Neutral composite chemical for improving production of crude oil by increasing permeability of rock stratum in oil deposit

A compound agent and permeability technology, which is applied in the direction of drilling composition, cleaning equipment, wellbore/well components, etc., can solve problems such as oil and gas layer damage, wellbore string corrosion, plugging, etc., and achieve increased permeability and safety Enhanced performance and convenience, obvious effect of advancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A neutral composite agent for increasing the permeability of reservoir rock formations to increase crude oil production. It is composed of polyethylene glycol glucoside fatty ether, biological enzymes and lignin carboxylate. The mass percentage of each component of the composite agent is polyethylene glycol glucose Glycoside fatty ether 80%, biological enzyme 10%, lignin carboxylate 10%.

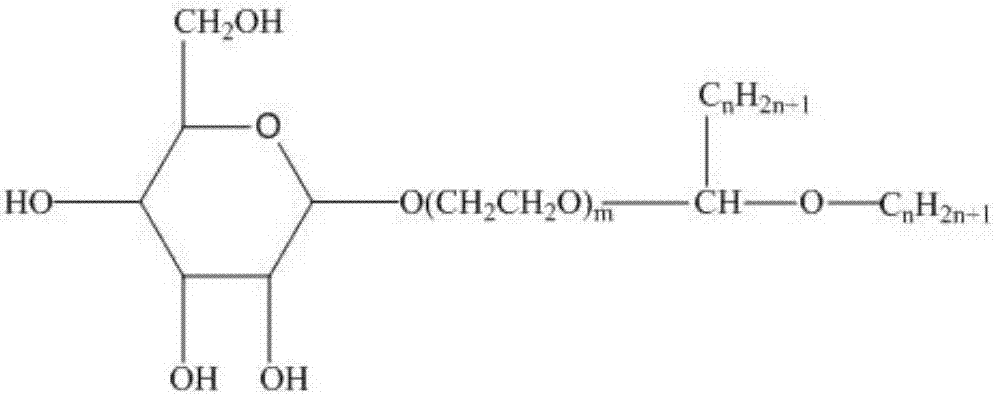

[0024] The structural formula of polyethylene glycol glucoside fatty ether is

[0025]

[0026] Among them, m=16 to 25, n=12 to 20

[0027] The biological enzyme is immobilized glucose isomerase, and the lignin carboxylate is sodium lignin carboxylate.

[0028] The neutral compound agent for increasing crude oil production is made by mechanically mixing polyethylene glycol glucoside fatty ether, biological enzymes, and lignin carboxylate.

Embodiment 2

[0030] Preparation and field application of a neutral compound agent for increasing the permeability of reservoir rock formations to increase crude oil production:

[0031] A neutral compound agent for increasing the permeability of reservoirs and increasing crude oil production. It is composed of polyethylene glycol glucoside fatty ether, biological enzymes and lignin carboxylate. The compounding agent composition ratio (by weight): polyethylene glycol Glucoside fatty ether 88%, biological enzyme 4%, lignin carboxylate 8%.

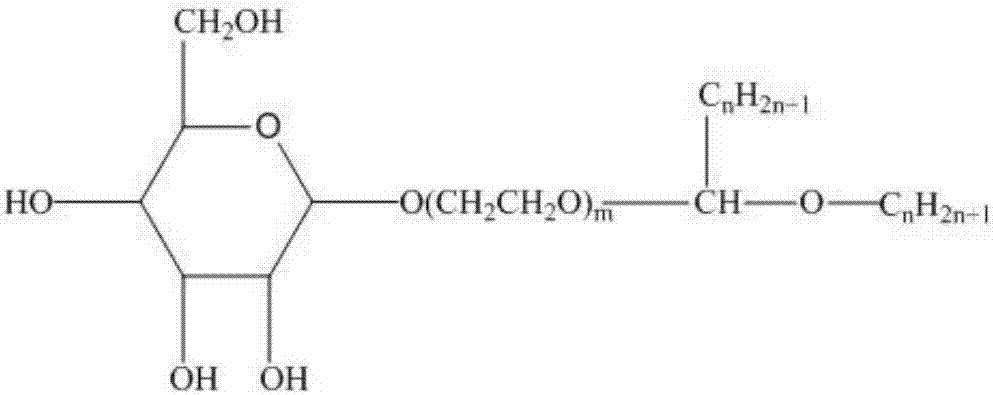

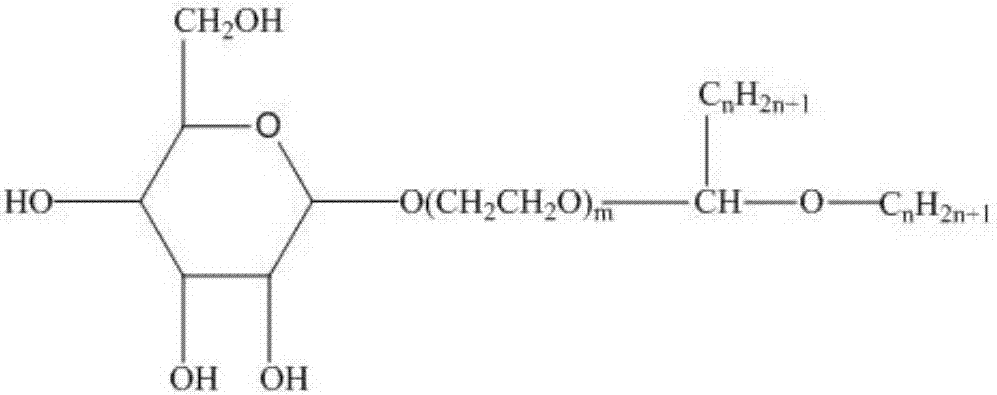

[0032] The structural formula of polyethylene glycol glucoside fatty ether is

[0033]

[0034] Among them, m=16 to 25, n=12 to 20

[0035] The biological enzyme is immobilized glucose isomerase, and the lignin carboxylate is sodium lignin carboxylate.

[0036] Preparation method: According to the formula amount, it is made by mechanically mixing uniformly. The preparation process of polyethylene glycol glucoside fatty ether: In a three-necked flask equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com