Device for removing impurities in PVC-U pipe powder

A PVC-U and impurity technology, applied in the field of PVC-U pipe powder impurity removal device, can solve the problems of stopping the replacement of the magnetic base, troublesome operation, difficult selection and removal of anti-magnetic metals and non-metals, etc., and achieves fast Clear, strong advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

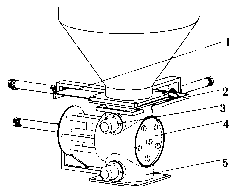

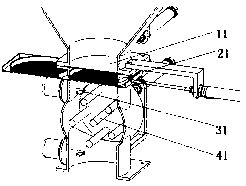

[0026] figure 1 A schematic structural view of a device for removing impurities from PVC-U pipe powder provided in this embodiment, figure 2 A cross-sectional view of the device. As shown in the figure, the device includes a mechanism body 5, on which two sets of magnetic metal impurity screening mechanisms 4, material level gauges 3, antimagnetic metal / non-metallic impurities screening mechanisms 2 and powder Material isolation mechanism 1.

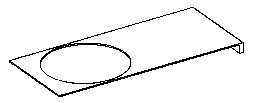

[0027] Wherein, the powder isolation mechanism 1 includes an isolation plate 11 (such as image 3 shown), the separating plate 11 is provided with a discharge hole, and the size of the discharge hole is smaller than the size of the extruder storage hopper hole. The powder isolation mechanism is installed under the storage hopper of the extruder. Under normal conditions, the hole of the isolation plate is vertical and concentric with the hole of the storage hopper of the extruder. At this time, the powder can fall into the extruder sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com