A kind of rubber roller for Siro fancy yarn and its production method

A fancy yarn and siro technology, which is applied to the cots and production fields of siro fancy yarns, can solve the problems of difficulty in obtaining the expected drafting force, and the finished pattern is difficult to play an auxiliary role, and achieves the effect of increasing varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

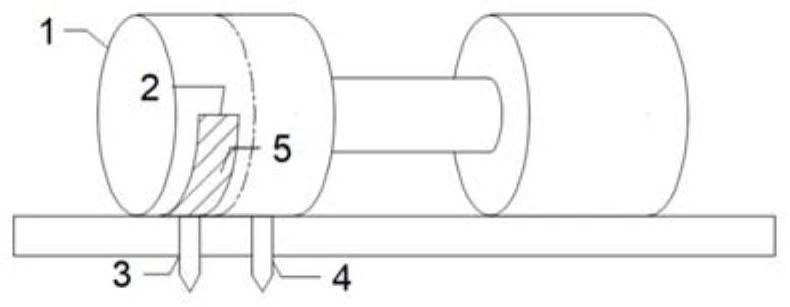

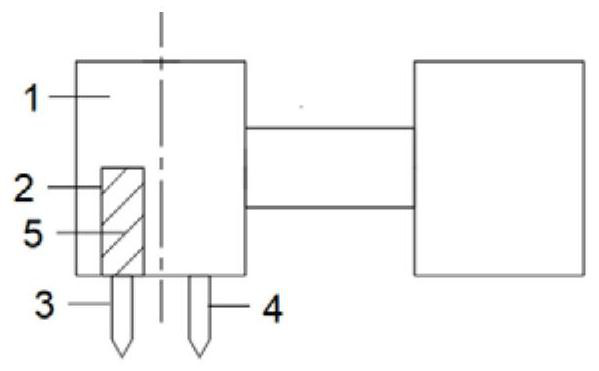

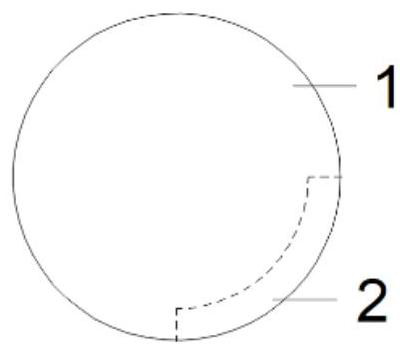

[0032] Such as Figure 1-3 As shown, a rubber roller for Siro fancy yarn includes a roller roller body 1, and the roller roller body 1 is set as three coaxially connected cylinders, which are respectively a cylinder with a larger diameter at both ends and a cylinder connecting the two ends. A cylinder is a cylindrical rod with a smaller diameter. A first groove 2 is provided on the outer surface of the cylinder at one end of the roller body 1, and the first groove 2 in this embodiment is a rectangular groove. With half the axis of the cylindrical end as the boundary, the first groove 2 is arranged on the side of the cylinder away from the cylindrical rod; let the half of the axis of the cylindrical end, that is, the circumference of the middle position of the cylindrical end, be the reference, the first groove 2 The distance between a groove 2 and the reference is 2-3 mm, and 2.5 mm is used in this embodiment. The groove width range of the first groove 2 is 5.5-6.5mm, and th...

Embodiment 2

[0037] The difference from Example 1 is that, as Figure 8 As shown, the arc at the groove bottom of the groove 2 is set coaxially with the outer circle of the roller body 1, and the drafting teeth 5 are set as several sawtooths 52 with the same shape and size. The projection on the top is pointed, and the serrations 52 are arranged in a circular array at the bottom of the groove 2 , and the tooth roots of the serrations 52 are in contact with the bottom of the groove.

Embodiment 3

[0039] The difference from Embodiment 1 or 2 or 3 is that the roller body 1 can be engraved with grooves 2 on each spindle roller body 1 according to the actual design and color requirements, and the number of grooves 2 in each row is 0- 4, the total number of grooves 2 is at least 1, the difference from embodiment 1 is that, as Figure 4-6 As shown, in the present embodiment, two grooves 2 are engraved on a roller body 1 of a spindle.

[0040] The two grooves 2 are on the outer circular surface of the same cylindrical end, and are located on both sides of the center line of the outer circular surface of the cylindrical end, and the distance between the two grooves 2 and the center line is 2-3mm. In this embodiment The selected node value of the distance is 2.5 mm, that is, the distance between two rows of grooves 2 is 4-6 mm, which is 5 mm in this embodiment. The groove 2 on the left side and the groove 2 on the right side are distributed in a staggered manner. The groove wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com