Steel rail surface flaw detection system and method based on machine vision and pulse eddy currents

A pulsed eddy current and defect detection technology, applied in general control systems, control/adjustment systems, optical testing flaws/defects, etc., can solve the problems of inapplicability, high flaw detection sensitivity, high false detection rate, and achieve strong technical innovation and The effect of advanced nature, high application value and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

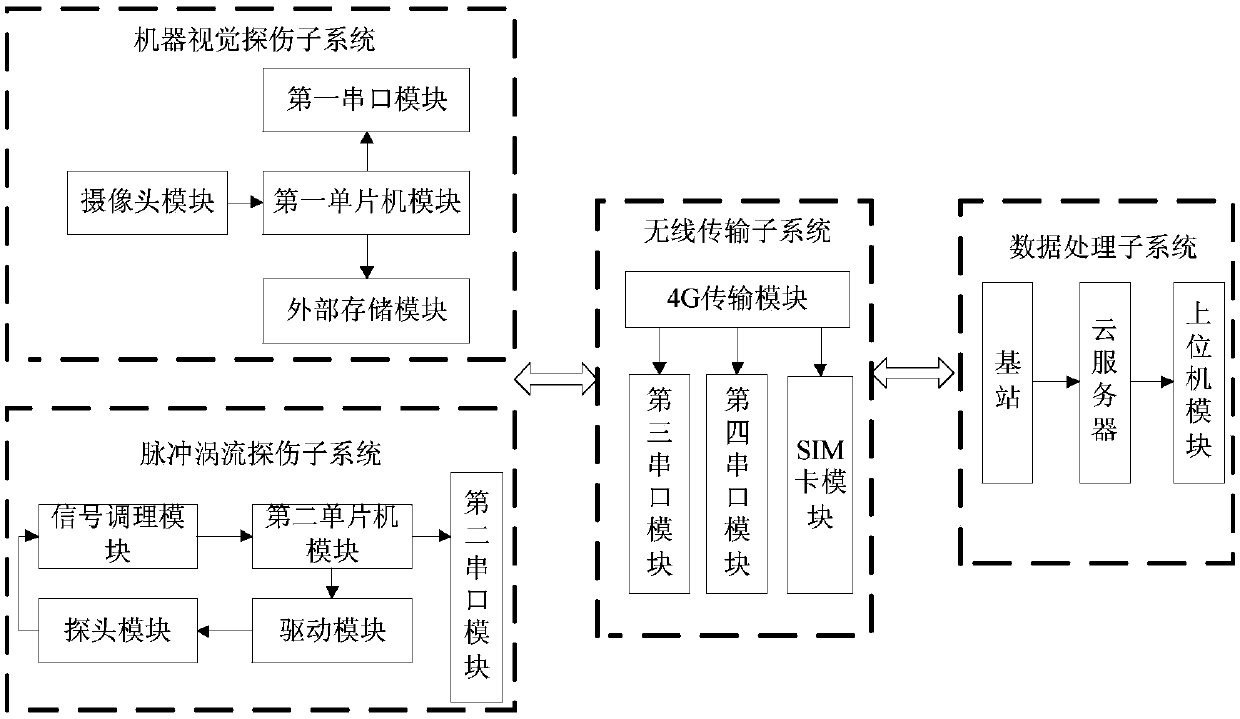

[0044] like figure 1 As shown, in order to solve the above-mentioned technical problems, the present invention provides a rail surface defect detection system based on machine vision and pulsed eddy current, the system includes a visual flaw detection subsystem, a pulsed eddy current flaw detection subsystem, a data transmission subsystem and a data processing Subsystem; where:

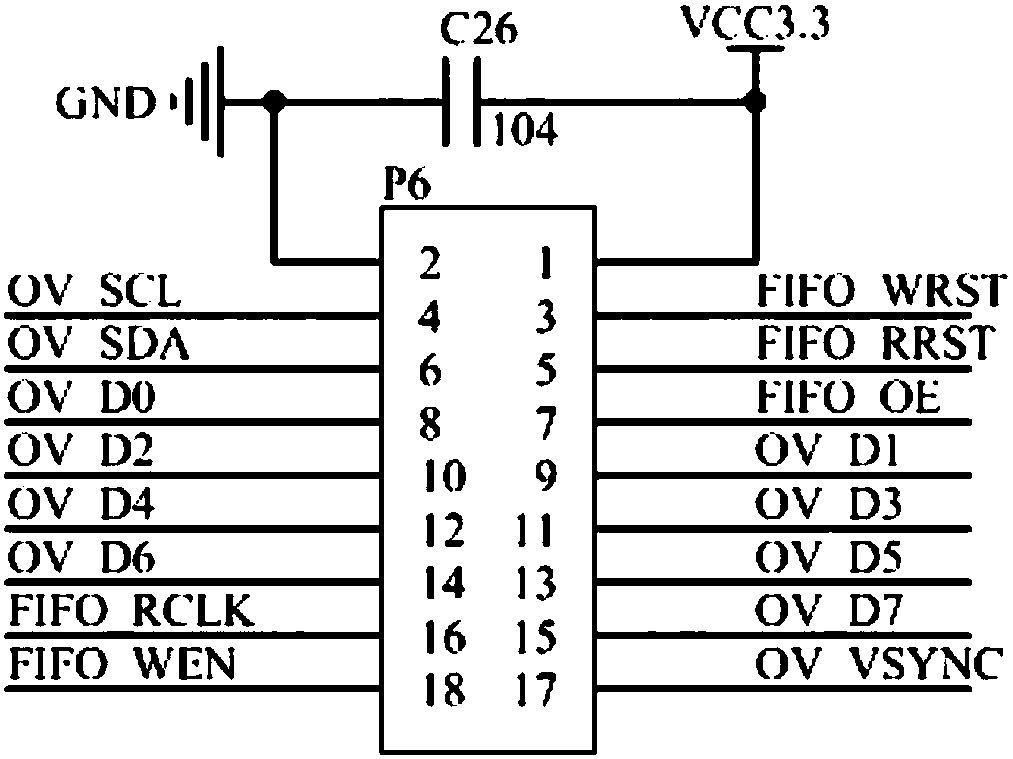

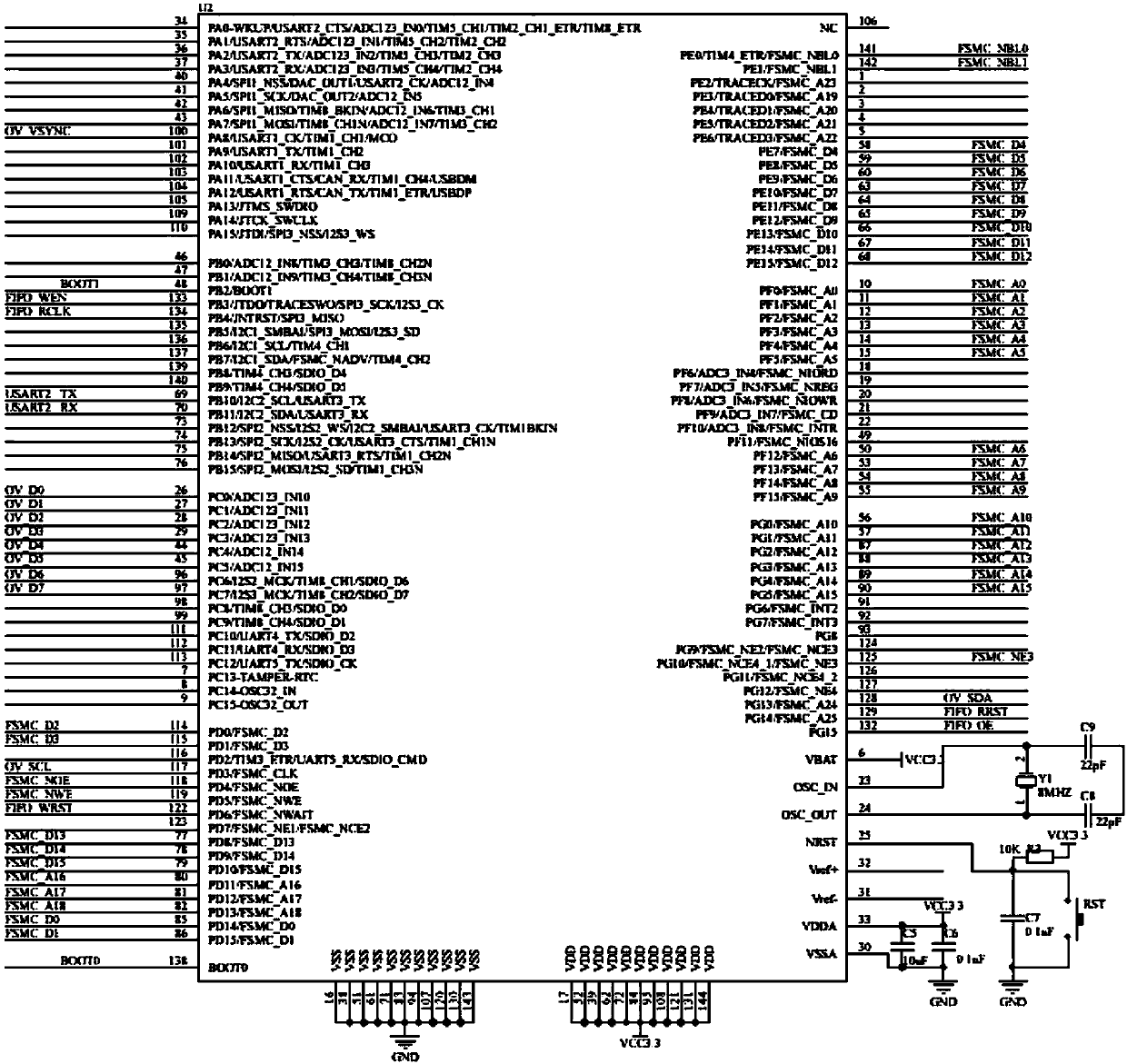

[0045] The visual flaw detection subsystem includes a first single-chip microcomputer module, a camera module and a first communication module. Under the control of the first single-chip microcomputer module, the camera module acquires images of the surface of the detected object, and the first single-chip microcomputer module The images acquired by the camera are processed to extract the morphological features of defects as the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com