Universal controller for whole solid-state high-power laser

A high-power laser and all-solid-state technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of external equipment linkage, laser damage, lack of protection, etc., to achieve stable performance, low operating costs, rich creative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

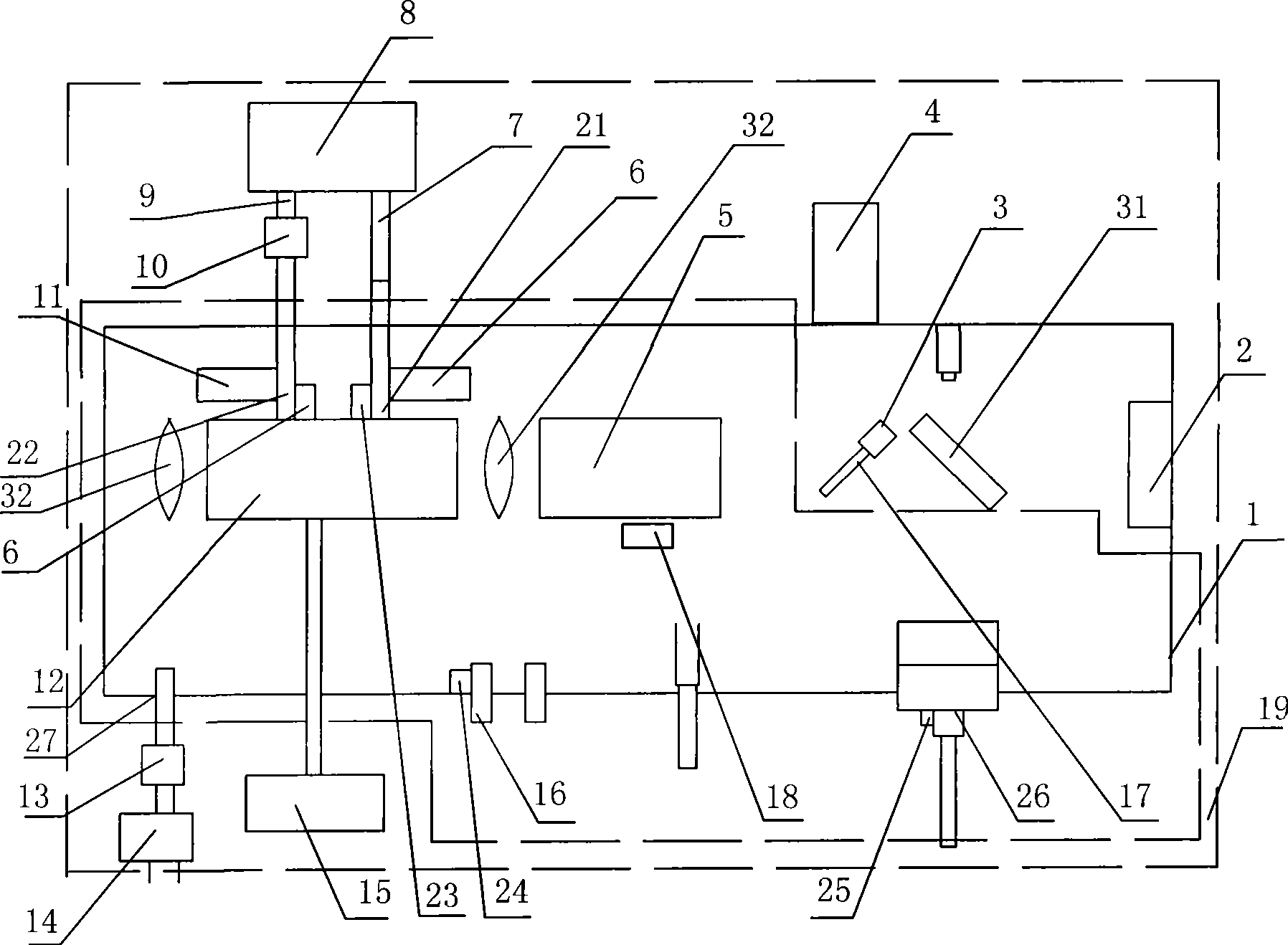

[0046] The general controller of all solid-state high-power lasers is composed of hardware and software. The hardware includes signal detection and execution unit, operation unit and main control unit;

[0047] The signal detection and execution unit includes a laser head power control and detection mechanism, a cooling water control and detection mechanism, a shielding gas control and detection mechanism, an optical cavity water leakage detection mechanism, an optical gate switch control mechanism, and a power detection mechanism;

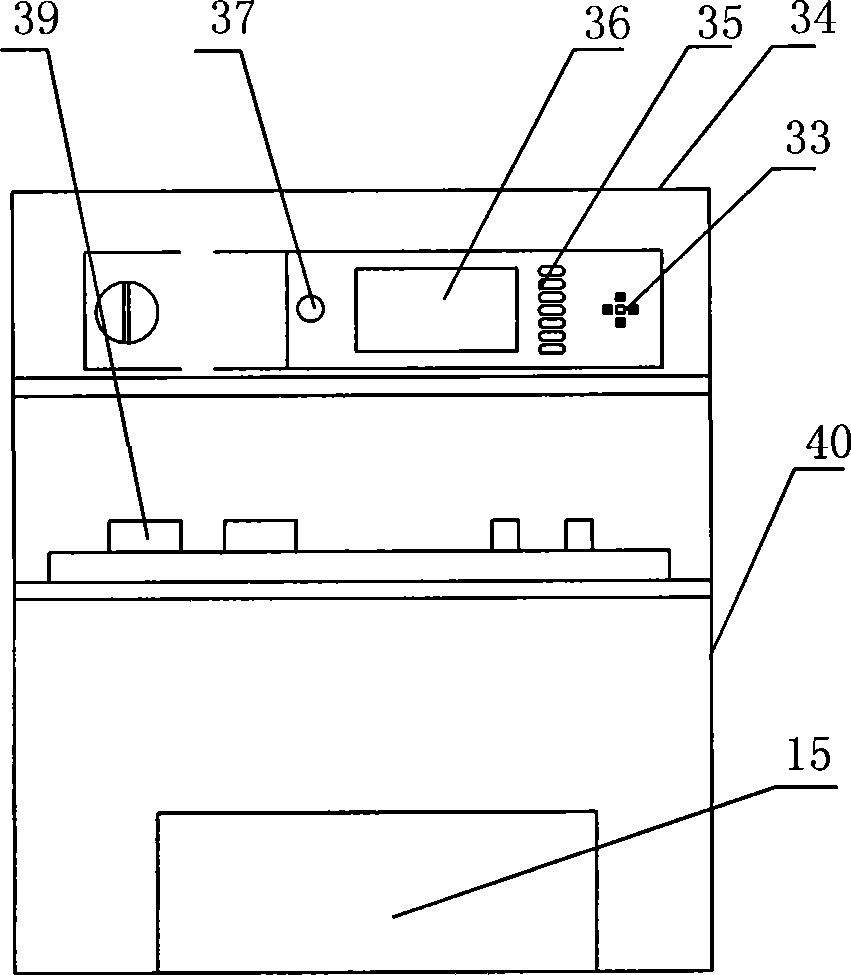

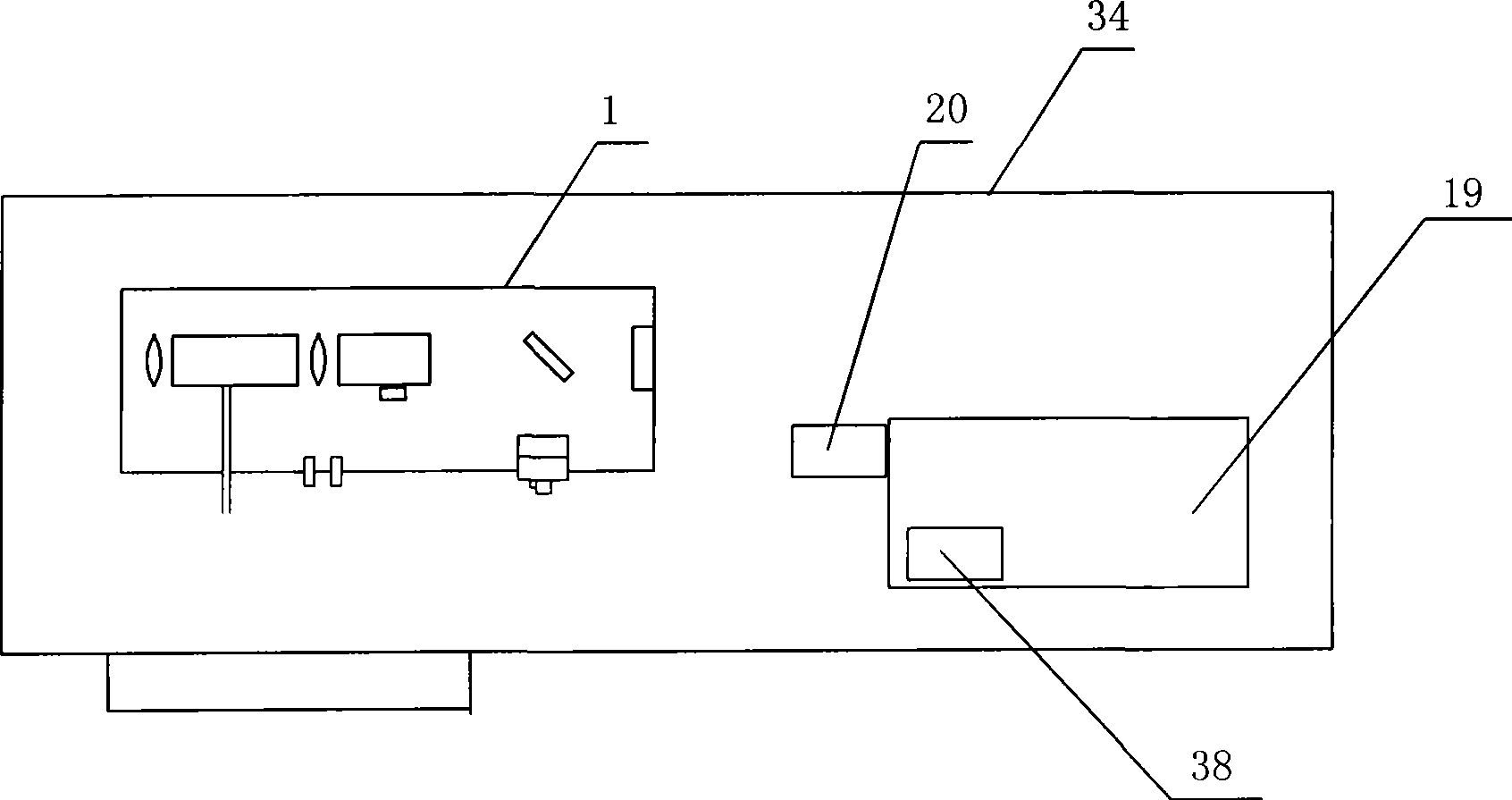

[0048] Laser head power supply control and detection mechanism includes laser head power supply 15, main controller 19 and serial port 20; The power input end of the laser head power supply 15 is connected correspondingly, and the control end, current and voltage detection end of the laser head power supply 15 are respectively connected with the corresponding end of the serial port 20 by wires, and the serial port 20 is connected with the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com