Intelligent control PCB conveying device

A conveying device and intelligent control technology, applied in the direction of conveyor objects, transportation and packaging, electrical program control, etc., can solve the problems of poor flexibility, design of the direction of the conveyor belt, and the inability to add feeding ports to the conveyor belt, so as to extend the transmission function and enhance The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and example.

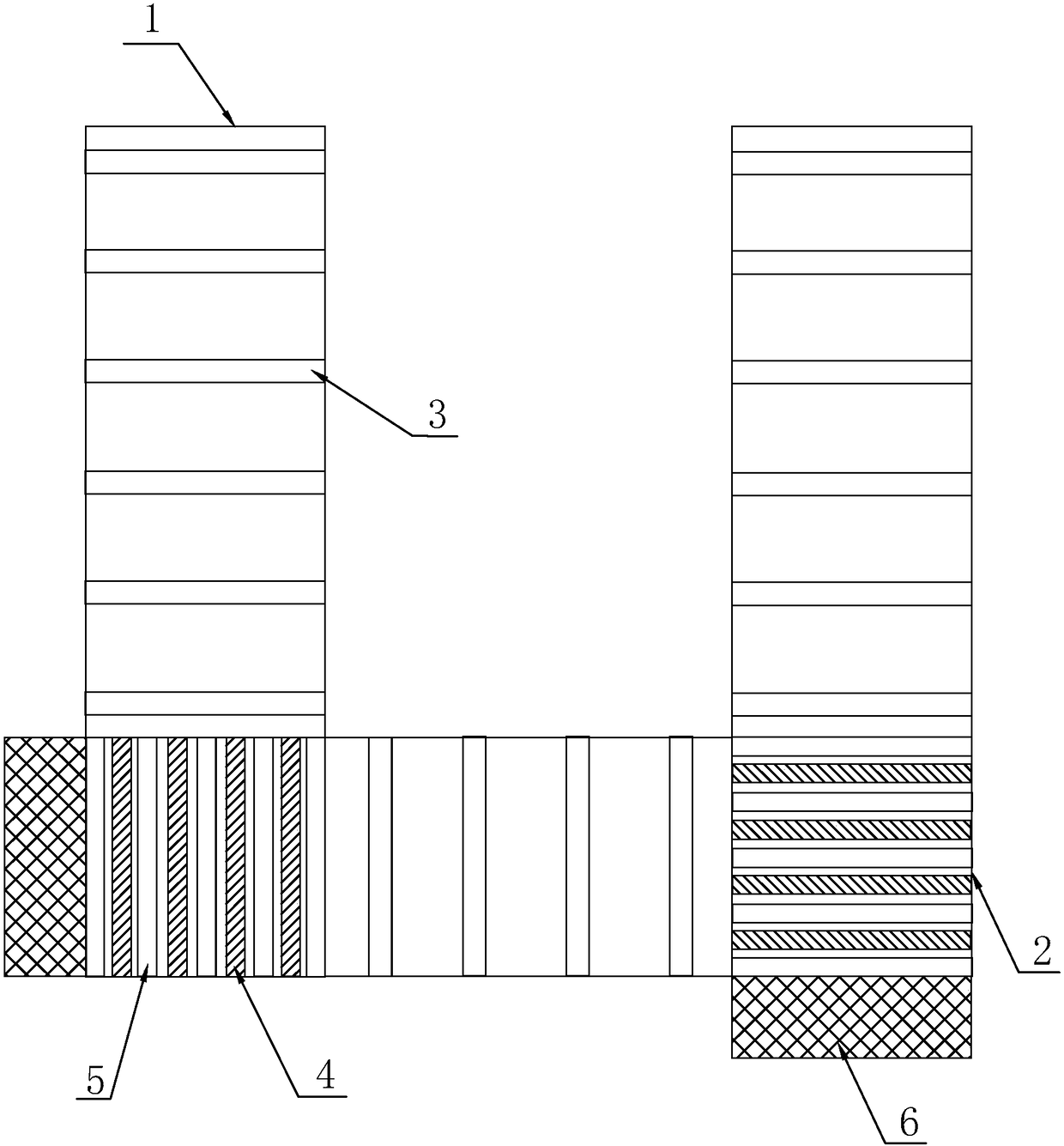

[0015] Such as figure 1 As shown, the present invention provides an intelligent control PCB conveying device, including a conveyor 1 and a relay 2, and the conveyors 1 are spliced together through the relay 2 to form a conveying channel for transmitting PCB boards, and the relay 2 relatively conveys The device 1 is detachable, movable and operates independently. The conveyor 1 is provided with a plurality of first transmission shafts 3 parallel to each other. The relay 2 is provided with a bracket 4 for receiving the PCB board transmitted from the first transmission shaft 3 to the relay 2. , the relay 2 is also provided with a second transmission shaft 5, the second transmission shaft 5 and the bracket 4 are arranged at intervals with each other, the input end of the second transmission shaft 5 is connected to the feeding frame 6, and the output end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com