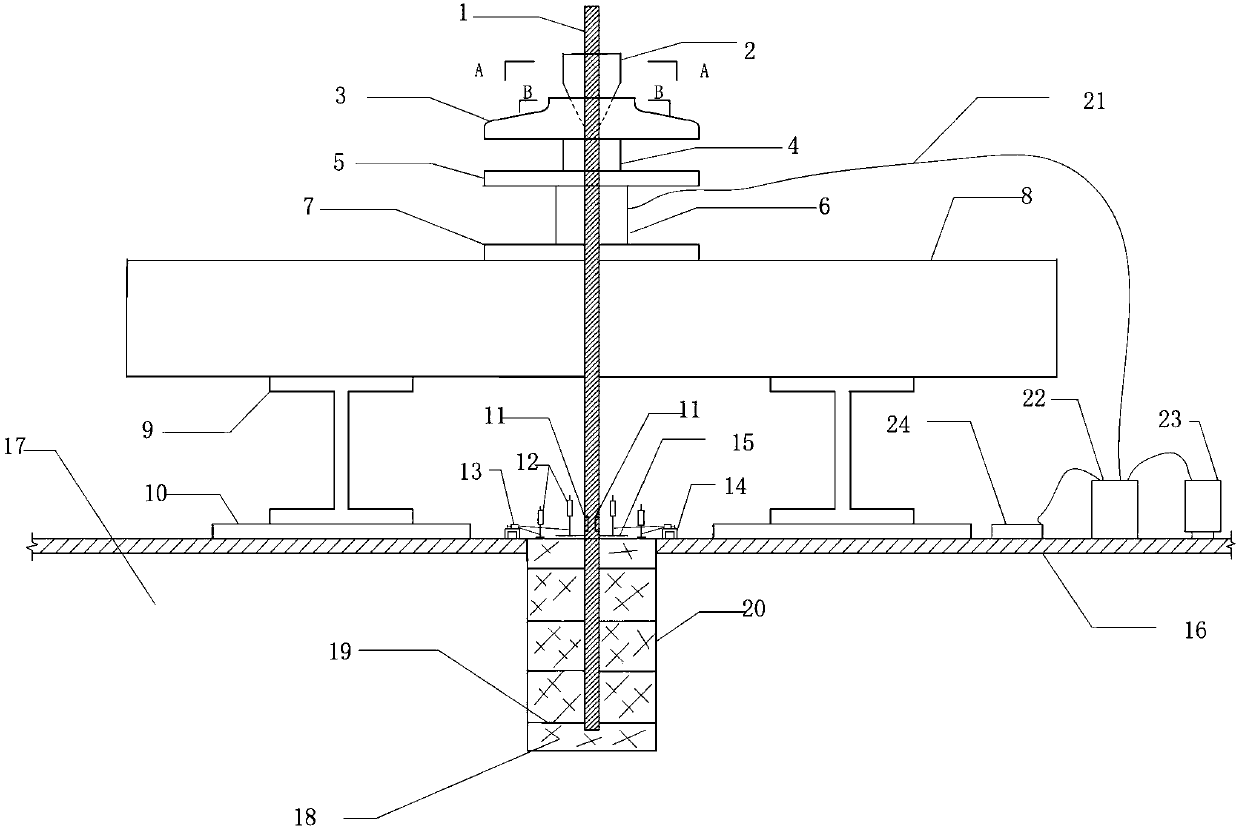

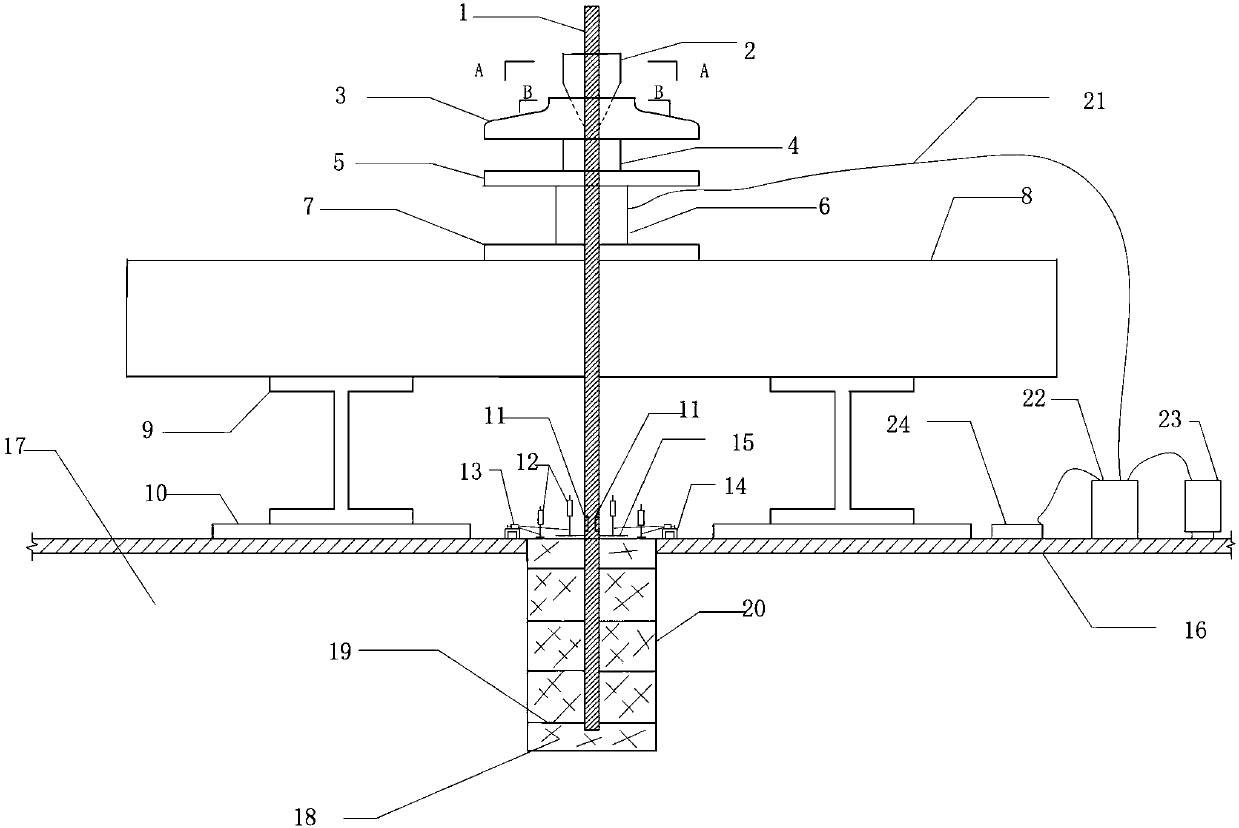

Fully-automatic test method for long-time deformation of nonmetal anti-floating anchor rod

InactiveCN107558511AMake up for manual loadingMake up for the lack of manual readingsFoundation testingAutomatic test equipmentTest analysis

The invention belongs to the technical field of civil engineering tests and relates to a fully-automatic test method for long-time deformation of a nonmetal anti-floating anchor rod. Firstly, calibration is conducted on a loading sensor and a hydraulic type centre hole jack, so that precision of the loading amount applied on each level in the test process is guaranteed; in the test process, it isrequired to guarantee that all components are in close contact; the counter force of the hydraulic type centre hole jack is controlled through a pressure sensor arranged on an electric oil pump, and the pressure sensor arranged on the electric oil pump can be calibrated through the loading sensor; and by means of an anchor rod test analysis system, the allowable off-load range is set. By means ofthe fully-automatic test method, automatic load replenishment can be achieved; it is guaranteed that the load on each level is constant for a long time; the process of the fully-automatic test methodis simple and convenient to implement; and an adopted device is simple in structure, convenient to test, high in test precision, great in operability and capable of achieving fully-automatic monitoring.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

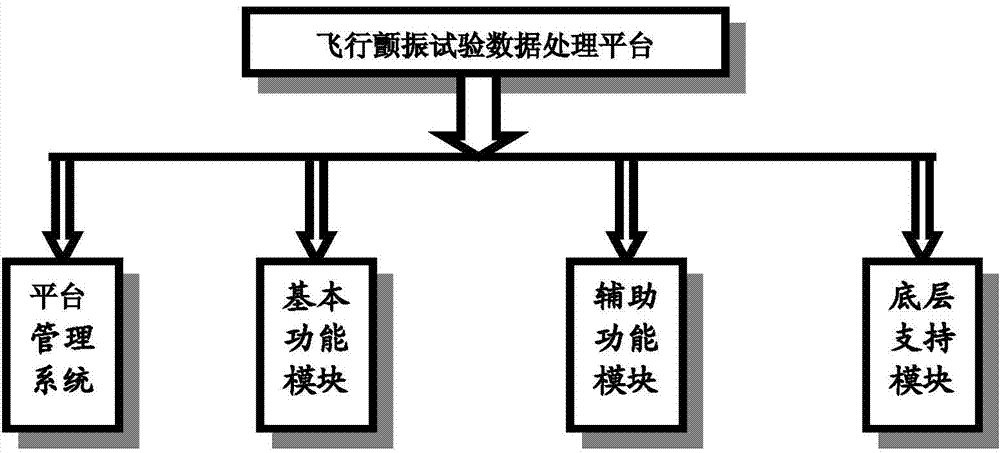

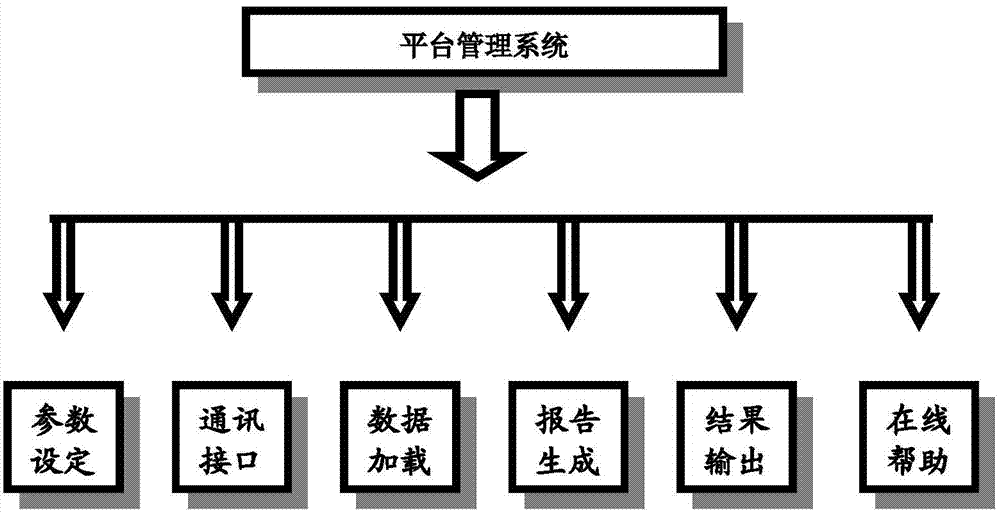

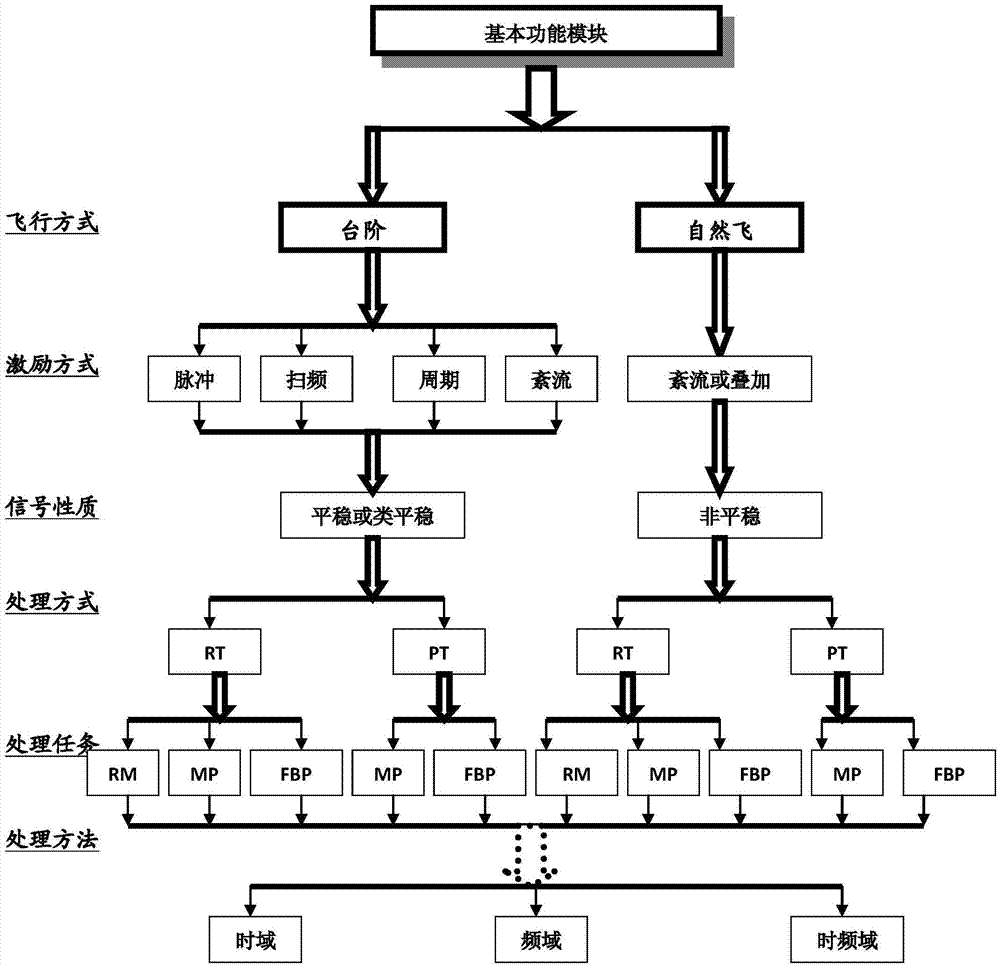

Flutter data processing framework based on flight test

InactiveCN103617323AProfessionalStrong advancedSpecial data processing applicationsAviationComputer module

The invention belongs to the technical field of aviation test flight, and particularly relates to a flutter data processing framework based on a flight test. The flutter data processing framework based on the flight test comprises a platform management system, a basic function module, an auxiliary function module and a bottom layer supporting module; the platform management system is used for resource dispatch and operational process management of a platform, the basic function module is used for processing data of a general flutter flight test, the auxiliary function module is used for analyzing flutter test flight data which are specific or are not provided with a currently established clear data processing technology system, the bottom layer supporting module is used for providing a basic environment supporting normal operation of the platform and basic software shared by each function module of the platform. The flutter flight test data processing platform concept and a top layer design framework are primarily raised, a plurality of layers such as a flight test mode, an incentive mode, the observation signal property, a processing mode, a processing task, a processing method and the like are projected in one unified framework, and therefore tradition, modernization, existence and development are coordinated in a higher level.

Owner:CHINESE FLIGHT TEST ESTAB

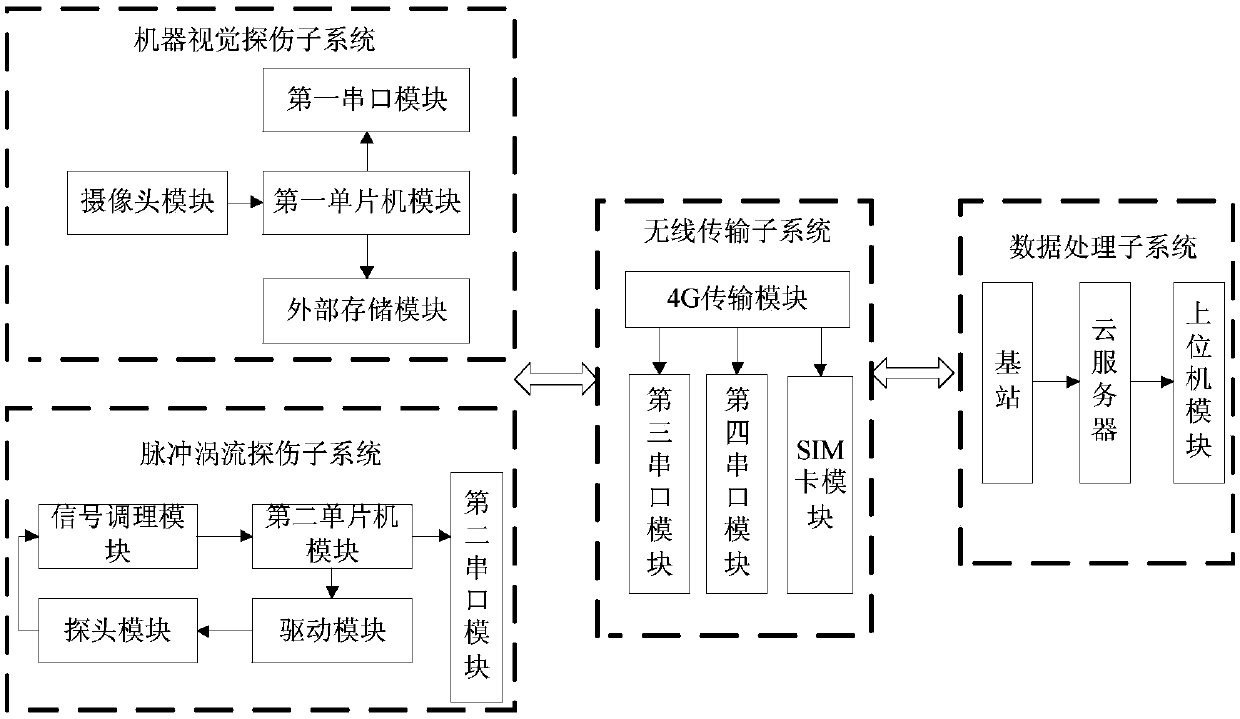

Steel rail surface flaw detection system and method based on machine vision and pulse eddy currents

InactiveCN107727660AAdd 4G-LTE transmission functionImprove transfer functionProgramme controlComputer controlEmbedded technologyThe Internet

The invention relates to a steel rail surface flaw detection system and method based on machine vision and pulse eddy currents. The system comprises a vision flaw detection subsystem, a pulse eddy current flaw detection subsystem, a data transmission subsystem and a data processing subsystem. The system and method are adopted, the detection system based on the machine vision and the pulse eddy currents is constructed through an embedded technology, by scanning and detecting a steel rail, the detection results of the machine vision and the pulse eddy currents are integrated, the size of a flawis judged in combination with characteristics of the flaw area, the length-width ratio and the like, and whether a defect exists or not on the surface of the steel rail is judged; an internet-of-things technology is introduced for wireless signal transmission, the functions of real-time detection, on-line locating, remote control and the like can be achieved, a 4G-LTE transmission function is added, Mobile, Unicom and Telecom 4G high-speed access is achieved, multi-system communication access is supported at the same time, the system and method have high stability, and flaw detection is conducted on the steel rail in real time at a super long distance; a pulse eddy current technology, a machine vision technology and the internet-of-things technology are utilized by the system and method, and the system and method have high application value.

Owner:ZHEJIANG SHUREN UNIV

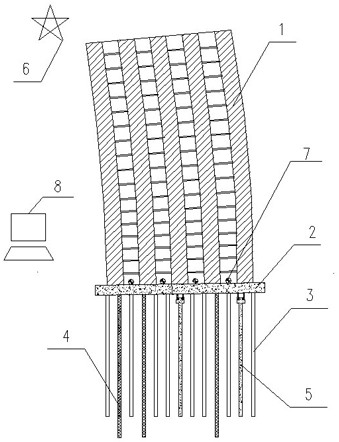

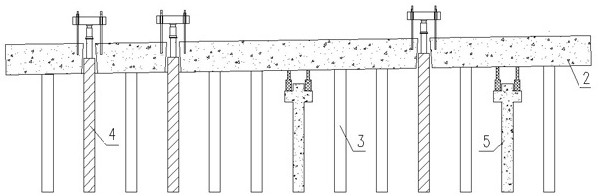

High-rise deviation-rectifying static pressure anchor rod pile and broken pile underpinning supporting device and monitoring method thereof

PendingCN112761199AAvoid over-correction sinkingGrasp the construction effect of deviation correction in timeFoundation testingFoundation repairData informationRock bolt

The invention discloses a high-rise deviation-rectifying static pressure anchor rod pile and broken pile underpinning supporting device and a monitoring method thereof. More static pressure anchor rod pile reinforcing structures are arranged on the side with large settlement displacement, a small number of static pressure anchor rod pile reinforcing structures and broken pile underpinning jack structures are arranged on the side with small settlement displacement, an original pile foundation, the static pressure anchor rod pile reinforcing structures and the broken pile underpinning jack structures jointly underpin and support an original inclined high-rise building on a basement floor structure, and through lifting adjustment of underpinning jacks, deviation-rectifying construction of the inclined high-rise building is conducted. A broken pile underpinning deviation-rectifying construction real-time monitoring system receives wireless transmission data information of a GPS automatic deviation-rectifying displacement monitoring system and a structural stress strain monitoring network system, parameters of a finite element calculation model are corrected, a reasonable deviation-rectifying construction scheme is formulated, the broken pile underpinning deviation-rectifying construction real-time monitoring system commands forced landing displacement numerical values of the jacks of the underpinning jack structures, and deviation-rectifying construction of the inclined high-rise building is electronically monitored.

Owner:江苏东南特种技术工程有限公司

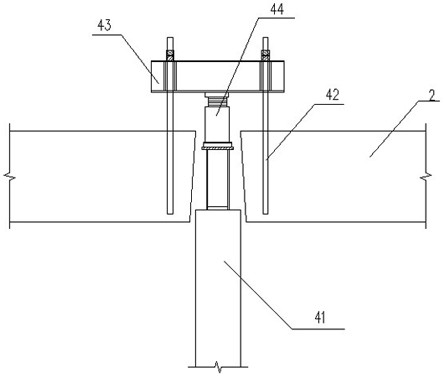

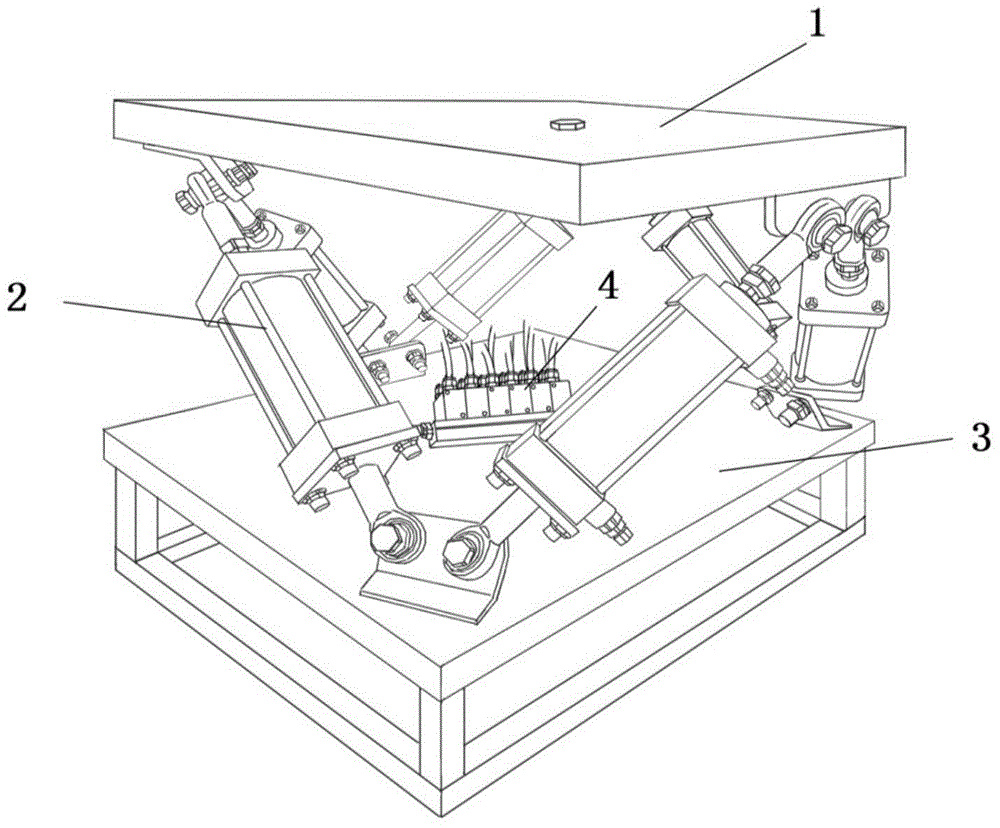

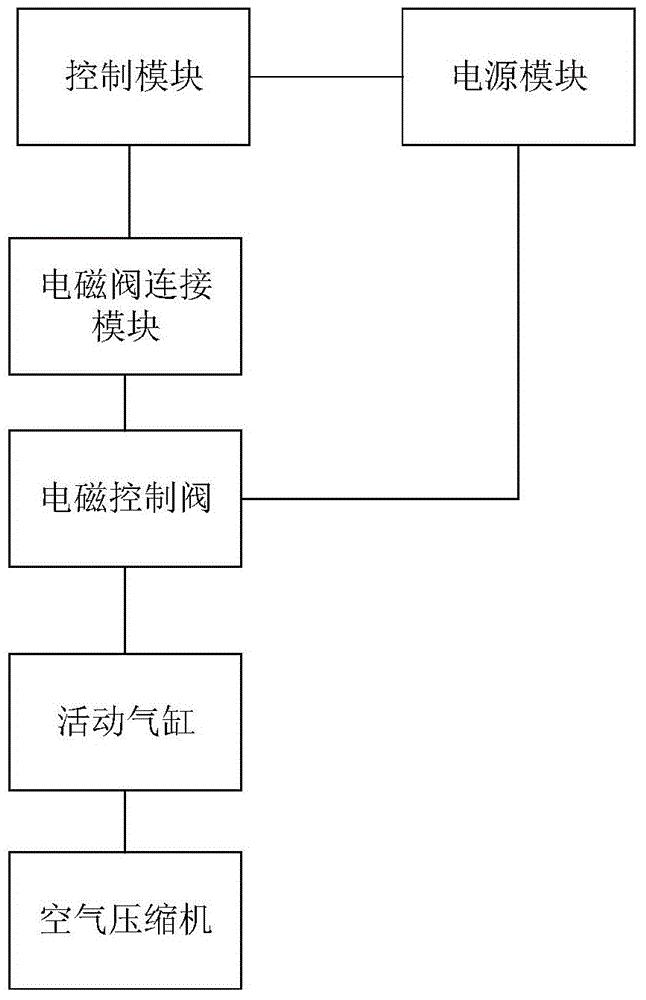

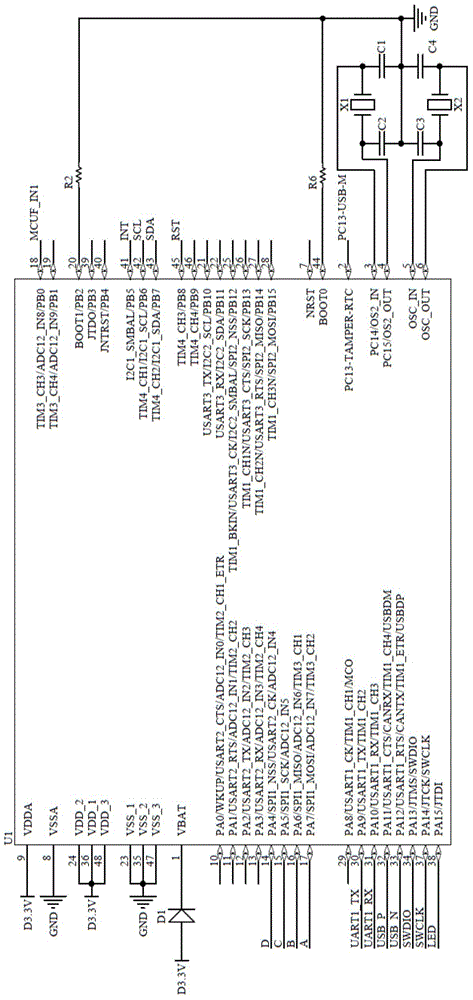

Force feedback seat for immersive roller coaster experience system

InactiveCN104834322AAvoid security issuesMeet different needsControl using feedbackRoller coasterSolenoid valve

The invention discloses a force feedback seat for an immersive roller coaster experience system. The force feedback seat comprises a seat platform, movable air cylinders, a fixed platform, solenoid control valves and a power supply circuit for power supply. The seat platform is mounted on the fixed platform through the movable air cylinders of six degrees of freedom. The six solenoid control valves are disposed on the fixed platform, and connected respectively with the movable air cylinders for control. The six solenoid control valves are connected with a control module through a solenoid valve connecting module. An air compressor is connected with the movable air cylinders of six degrees of freedom. The power supply is connected with the control module and the six solenoid control valves for power supply. According to the invention, the force feedback seat brings corresponding posture adjustment feedback as a virtual roller coaster moves at different positions on a track to a user, solves the problems of constraints of real roller coaster site factors, personal safety and other conditions, can achieve the experience requirements of a variety of roller coaster experience scenes by using virtual reality technology, is highly safe and has relatively high application value.

Owner:杭州映墨科技有限公司

Easily-degradable anti-shrinkage polypropylene master batch and preparation method thereof

InactiveCN106674728AImprove high temperature resistanceImproves shrink resistanceFungiMicroorganism based processesPolypropyleneAntioxidant

The invention discloses an easily-degradable anti-shrinkage polypropylene master batch, wherein polypropylene serves as a base material, the types and the formula of the master batch are optimized, and a production process is improved. A complex antioxidant which contains a biologic antioxidant, modified nanocarbon which can obviously improve high temperature resistance, shrinkage resistance, relative tensile load, strength and toughness and elasticity modulus of the polypropylene master batch, calcium fruit fibers which can obviously improve shock resistance of the polypropylene master batch, are easily biodegradable and lower production cost, polyethylene / winter rye peptide complexes which can greatly improve low temperature resistance of the polypropylene master batch and bitter almond oil which can effectively improve lubricating property and oxidation resistance of the polypropylene master batch are scientifically compounded; the obtained compound has a synergistic effect with other processing aids; finally, the environment-friendly easily-degradable anti-shrinkage polypropylene master batch with good physical property is obtained.

Owner:NINGXIA YANCHI WEST CHANGXIANG AGRI BIOTECH

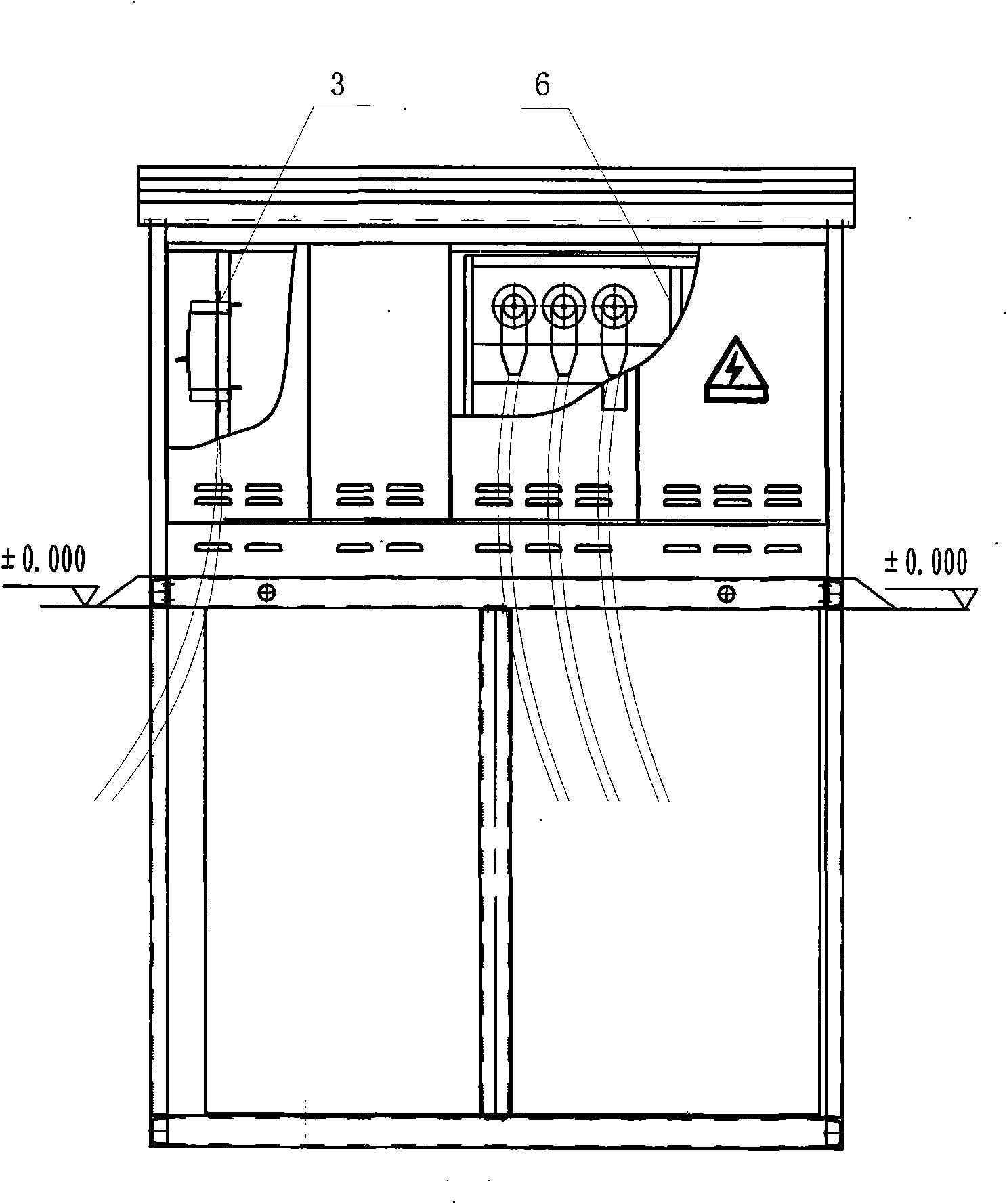

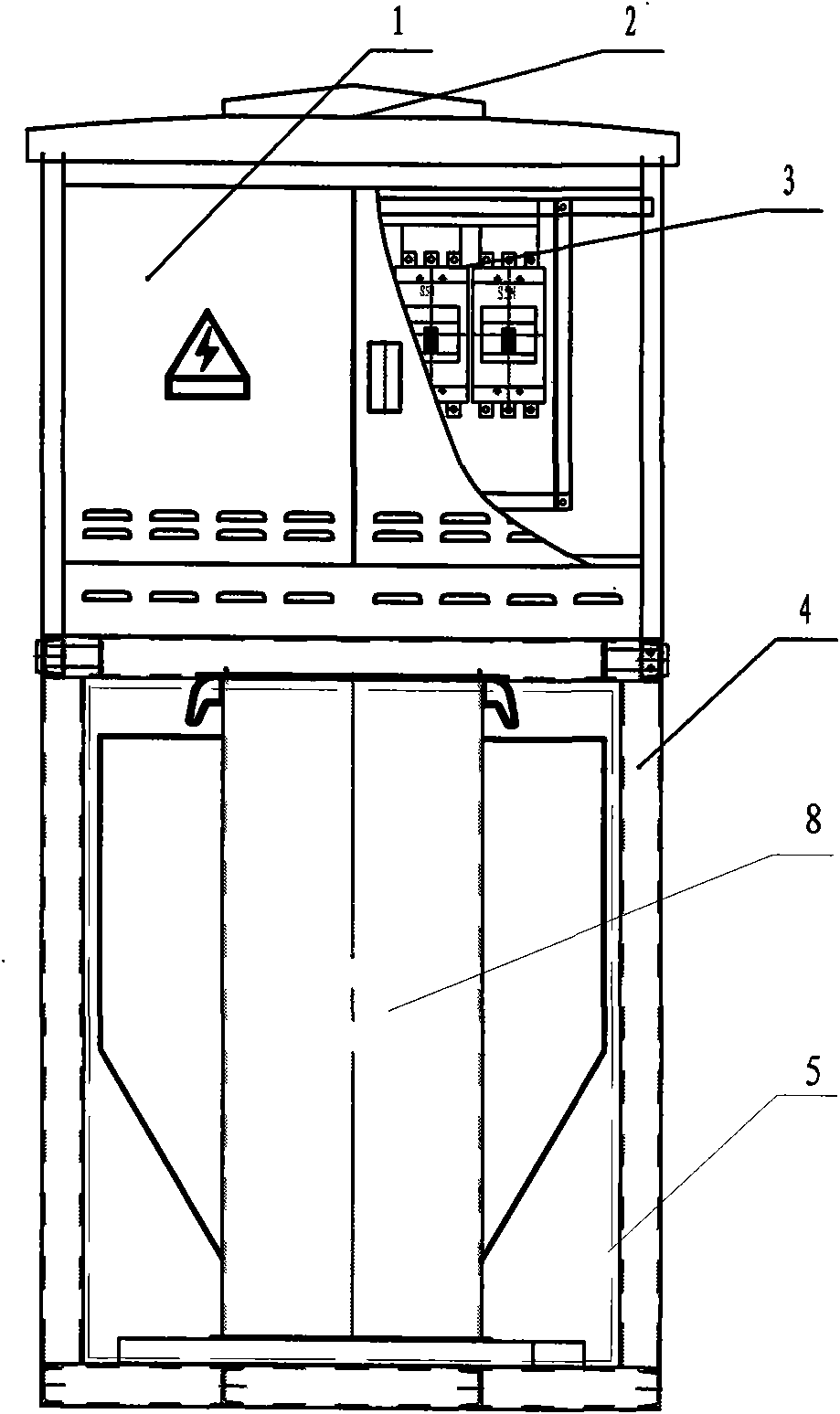

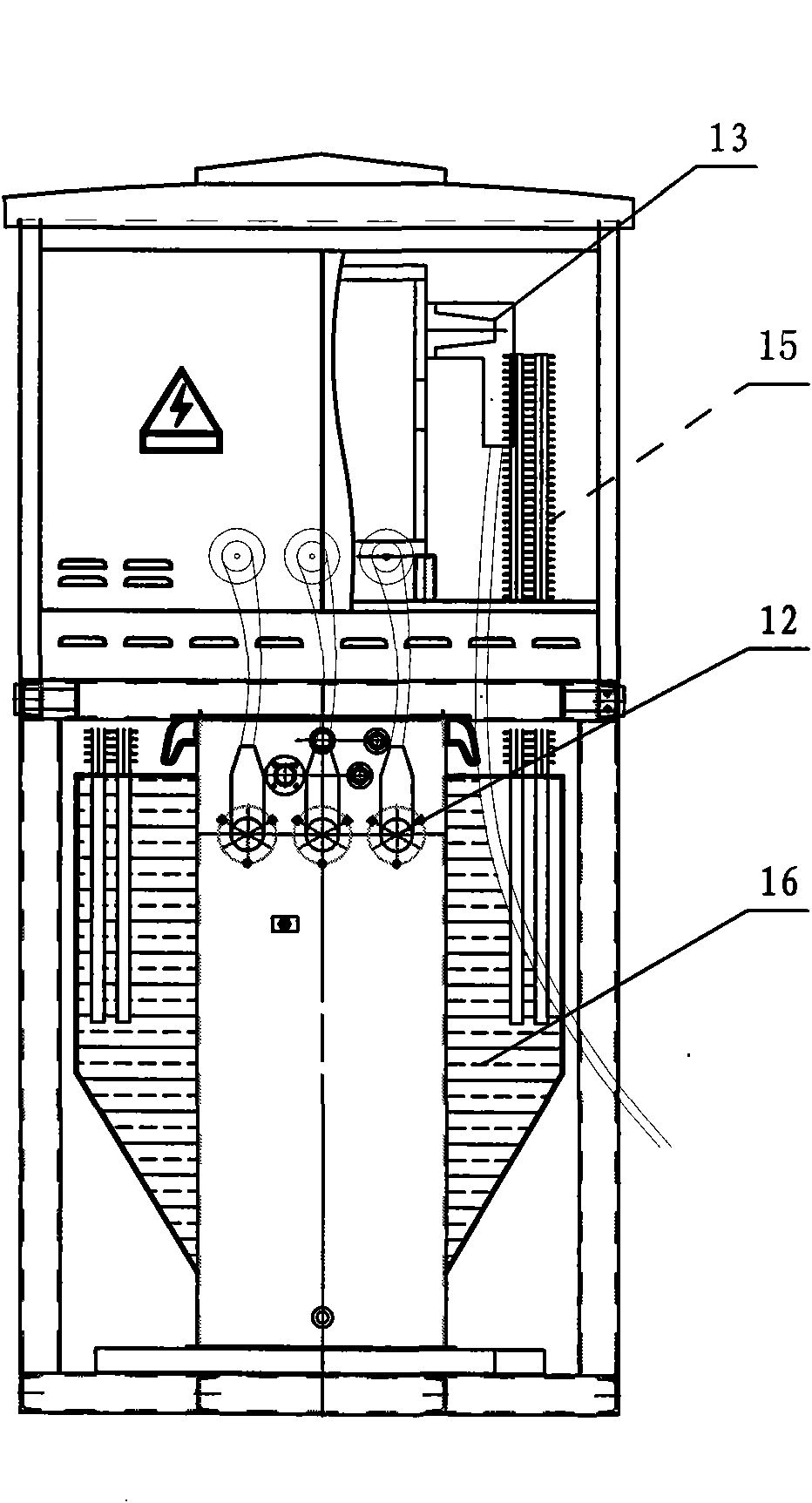

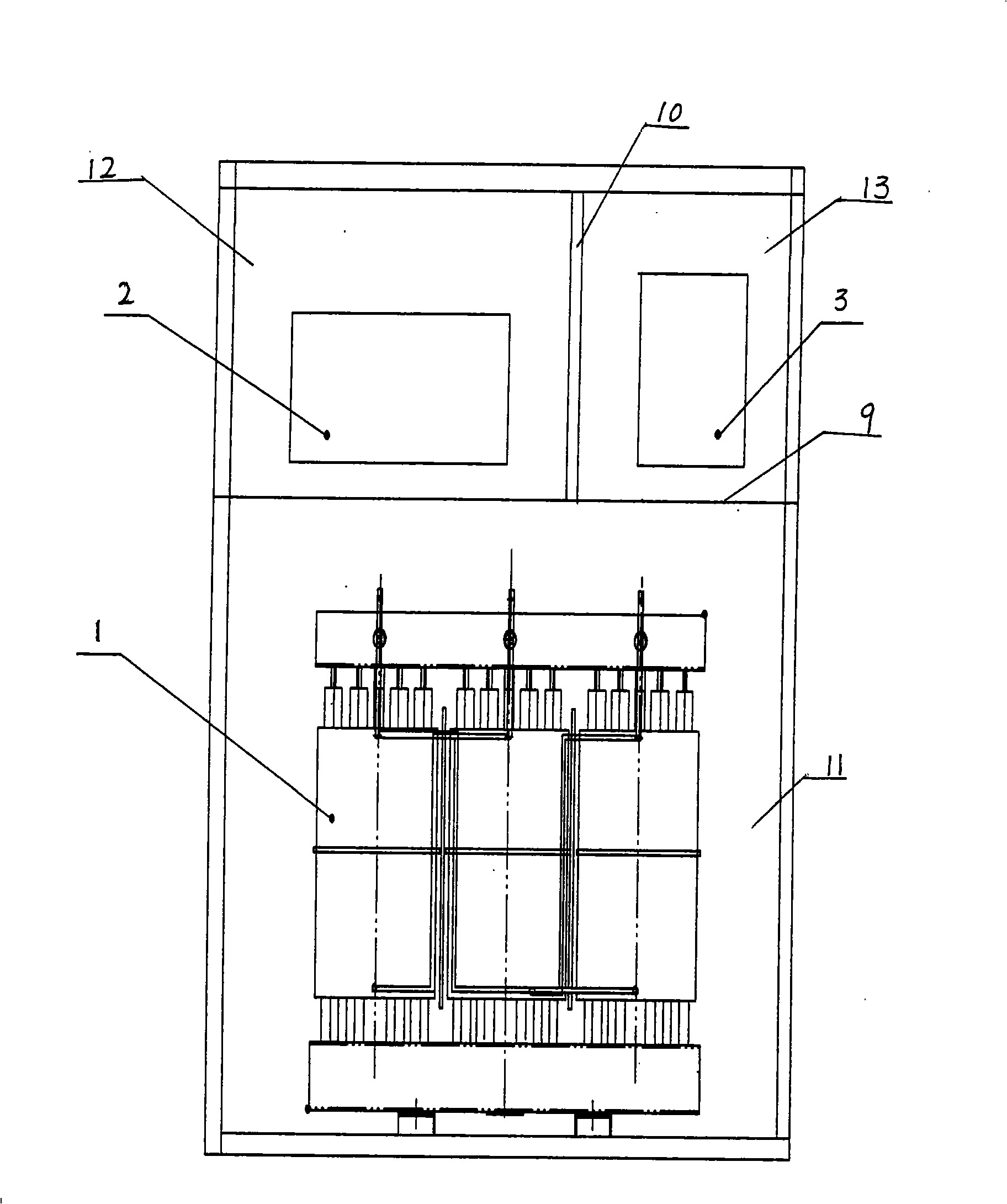

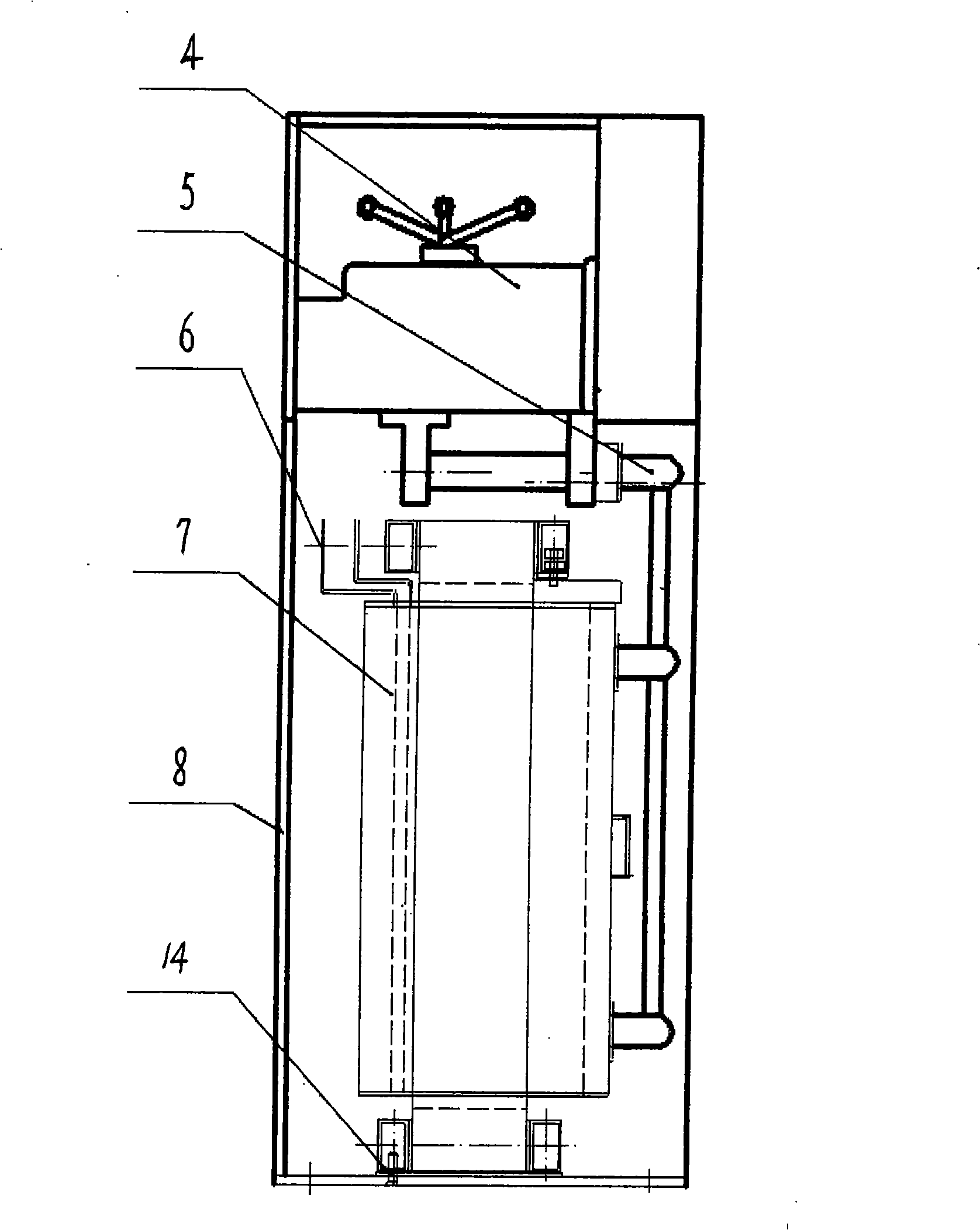

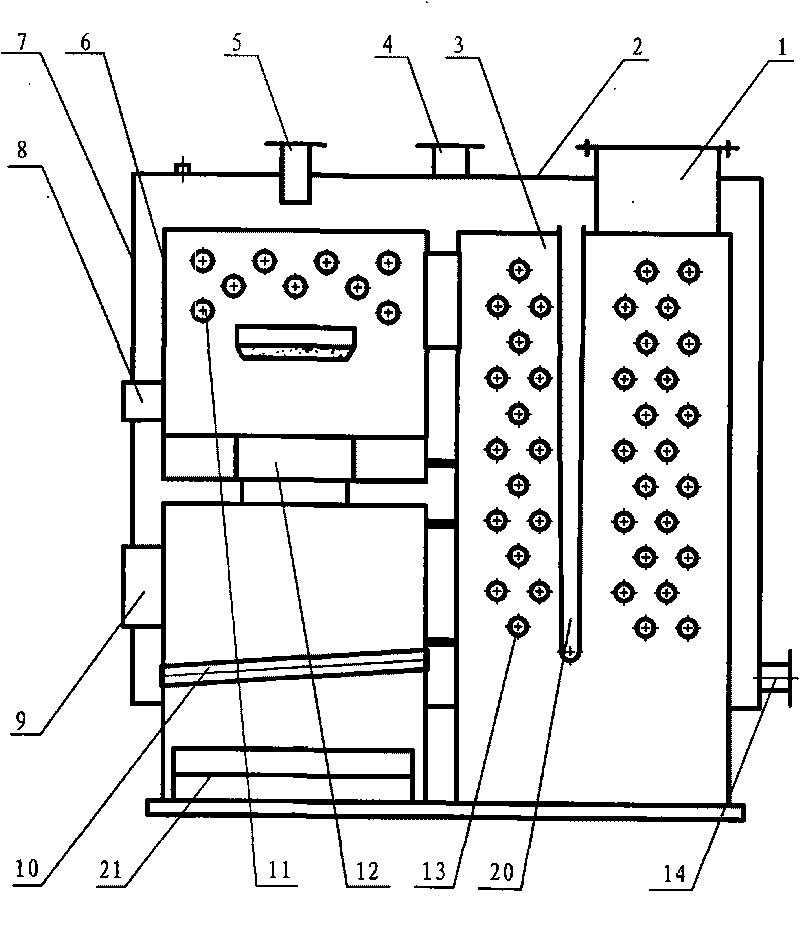

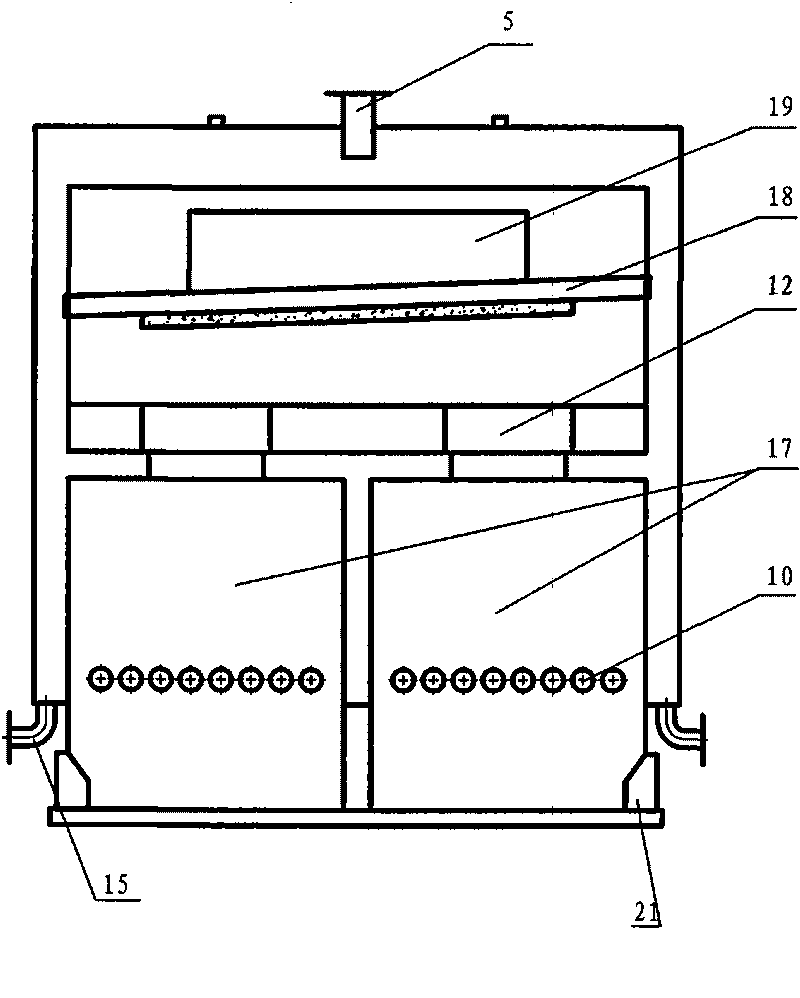

Fully insulated buried substation

InactiveCN101888066APracticalStrong advancedSubstation/switching arrangement cooling/ventilationEnclosed substationsLow voltageDisplay device

A fully insulated buried substation comprises a frame and a high-voltage unit, a transformer unit and a low-voltage unit which are arranged in the frame, wherein a transformer is arranged in a transformer protection box; the lower half frame, the transformer protection box and the transformer are arranged underground; the high / low-voltage units are positioned on the transformer unit and are arranged above the ground; a plurality of heat pipes are vertically arranged in transformer oil grooves; the upper parts of the heat pipes are respectively positioned at one side of the high-voltage unit and one side of the low-voltage unit; the moving contact of a high-voltage solid insulated switch is connected with an operating mechanism; and secondary-side connection terminals of the transformer are connected with the upper ends of low-voltage switches by penetrating through low-voltage sleeves via the cables. The substation adopts the modular integrated combination structure and the components can be replaced separately. The substation is scientific, reasonable and creative in design, small in volume and convenient to maintain and operate since the monitor display devices are arranged at one side, reduces energy consumption, is easy to install, strong in economical applicability and stable and reliable, and has good development prospect. The substation is suitable for power supply departments.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

Full-automatic testing apparatus for nonmetal anti-floating anchor long-term deformation

The invention belongs to the field of civil engineering testing equipment, and relates to a full-automatic testing apparatus for nonmetal anti-floating anchor long-term deformation. A fastening nut and an anchoring tray are connected to an anchor rod body, a steel shim is placed on the surface of a concrete cushion, an I-shaped buttress is placed on the upper surface of the steel shim, a second cross-core steel base plate is placed on the upper surface of a cross-core counter-force beam, and the second cross-core steel base plate, an oil pressure type cross-core jack, a first cross-core steelbase plate and a loading sensor are sequentially stacked on the upper surface of the cross-core counter-force beam from bottom to top; the oil pressure type cross-core jack is connected with an electric oil pump, and the electric oil pump is connected with an anchor rod test testing system and a repeater; the inner wall of a semi-circular steel pipe is pasted to the outer side of the anchor rod body; an angle iron is welded to the outer side face of the semi-circular steel pipe, and a centering support is fixed to the outer surface of the anchor rod body of an anchor section; and displacementsensors are installed on the surfaces of the angle iron and a grouting body. The full-automatic testing apparatus is simple in structure, convenient to test, high in testing accuracy, high in maneuverability and capable of achieving full-automatic monitoring.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Cold-mixing repairing material SBS pitch liquid for pit or slot of pitch road surface, and its producing technology

InactiveCN100434479CTo overcome the construction affected by the climate environmentOvercoming many factors such as construction affected by climate and environmentIn situ pavingsBuilding insulationsGasolineRepair material

The present invention discloses SBS pitch fluid for repairing road pits and holes after cold mixing and its production process. The SBS pitch fluid has the material comprising diesel oil 7-10 wt%, glycol 4-5 wt%, gasoline 8-10 wt%, SBS 6-8 wt%, antiager 5-10 wt% and stripping resisting agent 0.3-0.4 wt% except pitch. The production process of the SBS pitch fluid is also disclosed. The SBS pitch fluid is liquid at normal temperature and low temperature and may be mixed directly before being used, so that it may be used conveniently all the year round without environmental pollution caused by heating pitch.

Owner:张坚

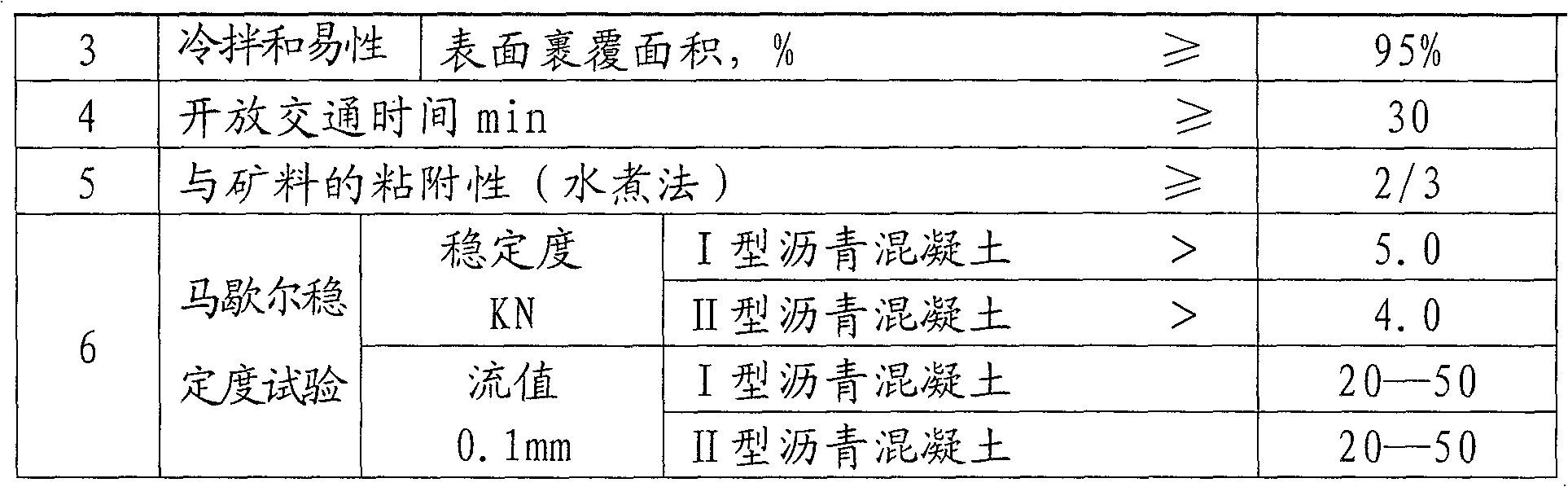

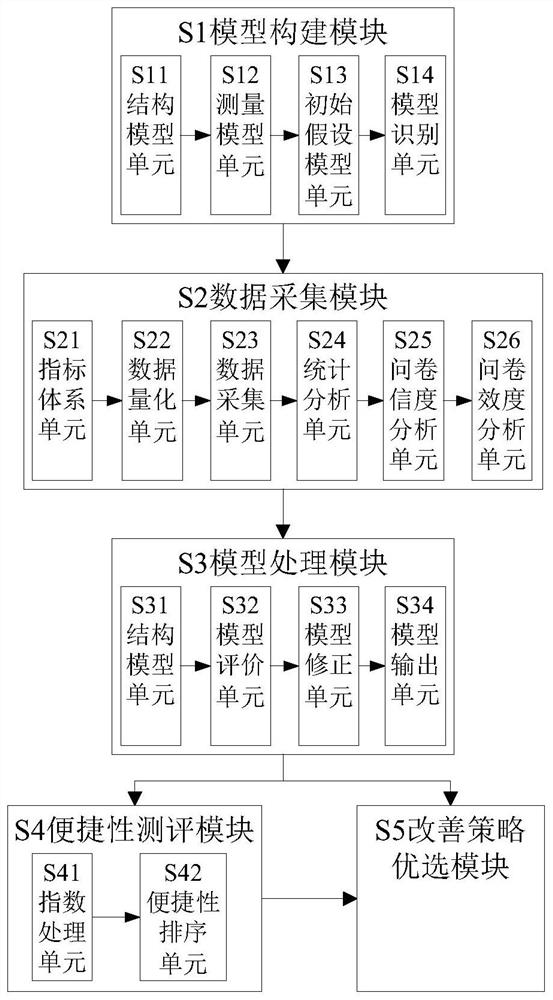

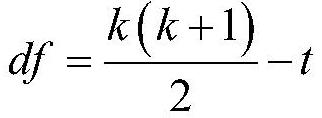

Comprehensive passenger transport hub transfer guide system convenience evaluation method and system

ActiveCN112200455AImprove operational efficiencyEasy to manageInternal combustion piston enginesResourcesData modelingComputer science

The invention relates to the field of transportation, and provides a comprehensive passenger transport hub transfer guide system convenience evaluation method and system. Therefore, the technical scheme adopted by the invention is as follows: the comprehensive passenger transport hub transfer guidance system convenience evaluation method comprises the following steps: a transfer guidance system convenience structural equation model is constructed by taking a mathematical statistics theory and a data modeling method as technical means on the basis of a traveler psychological perception angle and in combination with traveler subjective willingness and transfer facility objective factors; transfer convenience among different traffic modes is transversely compared and evaluated, an importanceperformance analysis method is combined, a convenience optimization improvement strategy of the transfer guide system of the specific traffic mode is identified, and effective guidance is provided forimproving the operation efficiency of the comprehensive passenger transport hub. The method is mainly applied to transportation management occasions.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

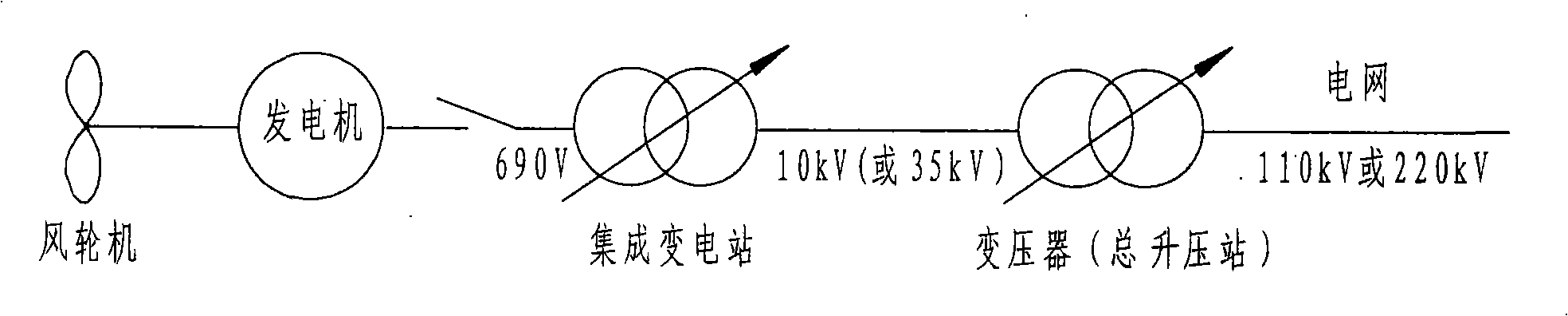

Integration transformer substation for wind power generation

InactiveCN101355237AAvoid risk of crackingImprove heat resistanceSubstation mounted on poleSubstation/switching arrangement boards/panels/desksChinese charactersLow voltage

The invention provides a special integrated-type substation for wind power generation, comprising a semi-encapsulated impregnated insulated transformer unit, as well as a high voltage unit and a low voltage unit which are cast and sealed by epoxy resin. The transformer unit, the high voltage unit and the low voltage unit are fixed in a shell, showing a shape like a Chinese character 'pin'. The high voltage unit is connected to a high voltage end of the transformer unit through a touchable connecting cable, and the lower voltage end of the transformer unit is connected to an input end of the low voltage unit. The special integrated-type substation for wind power generation is arranged in a wind power generation host tower cylinder. The substation not only overcomes the disadvantage that the transformer unit, the high voltage unit and the low voltage unit in the prior substation for wind power generation are arranged independently and separately, but also completely gives play to the superiority of solid insulated electrical equipment, is long in life span and little in overload time, can automatically adopt speed limit measures or stop operating when a blower is overloaded, and can not be overloaded on the whole. The design that the substation is unattended reduces maintenance cost.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

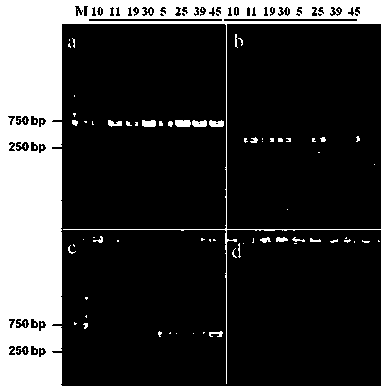

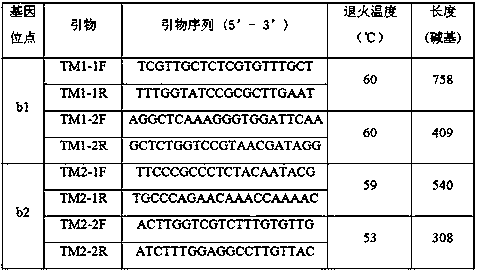

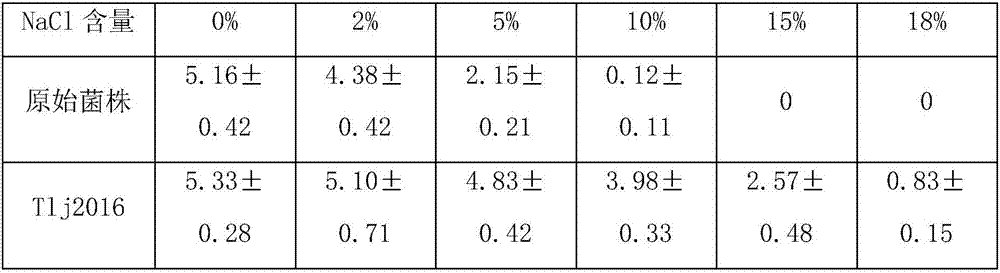

Method for identifying homokaryotic strains in T. trogii S0301

ActiveCN108486269AStrong advancedThe method is simpleMicrobiological testing/measurementMicroorganism based processesMating typeSpecific primers

The invention discloses a method for identifying homokaryotic strains in T. trogii S0301. According to the method, regenerated single bacteria prepared by using mating type gene primer pair protoplastregeneration technology are subjected to PCR verification, and if one mating type gene is amplified, the bacteria are homokaryotic strains; mating type gene primers comprise the specific primer pairTM1-1F / TM1-1R and / or the specific primer pair TM1-2F / TM1-2R used for detecting the locus b1 of the mating type gene, and the specific primer pair TM2-1F / TM2-1R and / or the specific primer pair TM2-2F / TM2-2R used for detecting the locus b2 of the mating type gene. Compared with conventional methods for observing whether mycelia have the microscopic feature clamp connection or not in virtue of an oilimmersion objective, the method provided by the invention has the beneficial effects that the identification of homokaryons by the method is completely consistent with clamp connection observation results; and detection results are specific, stable and reliable, and homokaryotic strains of different types can be accurately and quickly distinguished.

Owner:KUNMING UNIV OF SCI & TECH

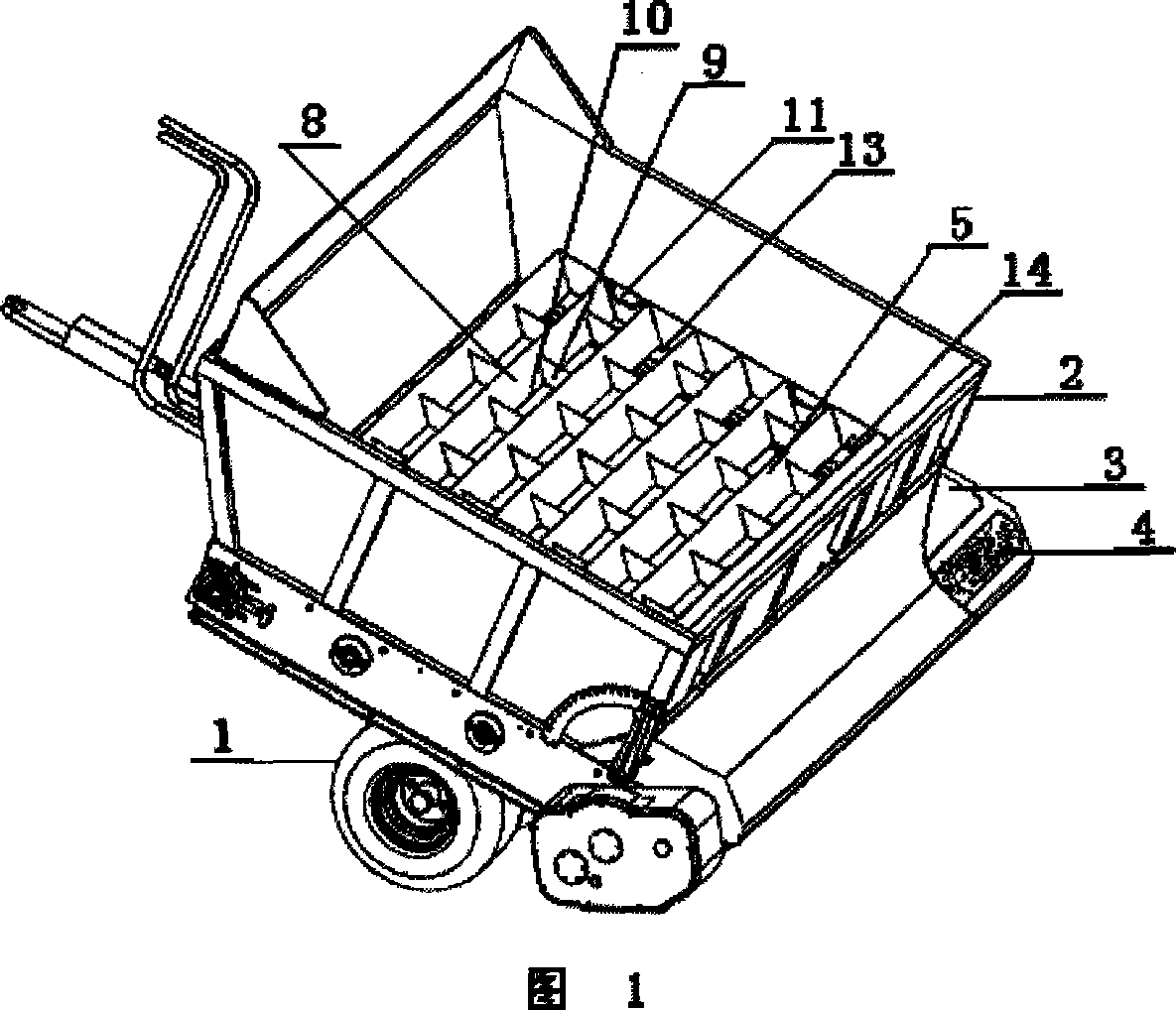

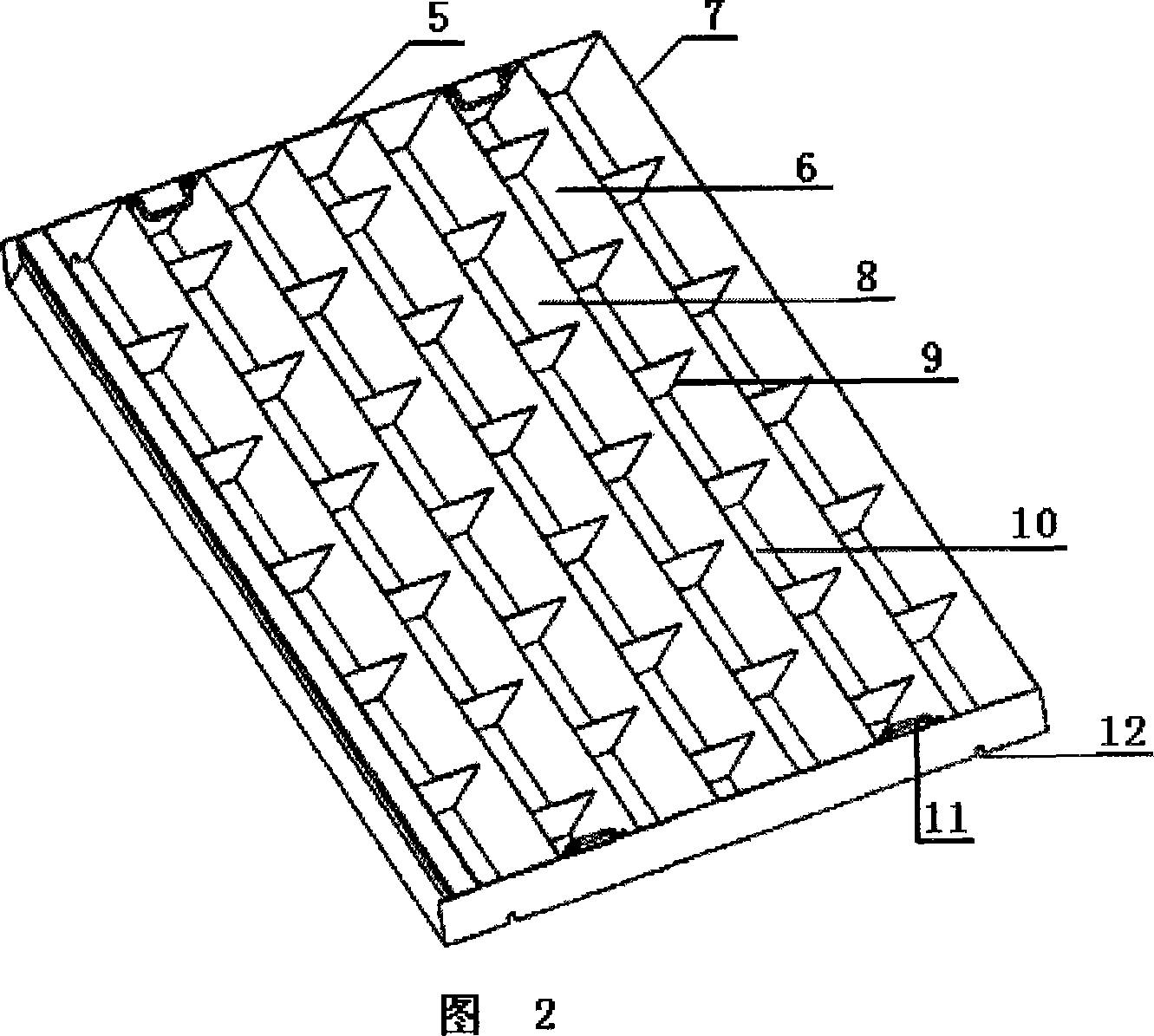

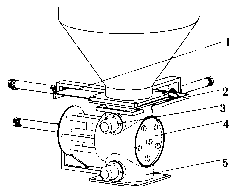

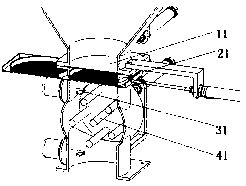

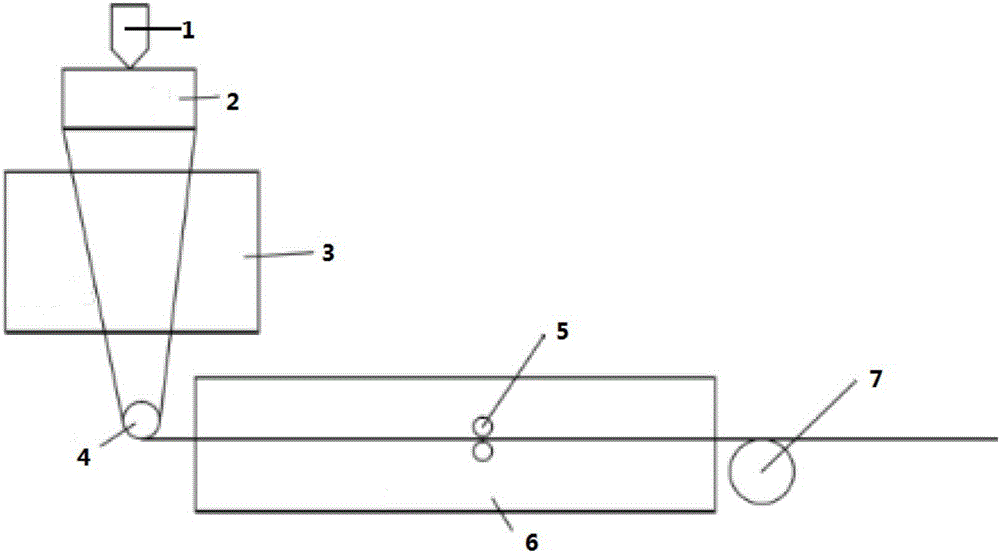

Sand layer with sand reducing and sand guiding function

InactiveCN101063295AExtended service lifeImprove work efficiencyRoads maintainenceEngineeringFeeding Ability

The invention relates to a sand spreader with pressure reduction sand guiding function, composed of a frame, a sand box with a sand outlet, a transmission band driven by power and a rolling brush, wherein the sand box is on the frame, the band is through arranged on the bottom of the box, the brush is arranged under the sand outlet, the chamber of the box near the bottom and above the band is arranged horizontally with a pressure-reducing sand guiding grid plate with an inclined side surface, a middle main board formed by connected a plurality of small grids made from strength bars between the inclined surface, and a frame with a lifter and a limit buckle, since the inclined face can bear part load of sliding sand, while the sand direction is in an angle with the band, the sliding sand can generate a co-direction pushing force on the band to improve the feeding ability of the transmission band, reduce real bearing pressure, improve load of the box, improve spreading efficiency and improve the service life of the band.

Owner:李明

Device for removing impurities in PVC-U pipe powder

PendingCN108688123AQuick clearStrong advancedMagnetic separationTubular articlesPlastic pipeworkEngineering

The invention relates to a device for removing impurities in PVC-U pipe powder. The device comprises a mechanism body. Magnetic metallic impurity removal mechanisms, a level gauge, an anti-magnetic metallic / non-metallic impurity removal mechanism and a powder isolation mechanism are sequentially arranged on the mechanism body. The number of the magnetic metallic impurity removal mechanisms is twoor more. The powder isolation mechanism comprises an isolation plate. A discharging hole is formed in the isolation plate, and the size of the discharging hole is smaller than that of a storage hopperhole of an extruding machine. The anti-magnetic metallic / non-metallic impurity removal mechanism comprises a plate pushing cylinder and an impurity removal plate. Two sets of screens are arranged onthe impurity removal plate and are perpendicular to and concentric with the storage hopper hole of the extruding machine. According to the device for removing impurities in PVC-U pipe powder, magneticmetallic impurities, anti-magnetic metallic impurities and non-metallic impurities in pipe powder can be rapidly removed without halts and interruption of material supply; and the device has high performance in the field of plastic pipe manufacturing.

Owner:HESHAN LESSO IND DEV

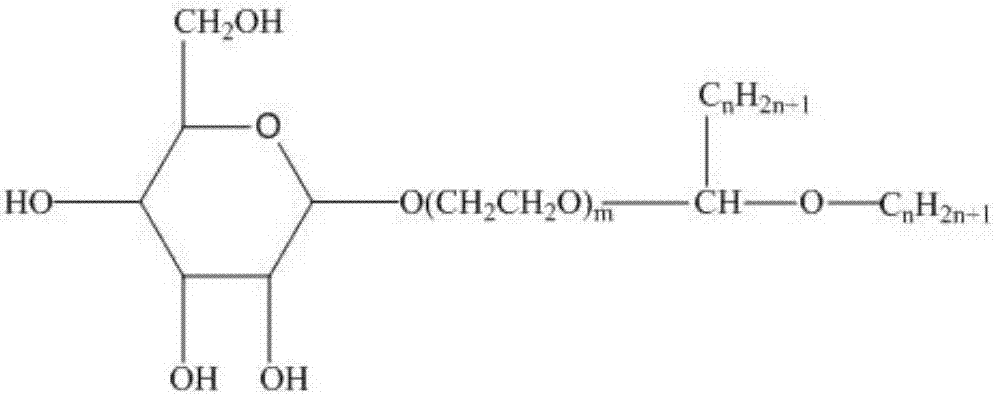

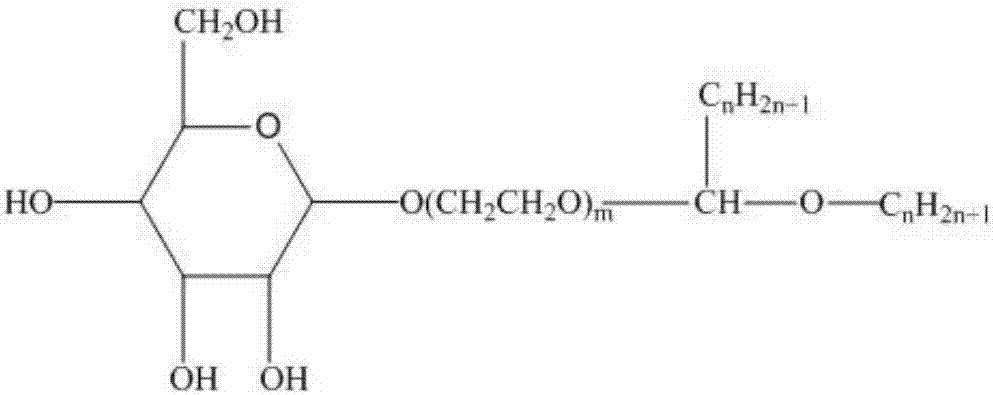

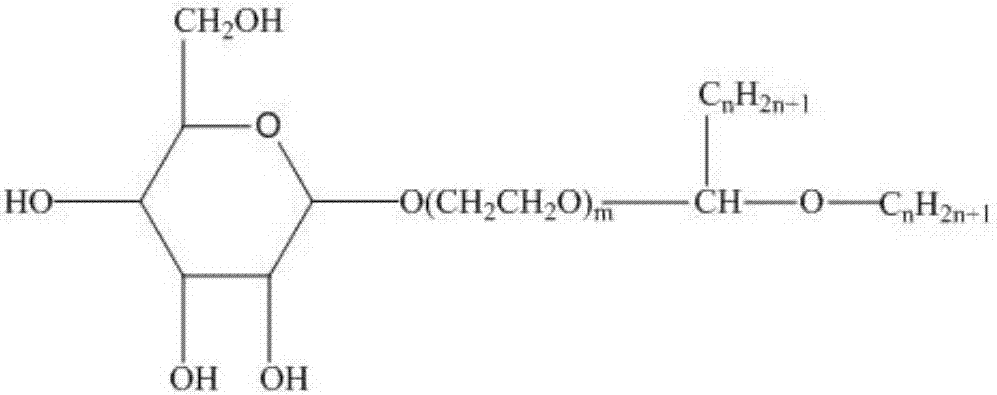

Neutral composite chemical for improving production of crude oil by increasing permeability of rock stratum in oil deposit

InactiveCN106957640AIncrease penetrationStrong advancedCleaning apparatusDrilling compositionEnzymeCarboxylate

The invention relates to a neutral composite chemical for improving the production of crude oil by increasing the permeability of a rock stratum in an oil deposit, and belongs to the technical field of offshore oilfield exploitation. The neutral composite chemical for improving the production of the crude oil by increasing the permeability of the rock stratum in the oil deposit is characterized in that: the neutral composite chemical for improving the production of the crude oil by increasing the permeability of the rock stratum in the oil deposit comprises 80%-90% of polyethylene glycol glucoside fatty ether, 5%-10% of a biological enzyme and 5%-10% of lignin carboxylate according to mass percent; the neutral composite chemical for improving the production of the crude oil has the characteristic that the neutral composite chemical is not acid or alkaline, a completely neutral plugging remover completely avoids the damages, caused by acids and alkalis, on the stratum and a gathering and transportation system, and the neutral composite chemical has the advantages that the safety and the convenience in operation are greatly improved, etc.

Owner:E TECH ENERGY TECH DEV CORP

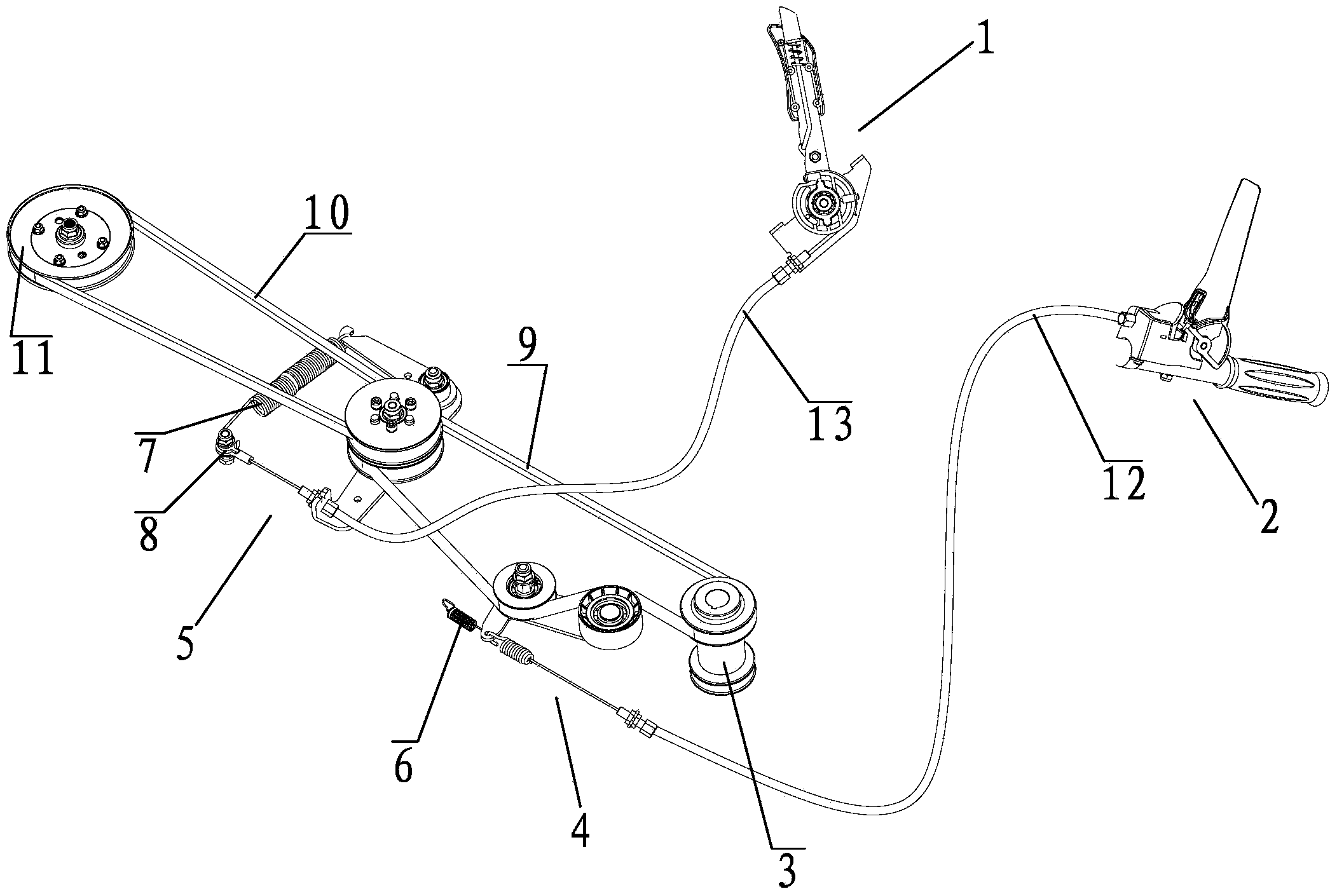

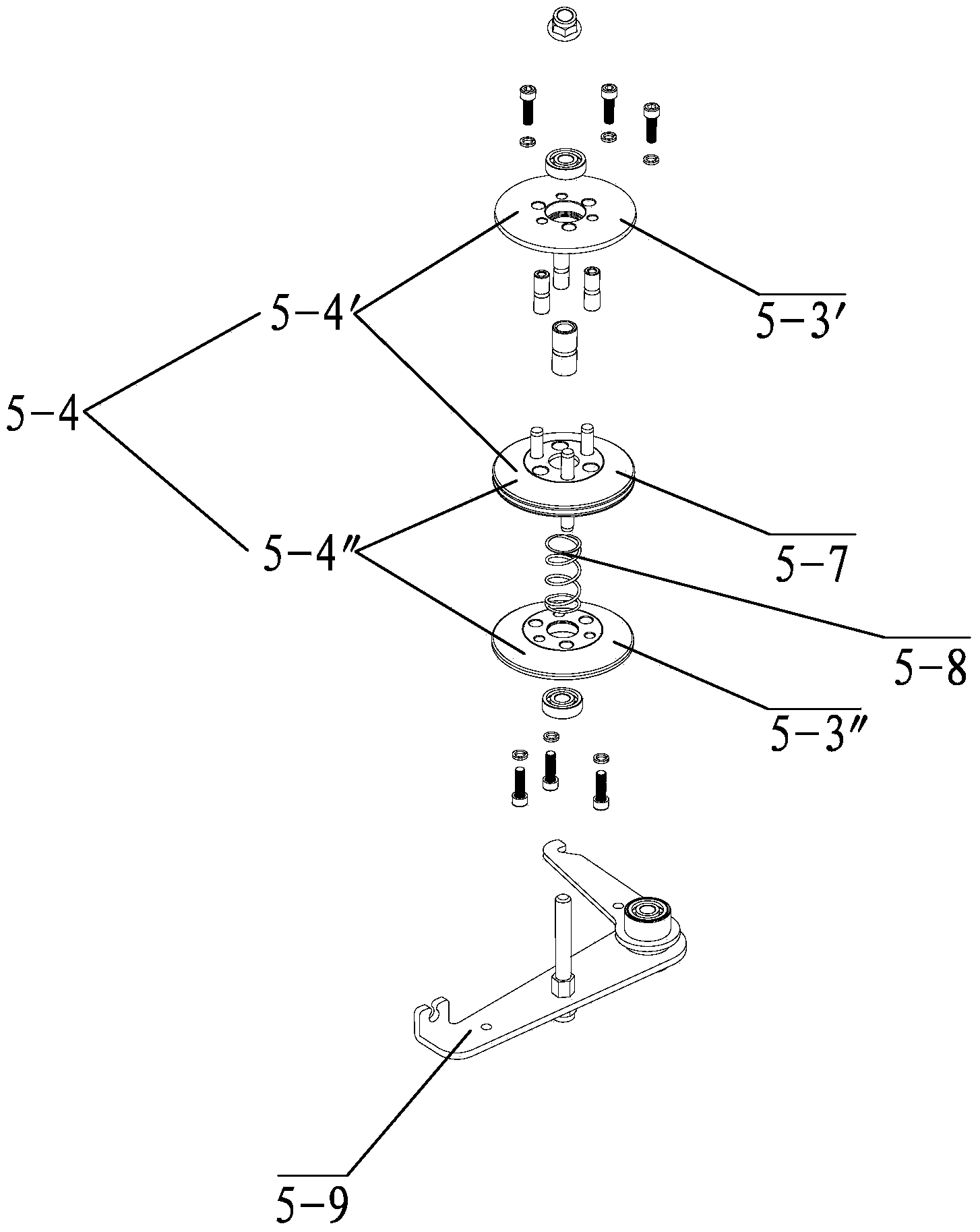

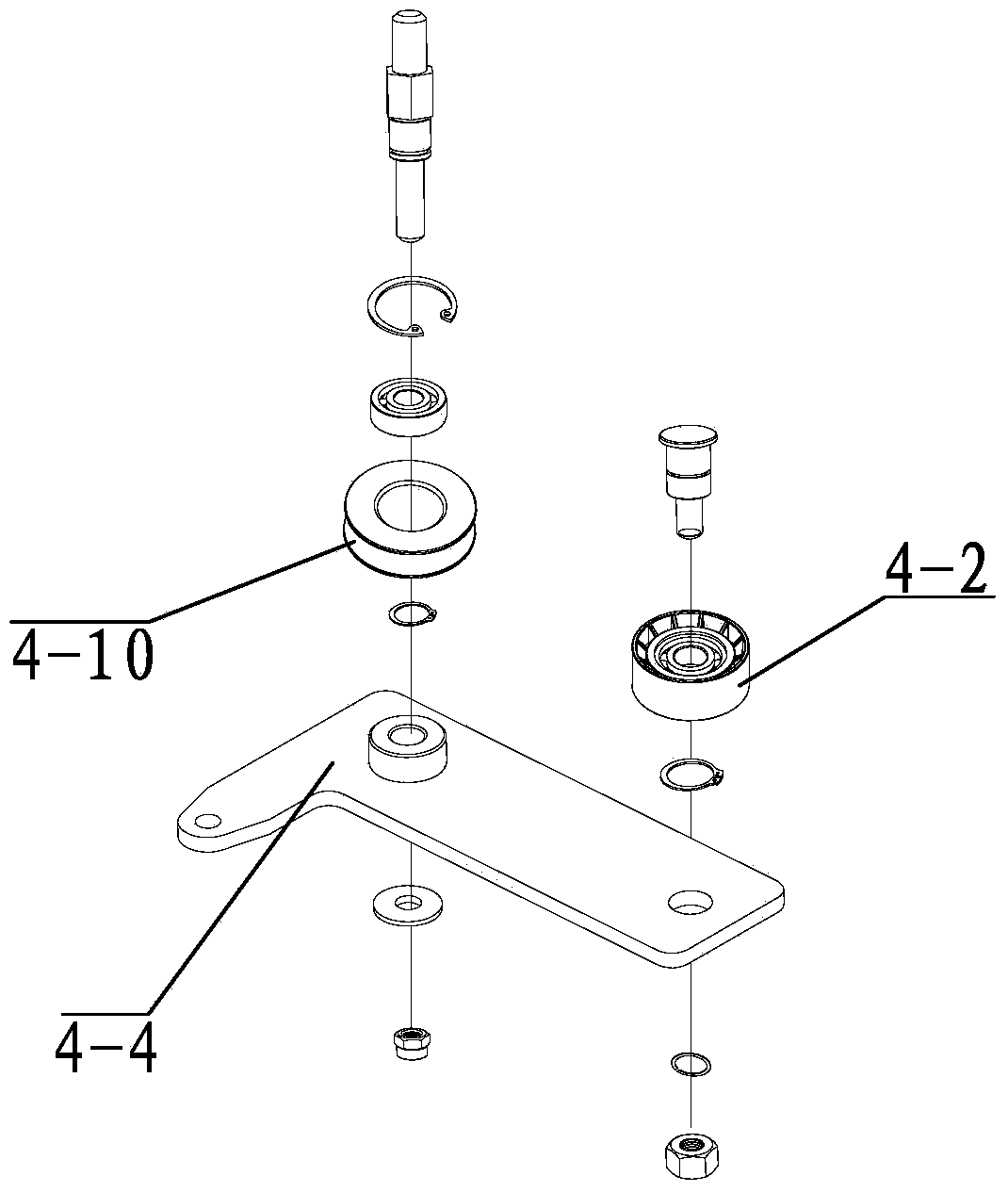

Roller brush speed control system for pavement sweeping machine

The invention belongs to the field of pavement sweeping mechanical equipment, and particularly relates to a roller brush speed control system for a pavement sweeping machine. The system comprises a driving wheel, a belt clutch control assembly, a variable speed belt pulley control assembly, a roller brush belt pulley, a roller brush speed control assembly and a roller brush starting assembly, wherein the variable speed belt pulley control assembly comprises a belt pulley set which is composed of an upper belt pulley and a lower belt pulley which rotate around the same central axis, the driving wheel is connected with the lower belt pulley through a primary transmission belt, the roller brush belt pulley is connected with the upper belt pulley through a secondary transmission belt, the roller brush starting assembly is connected with and controls the belt clutch control assembly through a first inhaul cable, and the roller brush speed control assembly is connected with and controls the variable speed belt pulley control assembly through a second inhaul cable. According to the system, the rotating speed of a roller brush can be controlled, the sweeping machine is made to be adapted to different sweeping targets, the application range is wider, and practicality and advancement are higher.

Owner:宁波新合博园林机械有限公司

Method for producing plastic tray by utilizing hollow blow molding machine

The invention discloses a method for producing a plastic tray by utilizing a hollow blow molding machine. The method comprises the steps of sealing an original air outlet of a blowing hole in the bottom of a traditional front die of the plastic tray, and arranging five blowing needles on the forming surface of the front die by utilizing a ventilation channel of the original bottom blowing hole; clamping the bottom of a tubular hollow blank when the blank is discharged, beginning to assemble, preblowing air to the hollow position of the tubular hollow blank through a blowing port in an extruding machine at the same time, stopping preblowing air when the tubular hollow blank is expanded to the set size, and continuing assembling; at the time, the five blowing needles are slowly close to the hollow blank, firstly, the hollow blank is punctured by the longest central blowing needle so as to blow air, and secondly, the hollow blank is punctured by the corner blowing needles with the same length at four corners so as to blow air, so that simultaneous blowing from five side surfaces is realized, and the tray blank is uniformly and closely adhered to the surface of a die cavity instantly. Finally, the method for producing the plastic tray, which has the advantages of uniformity in wall thickness, high intensity, low raw material consumption, low cost, stable quality and high efficiency, is provided.

Owner:吴忠市恒通塑料制品有限公司

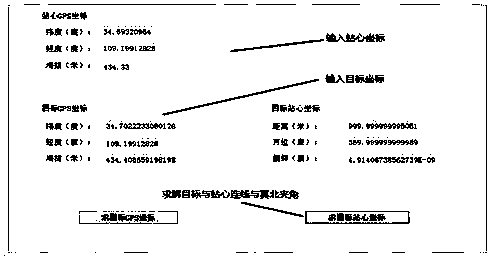

GPS positioning system, GPS positioning method and GPS positioning terminal

InactiveCN109613581AFit closelyShorten the timeSatellite radio beaconingLocation information based serviceGps positioning systemRadar detection

The invention relates to the technical field of a method for correcting a radar measurement error, and specifically discloses a GPS positioning system, a GPS positioning method and a GPS positioning terminal. A cooperative target performs pure radial movement to observe a declination of a plot detected by a radar and a GPS plot, wherein the declination is used for correcting an angle error. The delay of GPS plot transmission only has an error in the radial distance, and in this way, the error between 0 degrees of the radar and a true north angle can be accurately corrected. The cooperation target performs pure tangential movement to form two arcs taking a station center as an arc center at the interface of a radar monitoring and operation terminal. The distance difference between the two arcs is a radar distance error, which needs to be corrected. The delay of the GPS plot transmission only has front and back errors in the angle, and does not affect the correction of the radar distanceaccuracy. The invention has the advantage that the geodetic coordinate system and the radar coordinate system can be normalized through the personnel or other mobile carrier carrying the intelligentterminal pre-mounted with a transit APP, and the high-precision positioning and display of the target plot on the actual map is realized, so that the monitoring information output by the radar terminal is refined.

Owner:张科航

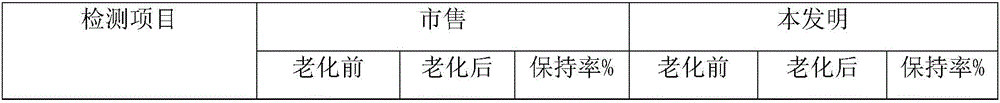

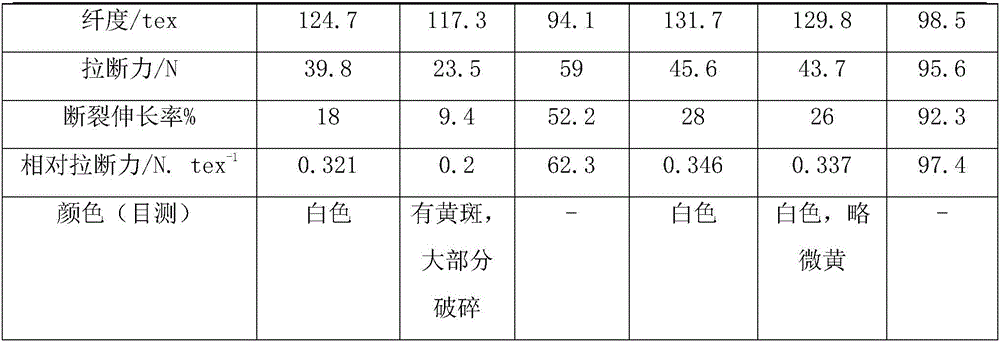

Solidification forming method of polyacrylonitrile-based carbon fiber precursors with high orientation degree and high fine denier

ActiveCN105970305APrevent double diffusionLow draftWet spinning methodsSpinning solutions preparationCarbon fibersMaterials science

The invention relates to the technical field of preparation of polyacrylonitrile-based carbon fiber precursors, in particular to a solidification forming method of polyacrylonitrile-based carbon fiber precursors with high orientation degree and high fine denier. The method specifically comprises four steps including pretreatment of a spinning solution, primary solidification, secondary solidification and solidification after secondary solidification. The homogeneity of the polyacrylonitrile-based carbon fiber precursors obtained with the provided solidification forming method is good, the orientation degree and the draft multiple are high, and the fine denier degree of the precursors is high.

Owner:ZHONGFU SHENYING CARBON FIBER

Normal-pressure horizontal fixed fire grate gasification layer firing boiler

InactiveCN101737767AEnergy savingCreate pollutionHollow bar grateSolid fuel combustionCombustion chamberBoiler furnace

The invention discloses a normal-pressure horizontal fixed fire grate gasification layer firing boiler, wherein the upper part of the boiler is provided with a flat top plate, corners are in circular R structures, the surface of the boiler is military green, the front surface, the back surface and both sides of a boiler body of the boiler are vertical surfaces, and the boiler body is in a horizontal square structure; the bottom of the boiler is provided with two bases, two fixed fire grates formed by respectively connecting two ends of a plurality of water tubes in parallel are arranged above the bases, the upper parts of the two fire grates are respectively provided with two combustion chambers, the upper parts of the two combustion chambers are respectively provided with larynx openings and are commonly provided with one boiler furnace, the middle of the boiler furnace is provided with a refraction arch, the upper part of the boiler furnace is provided with a front convection pipe bundle, the back side of the boiler furnace is provided with one smoke inlet entering the boiler back body, and the upper part of the middle part of the boiler back body is vertically provided with a vertical table flap downwards. The invention is a boiler with double combustion chambers, has the characteristics of high efficiency, energy saving, environment protection, security, reliability, scientific design, small size and low operation cost and is applied to offices, schools, hotels and bath centers.

Owner:吕世发

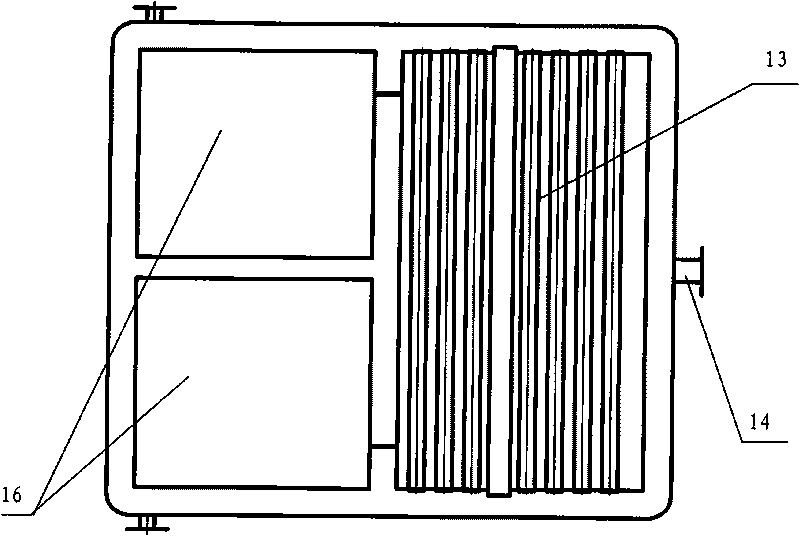

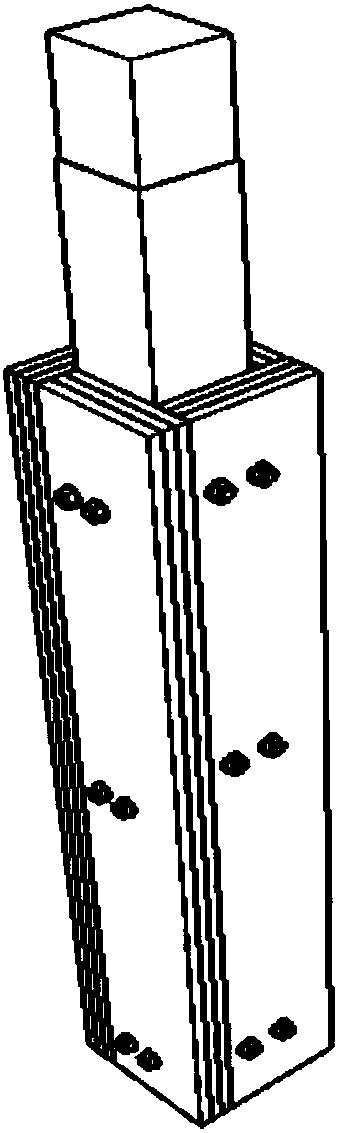

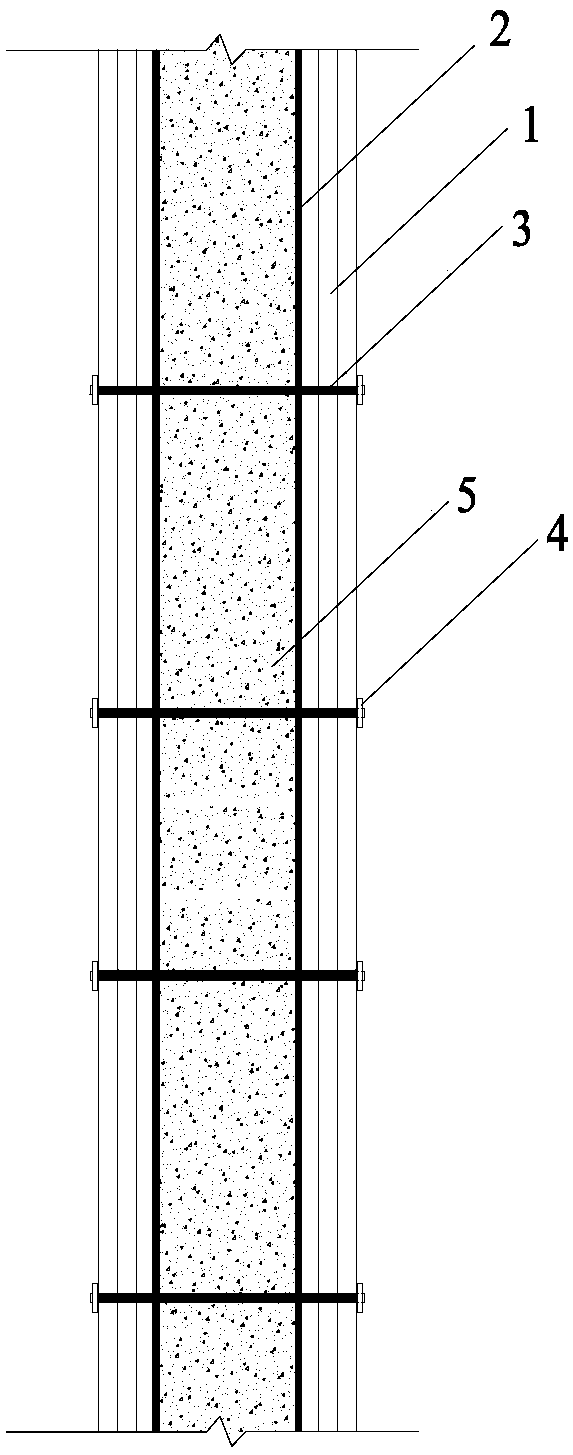

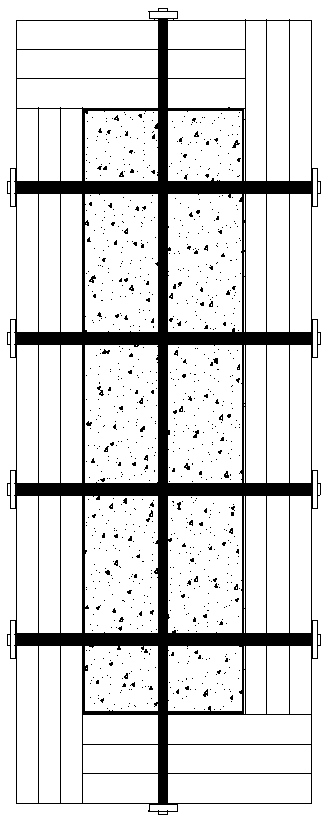

Semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column and manufacturing method thereof

PendingCN108505685AInhibit or delay glue openingReduce dependenceStrutsPillarsEngineeringEngineering structures

The invention relates to a semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column, further relates to a manufacturing method of the semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column and belongs to the technical field of engineering structure bearing columns. The semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column comprises a bamboo plywood layer, a steel pipe, a dust collection mountain flour concrete column, steel pull rods and nuts. The dust collection mountain flour concrete column is located in the steel pipe, the bamboo plywood layer is bonded on the outer wall of the steel pipe, and dust collection mountain flour concrete is prepared from cement adulterated with dust collection mountain flour. The steel pull rods are arranged perpendicular to the axial direction of the steel pipe in a crossed mode, the two ends of the steel pulling rods are providedwith the nuts, and the nuts are connected with the steel pulling rods through threads. According to the combined column, a steel pipe-dust collection mountain flour concrete reinforcement strategy isadopted, the slender proportion of the combined column can be reduced, anti-compression instable failure of the large-slender proportion combined column is regulated, the anti-compression strength isimproved to reduce anti-compression deformation and creeping, the anti-compression bearing capacity of the combined column is improved, and traditional decoration technological treatment such as embedding, wrapping, riveting, grinding and coating can be adopted on the surface.

Owner:GUANGDONG CONSTR VOCATIONAL TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com