Method for producing plastic tray by utilizing hollow blow molding machine

A plastic tray and blow molding machine technology, which is applied in the field of plastic product processing and molding, can solve the problems of uneven wall thickness, density that cannot meet the requirements, and easy welding of the tray.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

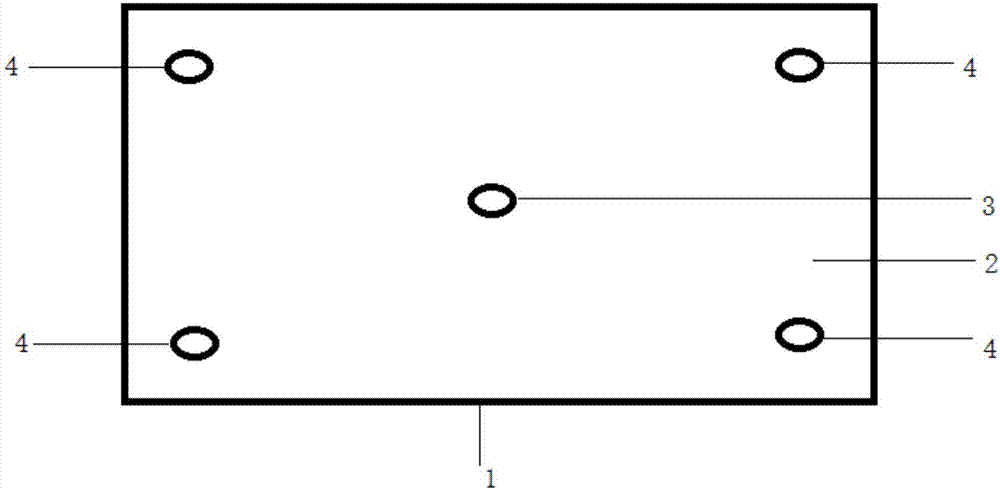

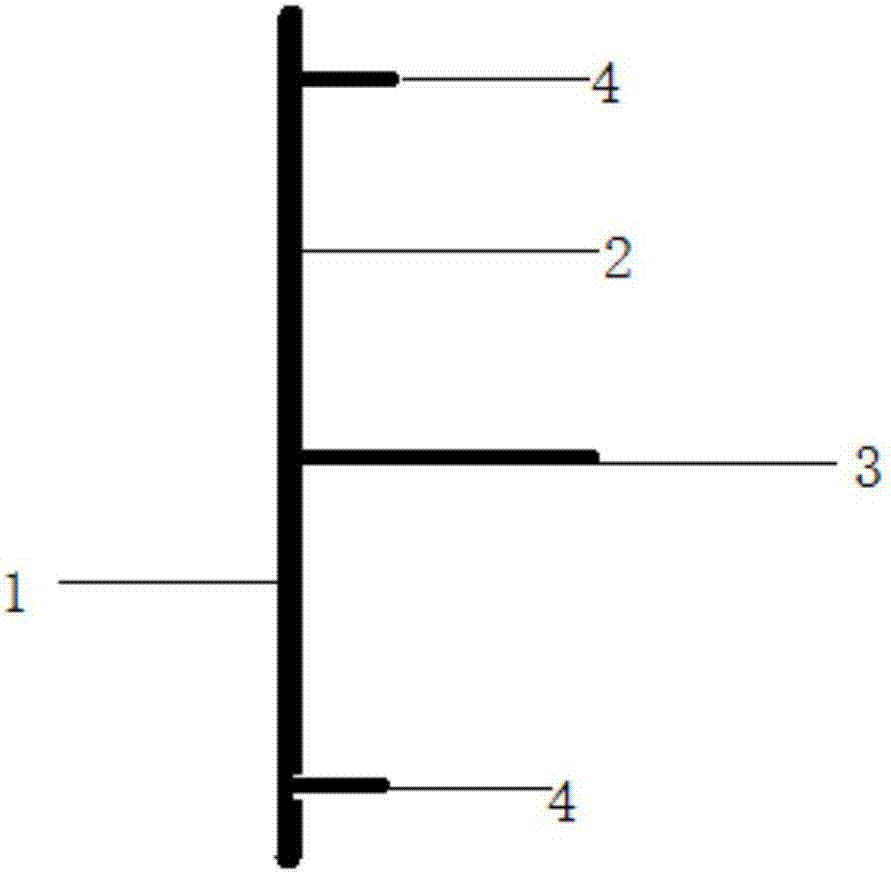

Method used

Image

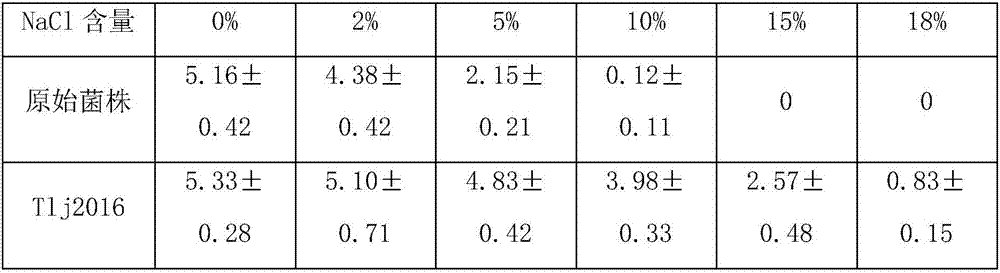

Examples

Embodiment 1

[0043] Embodiment 1 raw material preparation

[0044] 1. Preparation of modified nano-carbon:

[0045] The preparation method of the modified nano-carbon comprises the following steps: uniformly mixing the middle mold carbon fiber, single-walled carbon nanotube, ammonium persulfate and deionized water in a mass ratio of 1:1.1:90:1000, first at a power of 300W, Ultrasonic treatment with a frequency of 22KHz for 30min, and then high-voltage pulsed electric field treatment for 12min under the conditions of electric field intensity 10kV / cm, pulse time 300μs, and pulse frequency 200Hz; the treated mixture was reacted at a speed of 110r / min and a temperature of 60°C for 1.5h, and the reaction solution Filtrate with a PP microporous filter membrane with a pore size of 0.22 μm, wash repeatedly with deionized water until neutral, and finally vacuum-dry at 75° C. to constant weight and pulverize to obtain the modified nanocarbon.

[0046] 2. Preparation of biological antioxidant:

[004...

Embodiment 2

[0054] A method for producing plastic trays using a hollow blow molding machine, comprising the steps of:

[0055] 1) Material injection: Put the special material for the tray into the extruder for melting, wherein the screw temperature is 172°C, the screw speed is 65rpm, the temperature of the storage tank is 193°C, the die temperature is 198°C, and the tubular hollow parison is extruded;

[0056] 2) Mold clamping and inflation: Clamp the bottom of the tubular hollow parison, the front mold and the rear mold begin to close slowly, at the same time, the blowing port on the extruder pre-blows air to the hollow position of the tubular hollow parison, the air pressure is 0.55MPa, the tubular The hollow parison expands slowly, and stop the pre-blowing when the inflation ratio reaches 1.6:1. At this time, the pre-blowing time is 4s, the distance between the front and rear molds is 10cm, the mold temperature is controlled at 38°C, and the upper part of the hollow parison is clamped. ...

Embodiment 3

[0067] A method for producing plastic trays using a hollow blow molding machine, comprising the steps of:

[0068] 1) Material injection: Put the special material for the tray into the extruder for melting, wherein the screw temperature is 165°C, the screw speed is 60rpm, the temperature of the storage tank is 190°C, the die temperature is 195°C, and the tubular hollow parison is extruded;

[0069] 2) Mold clamping and inflation: Clamp the bottom of the tubular hollow parison, the front mold and the rear mold begin to close slowly, and at the same time, the blowing port on the extruder pre-blows air to the hollow position of the tubular hollow parison, the air pressure is 0.50MPa, and the tubular hollow parison The hollow parison slowly expands, and when the inflation ratio reaches 1.3:1, stop the pre-blowing. At this time, the pre-blowing time is 2s, the distance between the front and rear molds is 9cm, the mold temperature is controlled at 30°C, and the upper part of the holl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com