Solidification forming method of polyacrylonitrile-based carbon fiber precursors with high orientation degree and high fine denier

A polyacrylonitrile-based carbon fiber, coagulation molding technology, applied in the wet spinning method, spinning solution preparation, etc., can solve the problems of positive draft ratio restriction, spinneret stability, etc., to achieve fine grain structure, reduce Parallel phenomenon, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

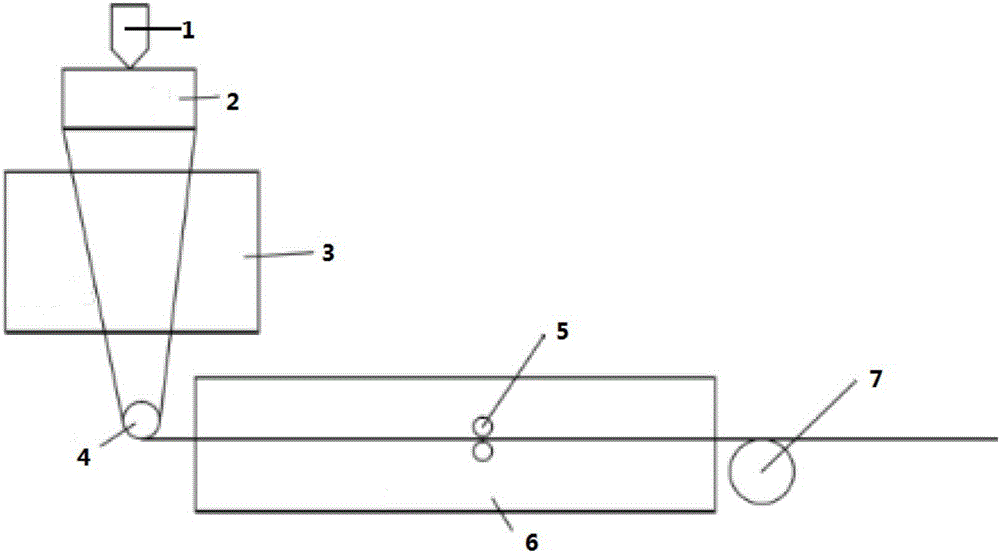

[0029] Control the temperature of the nozzle at 25°C, make the stock solution with a viscosity of 150pa.s, a solid content of 15%, and a pH value of 9.5. The solvent of the stock solution is dimethyl sulfoxide, and enter 5cm of air at a spinning speed of 30m / min. Layer, the tow enters the primary coagulation bath of 30% ethylene glycol aqueous solution, the temperature of the primary coagulation bath is set at -25°C, the bath liquid is 30% ethylene glycol aqueous solution, and the residence time is 4s, the surface will quickly exceed Deep quenching produces a dense dura mater, and the drafting ratio is 0.995-1.02 times;

[0030] Finally, under the flat turbine and the positioner, the positioner controls the width of the silk path to be 7cm and enters the secondary coagulation bath. The residence time is 5-10s, and the drafting ratio is 1.5-2.0 times;

[0031] The temperature of the third-stage coagulation bath is 5-2°C, the concentration of the coagulation bath is 10-40%, the...

Embodiment 2

[0033] Control the temperature of the nozzle at 20°C, make the stock solution with a viscosity of 160pa.s, a solid content of 24.5%, and a pH value of 9.0. The solvent of the stock solution is dimethylformamide, and enter 3cm of air at a spinning speed of 25m / min. layer, the tow enters the primary coagulation bath of 30% ethylene glycol aqueous solution, the temperature of the primary coagulation bath is set to 0°C, and the bath liquid is 30% ethylene glycol aqueous solution; the residence time is 8s, and the surface will rapidly exceed the depth Quenching produces a dense dura mater, and the drafting ratio is 0.995-1.02 times;

[0034] Finally, under the flat turbine and the positioner, the positioner controls the width of the silk path to be 4cm and enters the secondary coagulation bath. The residence time is 5-10s, and the draw ratio is 1.5-2.0 times; after the second grade, the positive draw ratio is 6.5 times; after washing, water drawing, oiling, drying, steam drawing, a...

Embodiment 3

[0036] Control the temperature of the nozzle at 30°C, make the stock solution with a viscosity of 200pa.s, a solid content of 22%, and a pH value of 9.5. The solvent of the stock solution is dimethyl sulfoxide, and enter an air layer of 8cm at a spinning speed of 40m / min. , the tow enters the primary coagulation bath of 30% ethylene glycol aqueous solution, the temperature of the primary coagulation bath is set to -30°C, and the bath liquid is 30% ethylene glycol aqueous solution; the residence time is 5s, and the surface will quickly exceed the depth Quenching produces a dense dura mater, and the drafting ratio is 0.995-1.02 times;

[0037] Finally, under the flat turbine and the positioner, the positioner controls the width of the silk path to be 9cm and enters the secondary coagulation bath. The residence time is 4-8s, the draft ratio is 2-2.5 times, and the positive draft ratio after the second grade is 7.2 times; after washing, water drawing, oiling, drying, steam drawing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com